Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Play an anti-wear role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prepn of antioxidant for lubricant oil

InactiveCN1191340CEffective protectionImprove solubilityAdditivesAntioxidantInternal combustion engine

The preparation of antioxidant for lubricant oil includes the condensation reaction between the mixture liquid containing shielding phenol, aldehyde and CS2 and added dialkyl amine at 40-120 deg.c and product separation and collection. The prepared antioxidant has the integrated structure of both free radical terminator and peroxide decomposing agent and has the capacity of trapping free radical and decomposing hydrogen peroxide to protect the oxidation safety of oil product. Containing S element in its structure makes it possess certain antiwear effect. The product of the present invention is liquid, easy to dissolve and compatible with other functional additives, and may be used in industrial lubricant oil and internal combustion engine oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Prepn of antioxidant for lubricant oil

InactiveCN1453347AEffective protectionImprove solubilityAdditivesAntioxidantInternal combustion engine

The preparation of antioxidant for lubricant oil includes the condensation reaction between the mixture liquid containing shielding phenol, aldehyde and CS2 and added dialkyl amine at 40-120 deg.c and product separation and collection. The prepared antioxidant has the integrated structure of both free radical terminator and peroxide decomposing agent and has the capacity of trapping free radicaland decomposing hydrogen peroxide to protect the oxidation safety of oil product. Containing S element in its structure makes it possess certain antiwear effect. The product of the present invention is liquid, easy to dissolve and compatible with other functional additives, and may be used in industrial lubricant oil and internal combustion engine oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

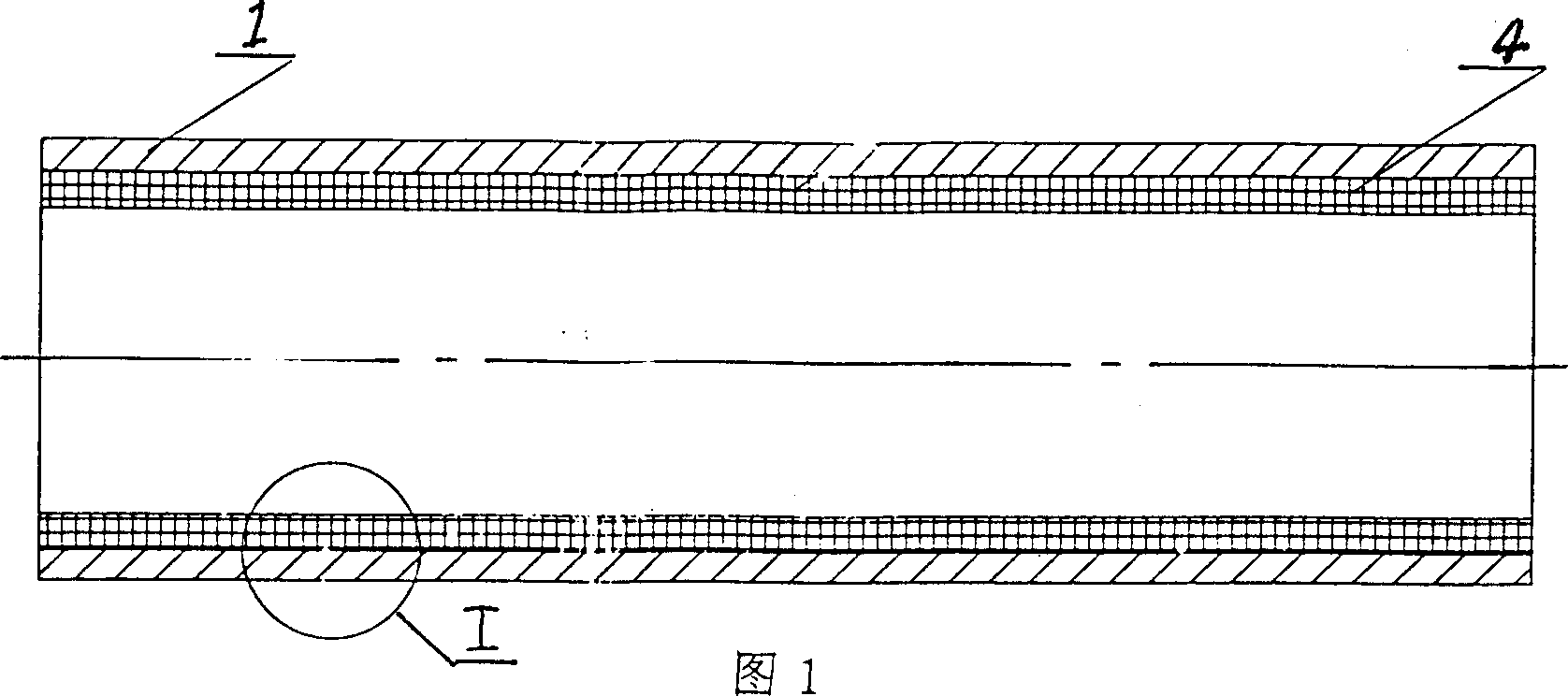

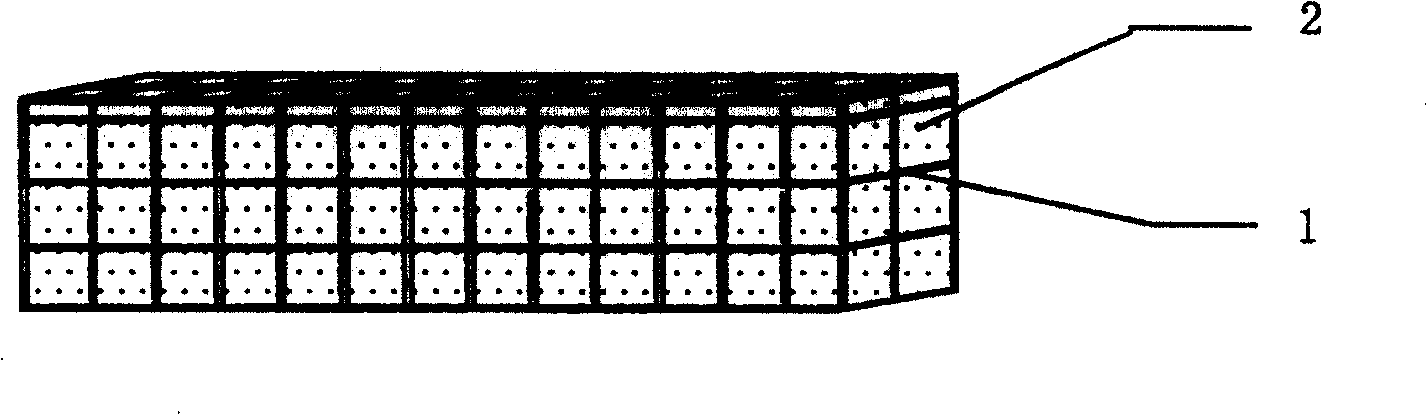

Metallic pipe with nano-structure metal wire screen-ceramic liner and its making technology

InactiveCN1397754AHigh strengthHigh hardnessCorrosion preventionPipe protection against corrosion/incrustationNano structuringMetallurgy

A composite metal pipe is composed of the external sleeve pipe and the composite liner pipe consisting of metallic wire net and antiwear ceramic material. Its advantages are controllable technological parameters, high productivity and quality and long service life.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

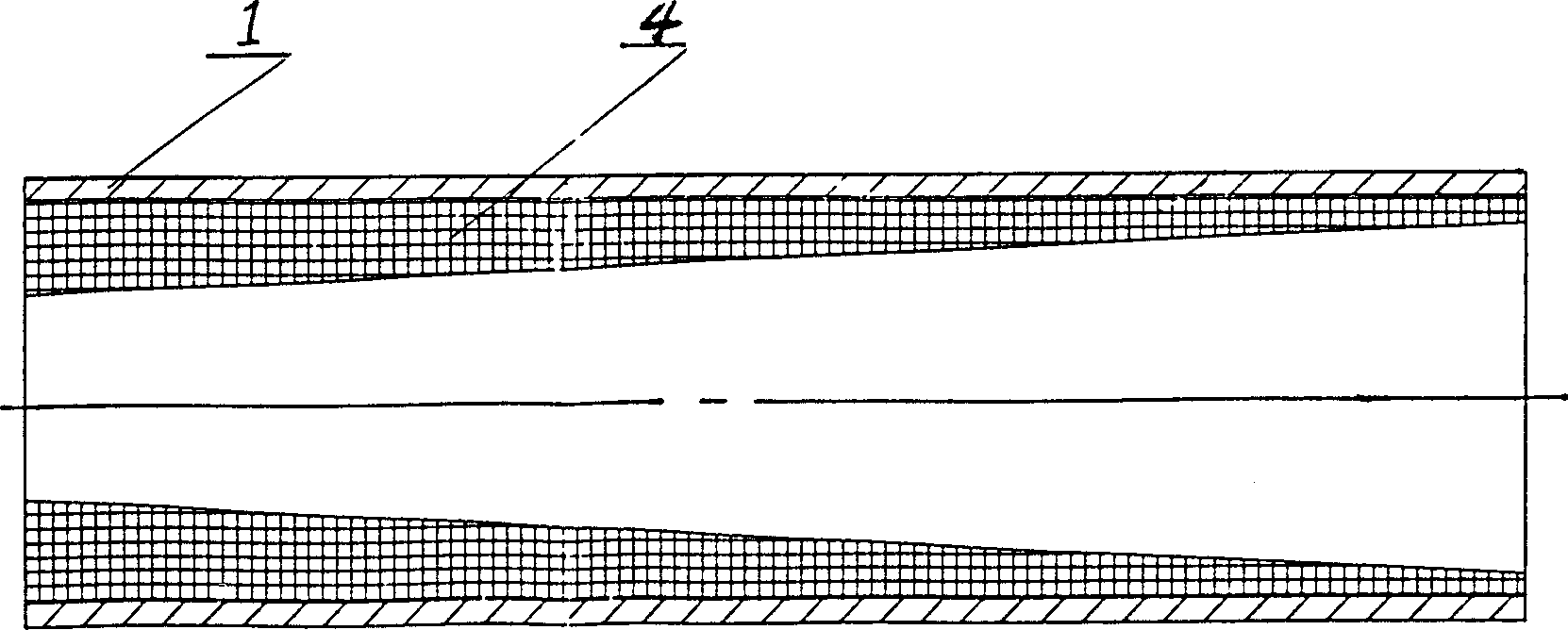

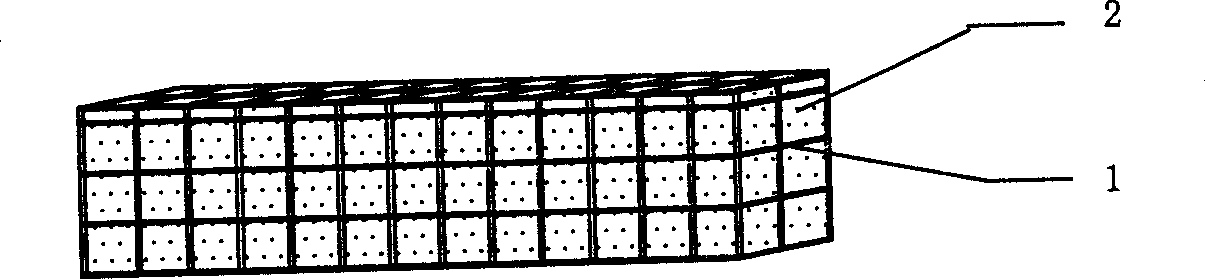

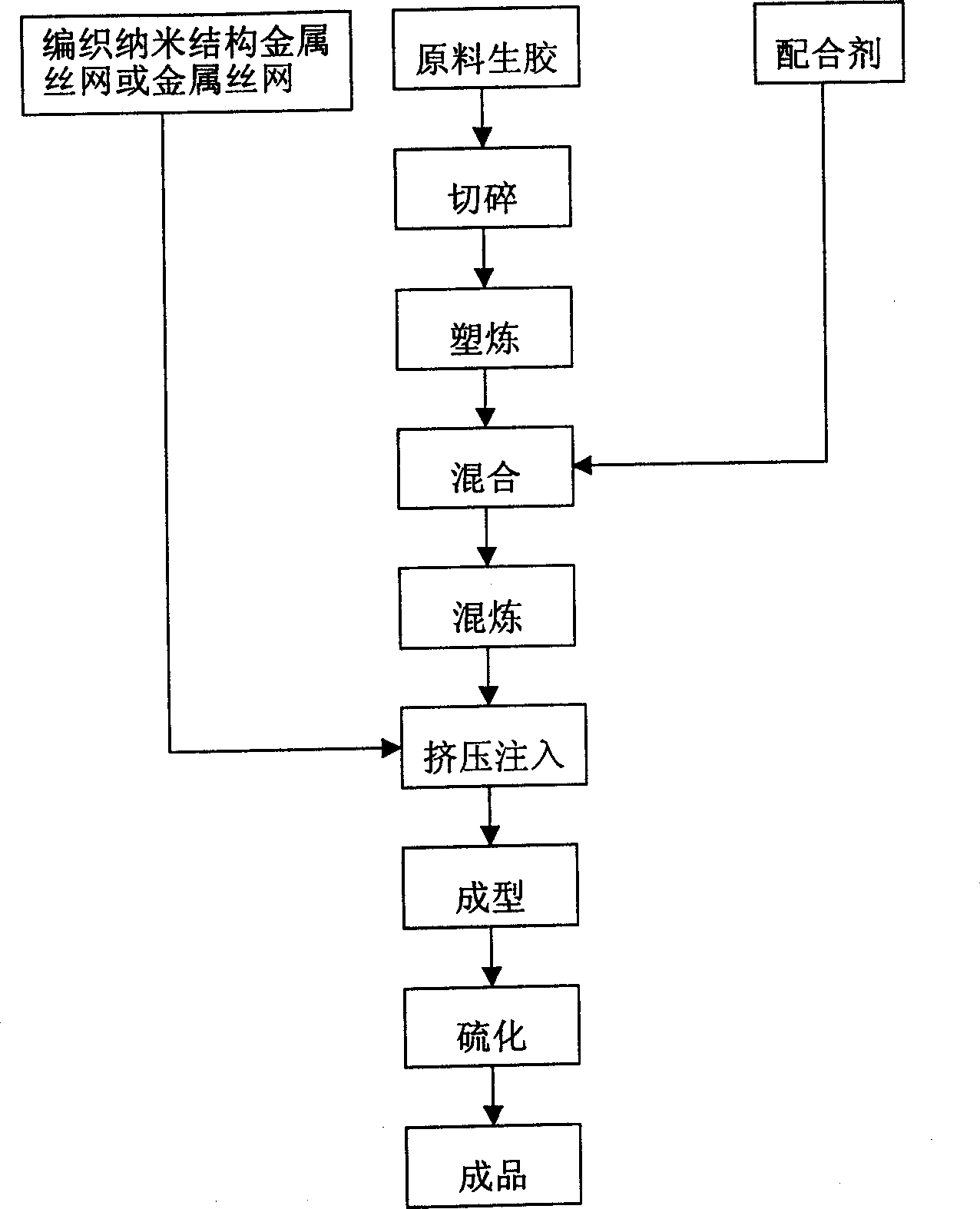

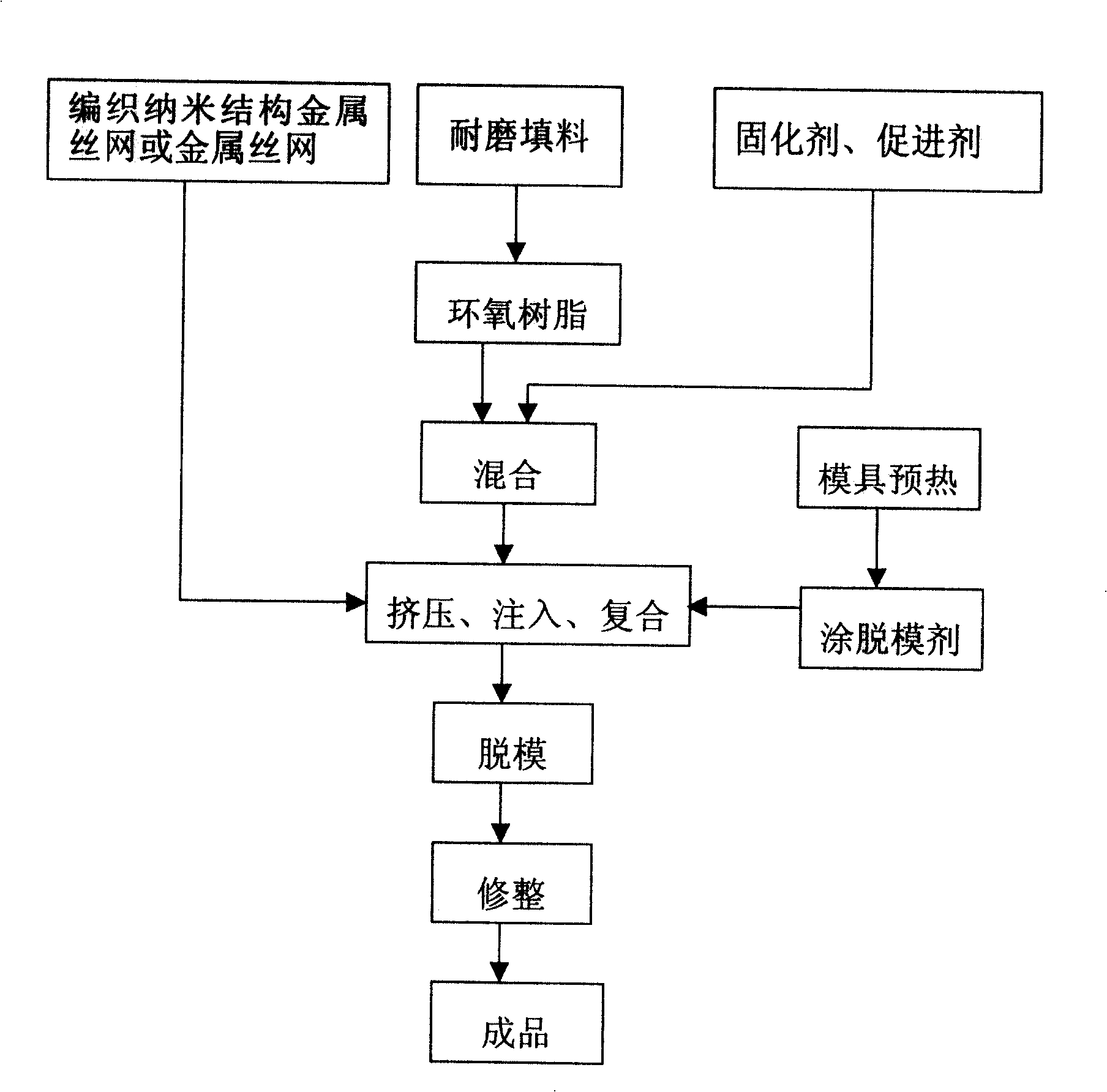

Composite lining with metal wire screen in nanometer structure and its production process

The present invention discloses a kind of nano structure wire gauze composite lining plate and its preparation process. Said lining plate is made up by using wire gauze and compounded filing materialthrough a compositive process. Said wire gauze can be integrally braided, also can be a multilayer structure pieced by using single-layer of wire gauze, said wire gauze can be placed in the interior of compounded filling material, then they are combined into a whole body. Said composite lining plate possesses high wear-resistance, water-resisting property, vibration-absorbing property and corrosion-resisting property, etc..

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

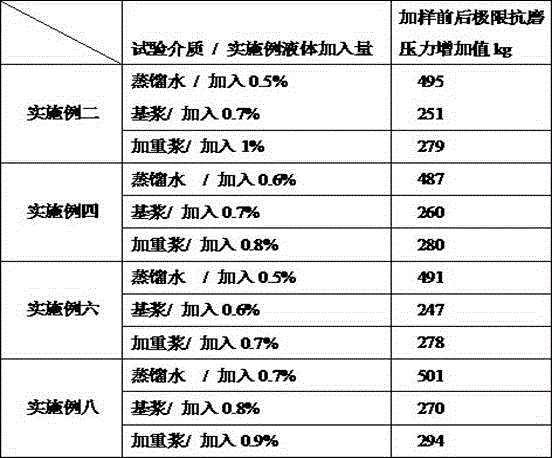

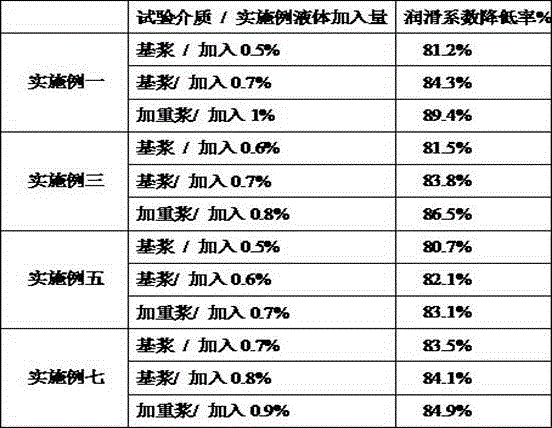

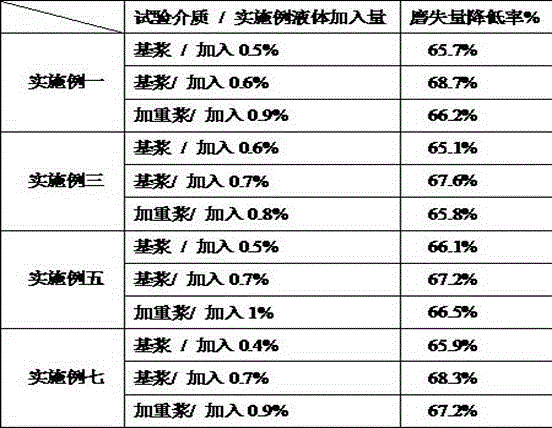

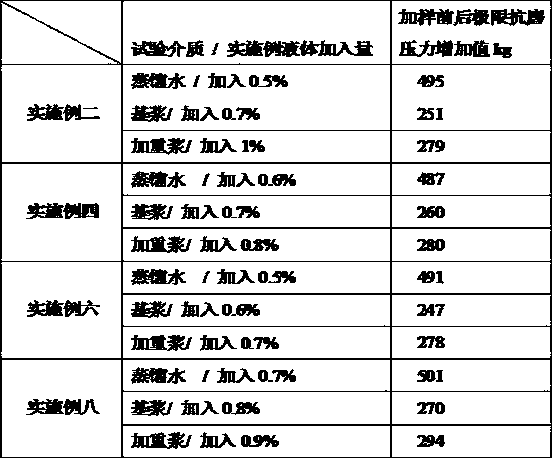

Organic antifriction composition for drilling fluid and preparation method of organic antifriction composition

ActiveCN105647490AReduce use costPlay an anti-wear roleDrilling compositionHigh densityHorizontal wells

Organic antifriction composition for drilling fluid is composed of, prepared in 100%, 45-65 parts of organic acidic metal salt, 15-35 parts of mineral oil, 5-10 parts of emulgator, and 8-15 parts of extreme-pressure additive. During preparation, the components are proportionally added into a reactor and react for 4-6 hours at 50-90oC, producing yellow or brown liquid which is antifriction composition. The antifriction composition can form a high-intensity extreme-pressure lubricating film to be antifriction through its organic negative ions adsorbing to the surface of a casing or a drilling rod, and can replace or partially replace lubricant, using cost of lubricant is reduced, and the antifriction composition is applicable to highly-deviated wells, horizontal wells, high-density drilling fluid and long-cycle prospecting wells.

Owner:成都西油华巍科技有限公司

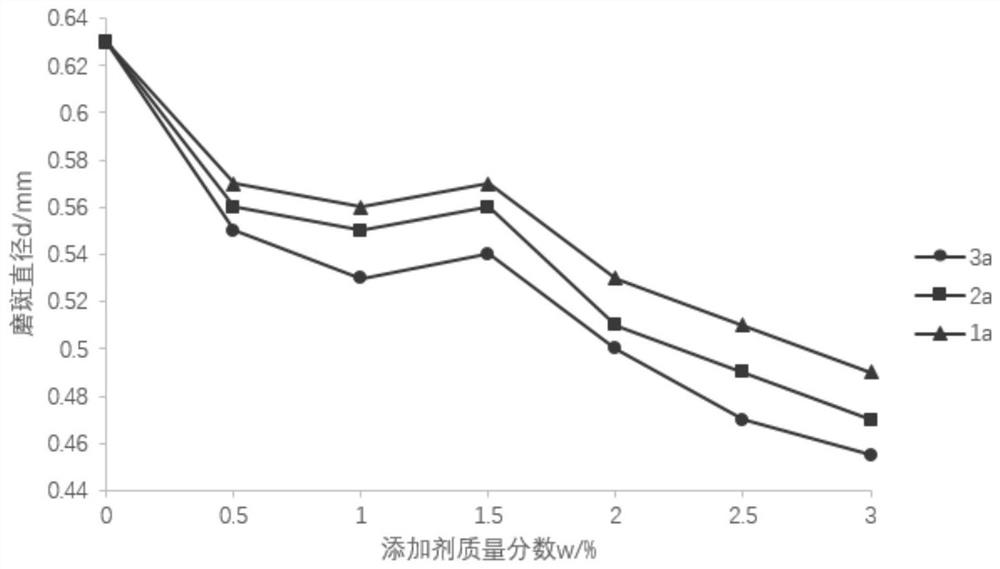

High-performance high water-based lubricant composition

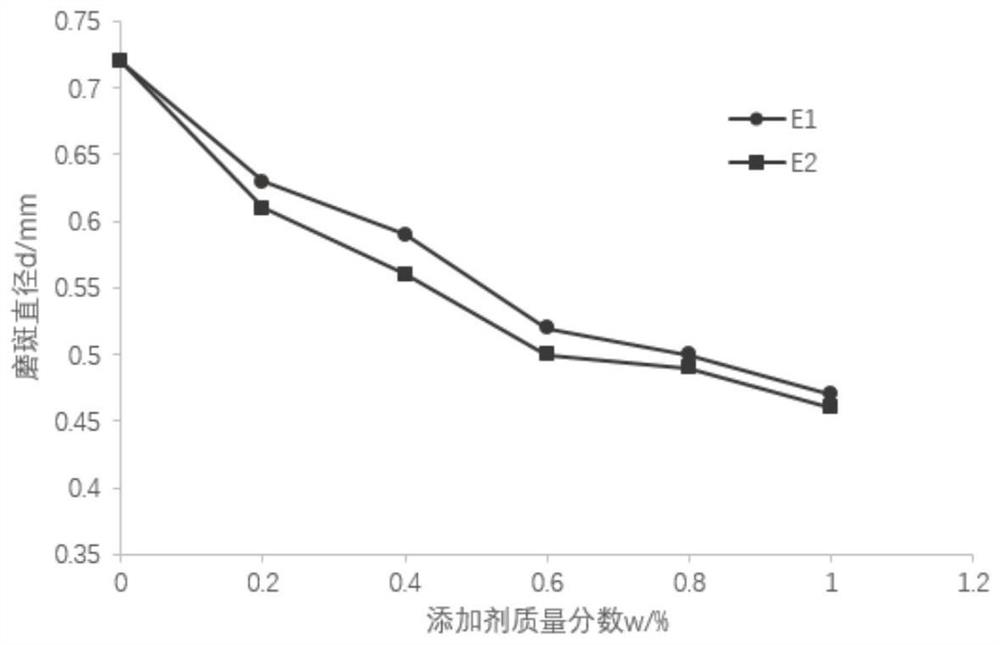

The invention discloses a high-property high-water based lubricant composition, which comprises the following parts: 95-99% water and 1-5% functional additive (lubricant and alkali) and lucricating additive with nanometer silica particle and soluble phosphate, wherein the even grain size of nanometer silica particle is 10-60nm; the high-water based lubricant consists of nanometer silica particle and soluble phosphate, which improves bearing capacity (PB value) and reduces spot-abrasion diameter (D3040); the water based lubricant is fit for metal manufacturing liquid to cut and polish.

Owner:SHANGHAI UNIV

A kind of copper-molybdenum alloy material with high conductivity and high wear resistance and preparation method thereof

The invention relates to a high conductivity and high wear resistance copper-molybdenum alloy material. The material of the invention comprises a matrix alloy Cu, a friction component Al2O3, a lubrication component MoS2, a high temperature component Mo, and copper. A product (the material) is prepared by preparing a mixed powder material through mixing powders of Al2O3, MoS2, Mo and copper according to a proportion and filling into a stainless steel grinding pot of a high energy bowl mill, sending the mixed powder material to a press machine, prepressing into a blank, sending the blank to a cold isostatic press machine to press, and sending the statically pressed blank to a vacuum sintering furnace to sinter. In the invention, quality fraction scopes of above components are determined on the basis of massive experiments, and the experiments prove that ingredients in the component scopes allow reactions to be stably and smoothly carried out, and optimal performances of the material of the invention to be realized.

Owner:HENAN UNIV OF SCI & TECH

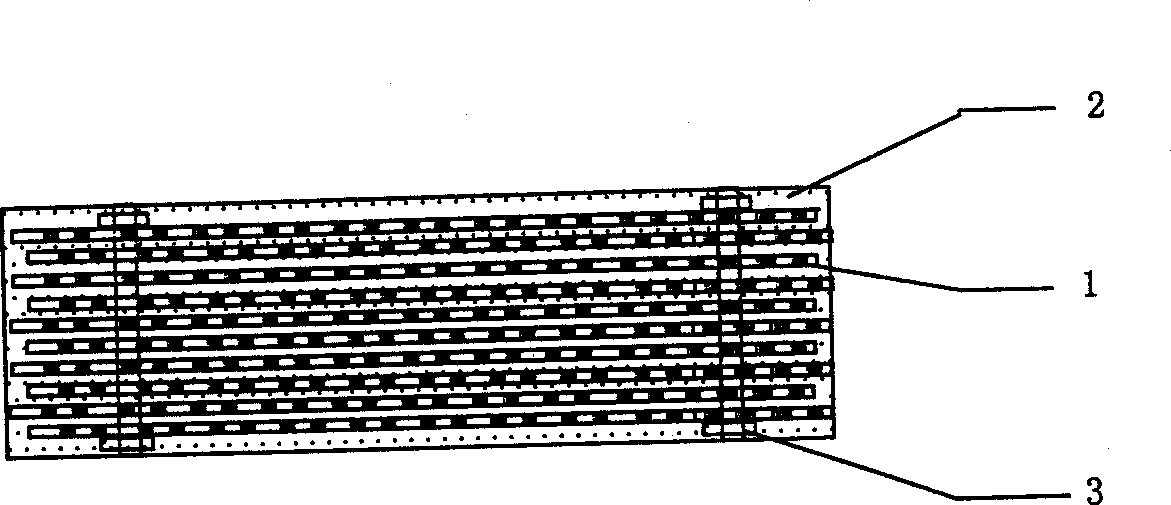

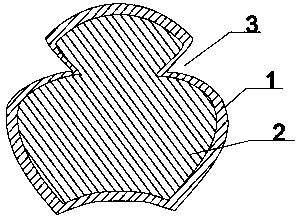

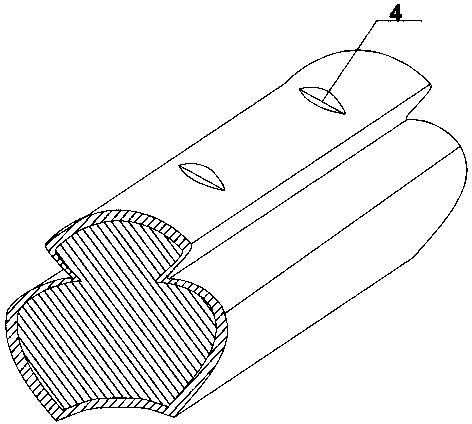

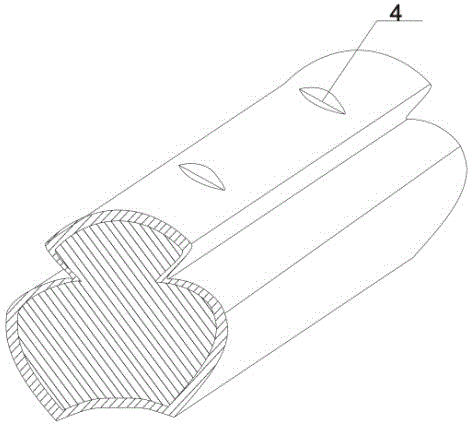

Highly compression-resistant double-layer copper-alloy contact wire and preparation method thereof

The invention discloses a highly compression-resistant double-layer copper-alloy contact wire and a preparation method thereof. The copper-alloy contact wire has the tensile strength of above 450MPa, the tensile failure force of above 48KN, and the conductivity of above 75% IACS, the two sides of the copper-alloy contact wire are provided with gaps, the copper-alloy contact wire comprises an outer tin coating layer and an inner copper alloy body, copper alloy body cross sections above or below the gaps are fan-shaped, a plurality of telescoping mouths are arranged on the tin coating layer, and copper alloy is prepared by processes of powder making, pre-compaction, billet ingot making and the like. The copper alloy contact wire has a unique structure, high conductivity can be guaranteed, at the same time, components can play effects of reducing wear and resisting abrasion, and during the use of the copper alloy contact wire, temperature difference and electric spark burn can be effectively prevented.

Owner:DATANG LUOYANG CO GENERATION POWER

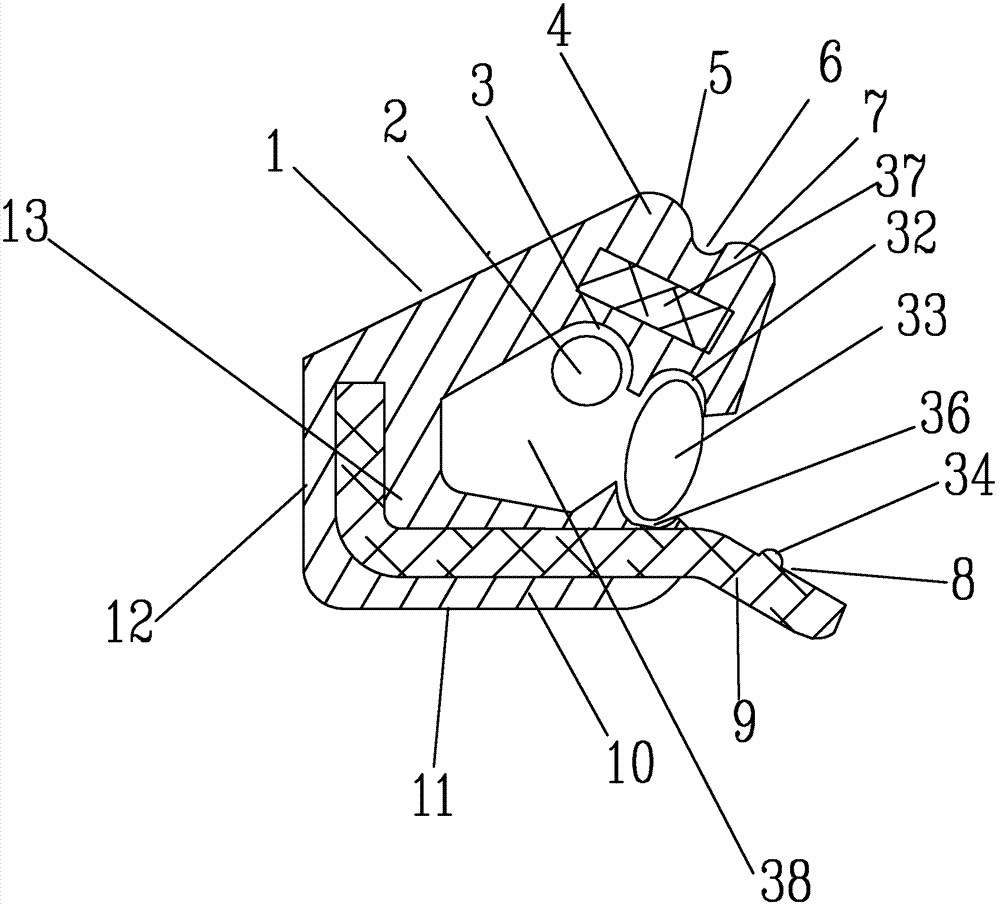

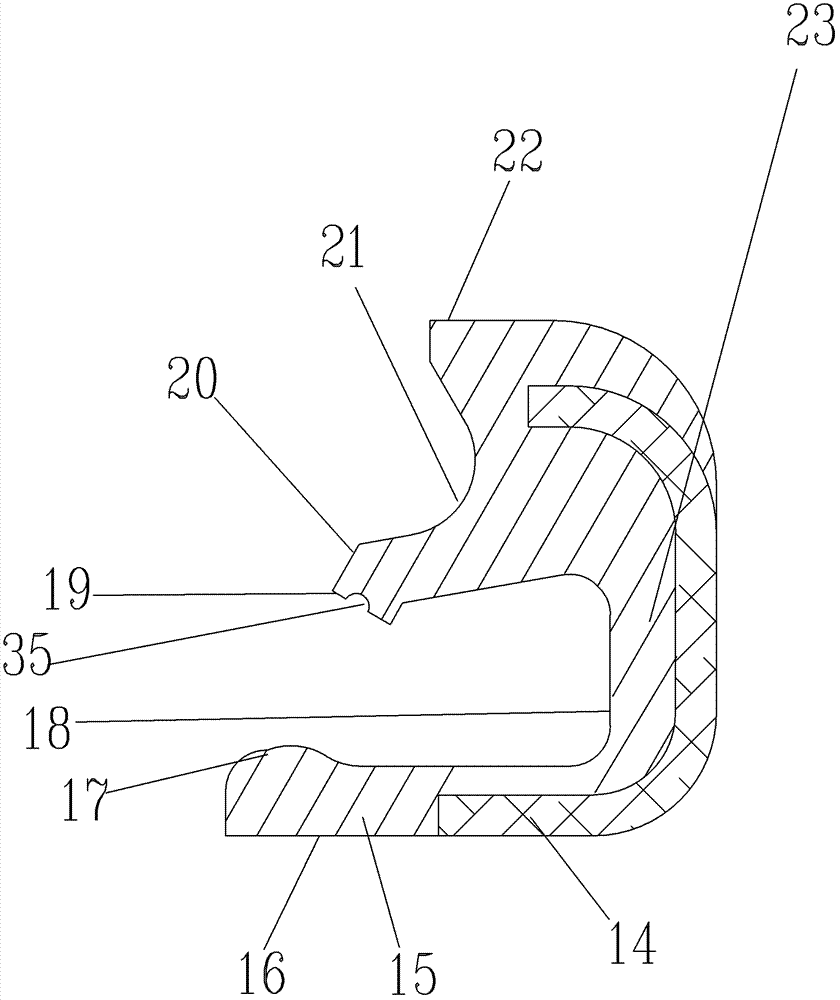

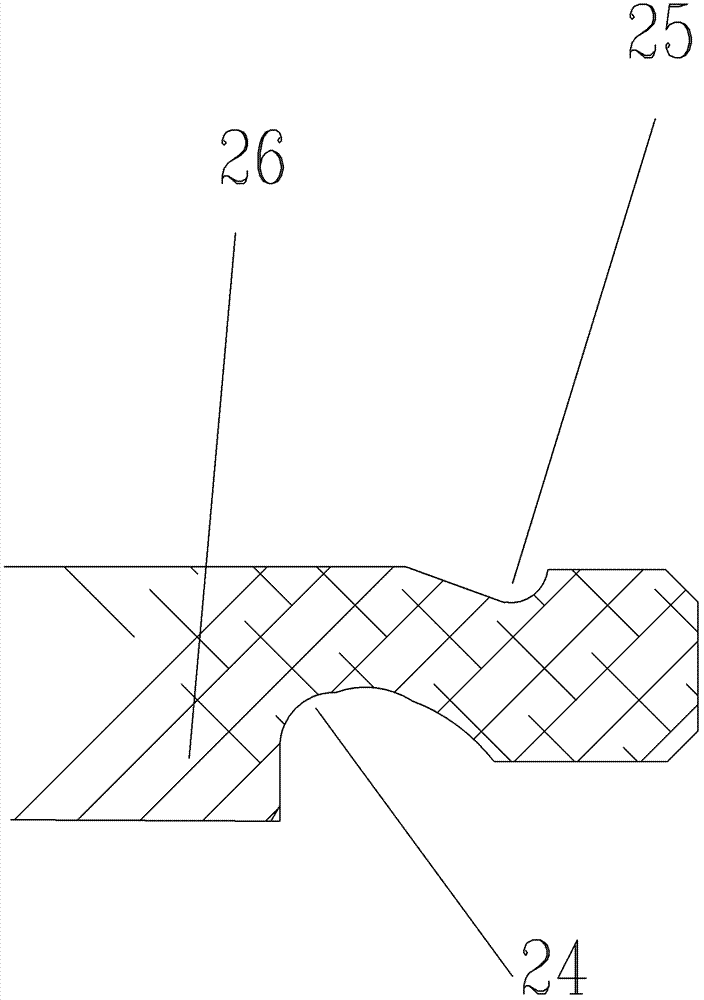

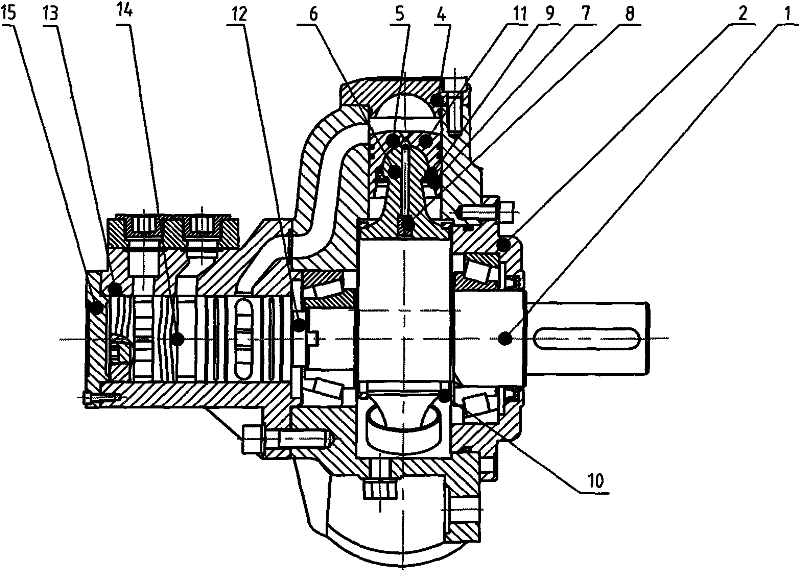

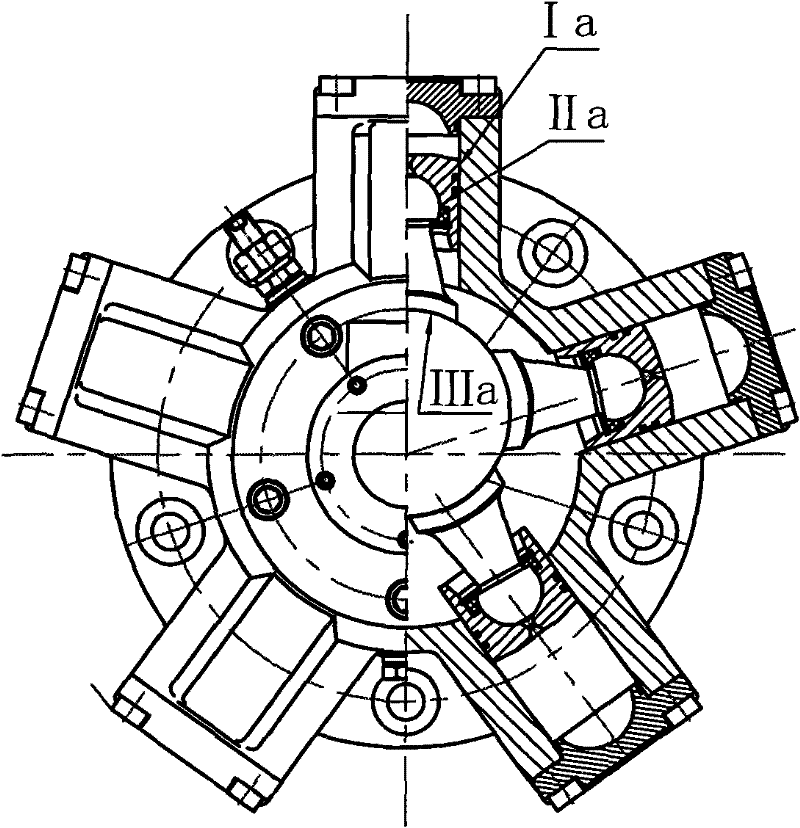

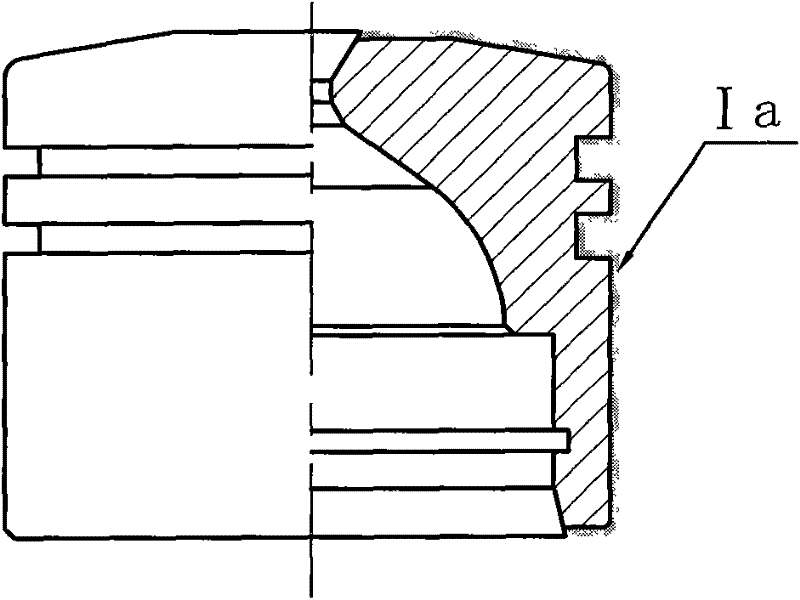

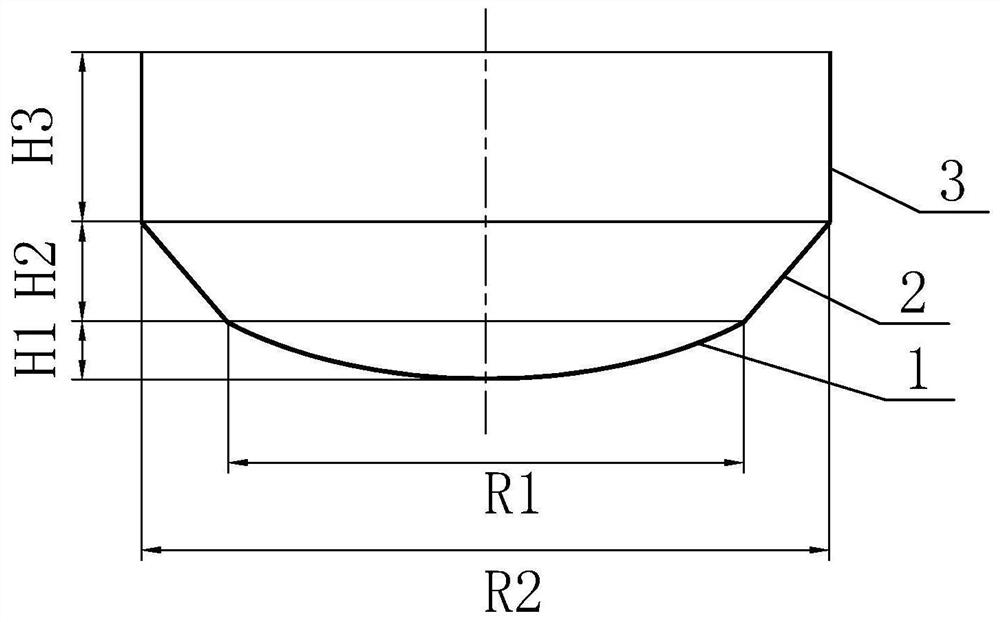

Cardan joint capable of compensating abrasion of sealing device

ActiveCN103362970AReduce contact areaIncrease contactYielding couplingManufacturing technologySoft body

The invention discloses a cardan joint capable of compensating abrasion of a sealing device. The cardan joint capable of compensating the abrasion of the sealing device can automatically conduct compensation after a lip of an oil seal ring is abraded, is good in sealing performance and is provided with a dust guard which is good in waterproof effect and sand-proof effect. The cardan joint comprises a shaft neck, a bearing, a roller pin, the oil seal ring and the dust guard. The bearing is installed on the shaft head of the shaft neck, the roller pin is installed in the bearing, the oil seal ring is installed at the outer end of the roller pin in the bearing, an outer bending ring (16) of the dust guard is connected with the bearing, an inner bending ring (22) of the dust guard is connected with the shaft head, the section of the oil seal ring is in a U shape, a lip of an outwards-protruded arc-shaped edge (5) is arranged on the outer side wall of a semiarc (1) in the oil seal ring, a balance skeleton (37) is embedded in an oil seal ring soft body (10) of the tail end of the semiarc (1) in the oil seal ring, a spring ring (2) is clamped on the inner side wall of the semiarc in the oil seal ring, and an elastic ball (33) is clamped in a U-shaped groove (38) in the oil seal ring. The cardan joint is mainly used in the manufacturing technology.

Owner:WANXIANGQIANCHAO CO LTD +1

Porous lightweight concrete and preparation method thereof

The invention discloses porous lightweight concrete, and also discloses a preparation method thereof, and the porous lightweight concrete comprises 280-300 parts by weight of cement, 200-250 parts byweight of concrete slag, 40-45 parts by weight of sand, 900-1200 parts by weight of gravel, 30-40 parts by weight of fly ash, 80-100 parts by weight of water, 2-5 parts by weight of polypropylene fiber, 30-80 parts by weight of fine sand, 4-5.5 parts by weight of a binder, 2-5 parts by weight of a water reducer, 15-22 parts by weight of ferric sulfate, 500 to 800 parts by weight of a reinforcing agent, 3 to 5 parts by weight of carbonate, 300 to 400 parts by weight of steel slag, 8 to 10 parts by weight of diatomite, 150 tO250 parts by weight of a lotus leaf hydrophobing agent, 100 to 150 parts by weight of activated carbon and 320 to 340 parts by weight of toughening fiber. According to the method, the steel slag and the concrete slag are added in the preparation process of the concrete,and wastes such as the steel slag, the concrete slag and the like improve the compressive strength of the concrete, improve the mechanical properties such as shear resistance and the like, reduce thecost, and implement the national technical and economic policies of saving resources and green production.

Owner:南通昆腾新材料科技有限公司

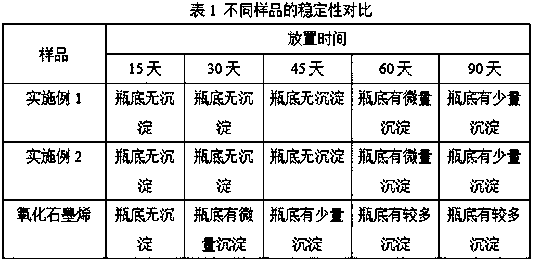

Graphene engine oil antiwear agent and preparation method thereof

InactiveCN110804477AImprove anti-wear performanceGood dispersionAdditivesIn situ polymerizationCarbon nitride

The invention discloses a graphene engine oil antiwear agent and a preparation method thereof, and the preparation method comprises the following steps: dissolving graphene oxide in toluene, and ultrasonically dispersing to form graphene oxide dispersion liquid; dissolving sodium azide and cyanuric chloride in toluene to form reaction liquid; adding the reaction liquid into the graphene oxide dispersion liquid, and performing secondary ultrasonic dispersion to form mixed liquid; adding the mixed liquid into a reaction kettle for solvothermal reaction to prepare a carbon nitride modified graphene composite material; and centrifuging and washing to obtain the graphene engine oil antiwear agent. According to the invention, the graphene oxide is taken as a main raw material, carbon nitride nanotubes are synthesized through in-situ polymerization between graphene oxide layers by a solvothermal method, and the graphene modified by the carbon nitride nanotubes has better abrasion resistance and dispersibility.

Owner:贵州明志典成科技有限公司

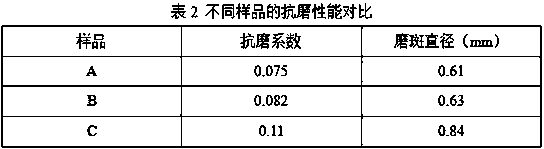

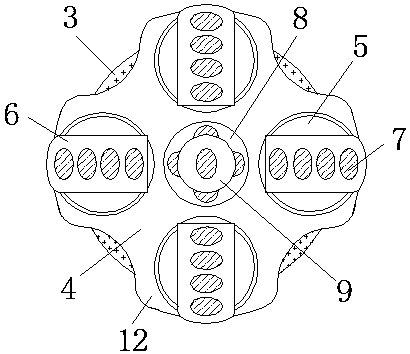

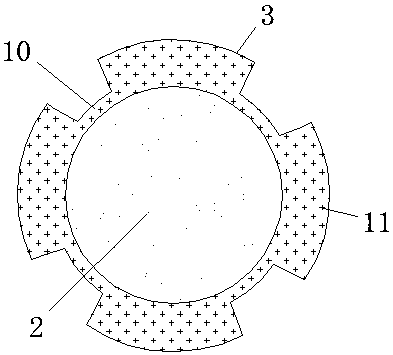

Spiral diamond drill bit

The invention discloses a spiral diamond drill bit. The drill bit includes a spiral rod, an extending block and a supporting block. A transition joint is installed at the upper end of the spiral rod,and stabilizing pieces are arranged at the upper end of the transition joint; a bracing piece is arranged at the upper ends of the stabilizing pieces, spiral connectors are fixed to the border of theupper end of the bracing piece, flank bases are fixed to the upper ends of the spiral connectors, and toothed addenda are fixed to the upper ends of the flank bases; the extending block is fixed to the portion among the flank bases, auxiliary pieces are fixed to the upper end of the extending block, a groove is formed in each stabilizing piece, a convex piece is fixed to one side of each groove, and the supporting block is arranged on the border of the interior of the bracing piece. According to the spiral diamond drill bit, toothed addenda are arranged on the surfaces of both the flank basesand the auxiliary pieces and can directly achieve an anti-wearing effect; through cooperation between the stabilizing pieces and the bracing piece, the impact toughness is enhanced; since the spiral connectors are fixed to the interior, the drill bit can have high impact toughness, great anti-wearing performance and high rock breaking speed, and the drilling efficiency is improved.

Owner:谷家菊

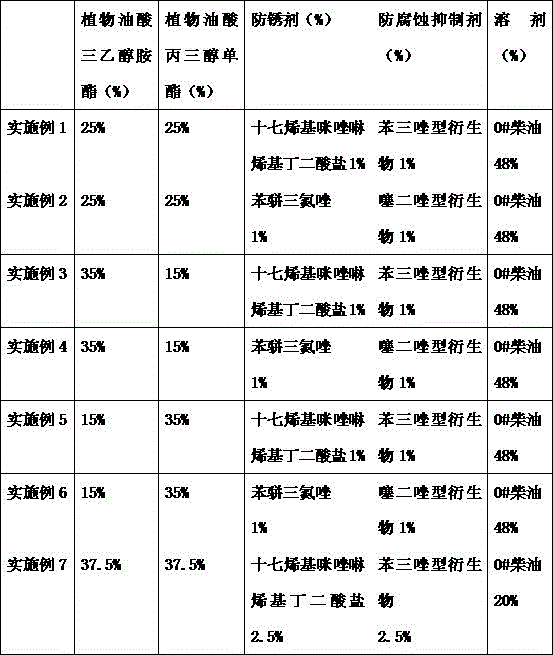

A kind of diesel antiwear agent and preparation method thereof

ActiveCN103952193BReduce corrosionGuaranteed uptimeLiquid carbonaceous fuelsFuel additivesTriethanolamine oleateVegetable oil

The invention provides an antiwear agent for diesel oil and a preparation method thereof. An antiwear agent for diesel oil, the components and the mass percentage of each component are: 0-50% of triethanolamine vegetable oleate, 0-50% of glycerol vegetable oleate, 1-5% of anti-corrosion components, The antirust component is 1~5%, and the rest is solvent. First, add a specified amount of solvent into the reaction kettle, raise the temperature to 70~80°C, and add vegetable triethanolamine oleate, vegetable glycerol oleate, anti-corrosion components and anti-rust components in proportion in sequence while stirring, and the addition is complete Then continue to stir for half an hour until the product is completely clear and transparent, stop heating, stop stirring when the temperature drops to room temperature, and take out the kettle for barreling. In the present invention, anti-wear, anti-corrosion and anti-rust components are compounded together and added to diesel oil, which can not only play an anti-wear role, but also reduce the corrosion of diesel oil on the oil pump, engine and other parts, and ensure the oil circuit and engine of diesel vehicles of smooth operation.

Owner:濮阳市佳华化工有限公司

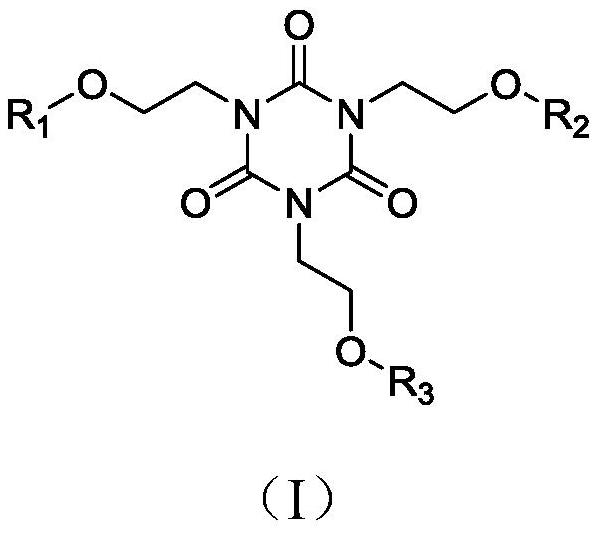

Chain transfer agent with flame retardance and preparation method thereof

The invention discloses a chain transfer agent with flame retardance and a preparation method thereof. The chain transfer agent with the flame retardance is prepared by the steps: carrying out acylating chlorination reaction on 3-phenylmethylmercaptothiocarbonyl propionic acid, and carrying out condensation reaction on the 3-phenylmethylmercaptothiocarbonyl propionic acid and 1,3,5-tri(2-hydroxyethyl) cyanuric acid, so as to obtain the chain transfer agent with the flame retardance. The synthesis process for preparing the chain transfer agent with flame retardance is simple to operate, no toxic by-product is generated, the synthesis raw materials are low in price, the prepared chain transfer agent has a good flame retardant effect, and the obtained chain transfer agent has good wear resistance as a lubricating oil additive.

Owner:李太杰

Composite lining with metal wire screen in nanometer structure and its production process

The present invention discloses a kind of nano structure wire gauze composite lining plate and its preparation process. Said lining plate is made up by using wire gauze and compounded filing material through a compositive process. Said wire gauze can be integrally braided, also can be a multilayer structure pieced by using single-layer of wire gauze, said wire gauze can be placed in the interior of compounded filling material, then they are combined into a whole body. Said composite lining plate possesses high wear-resistance, water-resisting property, vibration-absorbing property and corrosion-resisting property, etc..

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

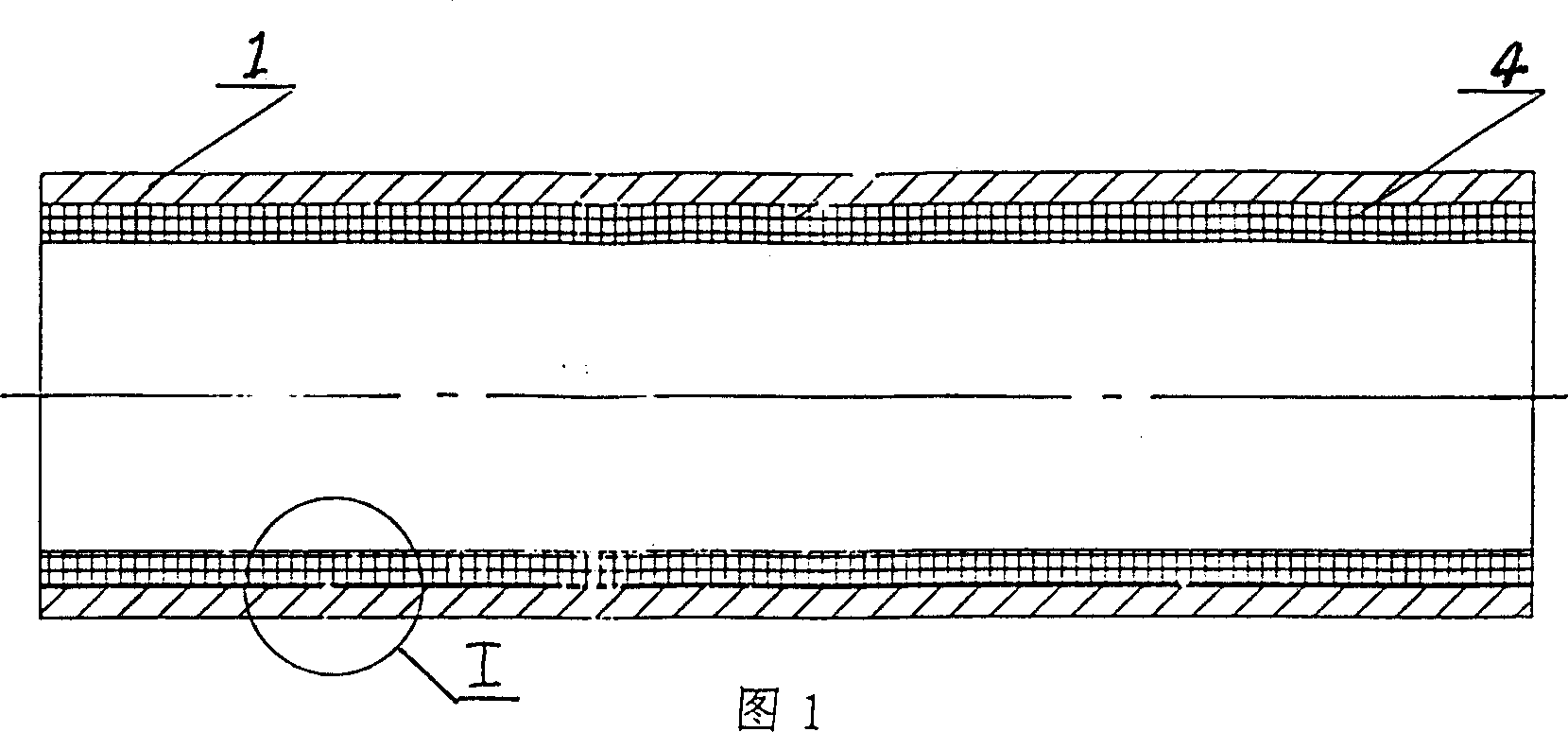

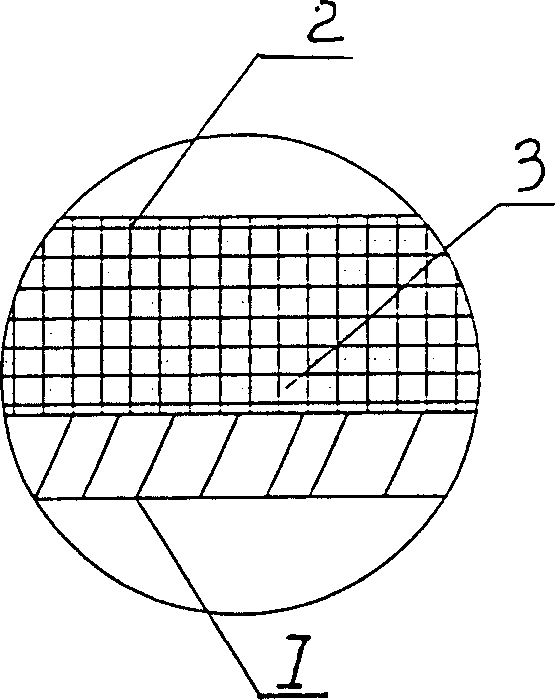

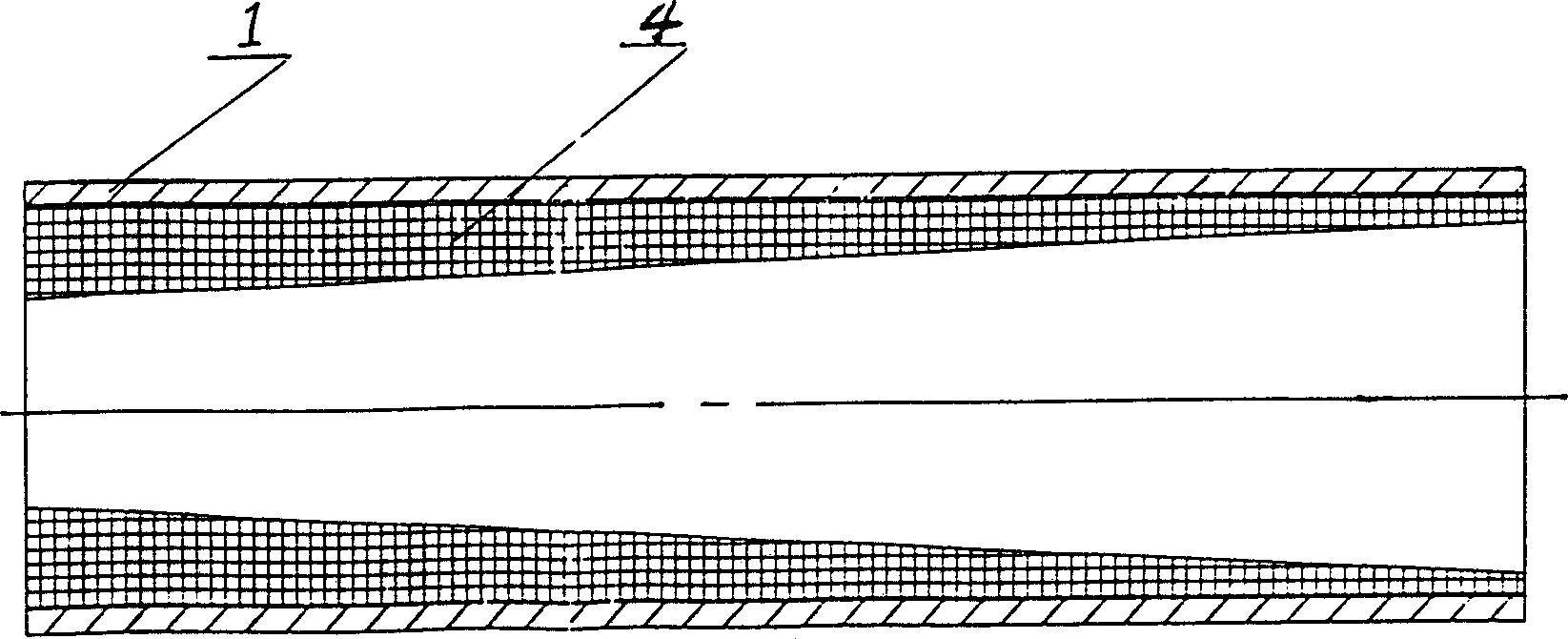

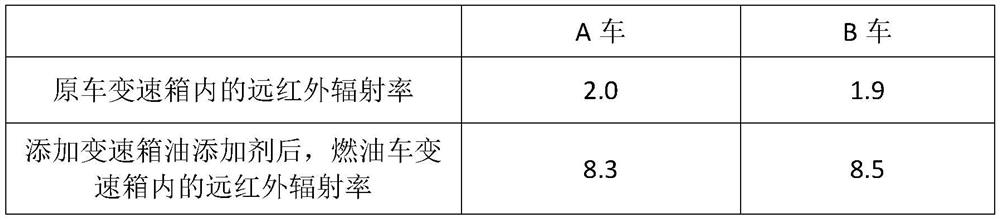

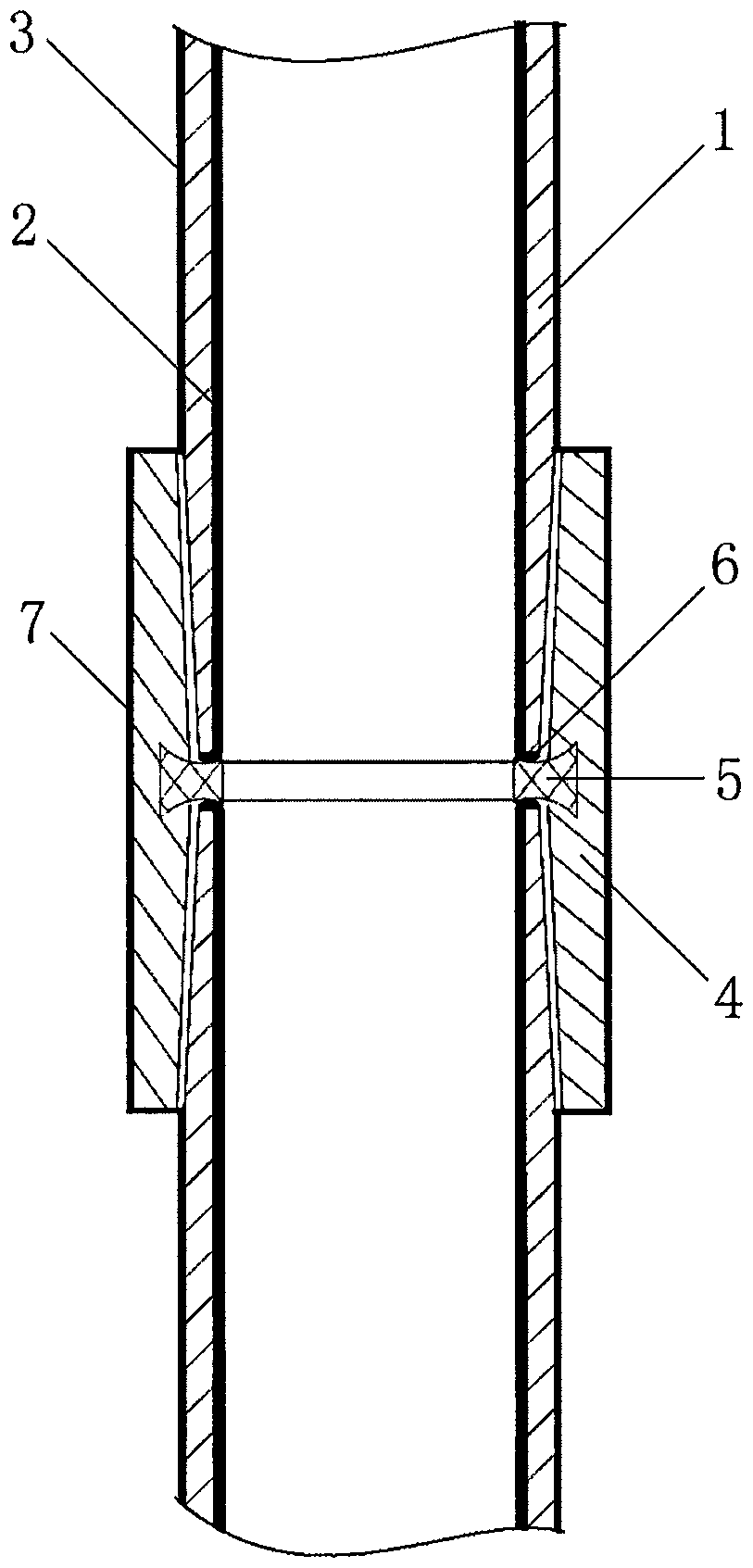

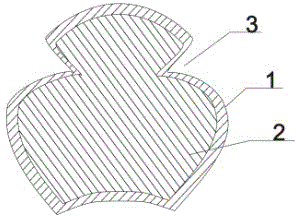

Technology for making metallic pipe with nano-structure metal wire screen-ceramic liner

InactiveCN1203272CHigh strengthHigh hardnessCorrosion preventionPipe protection against corrosion/incrustationCeramic compositeNano structuring

The invention discloses a preparation process of a nano-structure wire mesh-ceramic composite lining metal pipe. It is composed of an outer casing (1) and a composite lining pipe (4), and the composite lining pipe (4) is composed of a wire mesh (2) and a ceramic wear-resistant material (3). Preparation process: Weaving wire mesh (2), cutting, preparing ceramic wear-resistant material (3), evenly coating on the wire mesh (2) and inserting ceramic particles into the gaps of the wire mesh (2), placing The composite plate body of the lining pipe is rolled and placed in the outer casing (1), and the composite lining pipe (4) and the outer casing (1) are rolled and cured by heating, so that the composite lining pipe (4) is closely attached Inside the outer sleeve (1). The invention has the advantages of strong controllability of process parameters, high yield, stable quality and high production efficiency. The product has a long service life, and its wear resistance is 8 to 10 times that of ordinary steel, and 4 to 6 times that of rare earth steel. This process is suitable for the production of pipe products of any shape and size, and has a wide range of applications, and the composite thickness can be adjusted.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High conductivity and high wear resistance copper-molybdenum alloy material and preparation method thereof

The invention relates to a high conductivity and high wear resistance copper-molybdenum alloy material. The material of the invention comprises a matrix alloy Cu, a friction component Al2O3, a lubrication component MoS2, a high temperature component Mo, and copper. A product (the material) is prepared by preparing a mixed powder material through mixing powders of Al2O3, MoS2, Mo and copper according to a proportion and filling into a stainless steel grinding pot of a high energy bowl mill, sending the mixed powder material to a press machine, prepressing into a blank, sending the blank to a cold isostatic press machine to press, and sending the statically pressed blank to a vacuum sintering furnace to sinter. In the invention, quality fraction scopes of above components are determined on the basis of massive experiments, and the experiments prove that ingredients in the component scopes allow reactions to be stably and smoothly carried out, and optimal performances of the material of the invention to be realized.

Owner:HENAN UNIV OF SCI & TECH

Hydraulic motor provided with friction pair with nanometer graphite layer and method for processing nanometer graphite layer

InactiveCN101713298BImprove carrying capacityImprove mechanical efficiencyReciprocating piston enginesPositive-displacement liquid enginesHydraulic motorCrank

The invention relates to a hydraulic motor provided with a friction pair with a nanometer graphite layer and a method for processing the nanometer graphite layer. The hydraulic motor comprises a casing body; a plurality of cylinder bodies are uniformly distributed on the casing body in the radial direction; each cylinder body is internally provided with a plunger piston to form a sliding connection with the casing body; a crankshaft is supported on the casing body and a bearing cover through a bearing; a crank of the crankshaft is uniformly articulated with connecting rods having the same number with cylinder bodies in the radial direction; one end of each connecting rod is articulated with the corresponding part of the crank, and the other end is articulated with a corresponding plunger piston; at least one friction surface of the friction pair formed by the flexible connection parts of the crankshaft and the connecting rods, the connecting rods and the plunger pistons, as well as the plunger pistons and the cylinder bodies is provided with the self-lubricating nanometer graphite layer. The method for processing the nanometer graphite layer comprises the following steps of: painting, surface degreasing, water scrubbing, activating for scouring, sensitizing, film removing and chemical depositing. The formed nanometer graphite layer has antifriction, friction-resistant, heat-resistant and self-lubricating performances, and the carrying capacity, the mechanical efficiency and the service life of the hydraulic motor are enhanced.

Owner:KUNSHAN JINFA HYDRAULIC MACHINERY

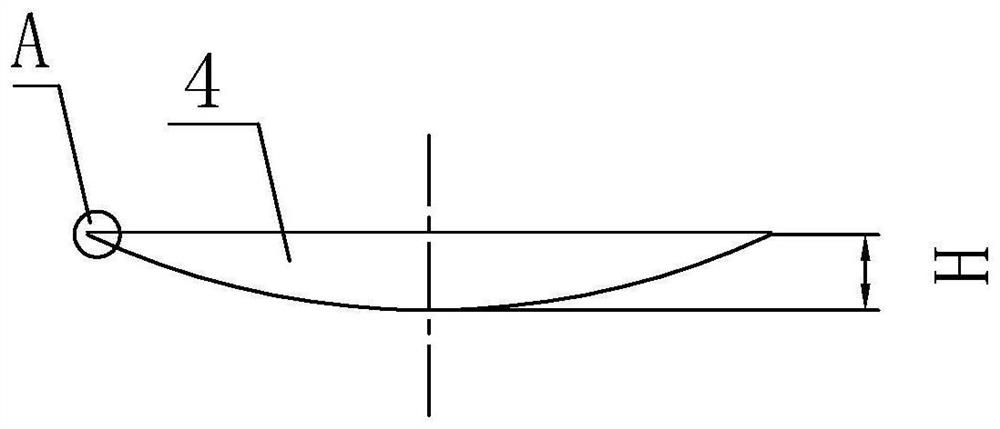

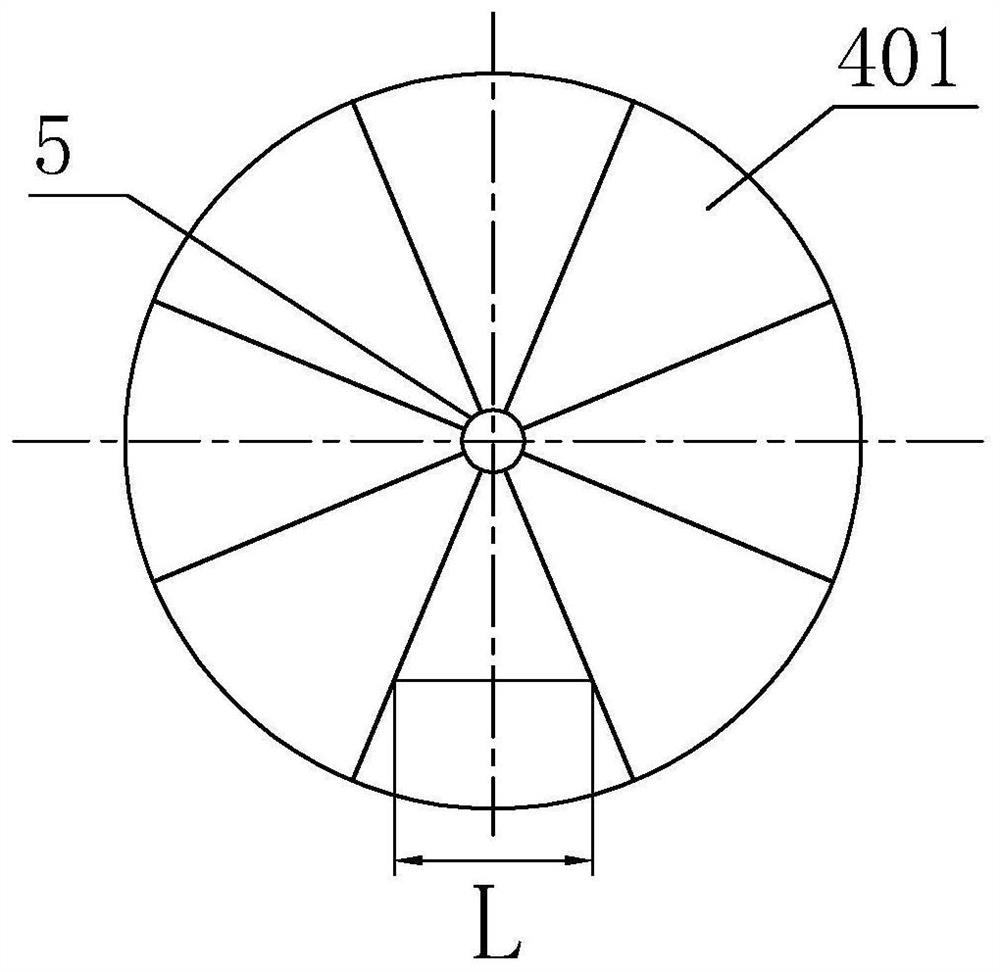

Ellipse head lining manufacturing process

The invention relates to a manufacturing process of an inner liner with an oval seal head, which comprises the following steps: S1, manufacturing an inner liner cover, which includes S11, marking theinner surface of the seal head into N equal parts, S12, drawing an outer edge trace line of the inner liner cover on the inner surface of the seal head, S13, measuring the arc size and the width sideL of the marked dividing area, S14, making one piece of watermelon petal inner liner cover sample, S15, making the remaining N-1 piece of watermelon petals inner liner cover samples, and S16, assemblywelding N pieces equal divided watermelon petal inner liner cover samples; S2, manufacturing an inner liner cone; S3, manufacturing an inner liner cylinder body and S4, assembling an oval seal head inner liner. The manufacturing process of the inner liner with an oval seal head adopts the rolling and forming of the plate bending machine, is not limited by the size of the diameter of the seal head, is convenient to manufacture, accelerates the construction period, saves the cost and has high assembly precision; the inner liner of the oval seal head has an anti-wear effect on a pressure container, and effectively prolongs the service life of the pressure container.

Owner:LIUZHOU ELEVEN METALLURGICAL MACHINERY MFG

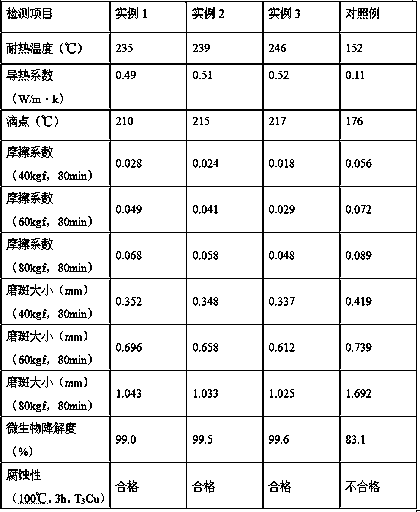

Preparation method of modified expanded graphite plant-based lubricating grease

InactiveCN108300547AImprove the lubrication effectPass wellLubricant compositionAcetic anhydrideChemical protection

The invention relates to the technical field of preparation of lubricating agents, and in particular relates to a preparation method of modified expanded graphite plant-based lubricating grease. According to the preparation method provided by the invention, mixed plant oil is used as lubricating basic oil, modified expanded graphite and pork liver are used as modifying agents, ethylene glycol, melamine and the like are added to prepare the modified expanded graphite plant-based lubricating grease; firstly, the plant oil is extracted from soybeans and peanuts, and fatty acid in the plant oil forms a fatty soap adsorption film on the surface of metal; the adsorption film has a wear-resisting effect; graphite powder is modified by utilizing a concentrated sulfuric acid solution, and is blended with acetic anhydride and potassium permanganate to obtain expanded graphite; then the pork livers and the melamine are continually added, and one layer of chemical protection film is formed on thesurface coated with the lubricating grease by utilizing elements including nitrogen, phosphorus, sulfur and the like in the pork livers and the melamine, so that a protection effect on the lubricatinggrease is realized; biological oil is used for replacing mineral oil, so that damages to human bodies and environment are not caused; the protection of resources is facilitated, and the lubricating grease has a wide application prospect.

Owner:陈毅忠

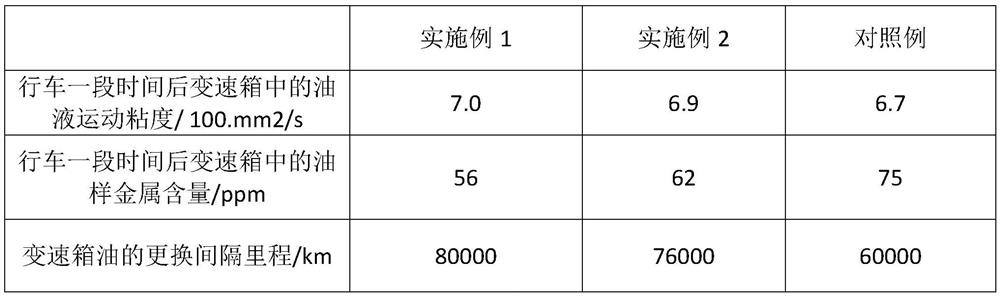

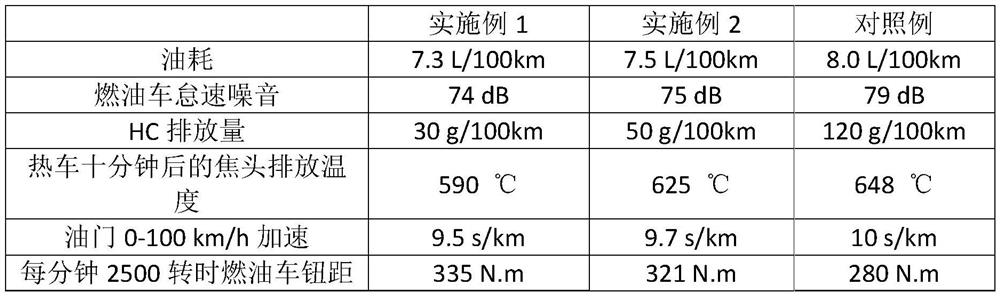

Gearbox oil additive for gearbox of fuel vehicle and preparation method of gearbox oil additive

The invention discloses a gearbox oil additive for a gearbox of a fuel vehicle, which is characterized in that the gearbox oil additive comprises gearbox oil, water-based nano gold and water-based nano platinum. The invention further discloses a preparation method of the gearbox oil additive. By adding the gearbox oil additive into the gearbox of the fuel vehicle and fusing the gearbox oil additive with the gearbox oil in the gearbox, the stability of the gearbox oil can be kept, and the anti-attenuation performance of the gearbox oil can be improved, so that the gearbox is better protected, and the service life of the gearbox is prolonged. Meanwhile, friction is generated under stirring of the gearbox, so that a large amount of far infrared rays are generated, the far infrared rays are guided into the engine in a penetrating mode through the contact parts of the main shaft, the gearbox shell and the engine shell, the engine is indirectly affected, and the combustion efficiency of the engine is improved.

Owner:速马力(广州)环保研究院有限责任公司

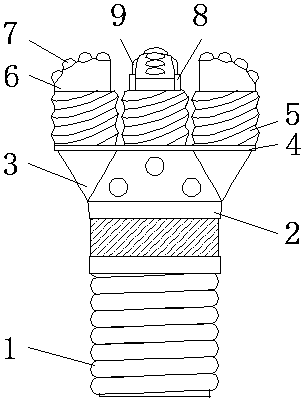

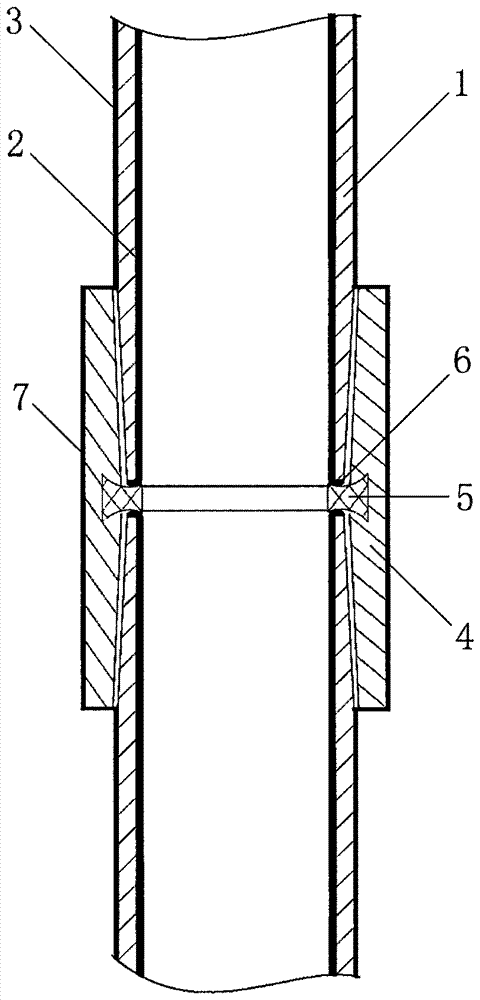

Oil and water well extraction and injection tubular column internally and externally wrapped with hot melting plastic layers and manufacturing method of tubular column

ActiveCN107165584AExtension of Advanced Standing PeriodLow failure rateDrilling rodsFluid removalFailure rateExposed point

The invention discloses an oil and water well extraction and injection tubular column internally and externally wrapped with hot melting plastic layers and a manufacturing method of the tubular column. The inner wall and the outer wall of each extraction and injection steel pipe are wrapped with the hot melting plastic layers, and the extraction and injection steel pipes are in screw connection with each other through pipe couplings. As for a pipe opening gasket between pipe openings of every two extraction and injection steel pipes, an inner ring is in a slab shape, the outer ring is in a trapezoid with the larger outside and the smaller inside, and the trapezoidal outer ring of the pipe opening gasket is firmly embedded into a trapezoidal groove of the corresponding pipe coupling. The inner wall and the outer wall of the overall tubular column are both wrapped with plastic, no gas and no steel exposed point exist between the inner walls of the extraction and injection steel pipes and the hot melting plastic layers, and the condition that liquid and gas make contact with steel is obstructed. Owing to the fact that inner layer plastic and the outer layer plastic cannot fall off, the effect that the tubular column inner walls of full oil extraction wells and injection wells are completely resistant to corrosion is achieved, and the wear-resistant effect of the tubular column pipe walls is achieved, so that the service life of the overall extraction and injection tubular column is prolonged by 3-5 times, and the repairing-free periods of the oil and water wells are prolonged by 2-3 times. According to the extraction and injection tubular column, steel is saved, the oil exploiting cost is reduced, the failure rate of the oil wells is decreased, and working efficiency is improved.

Owner:张志民

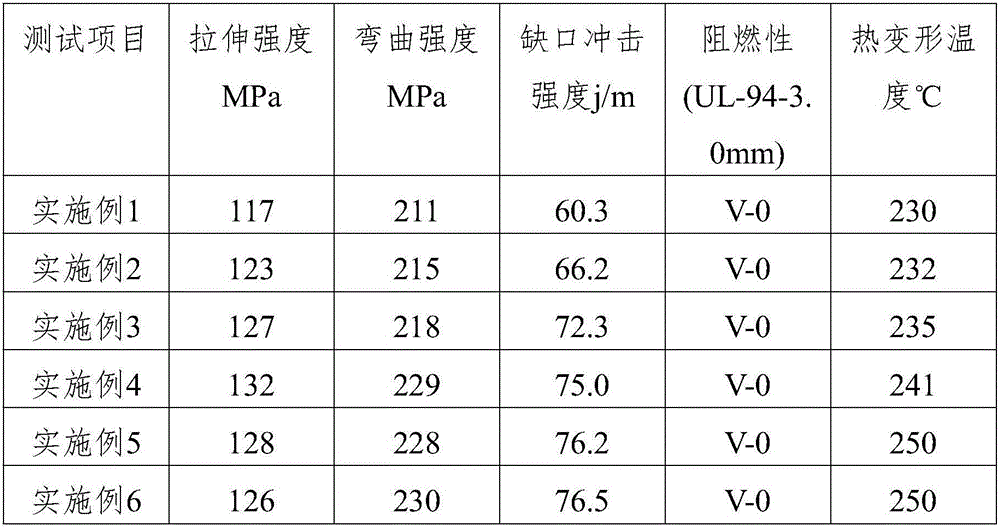

High-temperature resistance modified polyethylene glycol terephthalate

InactiveCN106009557AImprove high temperature resistanceImprove flame retardant performanceFiberMonoglyceride

The invention discloses a high-temperature-resistant modified polyethylene terephthalate, which is prepared from the following raw materials in parts by weight: polyethylene terephthalate, cellulose acetate butyrate, polybutylene Diene rubber, glyceryl monostearate, glass microspheres, antioxidant, reinforcing fiber, dibutyl phthalate, azobisisobutyronitrile, oleic acid diethanolamide, fumed silica. The invention has excellent high temperature resistance, flame retardancy, mechanical strength and hardness, can reduce production cost at the same time, and is suitable for large-scale promotion in industrial production.

Owner:ANHUI NINGGUO TIANCHENG ELECTRICAL APPLIANCES

Water-based cutting fluid and preparation method thereof

PendingCN114276863APrevent oxidationPrevent sinteringLubricant compositionMegasonic cleaningEngineering

The invention relates to a water-based cutting fluid and a preparation method thereof, and belongs to the technical field of cutting fluid preparation. The water-based cutting fluid disclosed by the invention does not contain grease substances, so that the prepared cutting fluid is colorless and transparent, and the surface of the cutting fluid does not contain any greasy dirt. And after the part is machined, only aluminum skimmings generated in the machining process need to be washed in clear water. The cutting fluid can perfectly replace traditional cutting fluid, and an ultrasonic cleaning link can be omitted. And the cutting fluid is excellent in rust resistance, good in cutting effect and wide in application prospect.

Owner:广西巨石新能源科技有限公司

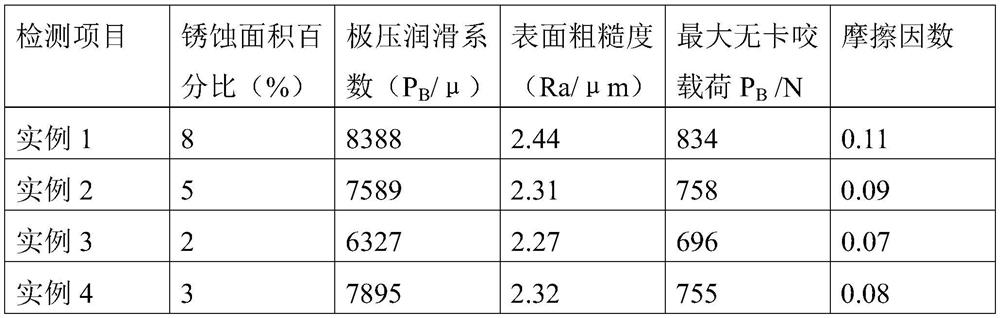

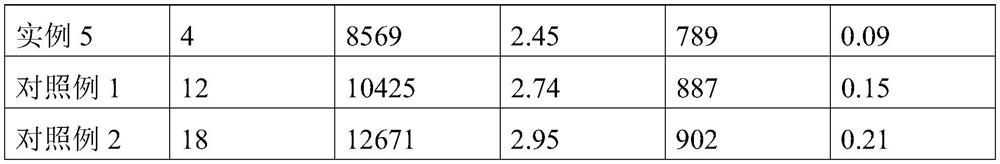

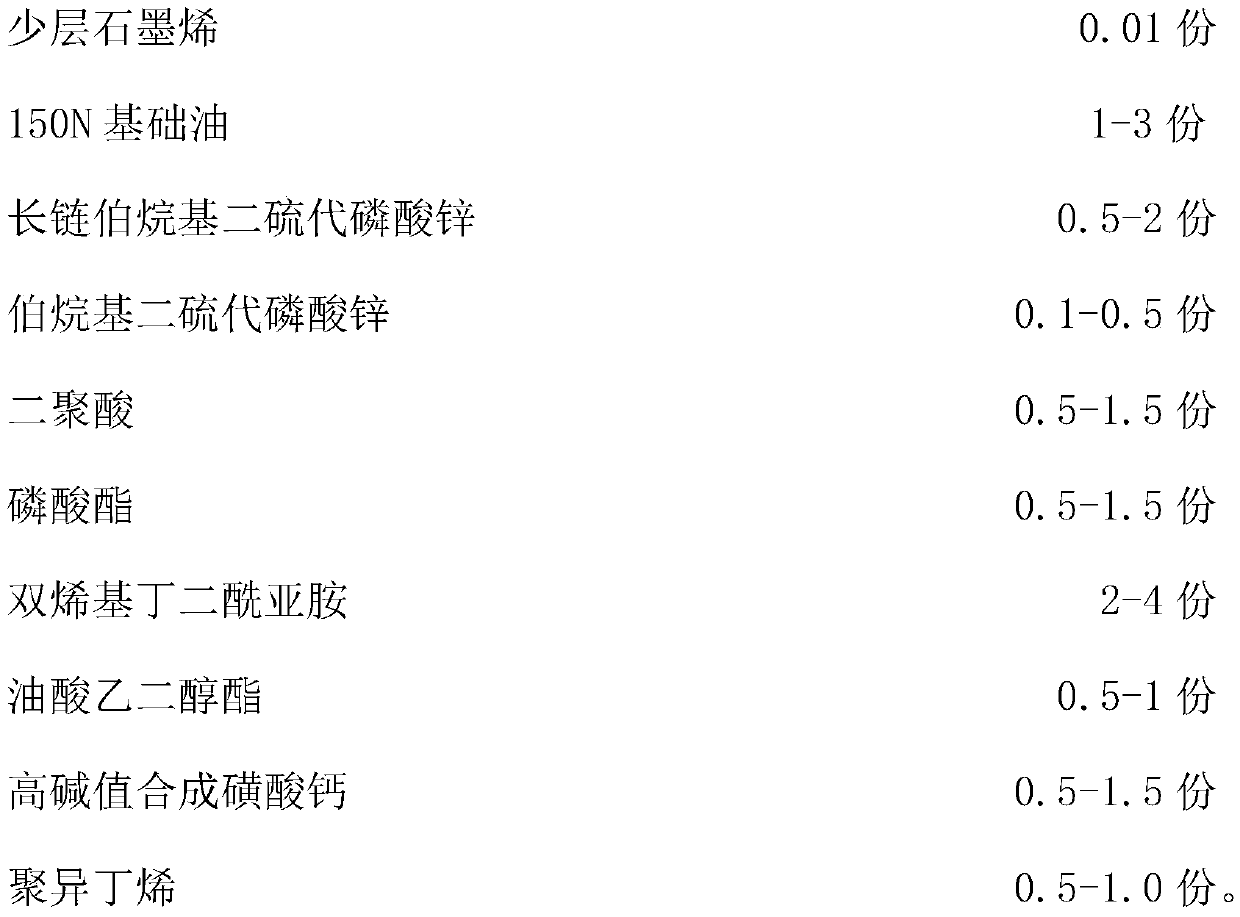

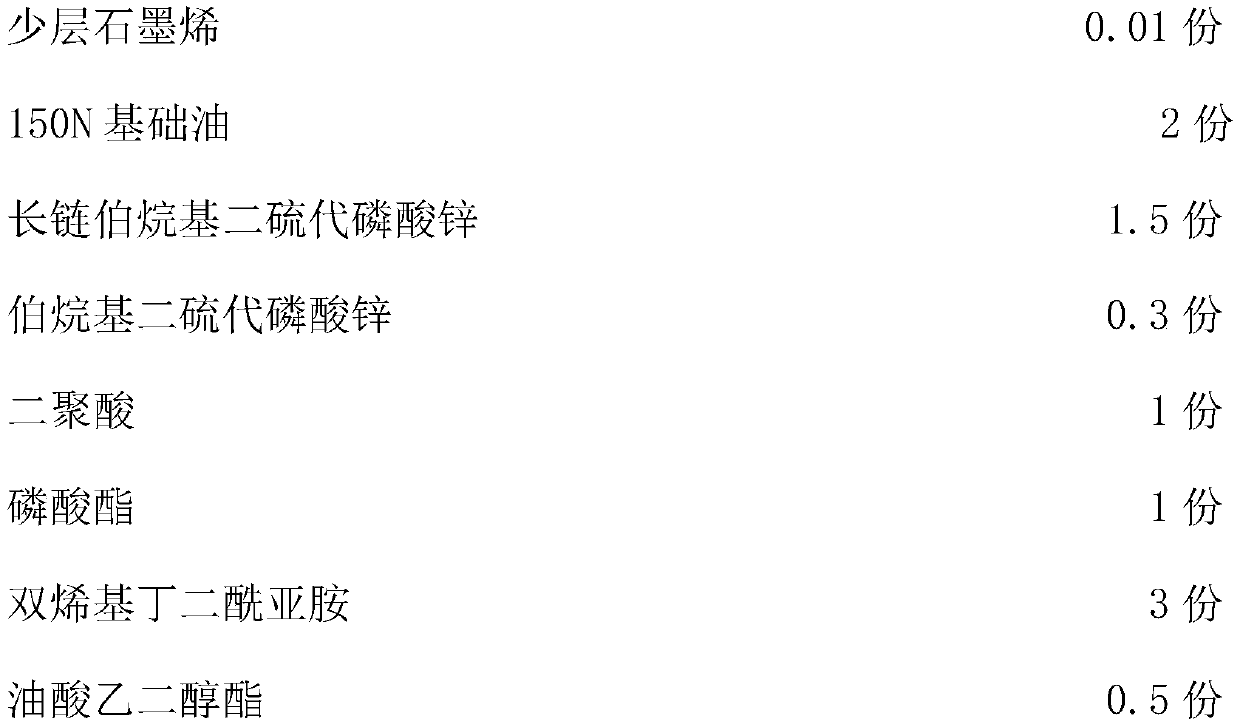

Anti-wear energy-saving agent, and preparation method and application thereof

The invention provides an anti-wear energy-saving agent, and a preparation method and an application thereof. The anti-wear energy-saving agent is prepared by mixing few-layer graphene with base oil,an anti-wear agent (few-layer graphene, zinc long-chain primary alkyl dithiophosphate and zinc primary alkyl dithiophosphate), an antirust agent (dimer acid and phosphate) and an anticorrosion agent (2,6-di-tert-butyl-p-cresol), an extreme pressure agent (zinc long-chain primary alkyl dithiophosphate and zinc primary alkyl dithiophosphate), a viscosity index improver (polyisobutylene), an oilinessagent (ethylene glycol oleate) and a purification dispersant (high-base-number synthetic calcium sulfonate) according to a specific ratio. The anti-wear energy-saving agent has excellent wear resistance, friction reduction performance, oxidation resistance and corrosion resistance.

Owner:贵州中时烯材科技有限公司

Oil and water well production string and production method thereof covered with hot-melt plastic layer inside and outside

ActiveCN107165584BExtension of Advanced Standing PeriodLow failure rateDrilling rodsFluid removalFailure rateExposed point

Owner:张志民

Highly compression-resistant double-layer copper-alloy contact wire and preparation method thereof

The invention discloses a highly compression-resistant double-layer copper-alloy contact wire and a preparation method thereof. The copper-alloy contact wire has the tensile strength of above 450MPa, the tensile failure force of above 48KN, and the conductivity of above 75% IACS, the two sides of the copper-alloy contact wire are provided with gaps, the copper-alloy contact wire comprises an outer tin coating layer and an inner copper alloy body, copper alloy body cross sections above or below the gaps are fan-shaped, a plurality of telescoping mouths are arranged on the tin coating layer, and copper alloy is prepared by processes of powder making, pre-compaction, billet ingot making and the like. The copper alloy contact wire has a unique structure, high conductivity can be guaranteed, at the same time, components can play effects of reducing wear and resisting abrasion, and during the use of the copper alloy contact wire, temperature difference and electric spark burn can be effectively prevented.

Owner:DATANG LUOYANG CO GENERATION POWER

A kind of organic antifriction agent for drilling fluid and preparation method thereof

ActiveCN105647490BReduce use costPlay an anti-wear roleDrilling compositionHigh densityHorizontal wells

Organic antifriction composition for drilling fluid is composed of, prepared in 100%, 45-65 parts of organic acidic metal salt, 15-35 parts of mineral oil, 5-10 parts of emulgator, and 8-15 parts of extreme-pressure additive. During preparation, the components are proportionally added into a reactor and react for 4-6 hours at 50-90oC, producing yellow or brown liquid which is antifriction composition. The antifriction composition can form a high-intensity extreme-pressure lubricating film to be antifriction through its organic negative ions adsorbing to the surface of a casing or a drilling rod, and can replace or partially replace lubricant, using cost of lubricant is reduced, and the antifriction composition is applicable to highly-deviated wells, horizontal wells, high-density drilling fluid and long-cycle prospecting wells.

Owner:成都西油华巍科技有限公司

A kind of environment-friendly gasoline additive and preparation method thereof

ActiveCN110373235BExtended service lifeOptimize geometryLiquid carbonaceous fuelsPolythylene glycolEthyl group

Owner:交城县万里通加油站

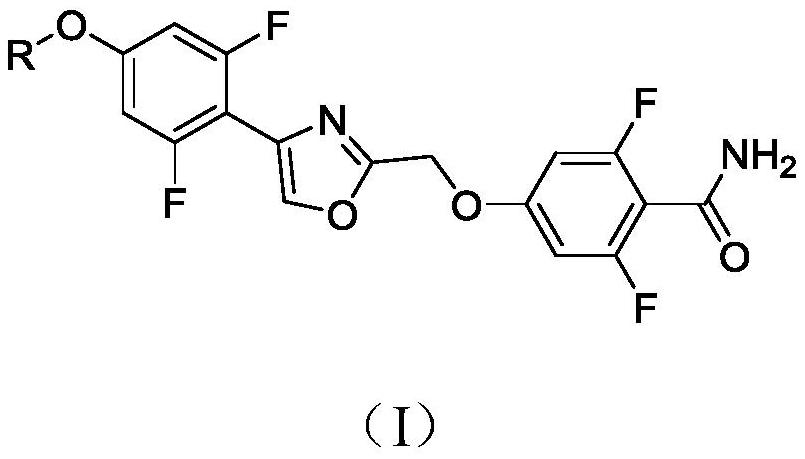

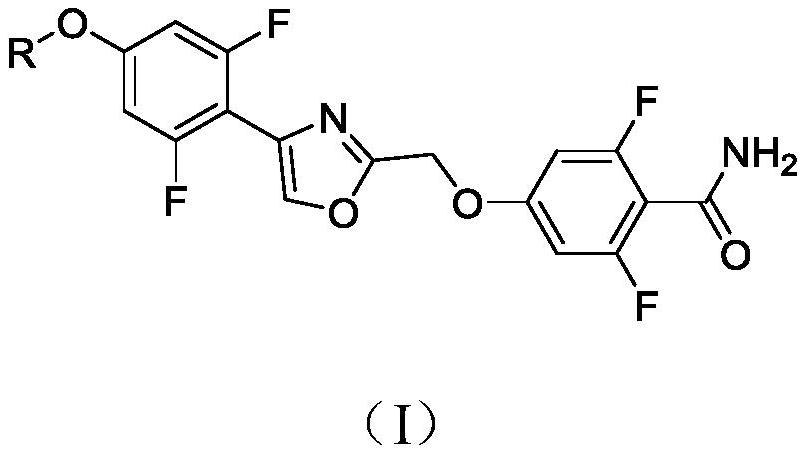

Chain transfer agent for preparing antibacterial polymer and preparation method thereof

InactiveCN111848540AThe synthesis process is simple to operateEasy to operateBiocideOrganic chemistryPolymer scienceOil additive

The invention discloses a chain transfer agent for preparing an antibacterial polymer and a preparation method of the chain transfer agent. The chain transfer agent for preparing the antibacterial polymer has a structure as described in the specification. In the formula, R is as defined in the specification. The preparation method for the chain transfer agent used for preparing the antibacterial polymer has the advantages that operation is simple, no toxic by-product is generated, and the price of synthesis raw materials is low; the polymer prepared from the chain transfer agent has a good bactericidal effect; and the chain transfer agent can be used as a lubricating oil additive and has good anti-wear and anti-friction effects.

Owner:吴张峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com