Chain transfer agent for preparing antibacterial polymer and preparation method thereof

A technology of chain transfer agent and polymer, which is applied in the fields of chemicals for biological control, botanical equipment and methods, animal repellent, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of 2-(Ethylmercaptothioformylthio)-2-methylpropionyl chloride.

[0038] Add 2-(ethylmercaptothioformylthio)-2-methylpropionic acid (5mmol) and 11.2mL carbon tetrachloride into a 25mL branch bottle, mix thoroughly, and then add 1.2mL acyl chloride reagent chlorine Add sulfoxide, stir continuously until clarification; heat the mixed solution to 77°C for 2 hours, after the reaction, evaporate the solvent in a vacuum rotary, petroleum ether: ethyl acetate (v / v) 10:1 as the mobile phase and pass through the column for purification , to obtain a yellow oily liquid, which was dried under vacuum at room temperature to obtain 2-(ethylmercaptothioformylthio)-2-methylpropionyl chloride with a yield of 91.4%.

Embodiment 2

[0040] Preparation of benzyltrithiocarbonate propionyl chloride.

[0041] The same reaction conditions as in Example 1, the chain transfer agent uses benzyl trithiocarbonate propionic acid to replace 2-(ethylmercaptothioformylthio)-2-methyl propionic acid to obtain benzyl trisulfide Substituted carbonyl propionyl chloride, the yield was 87.3%.

Embodiment 3

[0043] N 2 Under protection, 2'-bromo-2,6-difluoro-4-hydroxyacetophenone (5mmol), freshly distilled pyridine (10mmol) and 8mL tetrahydrofuran were added to a 50mL branched-necked flask, and 2'-bromo-2, After 6-difluoro-4-hydroxyacetophenone is completely dissolved; the 2-(ethylmercaptothioformylthio)-2-methylpropionyl chloride (5mmol) prepared in the above steps is dissolved in tetrahydrofuran and heated at 0°C Added dropwise to 2'-bromo-2,6-difluoro-4-hydroxyacetophenone solution, stirred at room temperature for 1 hour, then added 15 mL of chloroform, raised the temperature to 65°C and reacted for 10 hours, and washed with saturated sodium bicarbonate, Deionized water and dilute hydrochloric acid washed the mixed solution, and the obtained crude product was evaporated to dryness under reduced pressure, and petroleum ether: ethyl acetate (v / v) was 12:1 as the mobile phase for column purification to obtain chain transfer agent esterification product A1 , and the yield was 82.6...

PUM

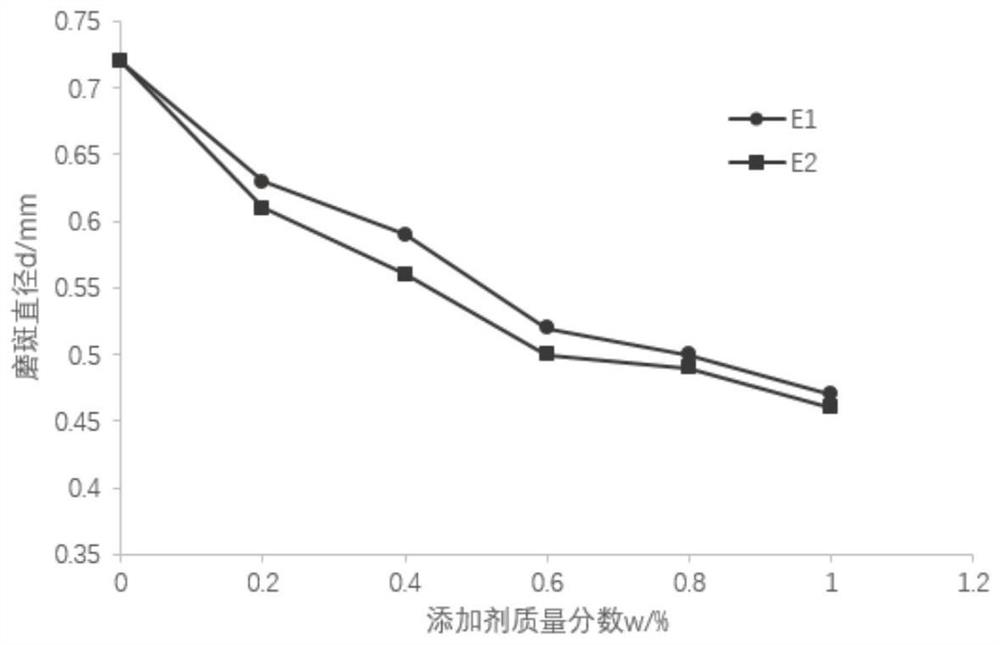

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com