Oil and water well extraction and injection tubular column internally and externally wrapped with hot melting plastic layers and manufacturing method of tubular column

A technology of hot-melt plastic and plastic layer, applied in drilling pipes, casings, production fluids, etc., can solve the problems of easy string movement, expansion and contraction, bulging, annular scaling, gasket deformation, etc., so as to reduce the cost of oil production and improve the The effect of working efficiency and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

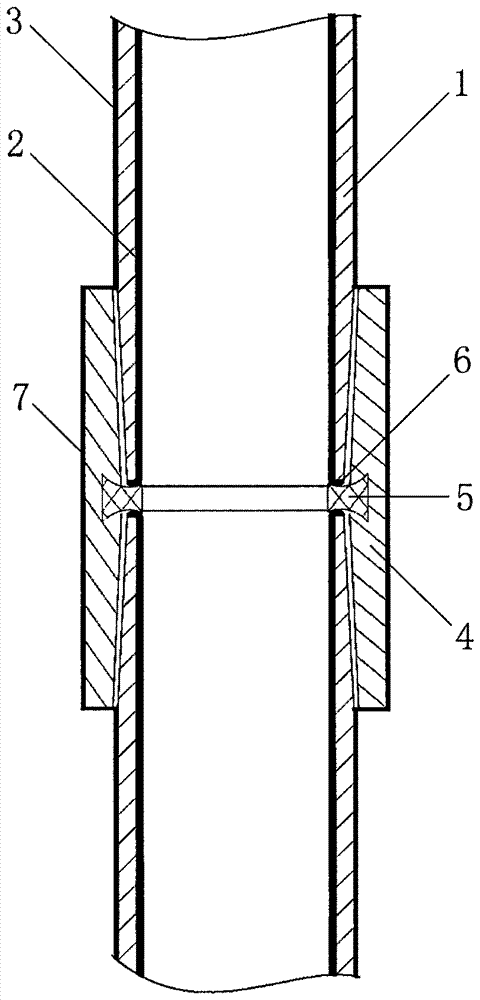

[0028] see figure 1 , the present invention is an oil and water well production and injection pipe string covered with a hot-melt plastic layer inside and outside, which is to connect the production and injection steel pipes 1 from top to bottom. The inner wall of each mining injection steel pipe 1 is covered with an inner hot-melt plastic layer 2 , and the outer wall is covered with an outer hot-melt plastic layer 3 . The inner hot-melt plastic layer 2 and the outer hot-melt plastic layer 3 use hot-melt technology to fuse the plastic on the inner and outer walls of the injection steel pipe 1, so that the three are firmly combined as one, and the inner and outer layers are completely eliminated. Danger, has played the effect that the inner and outer walls of mining injection steel pipe 1 are completely anti-corrosion and wear-resistant. The ends of each production and injection steel pipe 1 are threaded buckles, and every two production and injection steel pipes 1 are screwed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com