Damage self-healing polymer-based composite explosive and preparation method thereof

A polymer and self-healing technology, applied in the direction of explosives, aromatic nitration compositions, non-explosive/non-thermal agent components, etc., can solve the problems that the preparation methods are rarely reported, so as to prolong the life of explosive parts and make the preparation process simple , the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

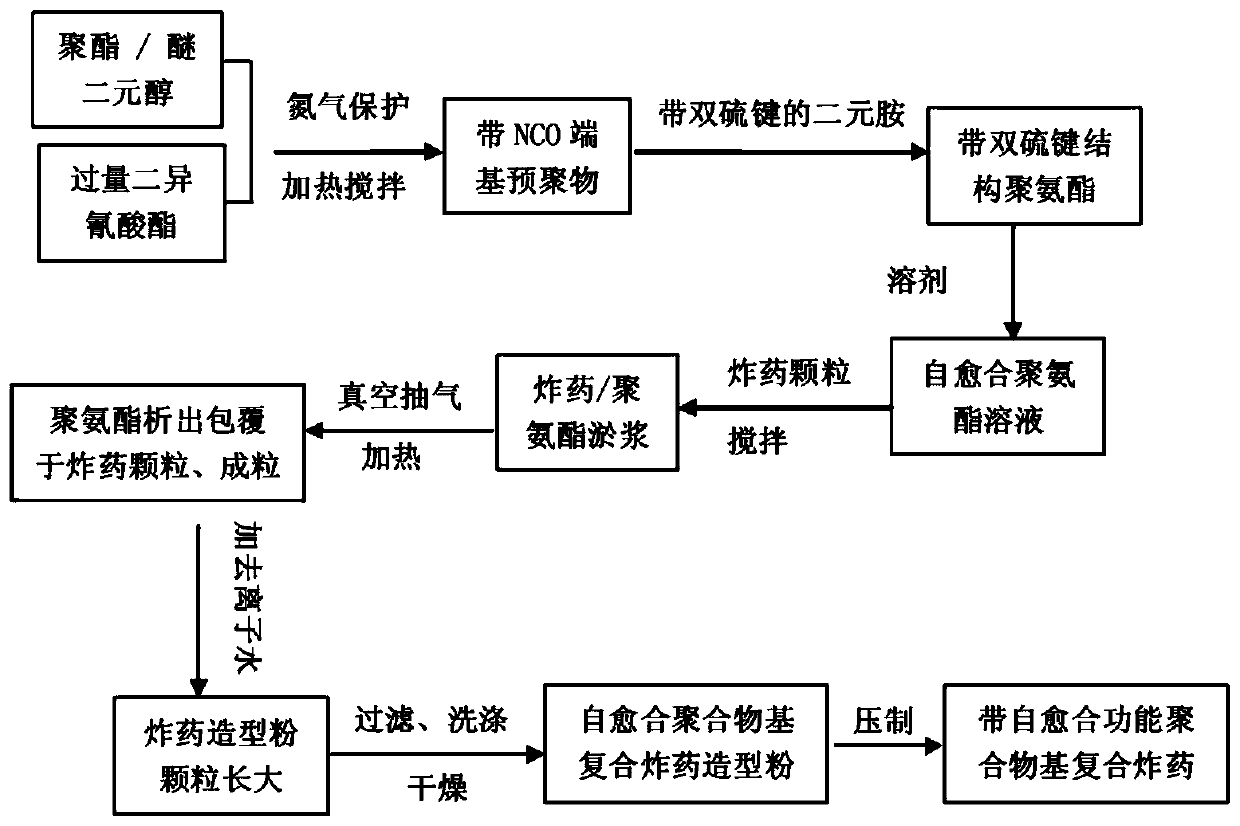

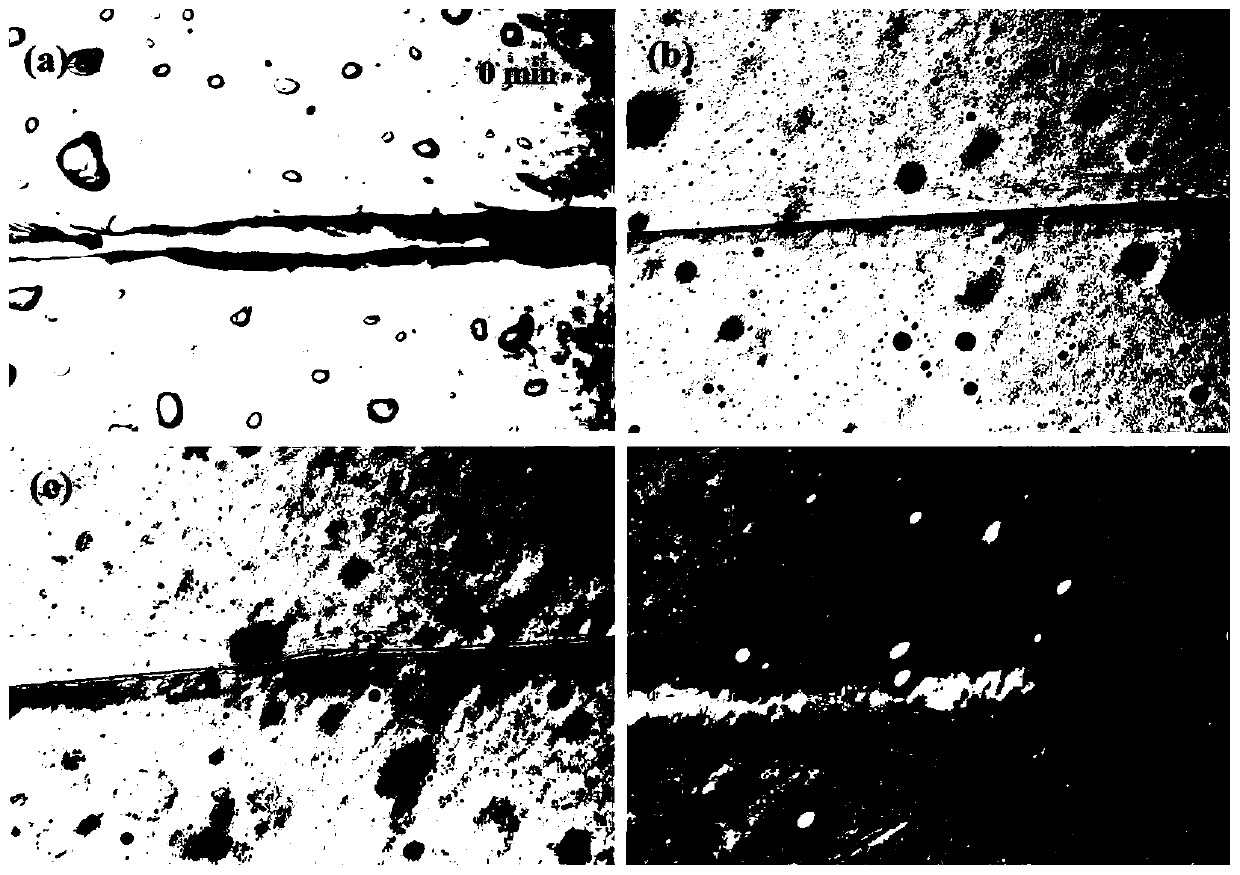

[0025] Such as figure 1As shown, under nitrogen protection and mechanical stirring conditions, the polycaprolactone diol-2000 (40.00g, 0.02mol) after water removal, isophorone diisocyanate (8.90g, 0.04mol) and 20mL N, N-dimethylformamide was mixed thoroughly; the temperature was raised to 70°C, and the reaction was carried out at a constant temperature for 3 hours; and then lowered to room temperature to obtain a prepolymer solution with isocyanate at both ends. Slowly add 4,4'-diaminodiphenyl disulfide (4.97g, 0.02mol) into the prepolymer solution dropwise, raise the temperature to 60°C, and react for 3 hours to obtain a polyurethane pre-finished product with a disulfide bond; The pre-finished product was poured into a polytetrafluoroethylene mold, and baked in a blast oven at 60° C. for 24 hours to obtain 53.53 g of polyurethane (DSPU) with a disulfide bond. Spectrum peaks representing the disulfide bond structure appeared on the nuclear magnetic resonance spectrum and Rama...

Embodiment 2

[0028] Under nitrogen protection and mechanical stirring conditions, polytetrahydrofuran diol-1000 (30.00g, 0.03mol), hexamethylene diisocyanate (10.09g, 0.06mol) and 20mL N,N-dimethyl The formamide was thoroughly mixed; the temperature was raised to 70°C, and the temperature was reacted for 3 hours; then the temperature was lowered to room temperature, and a prepolymer solution with isocyanate at both ends was obtained. Slowly add 4,4'-diaminodiphenyl disulfide (7.46g, 0.03mol) into the prepolymer solution dropwise, raise the temperature to 60°C, and react for 3 hours to obtain a polyurethane pre-finished product with a disulfide bond; The preform was poured into a polytetrafluoroethylene mold, and baked in a blast oven at 60° C. for 24 hours to remove the solvent to obtain 47.30 g of polyurethane (DSPU) with a disulfide bond.

[0029] Dissolve 10.0g of polyurethane (DSPU) with a disulfide bond in 190.0g of 1,2-dichloroethane to prepare a 5% dilute solution; add 40.0g of hexa...

Embodiment 3

[0031] Under nitrogen protection and mechanical stirring conditions, polyethylene glycol-1000 (20.00g, 0.02mol), 4,4'-diphenylmethane diisocyanate (5.01g, 0.02mol) and 15mL N, N-dimethylformamide was mixed thoroughly; the temperature was raised to 70°C, and the reaction was carried out at a constant temperature for 3 hours; and then lowered to room temperature to obtain a prepolymer solution with isocyanate at both ends. Slowly add 4,4'-diaminodiphenyl disulfide (4.97g, 0.02mol) into the prepolymer solution dropwise, raise the temperature to 60°C, and react for 3 hours to obtain a polyurethane pre-finished product with a disulfide bond; The pre-finished product was poured into a polytetrafluoroethylene mold, and baked in a blast oven at 60° C. for 24 hours to remove the solvent to obtain 29.80 g of polyurethane (DSPU) with a disulfide bond.

[0032] Dissolve 10.0g of polyurethane (DSPU) with a disulfide bond in 115.0g of N,N-dimethylformamide to prepare an 8.0% dilute solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com