Highly compression-resistant double-layer copper-alloy contact wire and preparation method thereof

A copper alloy and contact wire technology, applied in the field of copper alloy contact wire and its preparation, can solve the problems of pure copper melting point, low room temperature strength and high temperature strength, difficult to meet the requirements of harsh working conditions, etc., and achieve excellent physical and mechanical integration. Performance, easy control, well-distributed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The steps of a method for preparing a high-pressure-resistant double-layer copper alloy contact wire are as follows:

[0027] 1. Ni with a mass fraction of 0.2-0.5%, Si with a mass fraction of 0.1-0.5%, Mg with a mass fraction of 0.1-0.5%, Wc with a mass fraction of 0.2-0.5%, and Si with a mass fraction of 0.2-0.5% Co, Ti with a mass fraction of 0.1-0.5%, and Cr with a mass fraction of 0.1-0.3% 2 o 3 , PbO with a mass fraction of 0.1-0.3% and copper powder with a mass fraction of 96.4-98.9%. not less than 10 -3 Pa, dry nitrogen protection, made mixed powder material;

[0028] 2. Send the mixed powder material into the press, pre-press it into a billet, and hold the pressure for 20-35 minutes;

[0029] 3. Send the pre-pressed billet into the cold isostatic press for pressing at a pressure of 230-280 MPa and keep the pressure for 10-15 minutes;

[0030] 4. The billet after the static pressure in step 3 is made into a billet, sent into a vacuum sintering furnace for s...

Embodiment 1

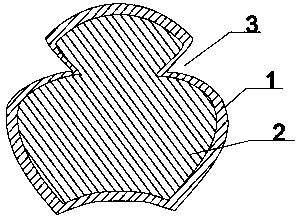

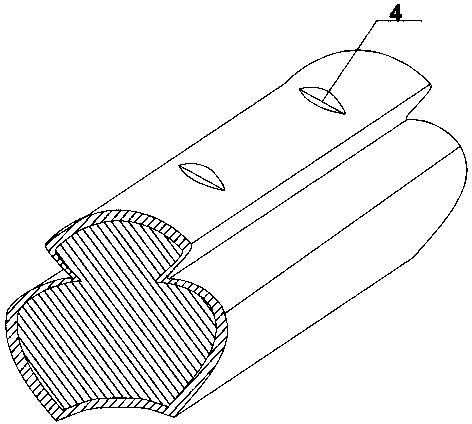

[0034] A high compressive double-layer copper alloy contact wire, the copper alloy contact wire has a tensile strength of 450MPa, a breaking force of 48KN, and an electrical conductivity of 75% IACS. Layer and inner layer of copper alloy body, the cross-section of the copper alloy body located below the gap is fan-shaped, and there are multiple telescopic openings on the tin-plated layer. The raw material of the copper alloy body is made of Cu, Ni, Si, Mg, Wc, Co, Ti, Cr 2 o 3 and PbO, the mass fraction of each material is: Ni0.2%, Si0.1%, Mg0.1%, Wc0.2%, Co0.2%, Ti0.1%, Cr 2 o 3 0.1% and PbO0.1%, the rest is copper; Ni, Si, Mg, Wc, Co, Ti, Cr in the prepared alloy 2 o 3 and PbO uniformly distributed in the copper matrix.

[0035] The steps of a method for preparing a high-pressure-resistant double-layer copper alloy contact wire are as follows:

[0036] One, the mass fraction is 0.2% Ni, mass fraction is 0.1% Si, mass fraction is 0.1% Mg, mass fraction is 0.2% Wc, mass ...

Embodiment 2

[0043] A high-pressure-resistant double-layer copper alloy contact wire. The tensile strength of the copper alloy contact wire is 470MPa, the breaking force is 50KN, and the electrical conductivity is ≥72%IACS. It is composed of the copper alloy body in the inner layer. The cross-section of the copper alloy body located below the gap is fan-shaped, and there are multiple telescopic openings on the tin-plated layer. The raw material of the copper alloy body is Cu, Ni, Si, Mg, Wc, Co , Ti, Cr 2 o 3 and PbO, the mass fraction of each material is: Ni0.5%, Si0.5%, Mg0.5%, Wc0.5%, Co0.5%, Ti0.5%, Cr 2 o 3 0.3% and PbO0.3%, the rest is copper; Ni, Si, Mg, Wc, Co, Ti, Cr in the prepared alloy 2 o 3 and PbO uniformly distributed in the copper matrix.

[0044] The steps of a method for preparing a high-pressure-resistant double-layer copper alloy contact wire are as follows:

[0045] One, the mass fraction is 0.5% Ni, the mass fraction is 0.5% Si, the mass fraction is 0.5% Mg, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| breaking force | aaaaa | aaaaa |

| breaking force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com