Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

176results about How to "Reduce eccentric wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

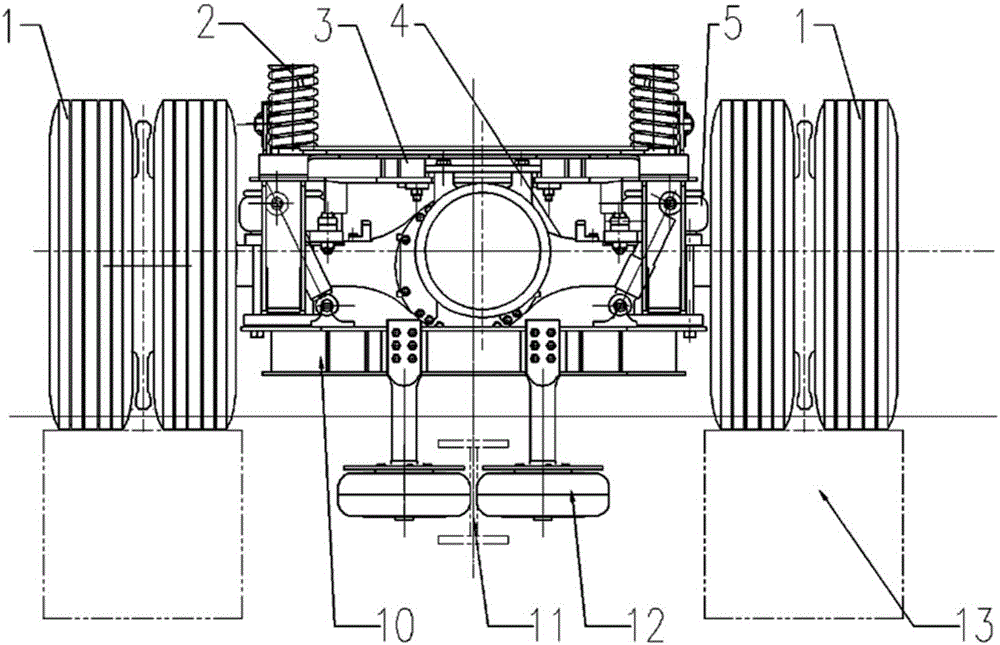

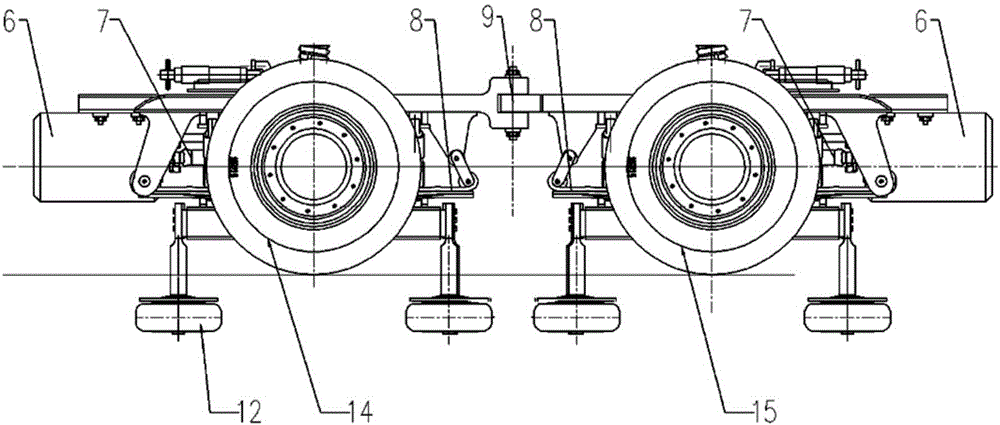

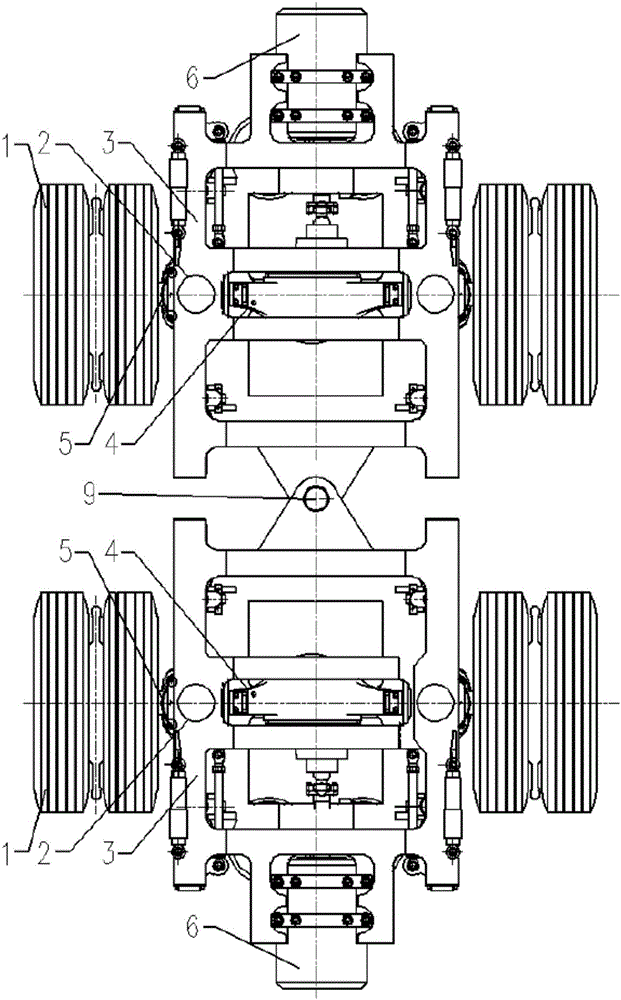

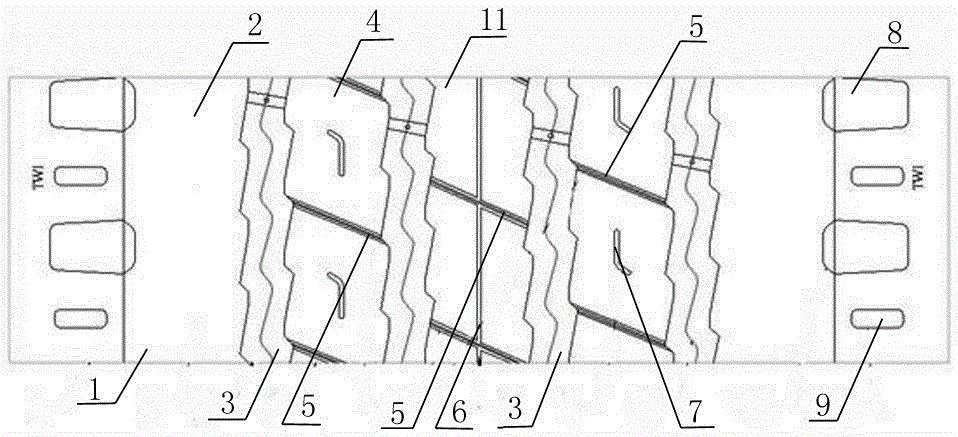

Hinged railway vehicle bogie and railway vehicle

ActiveCN106080644ASolve the distance problemSolve poor climbing abilityBogie-underframe connectionsBogieWheel and axle

The invention discloses a hinged railway vehicle bogie and a railway vehicle. The hinged railway vehicle bogie comprises a non-integral framework which is formed mainly by hinging a first portion to a second portion. A first wheel axle is installed on the first portion of the framework, a second wheel axle is installed on the second portion of the framework, and the first wheel axle and the second wheel axle form an included angle when the railway vehicle passes a curve. According to the hinged railway vehicle bogie and the railway vehicle, the accessible curve radius is small, the eccentric wear of a walking wheel is less, and the maintenance cost is low.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

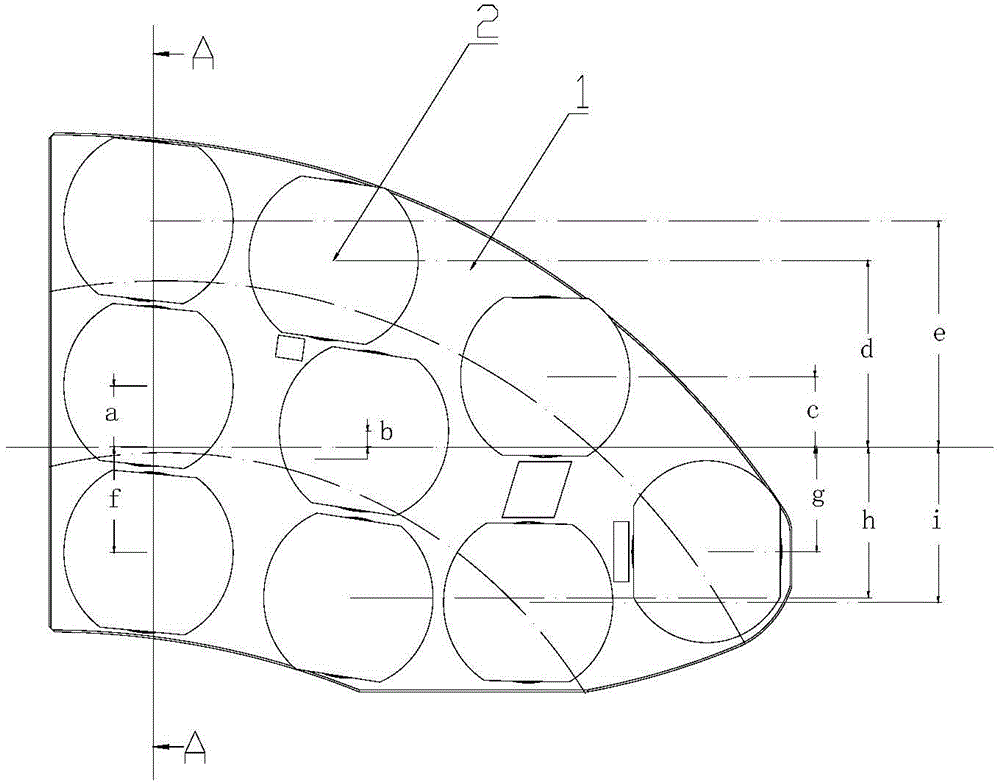

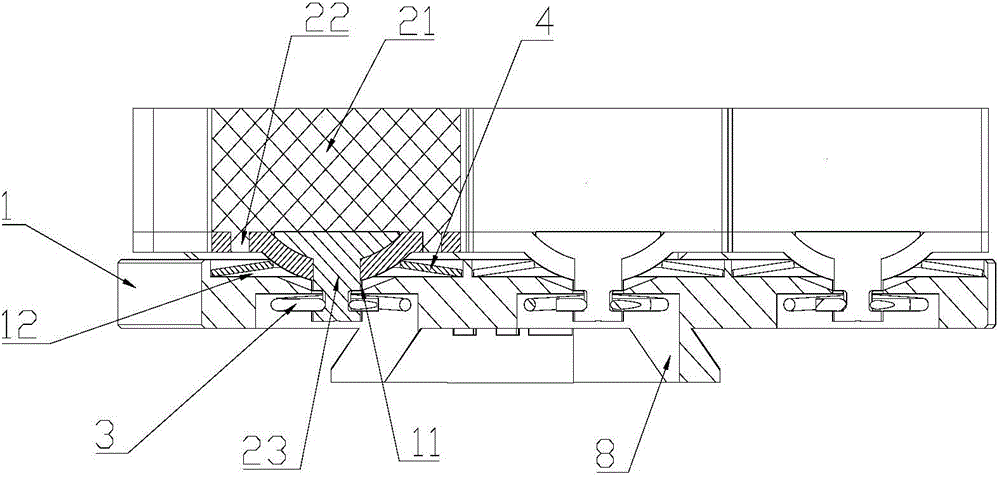

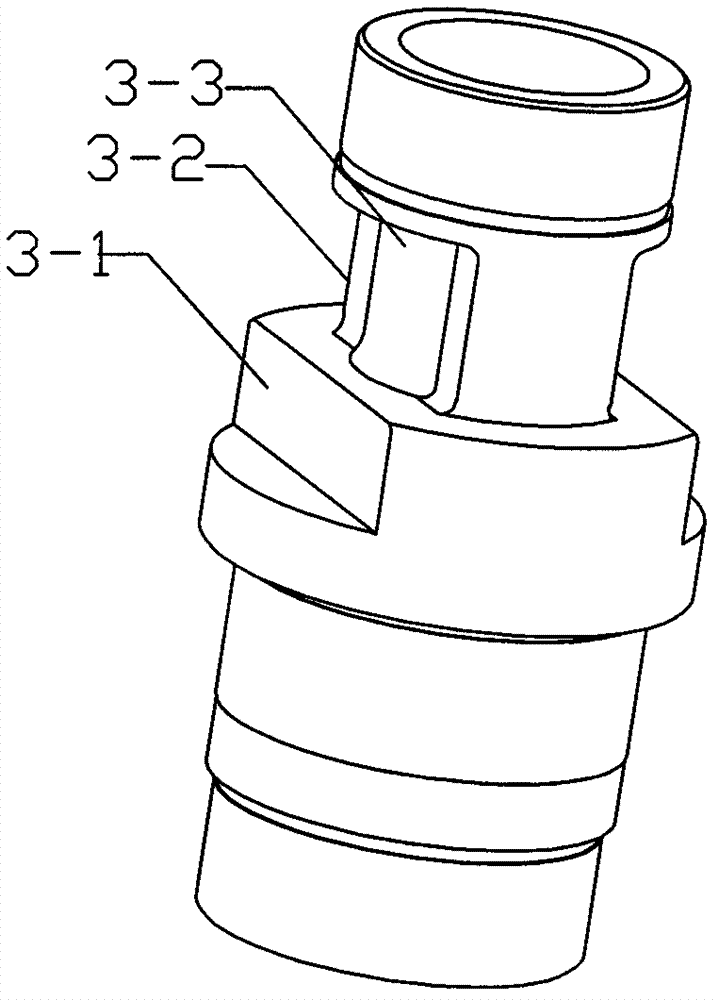

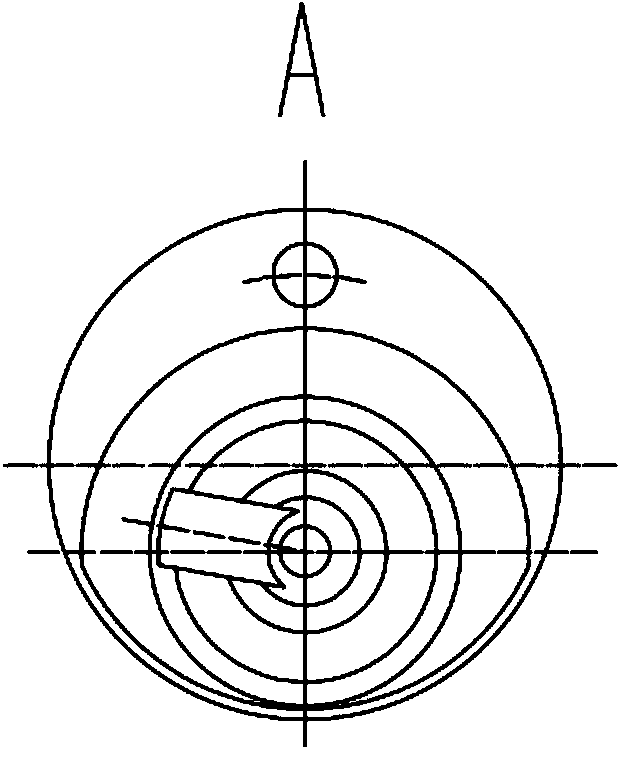

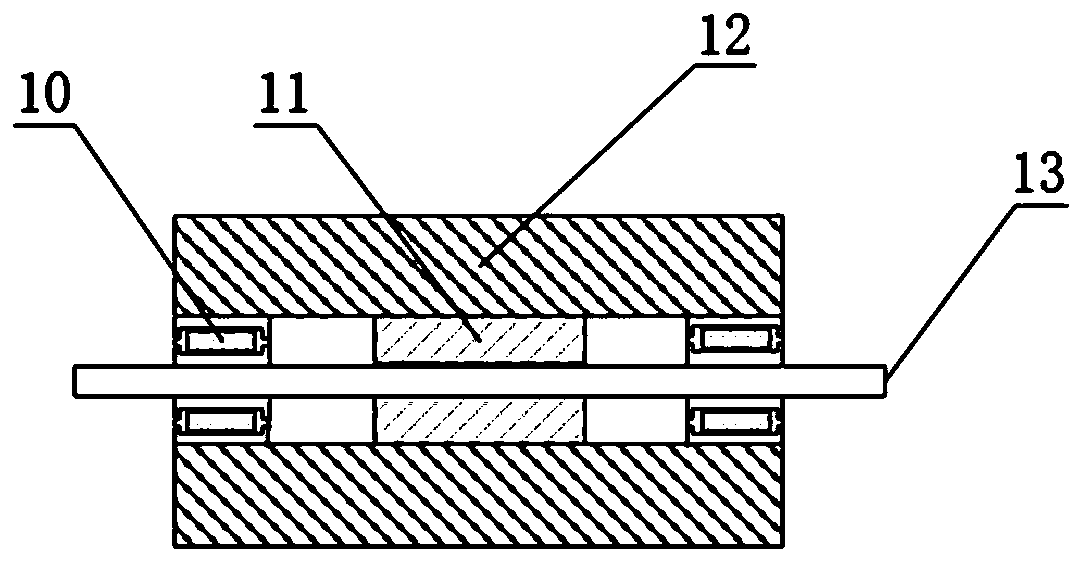

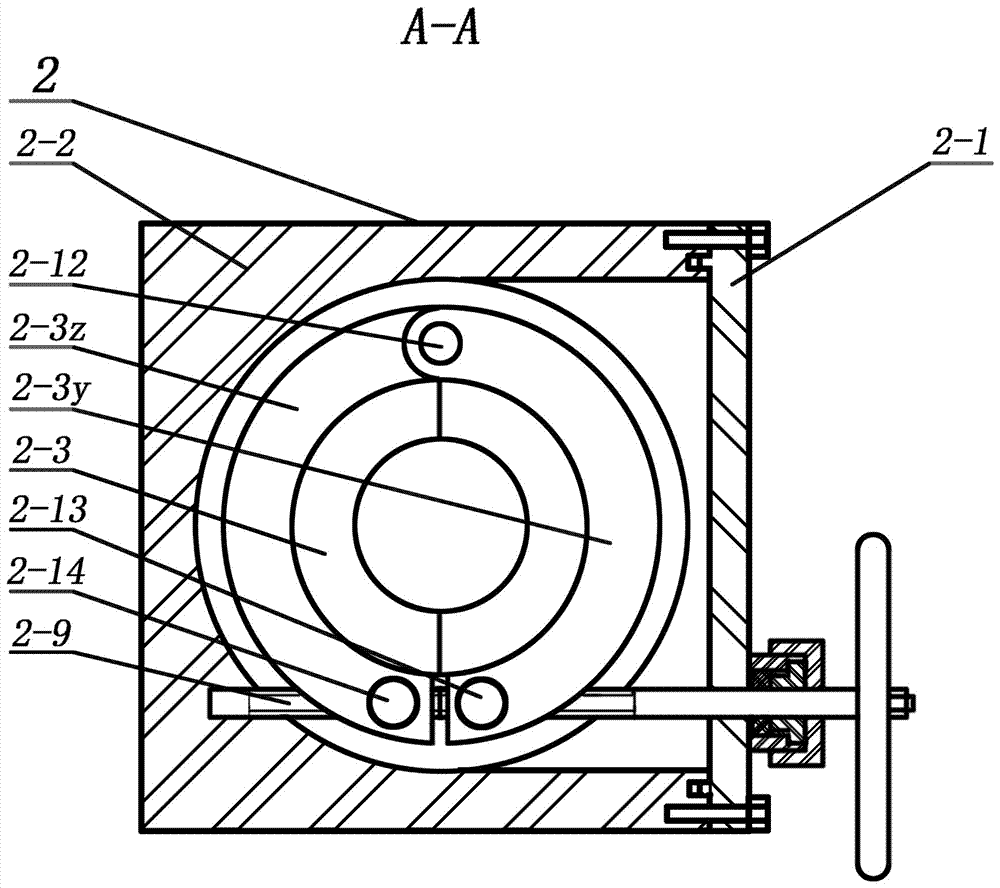

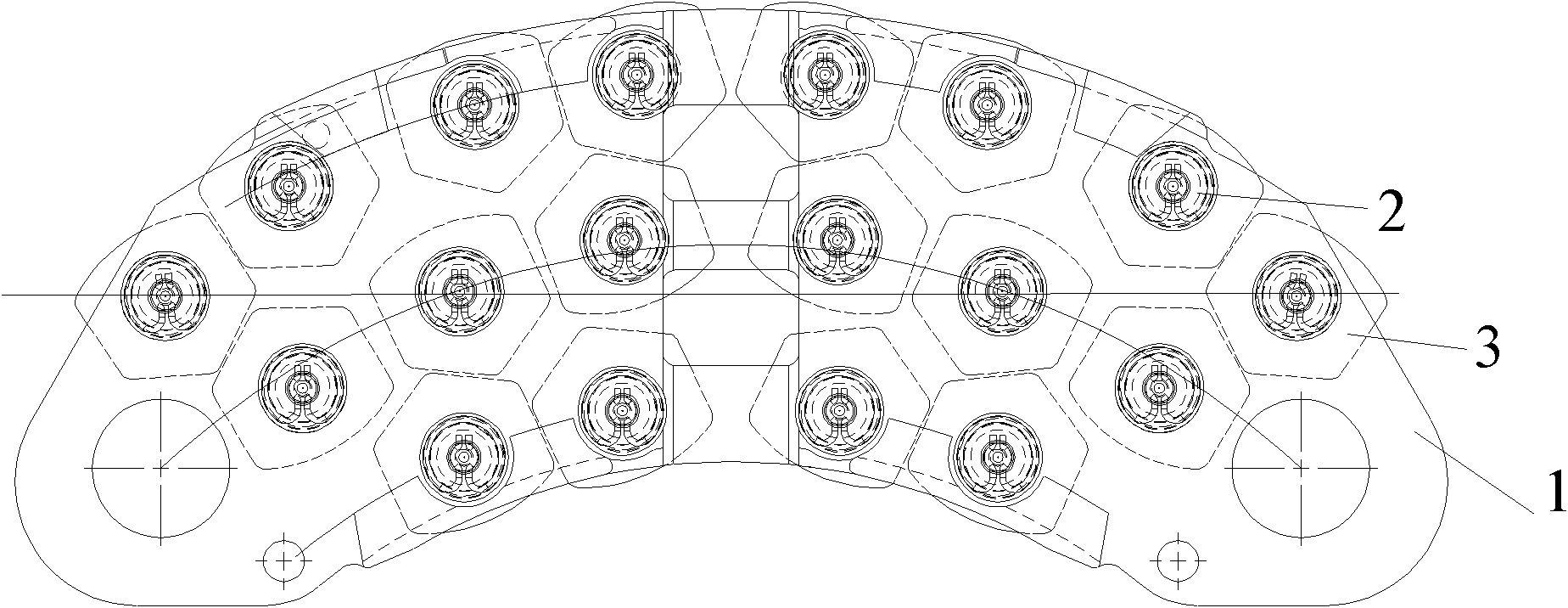

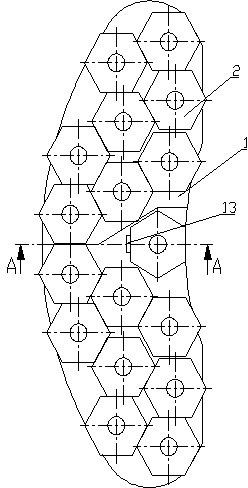

Floating type brake pad

InactiveCN104455105AConsistent heat fluxExtended service lifeBraking membersFriction liningStress concentrationEngineering

The invention discloses a floating type brake pad. The floating type brake pad comprises a back plate, a plurality of friction blocks, disc springs and clamping springs, wherein the friction blocks are arranged on the back plate, the disc springs are arranged between the friction blocks and the back plate, and the friction blocks are connected to the first back plate in a floating mode through the clamping springs. Positioning grooves are formed in the back plate, and the disc springs are arranged inside the positioning grooves. The back plate is divided into a plurality of concentric circular rings by using the circle center of a brake disc matched with the brake pad as the circle center. The circular rings are equal in radial length. The friction area of the friction block inside each circular ring is not larger than 15% of the standard average friction area compared with the standard average friction area. According to the floating type brake pad, the problem of fatigue cracks caused by instantaneous stress concentration during braking of existing disc springs is solved, meanwhile, gaps between the back plate and the friction blocks are reduced, oscillation of the friction blocks is small, meanwhile, the problem of eccentric abrasion of the friction blocks is avoided, and the brake stability is greatly improved.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

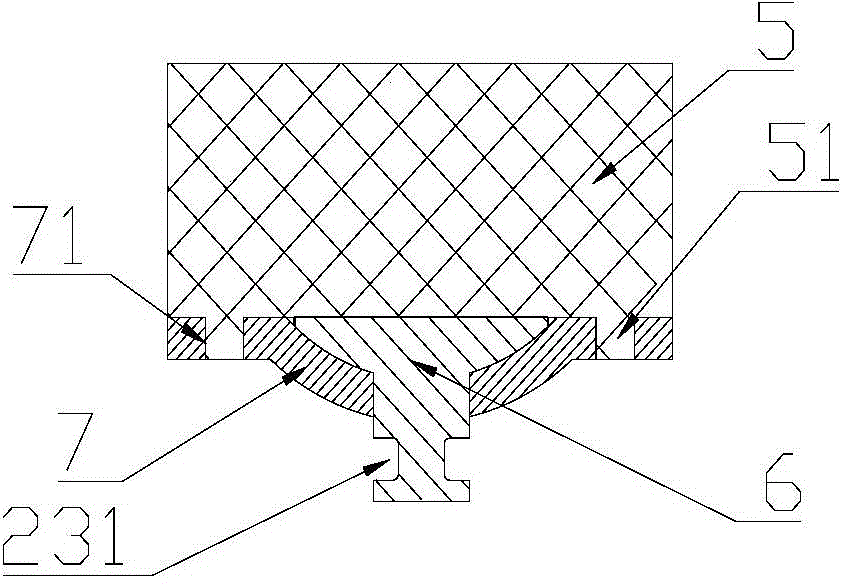

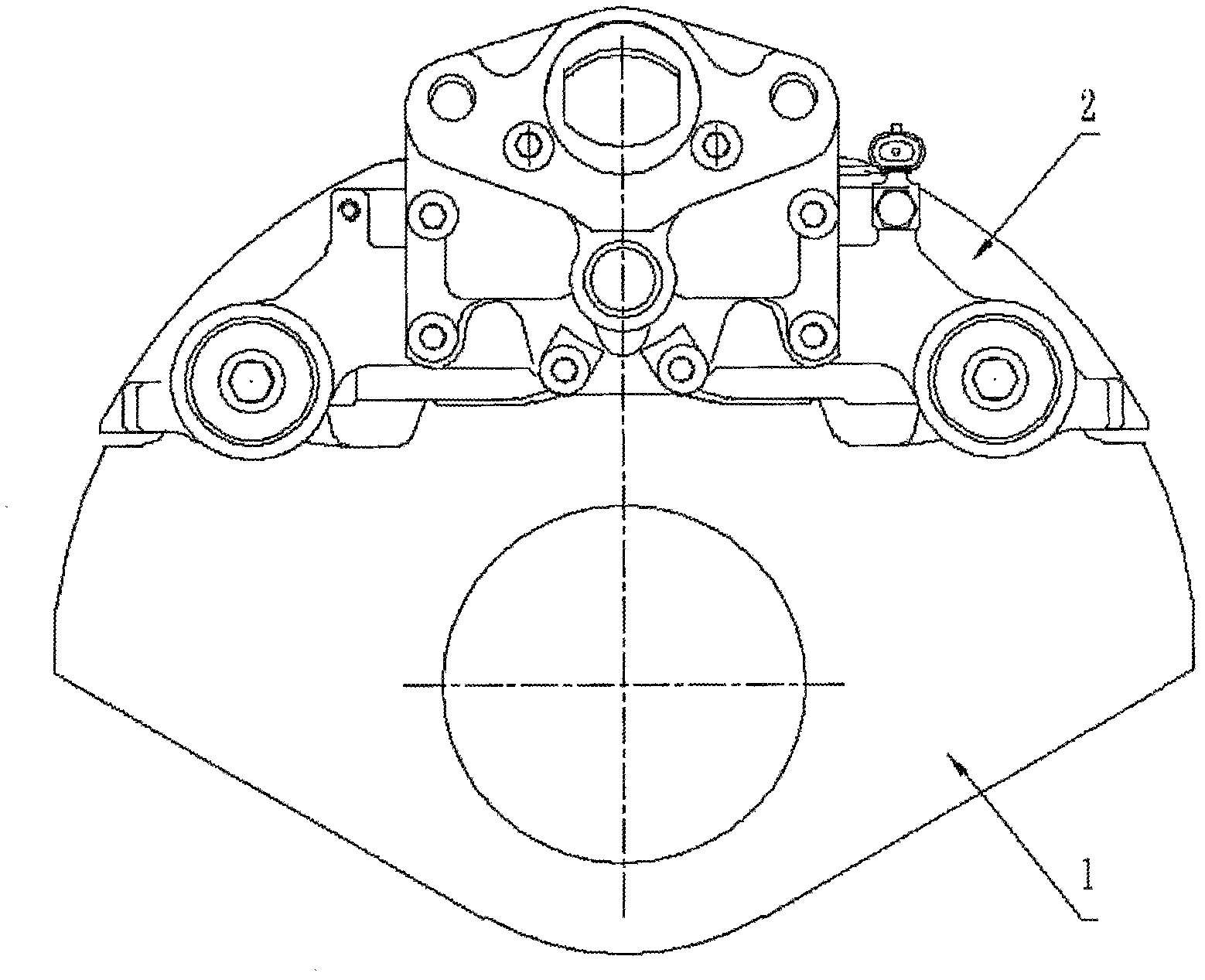

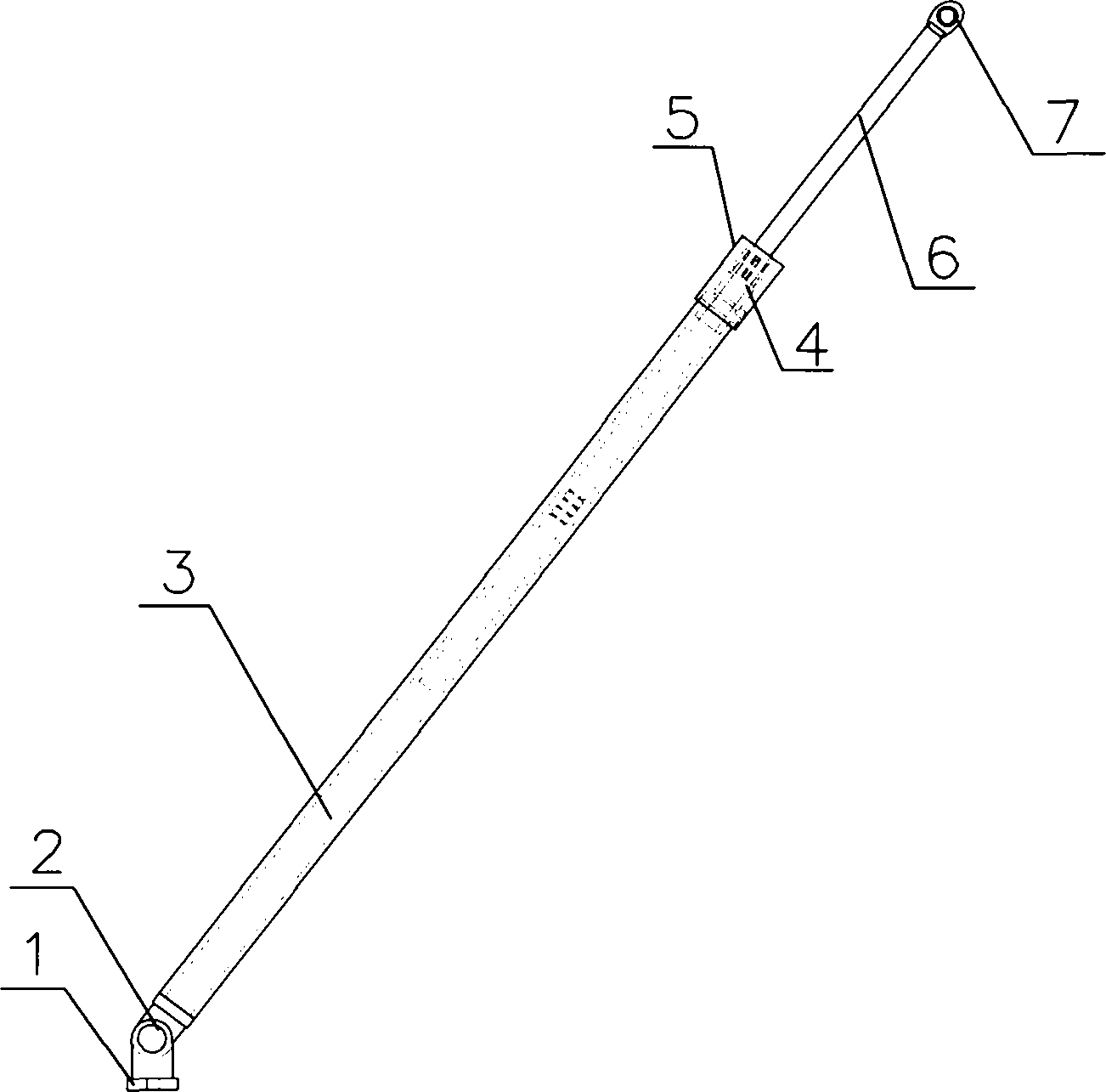

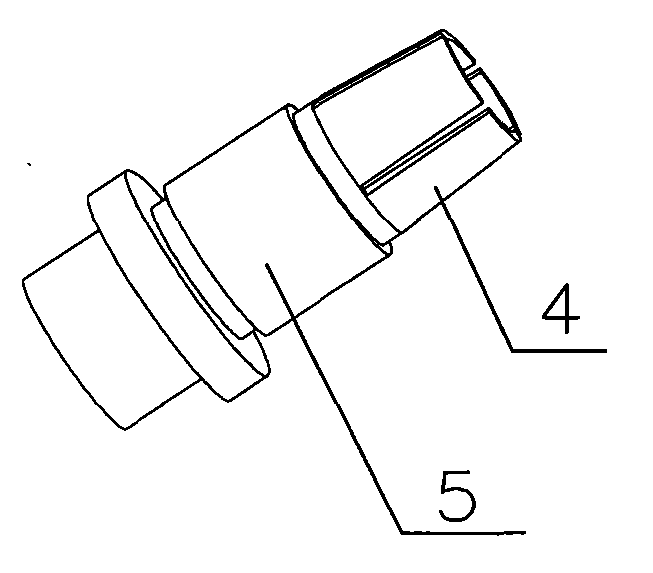

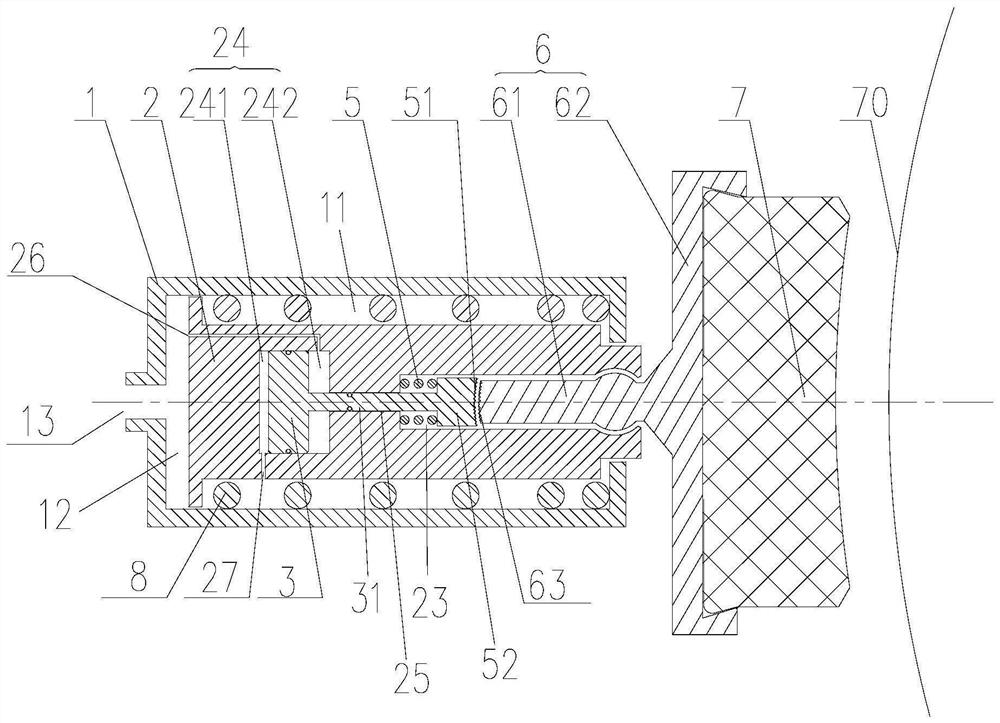

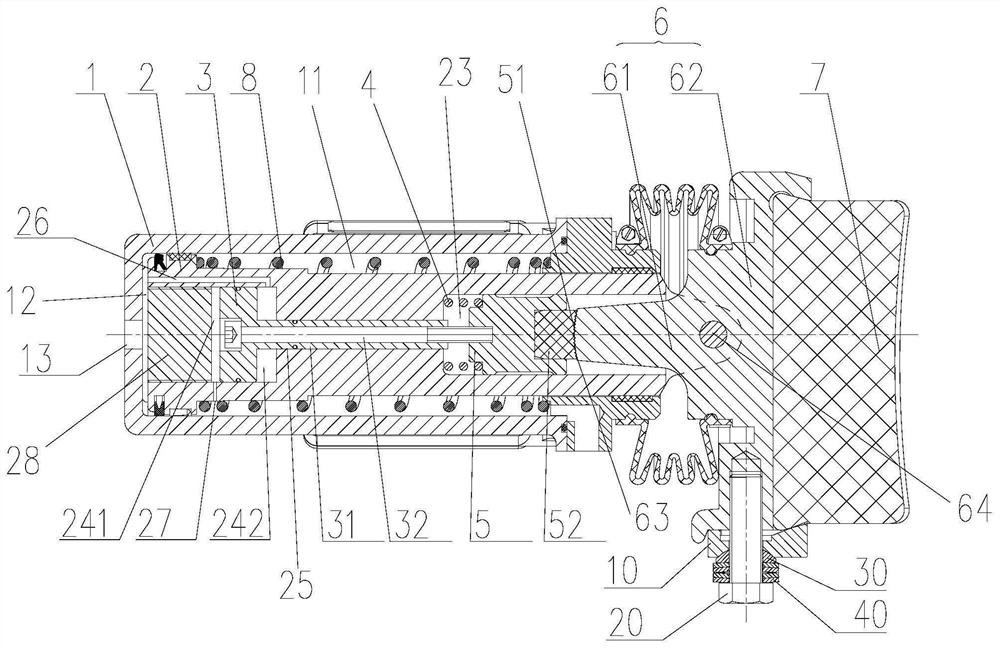

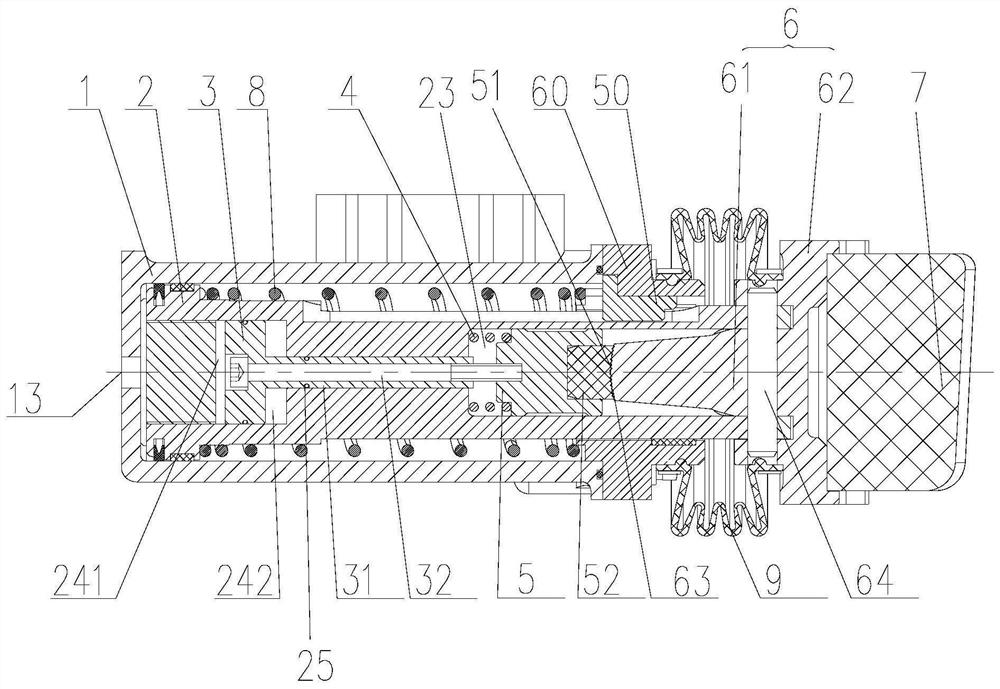

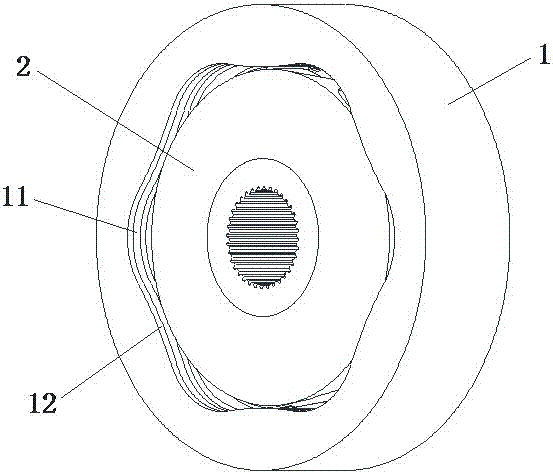

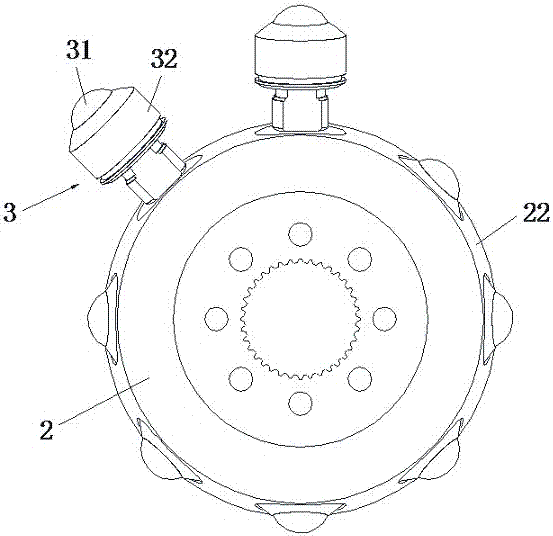

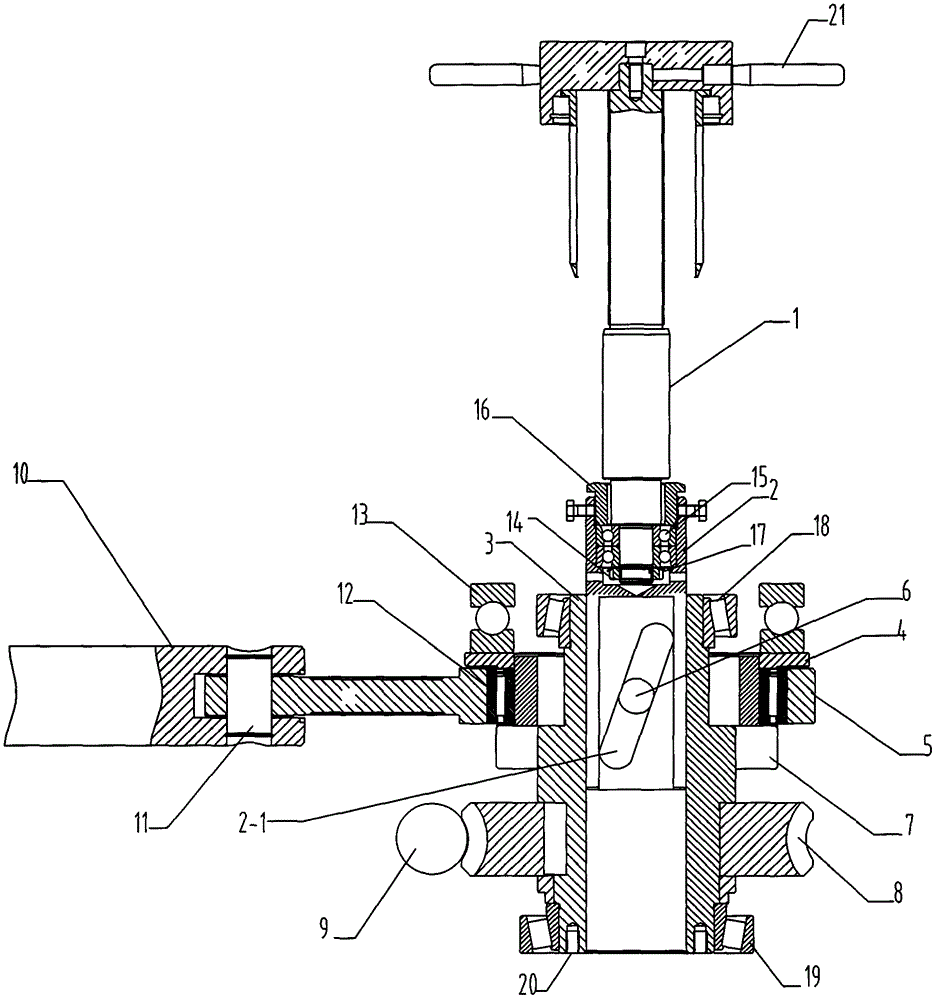

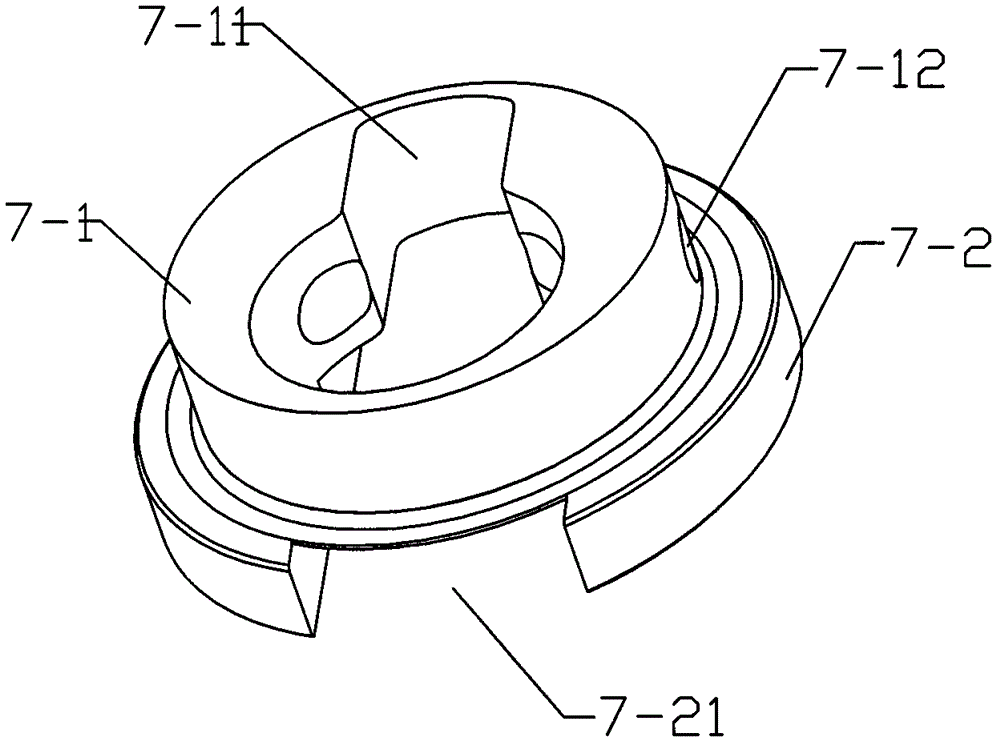

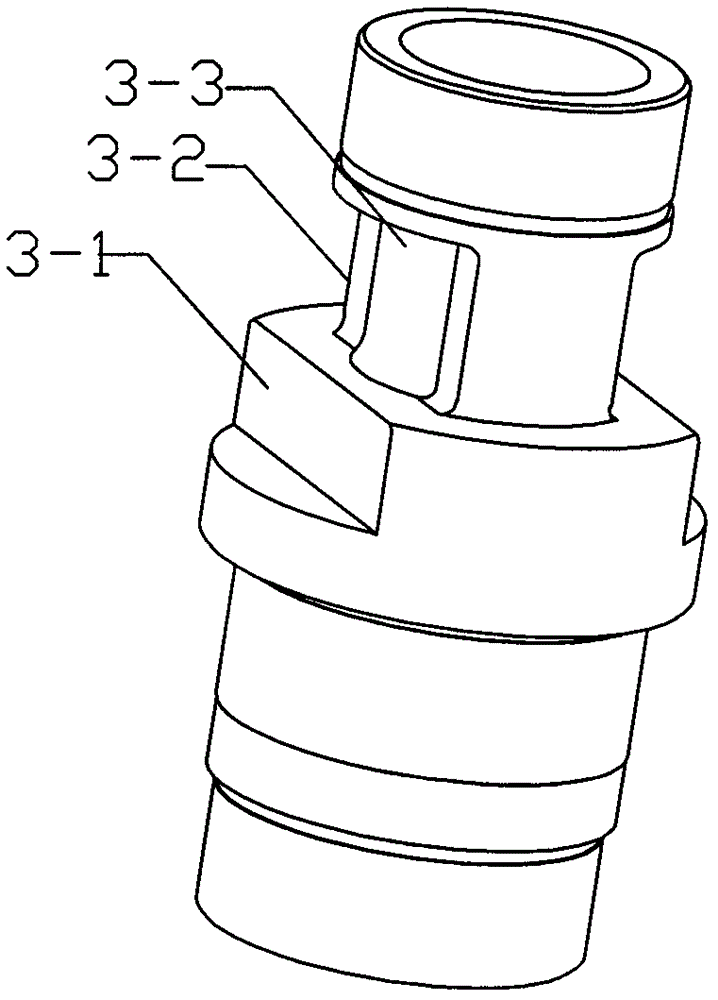

Bracket-free floating air pressure caliper disc brake

ActiveCN102252048ALow costReduce eccentric wearAxially engaging brakesBraking discsCalipersDisc brake

The invention discloses a bracket-free floating air pressure caliper disc brake. The brake comprises a mounting plate (1), a brake caliper assembly (2), two guide pins (3), a screw (4), a friction plate (5), a pressure spring (6) and a pressure plate (7), wherein the mounting plate (1) is provided with a central through hole, the central through hole is centered on a non-steering axle, and the brake caliper assembly (2) is directly fixed on the mounting plate (1) through the guide pins (3). The brake has simple structure, is convenient to assemble and maintain, cancels a bracket, saves the cost and the assembly step, meanwhile, can ensure the braking performance, and eliminates the negative effect of canceling the bracket.

Owner:WUHAN YOUFIN AUTOPARTS

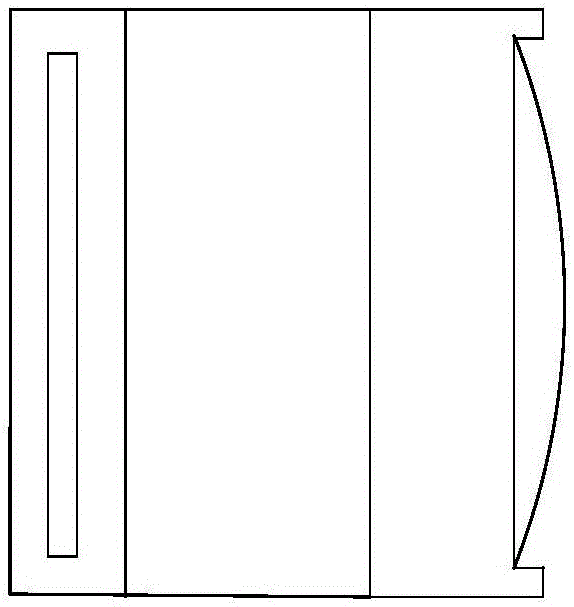

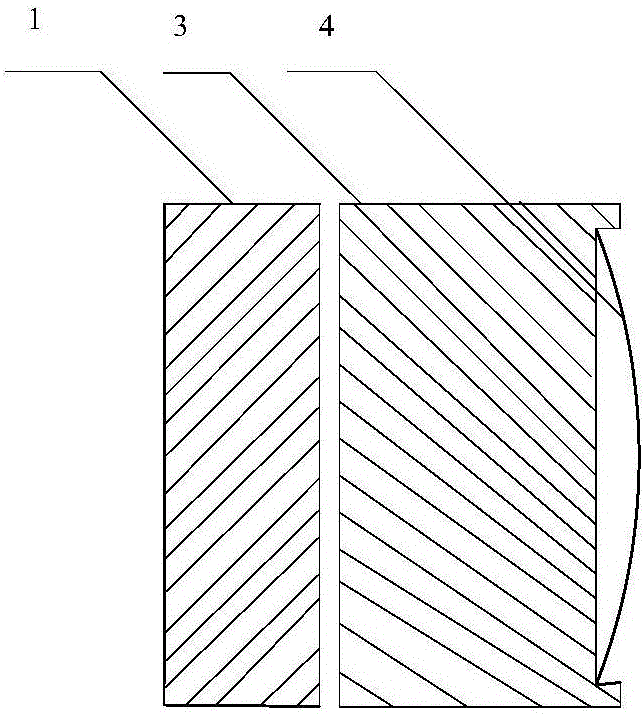

Working roll forming technology taking grinding precision and cold-rolled electrical steel edge drop control into consideration

ActiveCN104607468AImprove grinding accuracyImprove grinding efficiencyRollsMetal rolling arrangementsStress concentrationElectrical steel

The invention relates to a working roll forming technology taking grinding precision and efficiency and cold-rolled electrical steel edge drop control into consideration. The sectional roll forming function method is adopted, a special cold-rolled working roll forming curve is formed, and the coefficient of an exponential function curve in the roll forming curve is designed according to the situation of band steel edge drop; a primary straight line is a smooth transition section outside the exponential function curve and prevents stress concentration between rolls caused when a working roll makes contact with an intermediate roll under action of roll bending force; two flat roll sections are provided, wherein the first flat roll section is the section, making contact with a band steel body part, of the roll surface of the working roll, the second flat roll section is located at one end of the roll surface of the working roll, and the purpose is to improve the grinding precision and efficiency of the working roll. After curvilinear functions of all sections are determined, the curvilinear functions are expressed by sections. The working roll forming technology can effectively improve the cold-rolled electrical steel edge drop control level, improve the roll grinding precision and efficiency, reduce the roll consumption, and lower the cold-rolled electrical steel production cost.

Owner:UNIV OF SCI & TECH BEIJING

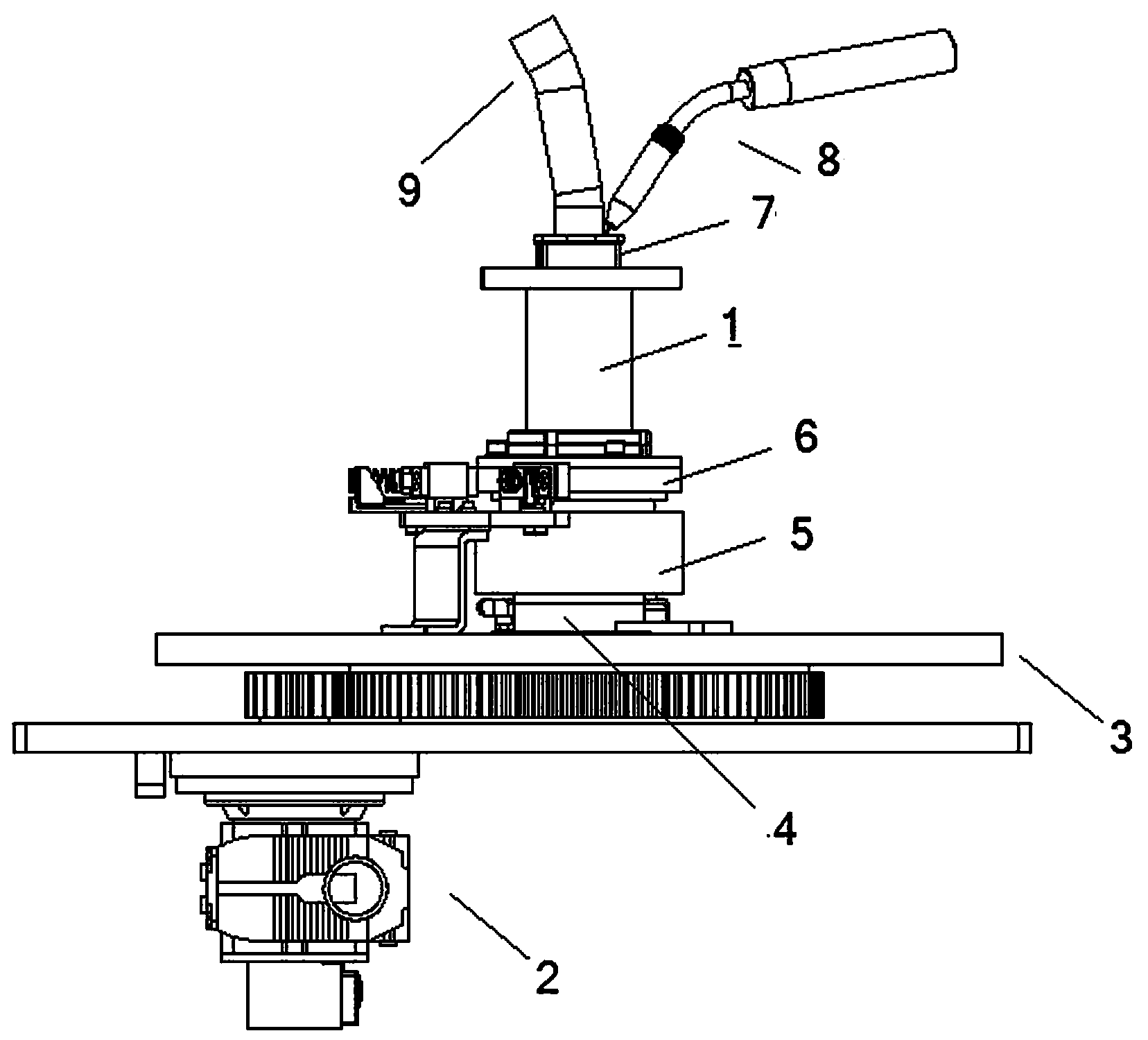

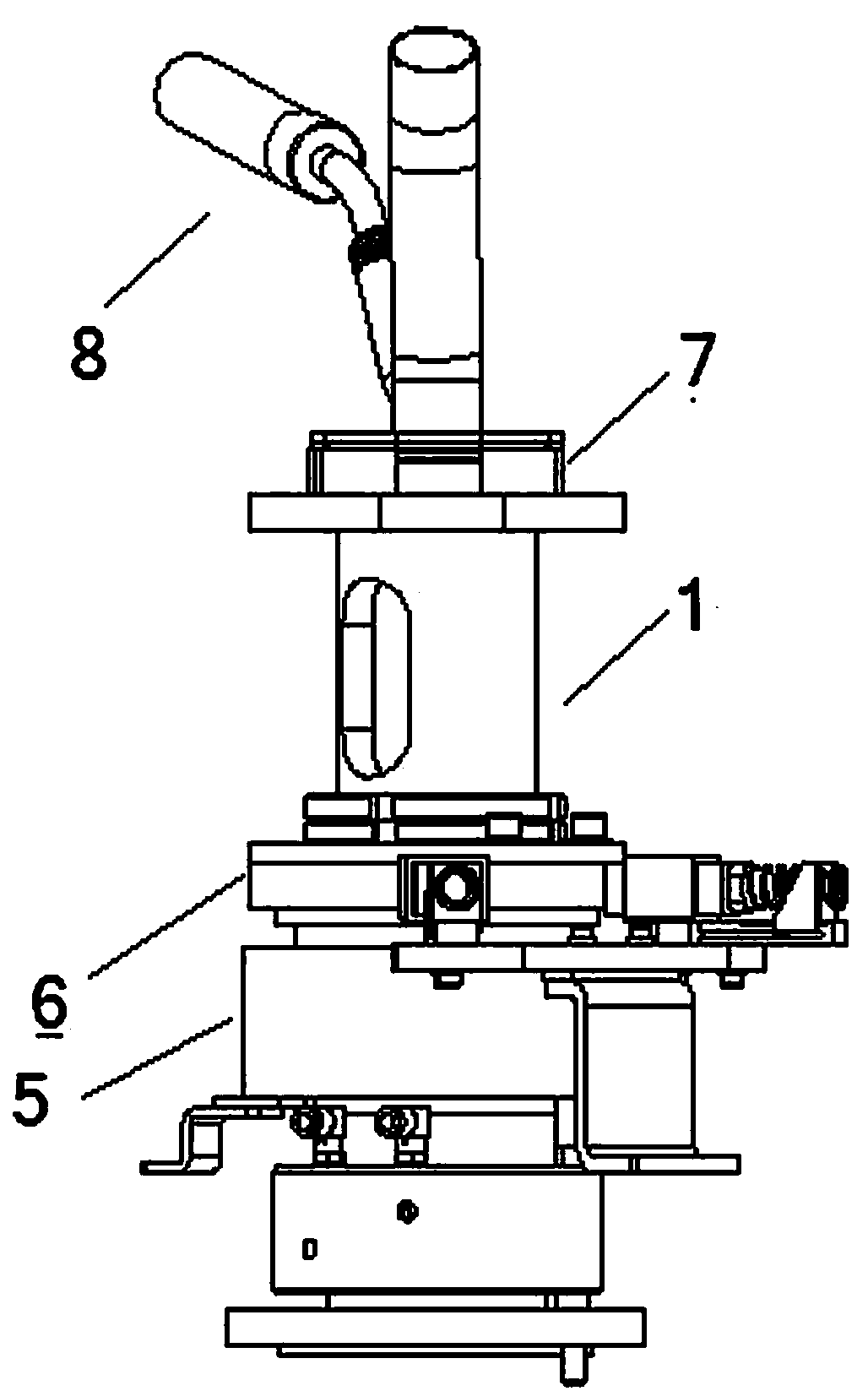

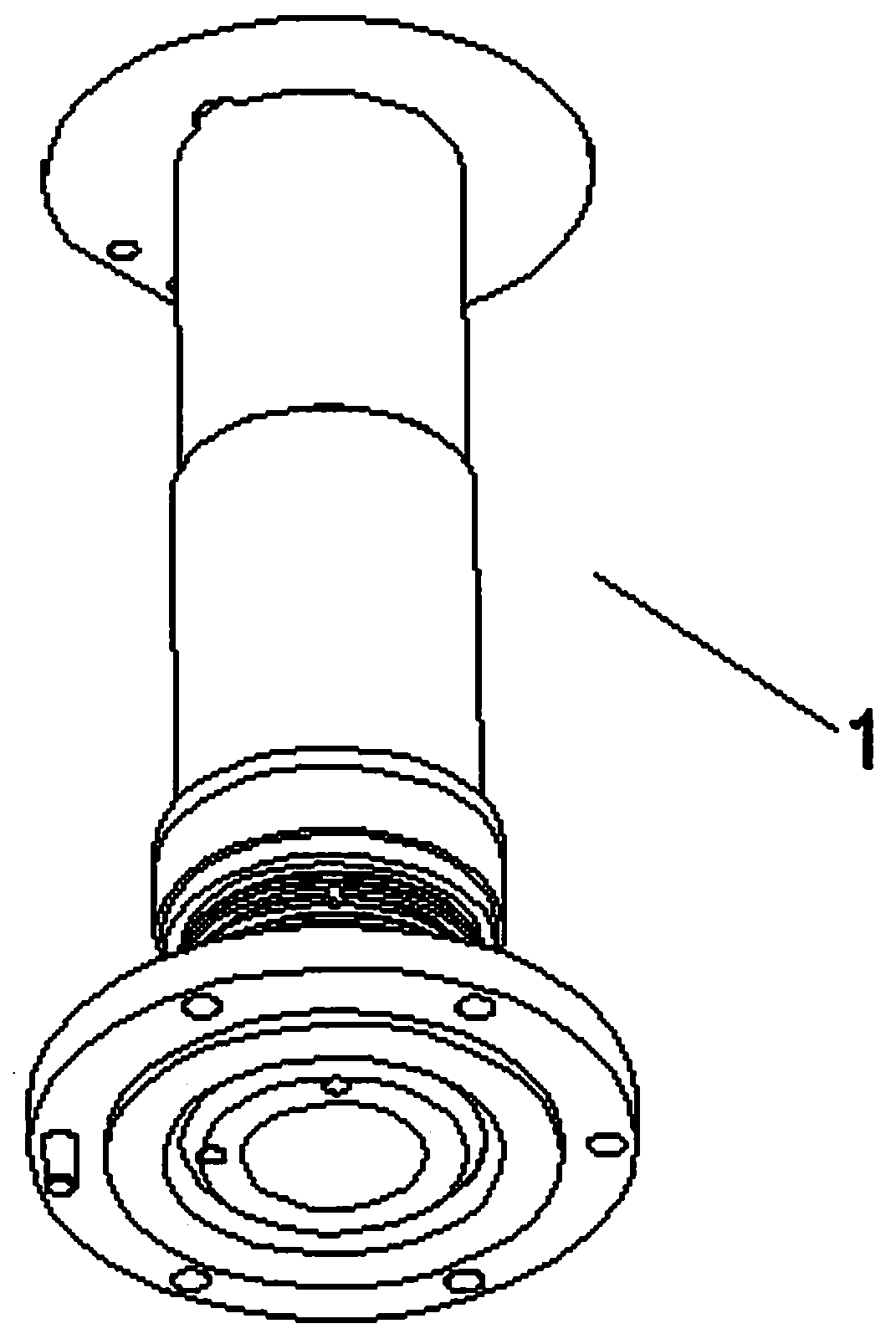

Vertical annular welding tool

ActiveCN104028884AImprove welding qualitySolve the entanglementWelding/cutting auxillary devicesElectrode holder supportersEngineeringStructural engineering

The invention discloses a vertical annular welding tool. The vertical annular welding tool comprises a rotatable platform and a hollow upright column, wherein the hollow upright column is perpendicular to the rotatable platform and sleeves the rotatable platform via a clearance; a gas guiding ring, a conductive ring and a ground wire grounding copper ring sleeve the upright column; a gas circuit, an electric control circuit and a welding ground wire are arranged in a hollow cavity of the upright column; a workpiece positioning mechanism is fixed on the upper portion of the upright column; and a wire feeding machine and a welding gun mechanism are fixed on the rotatable platform. Rotating power is provided by using a speed reducer; circuit transmission is carried out by using the conductive ring; and gas is turned on, turned off and changed over via the gas guiding ring, the welding gun can be adjusted multi-dimensionally in space, namely, the welding gun can be adjusted in the up-down direction and the left-right direction at an angle, annular welding between tubes, annular welding between a tube and a flange and annular welding between a tube and a plane can be performed, the product differentiation switching efficiency and the welding quality are improved, the welding angle and the welding speed can be freely adjusted, annular welding can be performed rotatably without limitation, workpieces do not need to rotate, and the time can be greatly saved. The vertical annular welding tool is suitable for annular welding between the tubes, annular welding between the tube and the flange and annular welding between the tube and the plane, or is suitable for welding an arc.

Owner:GREAT WALL MOTOR CO LTD

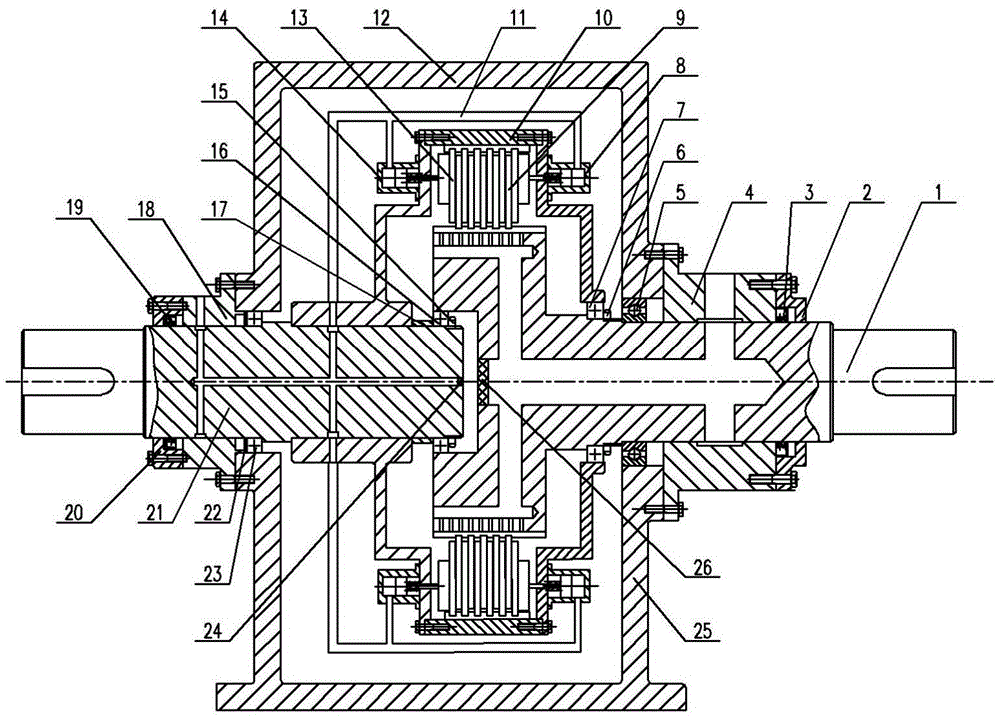

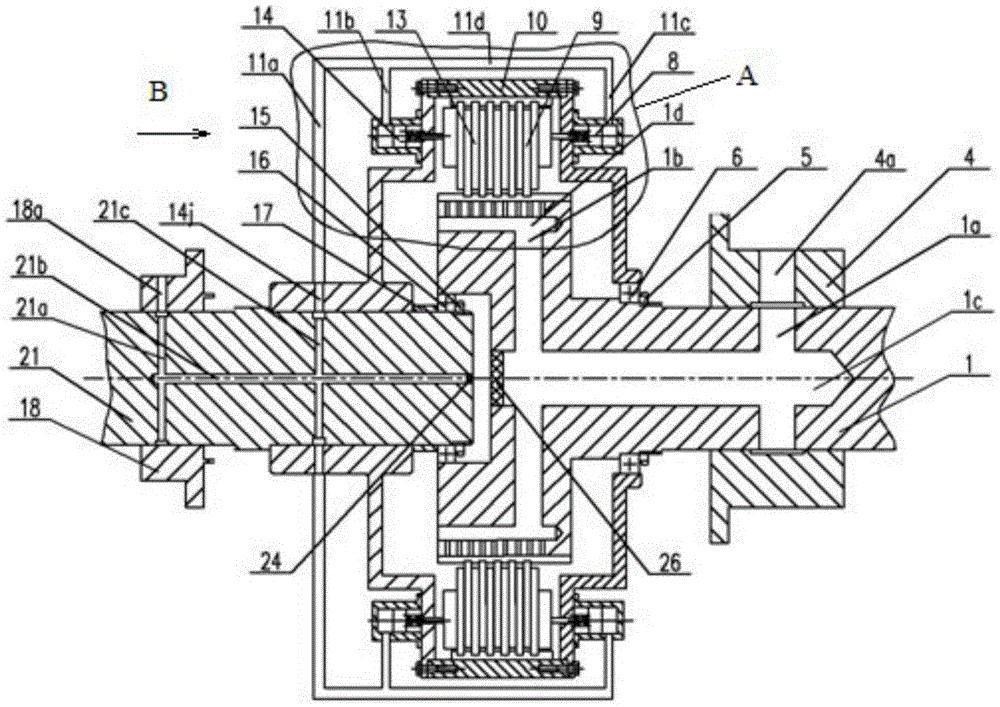

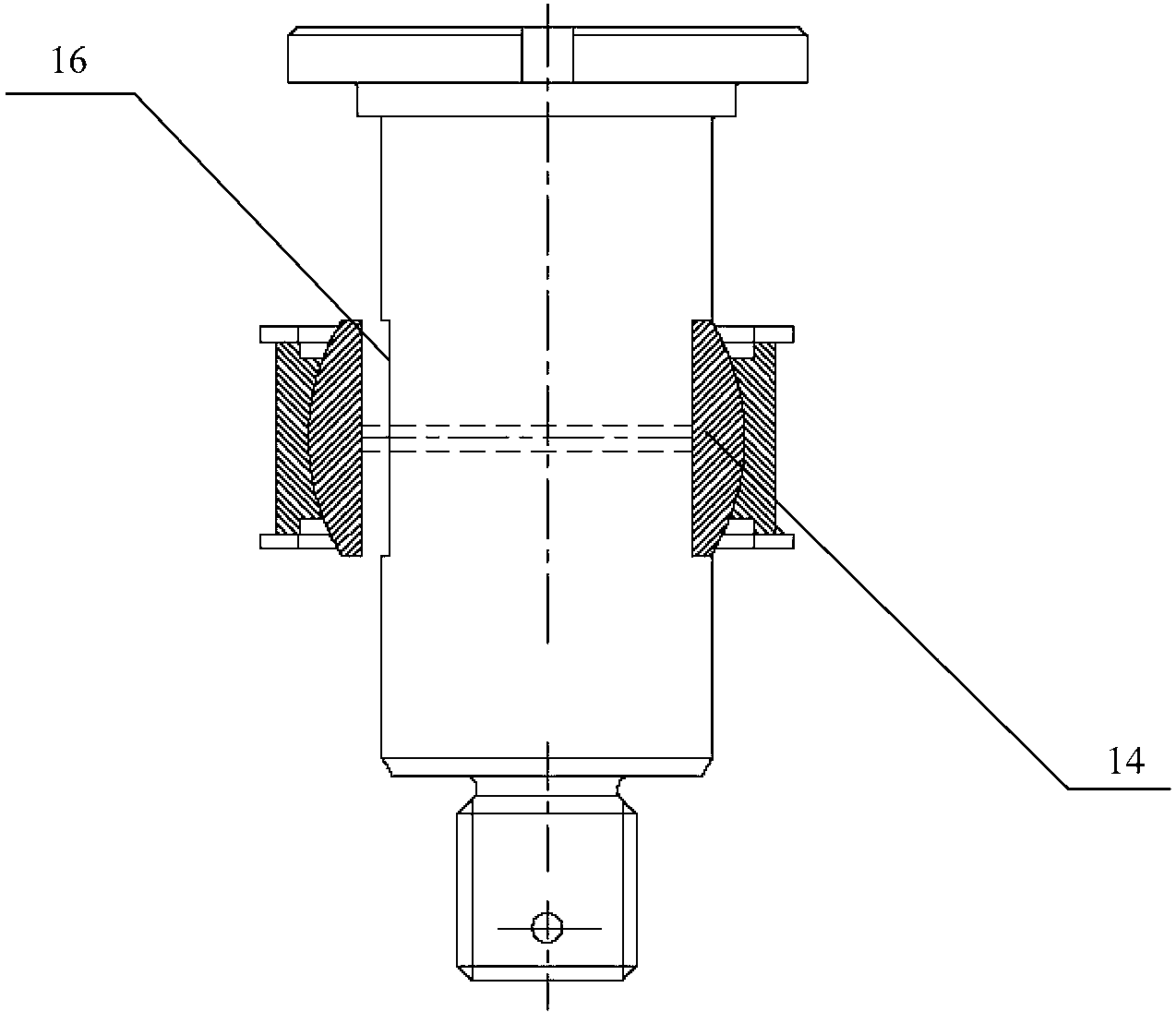

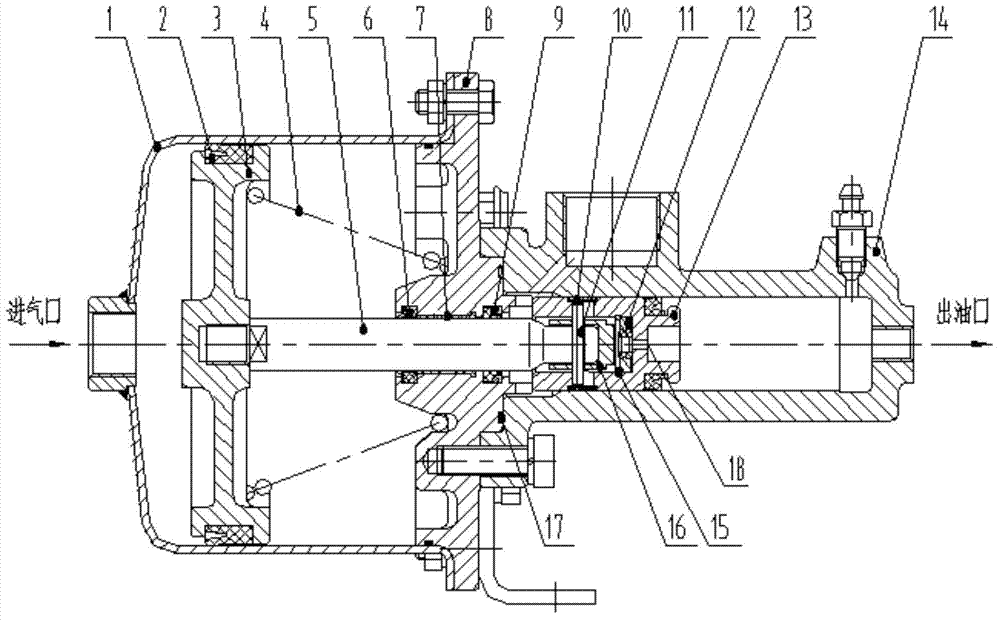

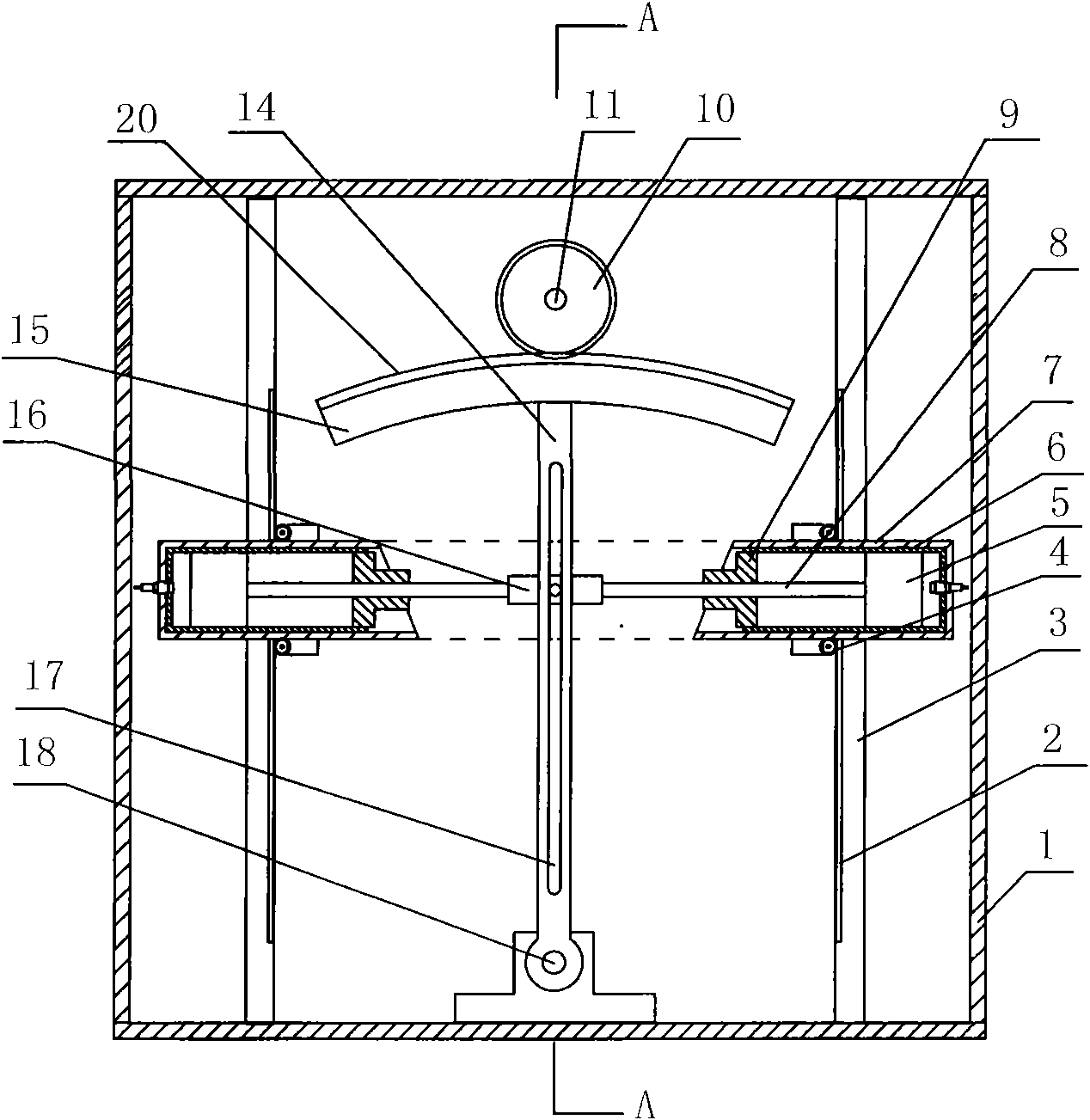

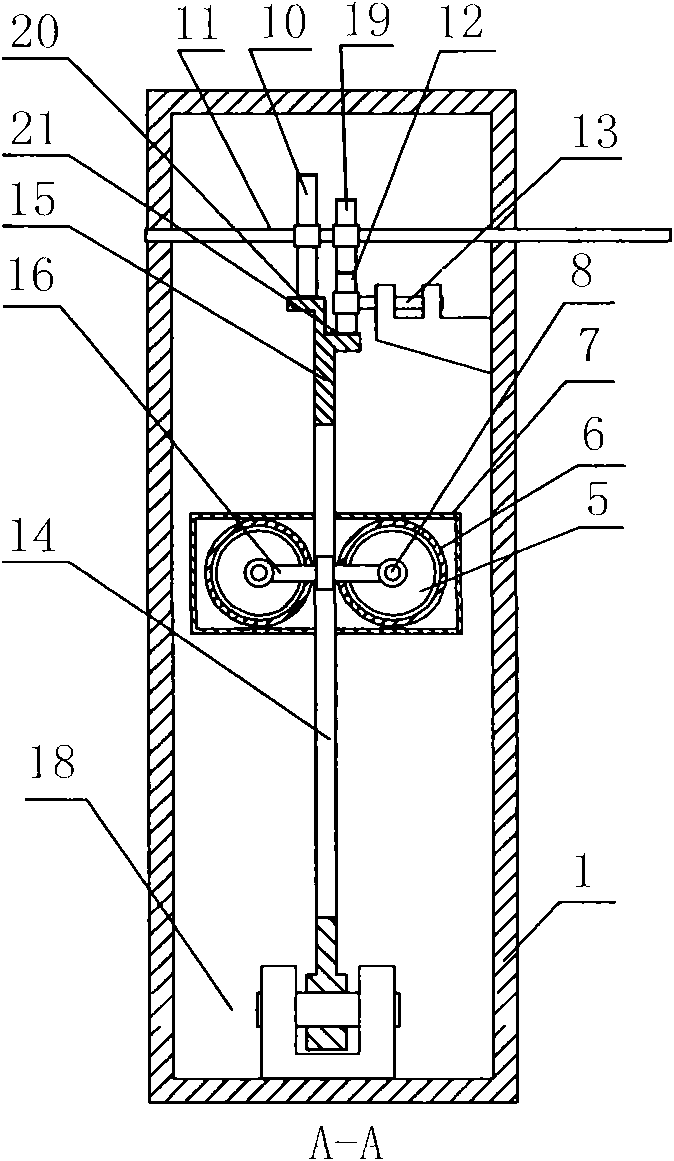

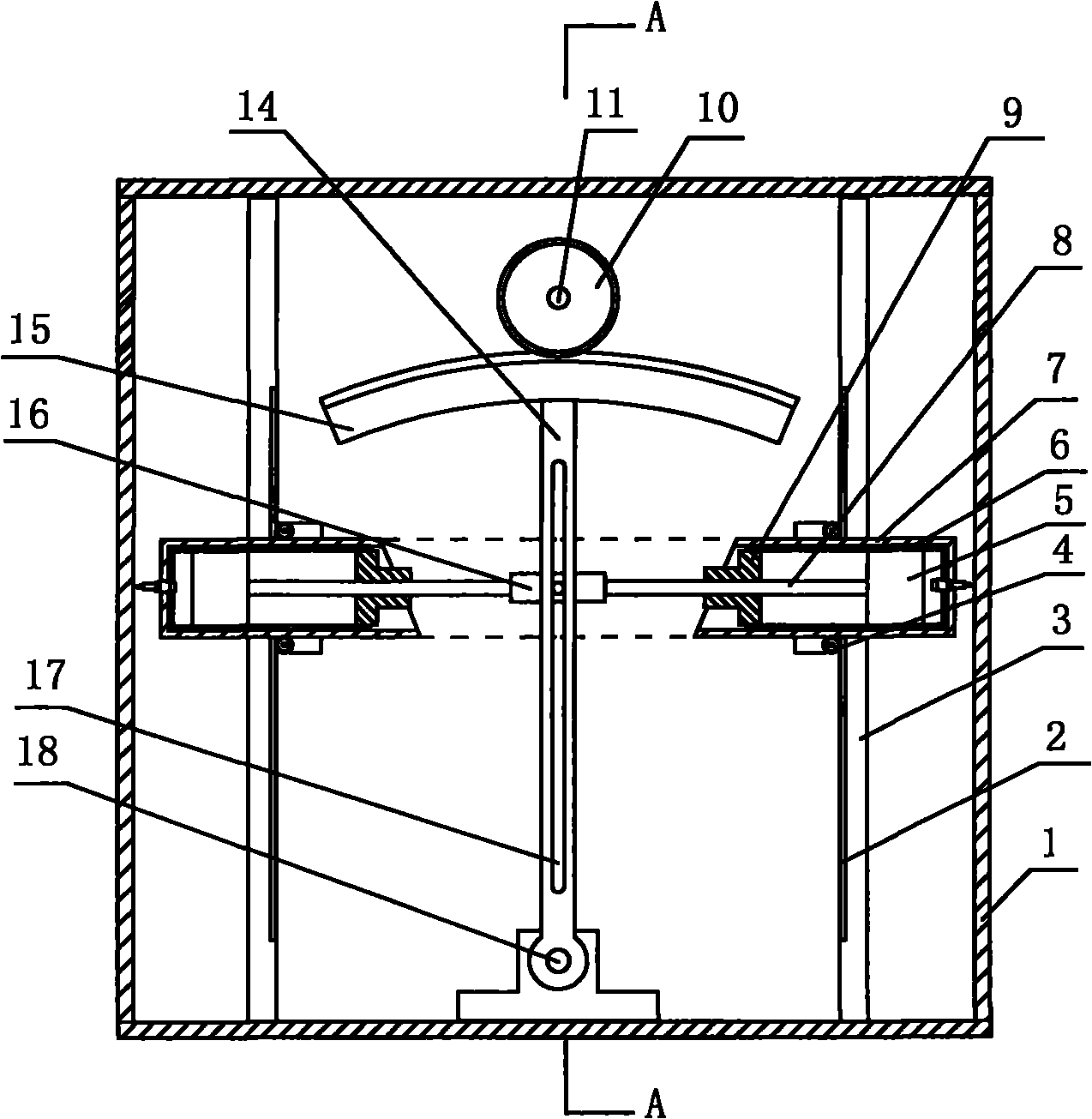

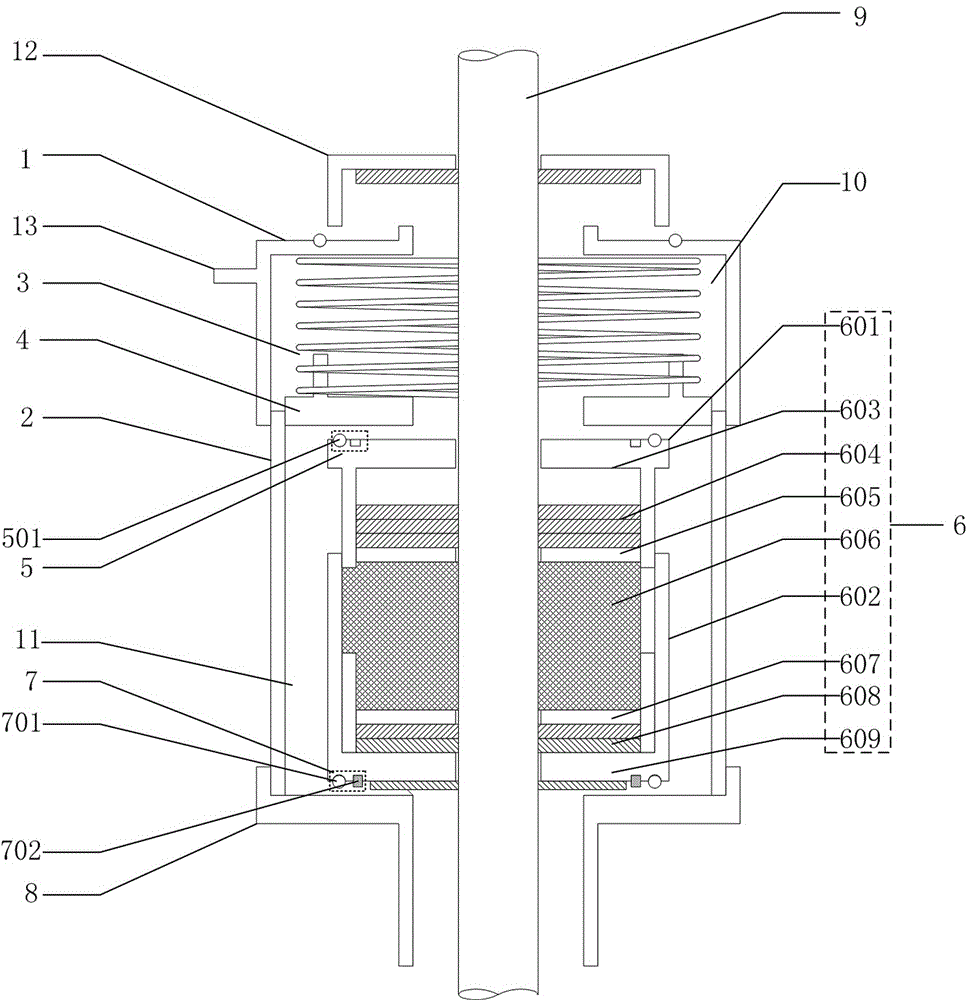

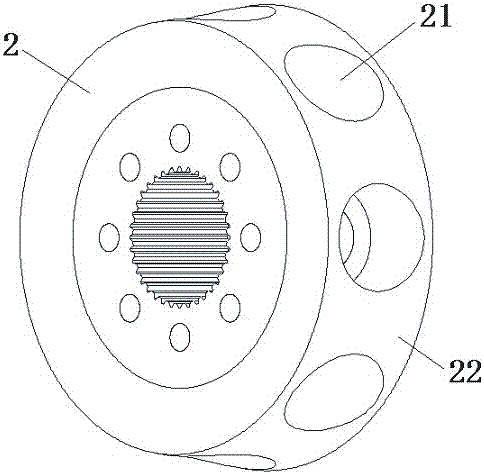

Large-power two-side control type adjustable-speed clutch

ActiveCN105605123AImprove uniformityReduce eccentric wearFluid actuated clutchesFluid clutchesDrive shaftOil separation

The invention provides a large-power two-side control type adjustable-speed clutch which comprises a driving shaft, an upper box body, a base, a driven shaft, an active friction piece set, a passive friction piece set, a driven drum, a first piston cylinder set, a second piston cylinder set and erected oil ways. The active friction piece set is installed on the outer side of the driving shaft. The passive friction piece set is installed on the driven drum. The two ends of the driven drum are fixedly connected with a first piston cylinder set supporting disc and a second piston cylinder set supporting disc respectively. The driving shaft is provided with a driving shaft first radial oil duct, a driving shaft axial oil duct, a driving shaft second radial oil duct and a driving shaft oil separation duct. The driven shaft is provided with a driven shaft first radial oil duct, a driven shaft axial oil duct and a driven shaft second radial oil duct. The erected oil ways comprise the first radial erected oil way, the second radial erected oil way, the third radial erected oil way and the axial erected oil way. According to the adjustable-speed clutch, the erected oil ways are additionally arranged outside a friction pair, the uniform degree of the friction pair gap is improved, and the service life of friction pieces is greatly prolonged.

Owner:JIANGSU UNIV

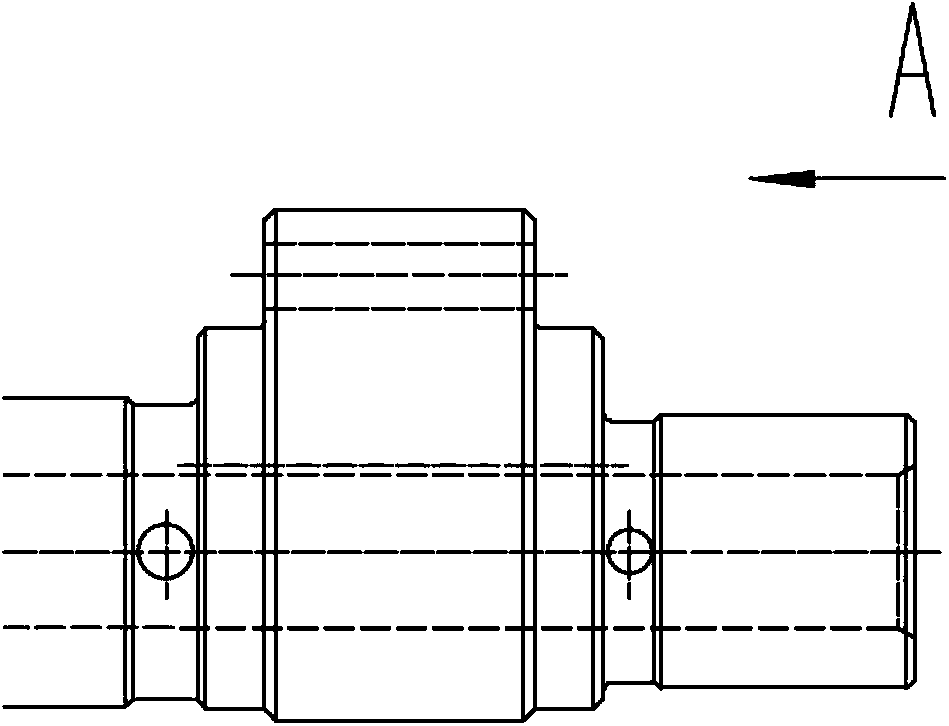

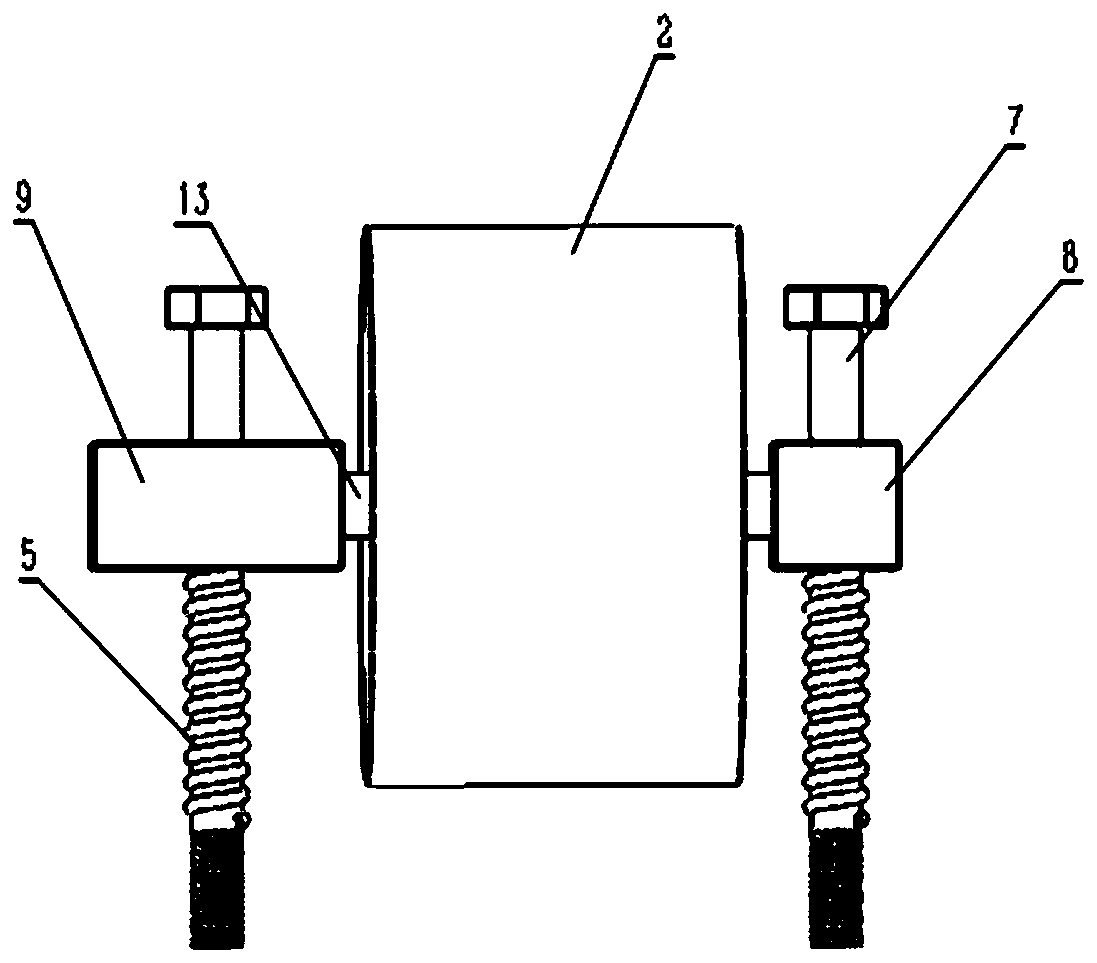

Metering pump with entire solid eccentric wheel travel adjustment mechanism

ActiveCN103362769AImprove bearing capacityGreatly increase the carrying capacityPump controlPumpsRelative motionMetering pump

The invention discloses a metering pump with an entire solid eccentric wheel travel adjustment mechanism. The metering pump comprises an amount adjustment lead screw, a moving shaft, a hollow shaft, a connection rod, the entire eccentric wheel, a worm gear, a worm and a slide rod, wherein one end of the amount adjustment lead screw is connected with the moving shaft in a mode of coaxial relative motion, the moving shaft is sleeved in the hollow shaft, a chute is formed in the moving shaft, a slide block is arranged in the chute, the entire eccentric wheel is sleeved on the hollow shaft and fixed with the connection rod, the connection rod is connected with the slide rod, and the worm wheel is in cup joint to the hollow shaft and is meshed with the worm. The metering pump is large in bearing capacity, high in metering precision and long in service life.

Owner:DEPAMU HANGZHOU PUMP TECH

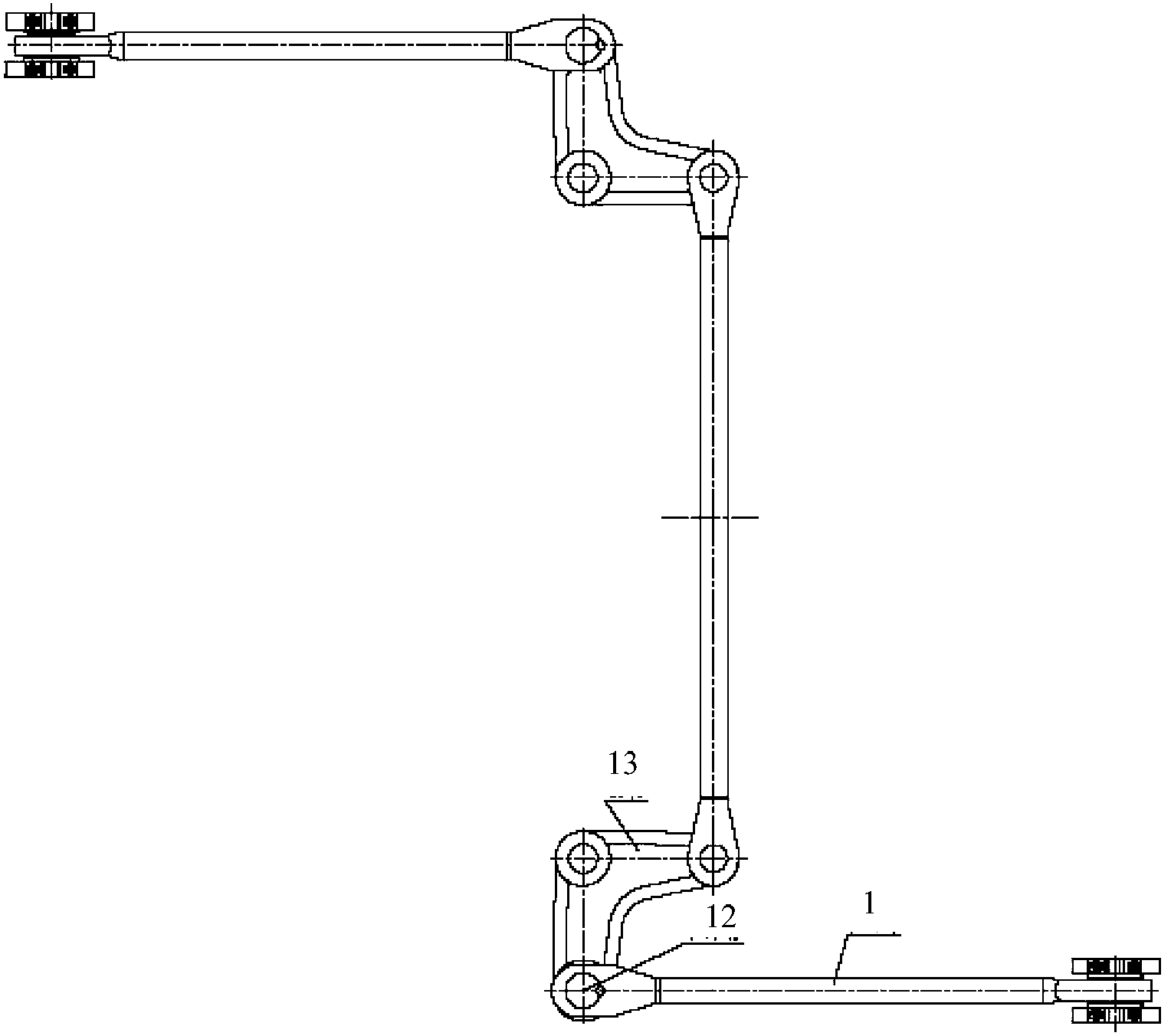

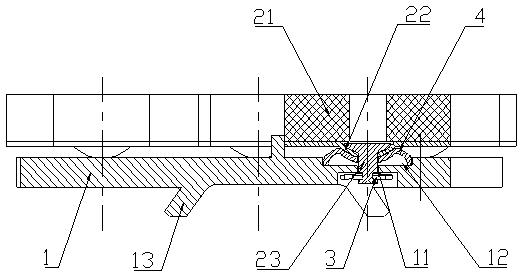

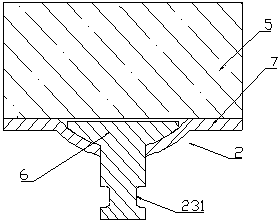

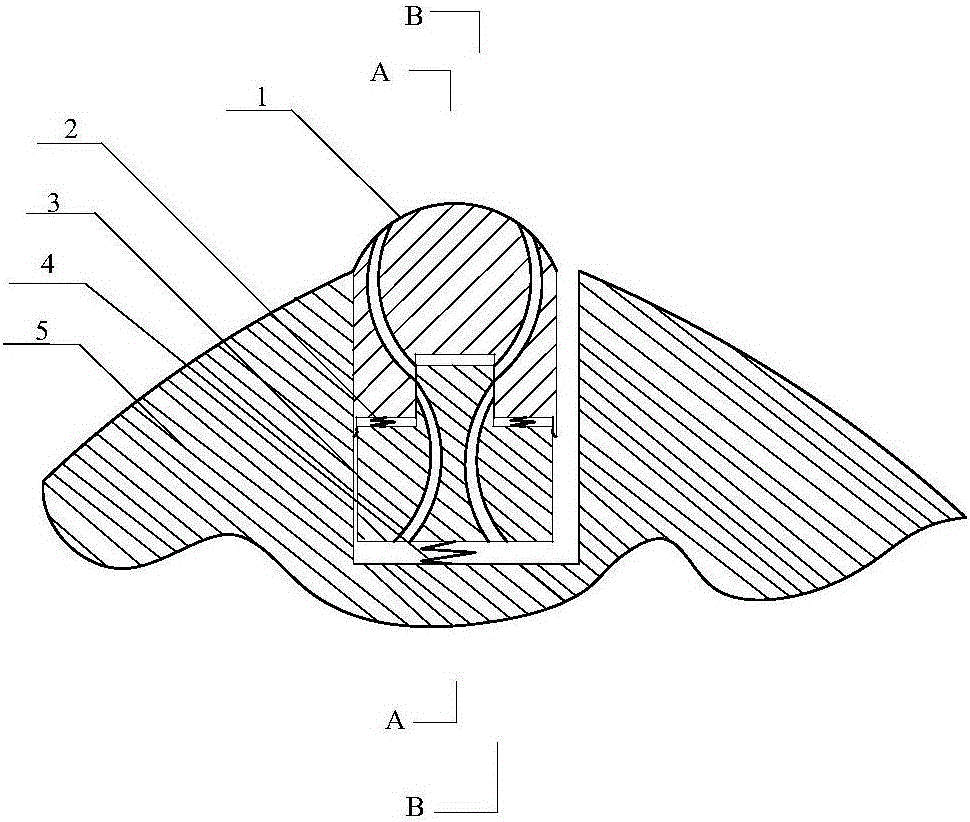

Traction pin for locomotive traction device

The invention provides a traction pin for a locomotive traction device. The traction pin comprises a cylindrical pin body. A positioning plate whose section area is larger than that of the pin body is fixed at the top end of the pin body. A second positioning plate is sleeved at the bottom end of the pin body. The second positioning plate is matched with the first positioning plate to axially fix the pin body. The second positioning plate can coaxially rotate relative to the pin body. The pin body sequentially comprises a first shaft section and a second shaft section from the top end to the bottom end. The diameter of the first shaft section is larger than that of the second shaft section. A separating groove is formed on the side of the first shaft section and along the circumferential direction. The separating groove separates the first shaft section into a first section and a second section. The traction pin has the advantages that abrasion borne by the pin body is even, eccentric abrasion is reduced, the service life of the traction pin is prolonged, the circumstance that a joint bearing is stuck in the worn-out groove and cannot be demounted is avoided, and the traction pin is convenient to mount and demount.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

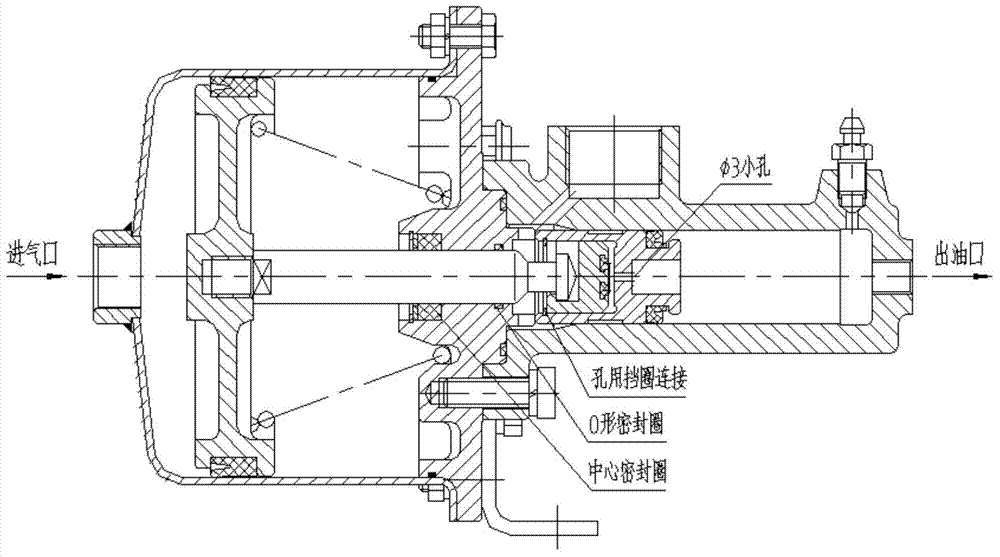

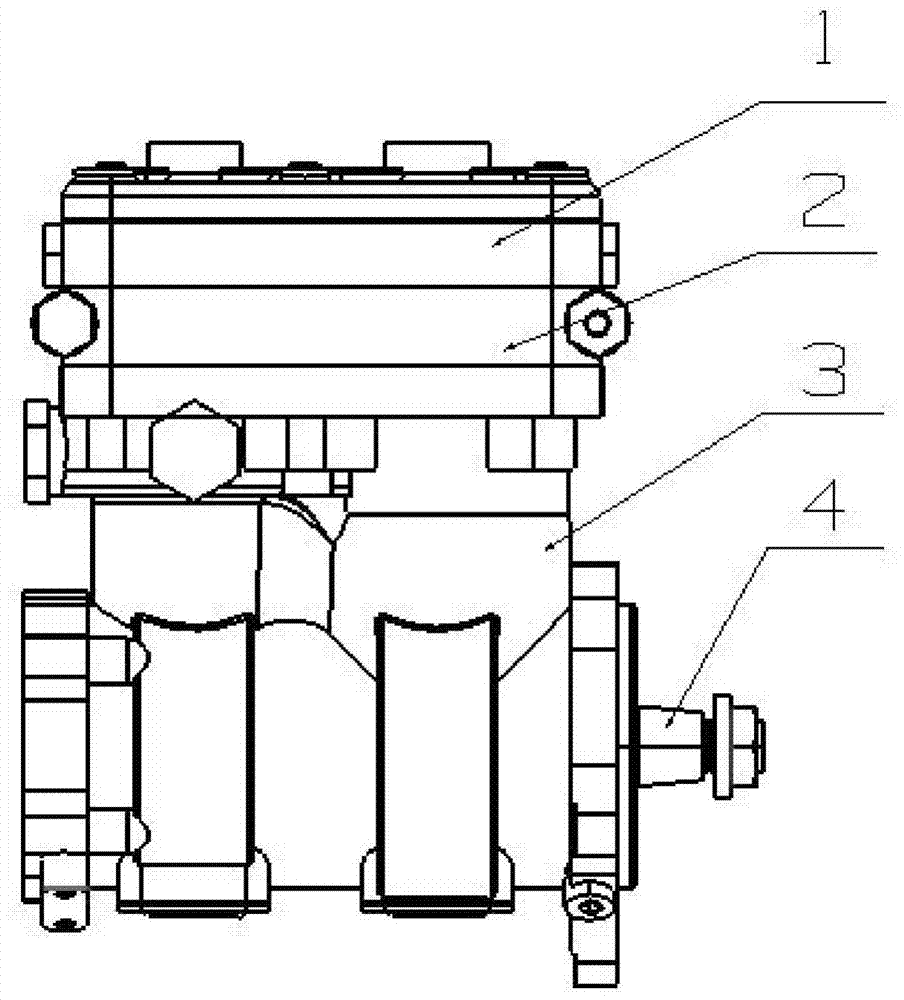

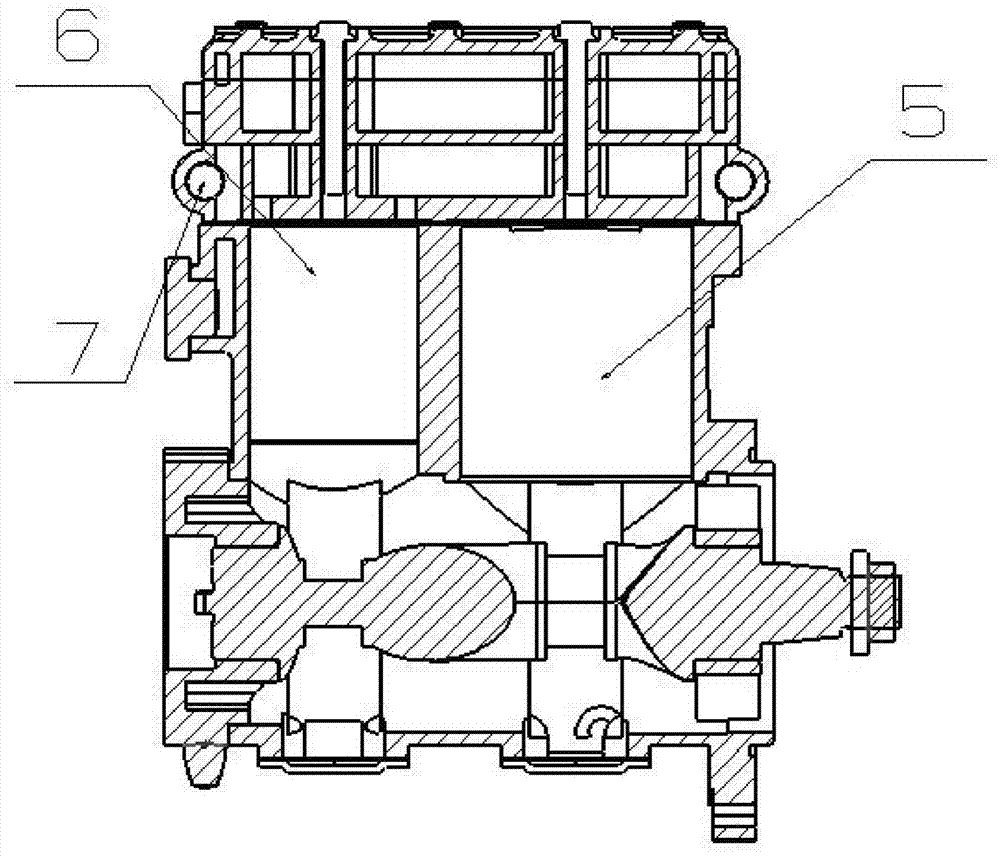

Air pump of engineering machinery braking system

InactiveCN103758723AReduce eccentric wearImprove reliabilityEngine sealsPositive displacement pump componentsHydraulic cylinderAir pump

The invention discloses an air pump of an engineering machinery braking system. The air pump comprises a cylinder casing, a cylinder piston, a push rod, a connection cover, a valve assembly, a hydraulic piston assembly and a hydraulic cylinder body. The cylinder casing and the connection cover form a cylinder assembly. The hydraulic piston assembly is arranged in the hydraulic cylinder body. The cylinder piston is arranged in an inner cavity of the cylinder assembly, one end of the push rod is connected with the cylinder piston in a fastening mode, and the other end of the push rod penetrates a center hole of the connection cover to be connected with the hydraulic piston assembly. The connection cover and the push rod are sealed through a Y-shaped sealing ring and a dustproof ring. By means of the technical scheme, the sealing mode between the connection cover and the push rod is changed, sealing is conducted through the Y-shaped ring, the guide sleeve and the dustproof ring, the guide sleeve is added to support the push rod, eccentric abrasion of a piston leather ring and the Y-shaped ring is reduced, and product reliability is improved. Connection of the hydraulic piston and the push rod is changed to be cylindrical pin connection, connection reliability is improved, and the service life of products is prolonged.

Owner:WUHU SHENGLI TECH SHARES

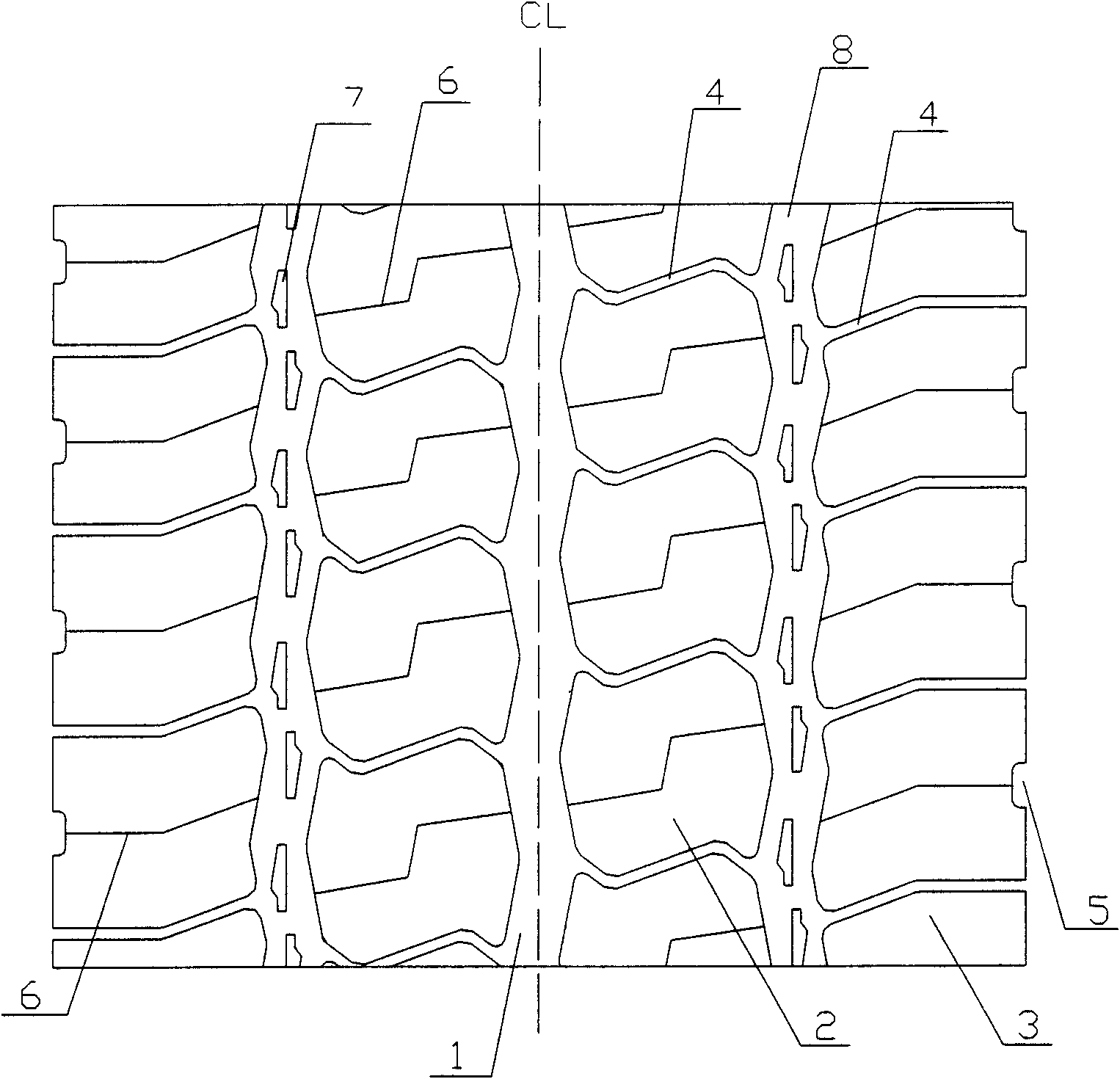

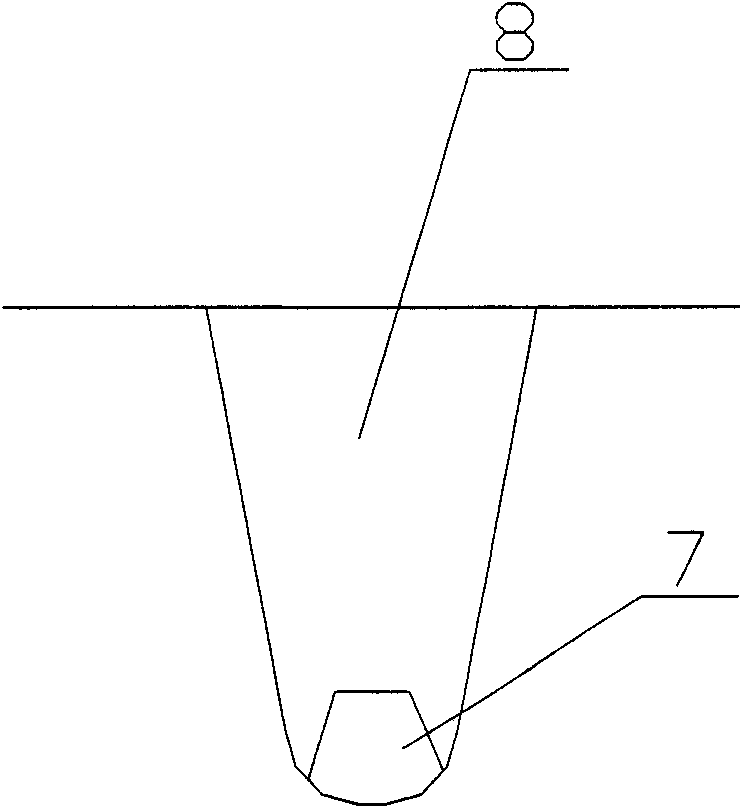

Truck tyre tread

ActiveCN101618664AAvoid eccentric wearImprove maneuverabilityTyre tread bands/patternsEngineeringTruck

The invention relates to an auto tyre structure, in particular to a tread pattern structure for a tyre of a truck. The truck tyre tread comprises a central vertical circumferential pattern groove arranged on the center position of the tyre tread, namely the center line of the tyre tread, wherein the central vertical circumferential pattern groove equally divides the tyre tread into two eudipleural parts, the left side and the right side of the central vertical circumferential pattern groove are provided with lateral pattern blocks and shoulder pattern blocks in turn regularly from inside to the outside, the lateral pattern blocks and the shoulder pattern blocks are spaced by the vertical circumferential pattern groove, and the groove bottom of the vertical circumferential pattern groove is provided with a bulge which is connected with the two side walls of the circumferential pattern groove; and two adjacent lateral pattern blocks and two adjacent shoulder pattern blocks are spaced by a transverse pattern groove respectively. The tyre tread of the truck tyre adopts mixed patterns and has sufficient braking force, good maneuverability, and elegant appearance.

Owner:QINGDAO YELLOWSEA RUBBER

Self-lubricating crankshaft and rotary compressor, air conditioner and heat-pump water heater using same

ActiveCN103696966AImprove the lubrication effectIncreasing the thicknessCrankshaftsRotary/oscillating piston pump componentsEngineeringHelix angle

The invention discloses a self-lubricating crankshaft which comprises a major semi-axis, an eccentric circle and a minor semi-axis. The center of the crankshaft is provided with an axial through hole; the top and the bottom of the eccentric circle are respectively provided with a first radial oil guide hole and a second rail oil guide hole which are communicated with the through hole; the outer surface of the minor semi-axis is provided with at least one spiral oil guide slot which is slantingly formed along the axial direction and is communicated with the through hole; the rotating direction of the spiral oil guide slot is opposite to that of the crankshaft; the outer surface of the minor semi-axis is also provided with a spiral communication groove extending towards the bottom of the eccentric circle from the top end of the spiral oil guide slot; the spiral communication groove does not run through the lower end face of the minor semi-axis; the spiral oil guide slot is spirally formed by using the center line of the crankshaft as the center; a helix angle alpha of the spiral oil guide slot has an angle range of 5 degrees to 85 degrees; a concave included angle beta of two opposite lateral surfaces of the spiral oil guide slot in the process of ascending along the spiral direction has an angle range of 2 degrees to 80 degrees; and the rotating direction of the spiral communication groove is the same with that of the spiral oil guide slot. The invention also discloses a rotary compressor, an air conditioner and a heat-pump water heater which use the self-lubricating crankshaft.

Owner:ZHUHAI LANDA COMPRESSOR +1

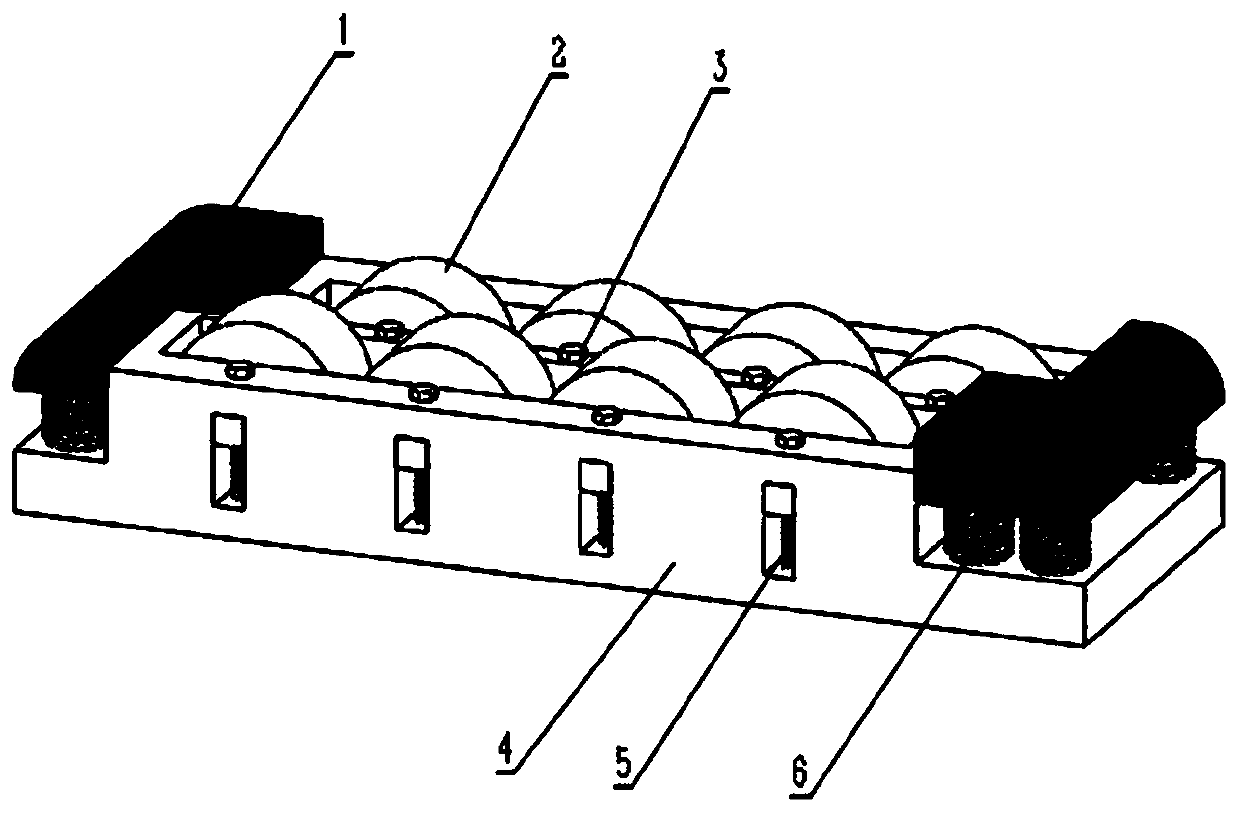

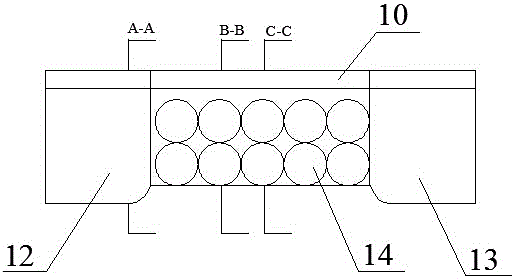

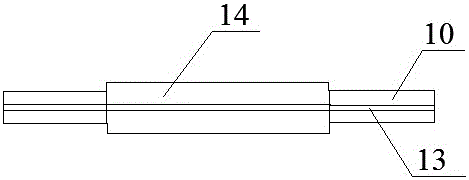

Double-row multi-roller type modular current-receiving device for electric locomotive

PendingCN110370936AReduce wearReduced service lifeRotary current collectorPower current collectorsModularitySlide plate

Disclosed is a double-row multi-roller type modular current-receiving device for an electric locomotive. According to the double-row multi-roller type modular current-receiving device for the electriclocomotive, two rows of metal rollers are annularly arranged on an insulating base; each rolling wheel is arranged in the manner that two insulating stand columns are fixed to the insulating base, compression springs sleeve the two insulating stand columns correspondingly, insulating blocks sleeve the insulating stand columns and are located above the compression springs, metal shells of the rollers are installed on metal shafts through two insulating bearings, the metal shafts are fixed to the two insulating blocks, the outer surface of an annular current receiving electric brush makes contact with the roller metal shells to receive current, the inner surface of the annular current receiving electric brush is fixed to the metal shafts, all the metal shafts are connected through cables and are then used for supplying power to vehicle-mounted power consuming equipment, and two pure carbon sliding plates are fixed to the insulating base through more than four springs. The friction forceand the friction noise of the current-receiving device and a rigid contact rail can be effectively reduced, and the double-row multi-roller type modular current-receiving device can adapt to the changes of locomotive traction power requirements and has good buffering performance, heat dissipation performance and rail attaching performance.

Owner:SOUTHWEST JIAOTONG UNIV

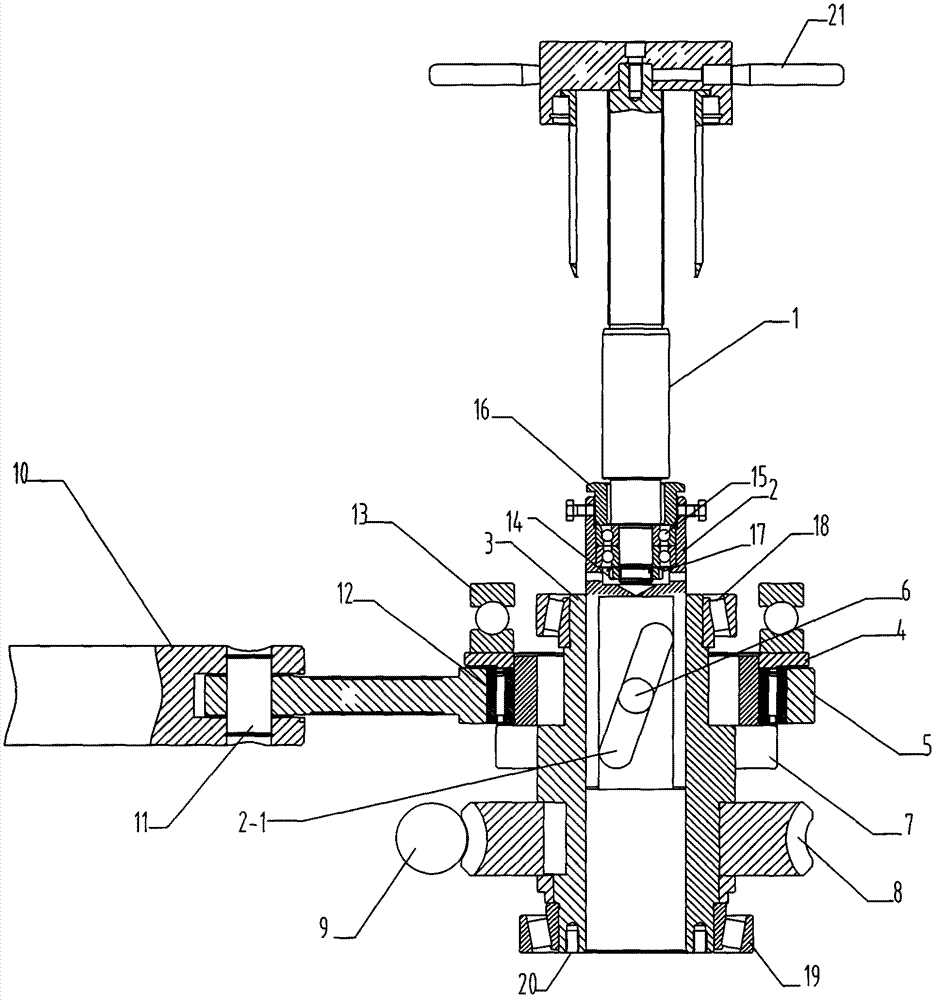

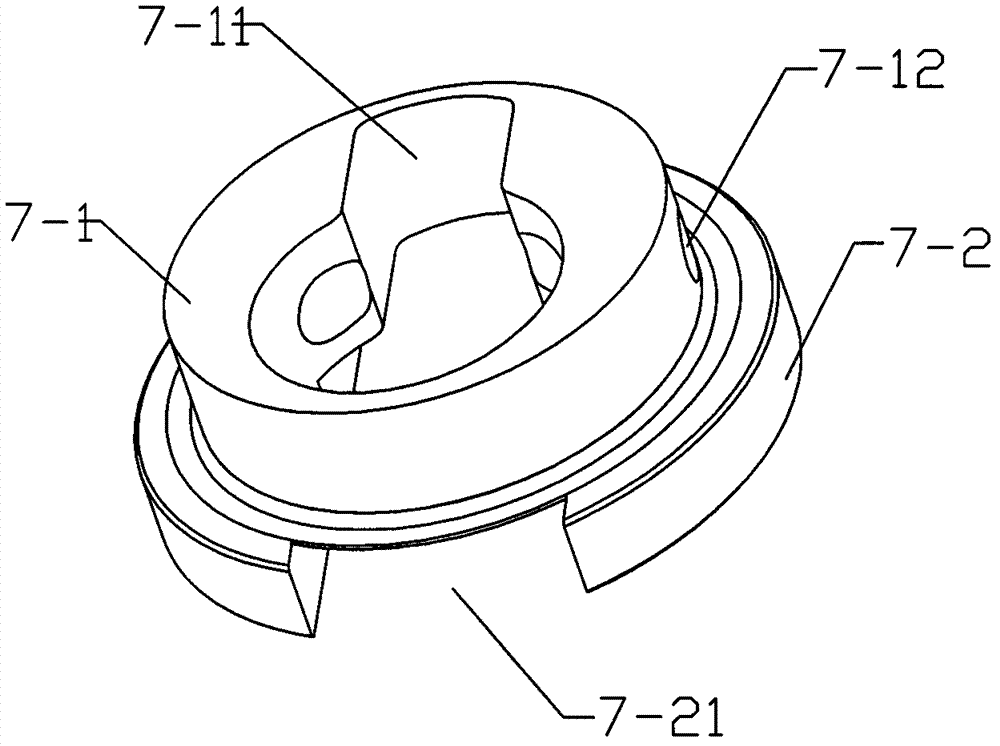

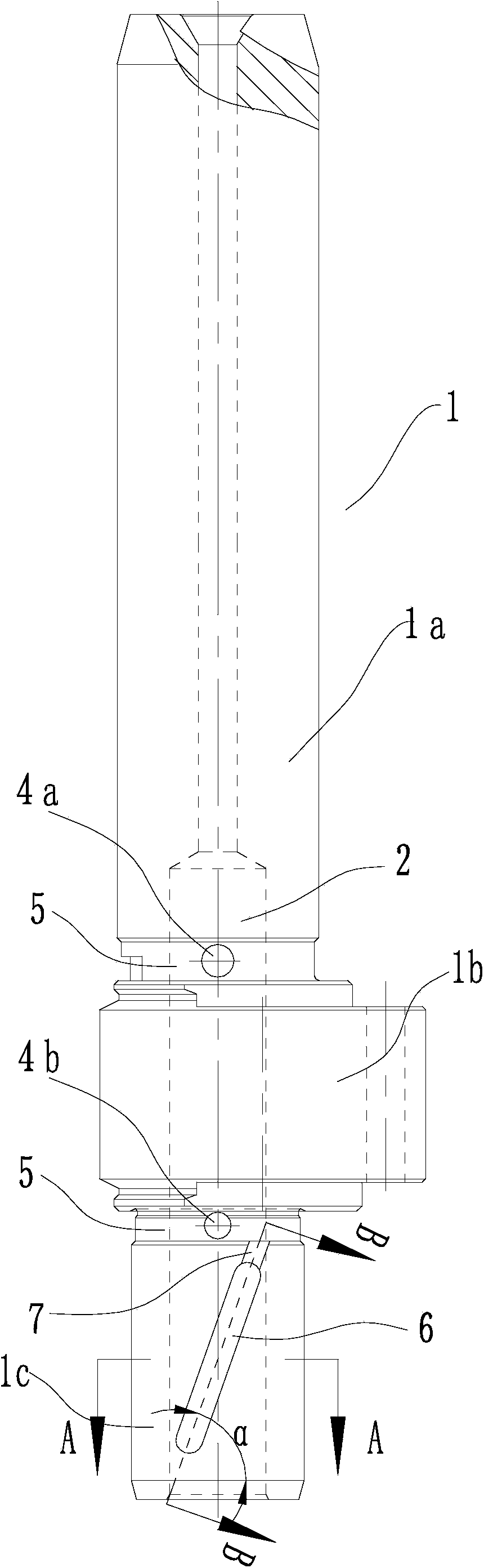

Polished rod sealing device

ActiveCN107178333AReduce eccentric wearImprove sealingEngine sealsGeothermal energy generationOil fieldEngineering

Provided is a polished rod sealing device which comprises a main sealing assembly, a secondary sealing assembly and a deviation adjusting and blowout controlling assembly. The polished rod sealing device is characterized in that the main sealing assembly is positioned on the upper portion, the secondary sealing assembly is positioned in the middle portion, and the deviation adjusting and blowout controlling assembly is positioned on the lower portion; when the main sealing assembly is used for achieving normal production of an oil well, a polished rod and a well opening are sealed, the secondary sealing assembly achieves temporary sealing when a main sealing packing is replaced, the lower portion of the deviation adjusting and blowout preventing assembly is connected with the well opening, and the adjustment of angle displacement and horizontal displacement between the polished rod and the well opening is realized, so that the polished rod and the well opening are arranged concentrically, and the function that blowout is prevented after the polished rod is broken is realized. The polished rod sealing device is novel in design and compact in structure, and hydraulic sealing, angle displacement, horizontal displacement and blowout preventing are integrally designed, and the polished rod sealing device can be adjusted and operated conveniently. According to the polished rod sealing device, the eccentric wear of the packing is lightened, the loading of a pumping unit is reduced, and electric energy is saved. By good sealing effectiveness of the packing, the polished rod sealing device is especially applicable to a heavy oil steam injecting area and a heavy oil polymer injecting area for sealing well openings of oil wells, so that crude oil loss is avoided, environmental pollution is prevented and oil filed management level is improved.

Owner:DONGYING CHANGRUI PETROLEUM MACHINERY PARTS CO LTD

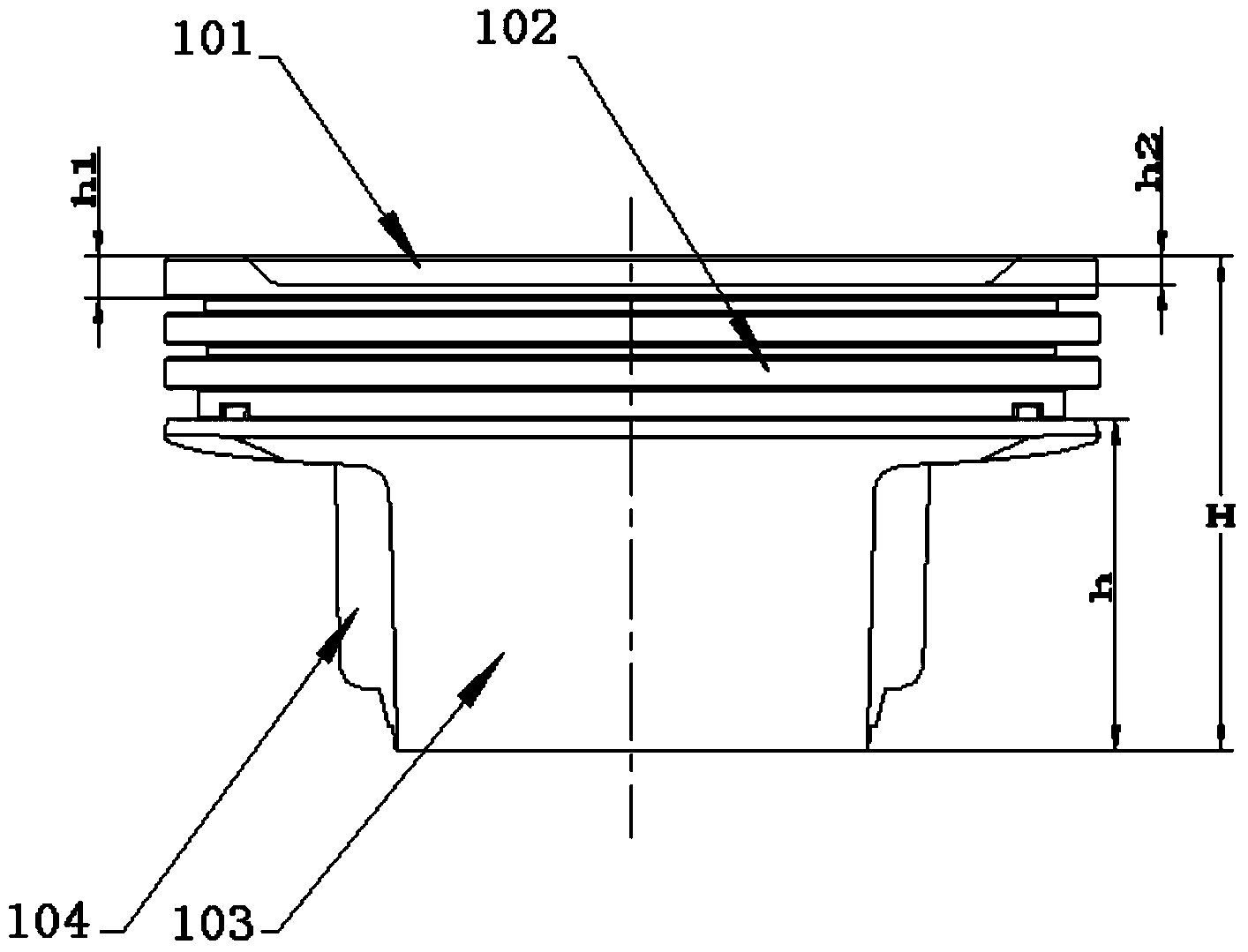

Brake pads for high-speed train braking systems

InactiveCN102261409AImprove operational efficiencyImprove braking efficiencyFriction liningEngineeringSpring steel

The invention discloses a brake pad for a high-speed train braking system, which comprises: a first steel back with an integral structure, and more than one spaced apart friction blocks are arranged above the first steel back; each friction block and the A second steel back is arranged between the first steel backs, and the middle area of the second steel back has a raised portion facing the first steel back; hole, and a concave part is provided on the side of the first steel back that contacts the second steel back, and the concave part is matched with the raised part, and the fixed pin is provided on the concave part to freely pass through the first steel back. The first installation hole of the back; on the side of the first steel back and away from the second steel back, there is a snap ring that snaps onto the other end of the fixing pin, and the snap ring is located on the first steel back Inside. The above-mentioned brake pads can withstand relatively high thermal loads, and can reduce the eccentric wear phenomenon of the friction blocks in the brake pads, so that the friction surfaces of the corresponding brake discs are evenly stressed, and the braking efficiency is improved.

Owner:MIN OF RAILWAY TRANSPORT BUREAU +1

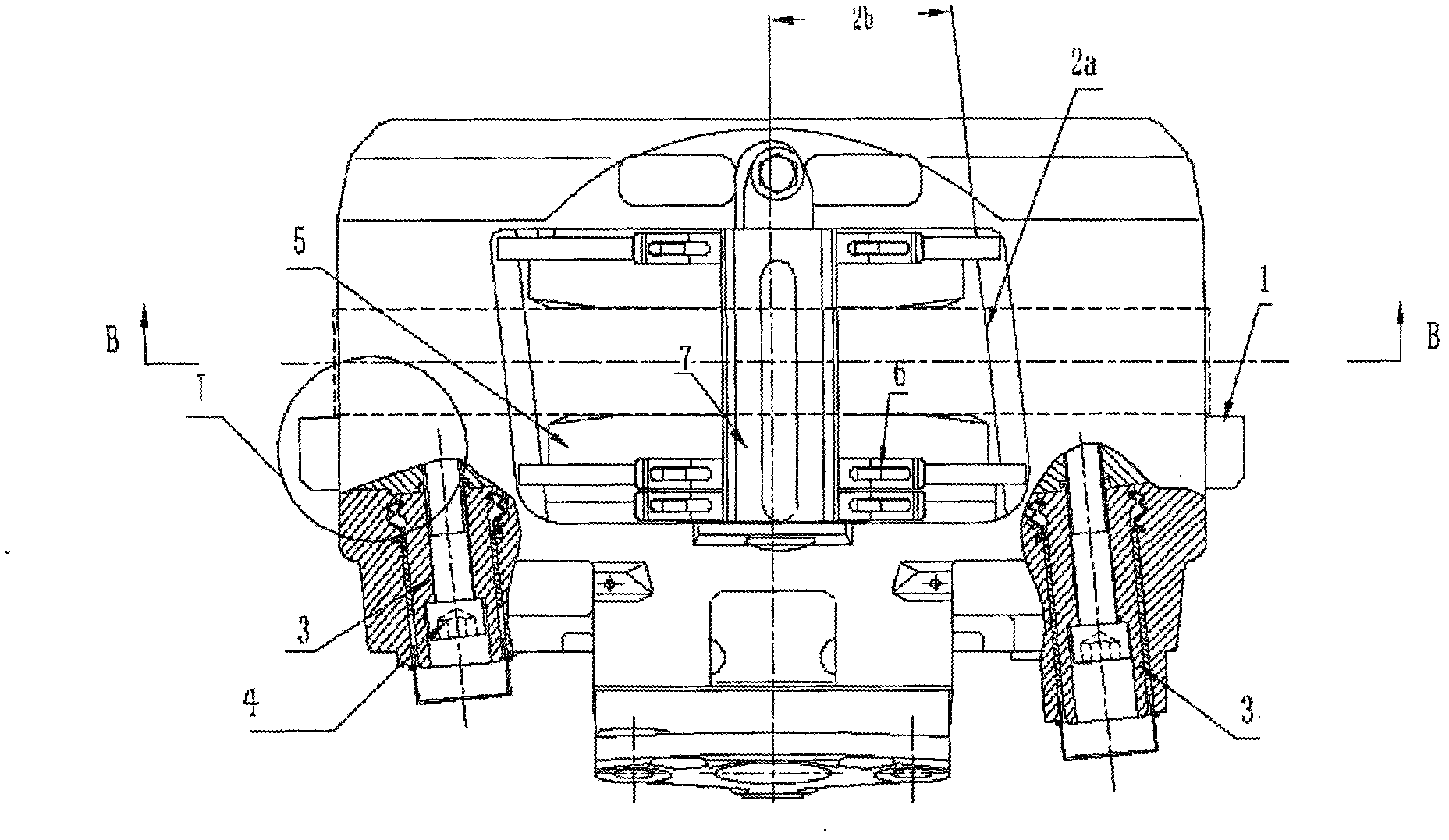

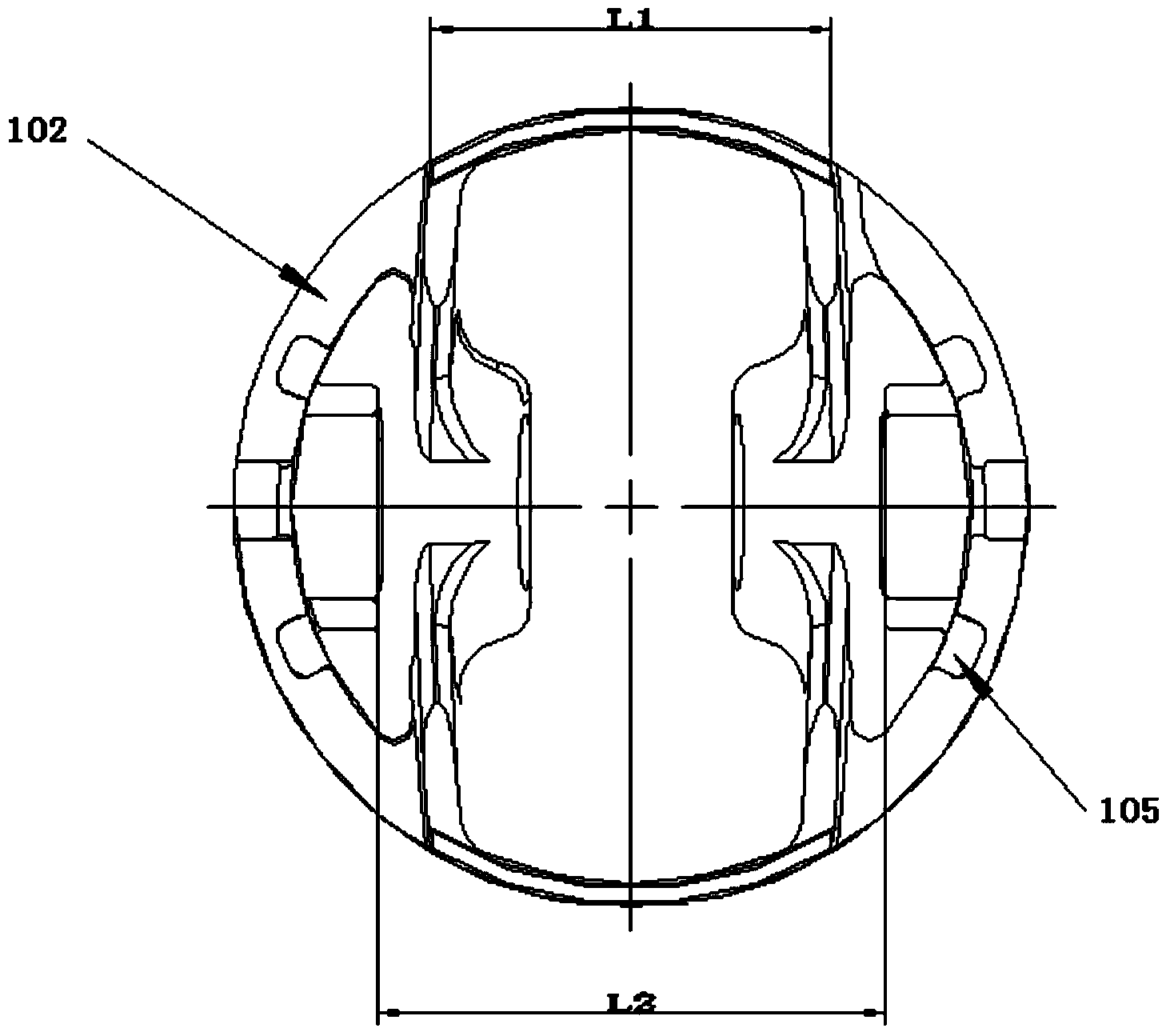

Combination floating type brake pad

ActiveCN103133570ALarge braking areaReduce eccentric wearBraking elementsEngineeringStructural engineering

The invention discloses a combination floating type brake pad. The combination floating type brake pad comprises a combination back plate formed by splicing two back plates together, a plurality of friction blocks arranged on the combination back plate, elastic support chips arranged between the friction blocks and the combination back plate and clamp springs connecting the friction blocks to a fist back plate in floatable mode. The elastic support chips comprise spherical support faces which are connected with spherical support portions of the friction blocks in fitting mode, guide holes which are formed at centers of bottoms of the spherical support faces and are suitable for locating portions of the friction blocks to penetrate through, and a plurality of support pawls arranged on outer sides of the spherical support faces, wherein the support pawls extend from edges of the spherical support faces to the bottoms of the spherical support faces and towards directions far away from the guide holes, connecting edges of the support pawls are connected with the edges of the spherical support faces through smooth transition sections, and extensions of support edges of the support pawls, which are opposite to the connecting edges of the support pawls exceed the bottoms of the spherical support faces. The brake pad solves the problem that due to the fact that pawls of elastic support pieces of an existing brake pad do not extend outwards but bend inwards, support of corresponding portions loses effectiveness.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

Two-stage supercharging vehicle-mounted air compressor

InactiveCN103758732AReduce power consumptionReduced service lifePositive displacement pump componentsPump installationsGas compressorLinear compressor

The invention discloses a two-stage supercharging vehicle-mounted air compressor and aims at providing an automotive two-stage supercharging air compressor which is low in power consumption, high in reliability and low in exhaust temperature. The two-stage supercharging vehicle-mounted air compressor comprises a cylinder cover, wherein the cylinder cover is connected with a cylinder body through a valve plate assembly, a crankshaft is arranged under the cylinder body, a primary air cylinder and a secondary air cylinder are arranged in the cylinder body in parallel, and an unloading mechanism is arranged on the valve plate assembly and comprises an unloading hole, a plunger piston, a pin, a rack, a spring and gear. The plunger piston is fixedly connected with the rack through the pin, one end of the plunger piston faces the unloading hole, the other end of the plunger piston is connected with the spring, the rack is meshed with the gear, a cooling system is arranged in the cylinder cover, air discharged by the primary air cylinder is cooled by the cooling system and then flows into the secondary air cylinder. The two-stage supercharging vehicle-mounted air compressor is suitable for modification of brake systems of large automobiles and existing automobiles.

Owner:GUANGXI YUCHAI MASCH CO LTD

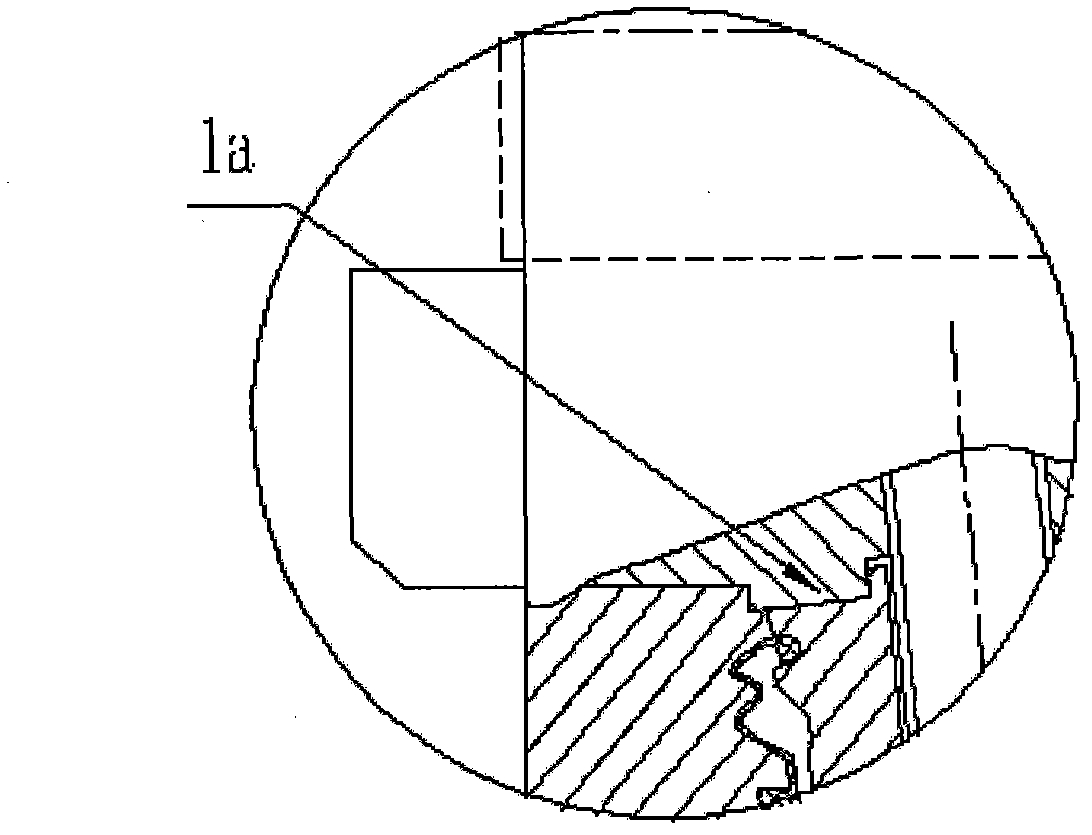

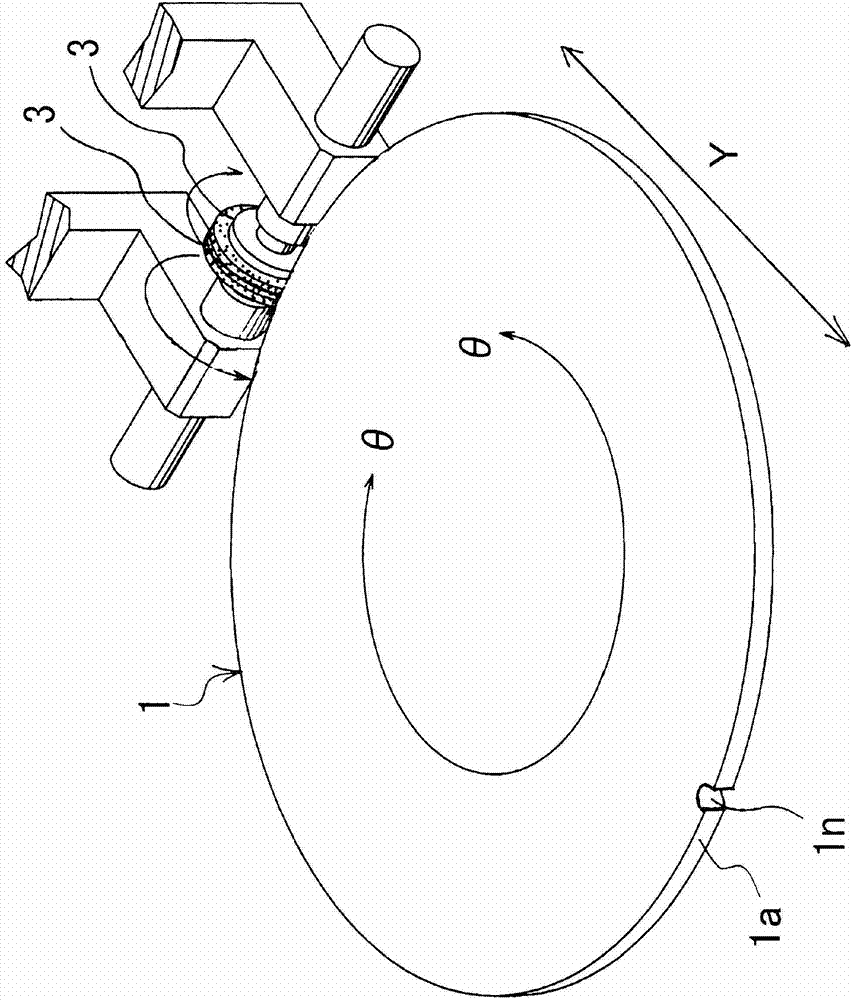

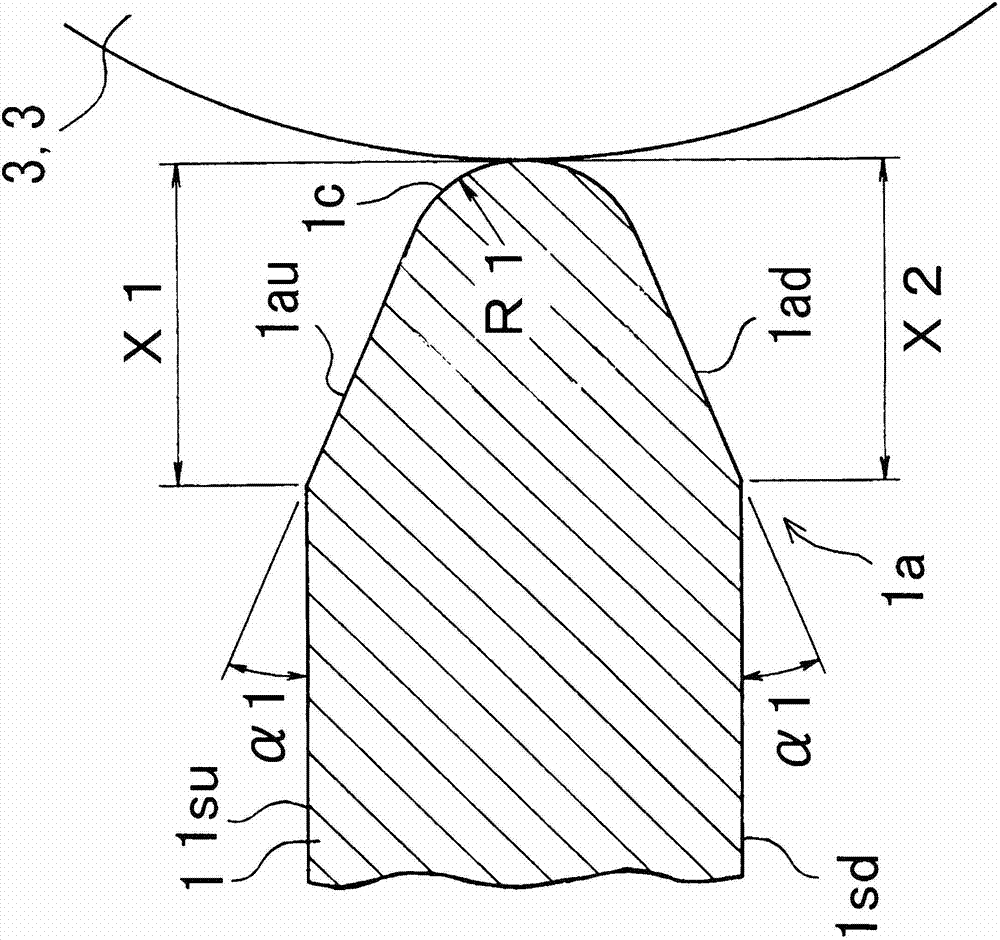

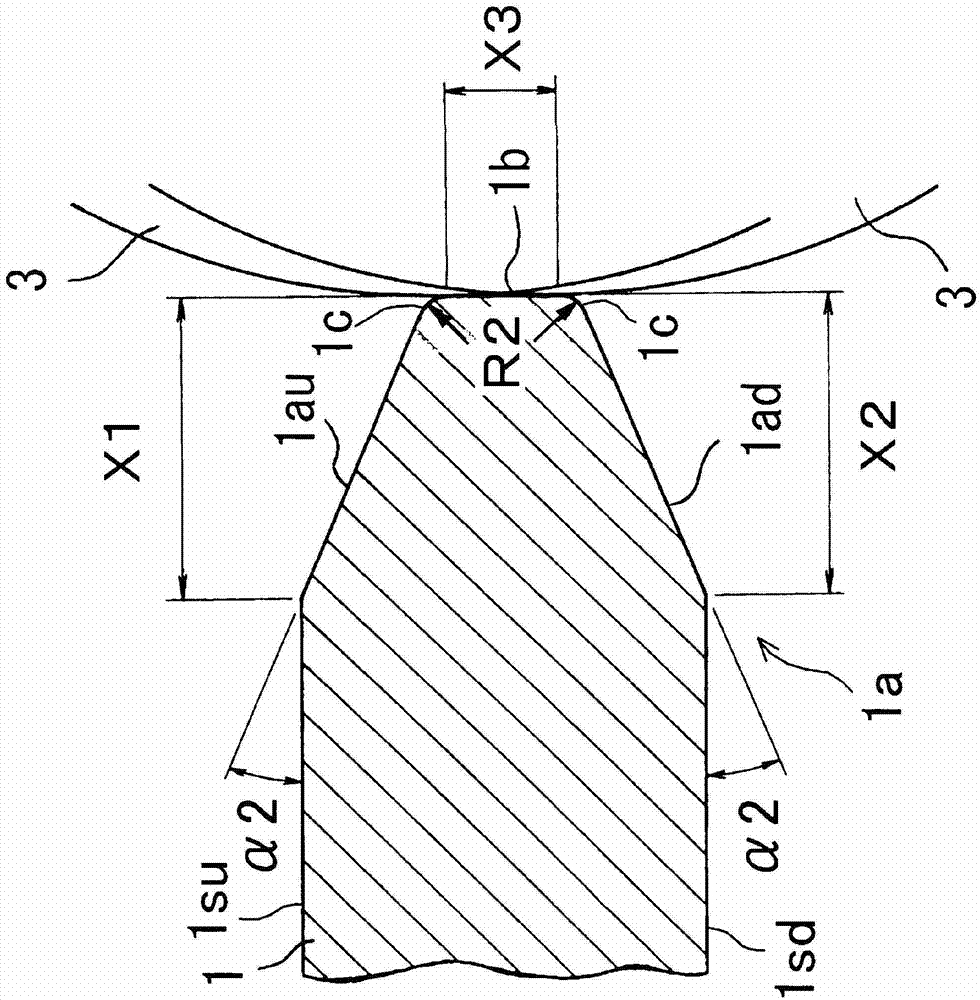

Method for chamfering wafer, apparatus for chamfering wafer, and jig for adjusting angle of grindstone

ActiveCN103586751AIncrease contact lengthIncrease throughputEdge grinding machinesGrinding machine componentsGrindstoneEngineering

The invention provides a method for chamfering a wafer, an apparatus for chamfering a wafer, and a jig for adjusting the angle of a grindstone. In the method for chamfering a wafer by using two groove-free grindstones, the time for reshaping (finishing) the groove-free grindstones is reduced. In addition, the contact length between the groove-free grindstones and a wafer is increased, and the time for hole shrinkage machining of the wafter and the time for machining the wafter into a wafer having a desired cross section profile are shortened. The method for chamfering a wafer includes loading a wafer (1) on a rotary bench in a centering manner and making the wafer rotate to enable two groove-free grindstones (3, 3) machining the rotary wafer to contact with the periphery (1a) of the wafer so as to chamfer the diameter or the cross section profile of the wafer (1). The method is characterized in that the above two groove-free grindstones (3, 3) are configured in a way that central lines (L, L) of the grindstones along the width are close to the side of the rotary axis (S) of the wafer (1) placed on the rotary bench, and are in contact with the wafer (1).

Owner:DAITO ELECTRON

Sealing device used for micro rotor engine

The invention discloses a sealing device used for a micro rotor engine, and belongs to the field of micro rotor engines. The sealing device comprises a top sealing block, a connection spring, a bottom sealing block and a pre-tightening spring. The sealing device is changed into a split type, the connection spring stretches and contracts through the gas pressure difference, a ventilation hole way of the top sealing block and a ventilation hole way of the bottom sealing block communicate, so that gas at the bottom of the bottom sealing block flows towards a low-pressure combustion chamber, and the gas pressure at the bottom of the bottom sealing block is reduced. Through adjustment on the overlapping area of a lower port of the ventilation hole way of the top sealing block and an upper port of the ventilation hole way of the bottom sealing block, the changing speed of the pressure difference of the top and the bottom of the sealing device can be adjusted. According to the sealing device, the pressure difference of the bottom gas and the top gas of the radial sealing device can be reduced, accordingly, the sealing device can guarantee radial sealing, meanwhile, abrasion of a radial sealing sheet can be reduced, the service life of the engine is prolonged, and the efficiency of the engine is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Gas Injection and Shallow Super Heavy Oil Production Integrated Device

The invention provides a gas injection and shallow super oil production integrated device,which includes tubing string and sucker rod string. Bottom of tubing string is connected with an injection and production integrated high angle pump of which bottom is connected with a chamfer tubing through a reducer union. Bottom of the chamfer tubing is connected with shoe guide plug. Flow regulator is arranged on the chamfer tubing. Bottom of anti-corrosion and anti-wear rod string is connected with anti-off-screw device of which bottom is connected with anti-corrosion weighing rod of which bottom is connected with anti-off-screw device of which bottom is connected with anti-corrosion and anti-wear sucker rod string and plunger piston. The anti-off-screw device is arranged at two sides of the anti-corrosion and anti-wear sucker rod string. The device achieves throughout and spinning of immobile string, which not only reduces operation times but also avoids cooling damage caused by operation liquid for stratum during the process of spinning operation. Moreover, the device ensures throughout and spinning effect and meanwhile significantly reduces costs of gas injection and oil production.

Owner:CHINA PETROLEUM & CHEM CORP +2

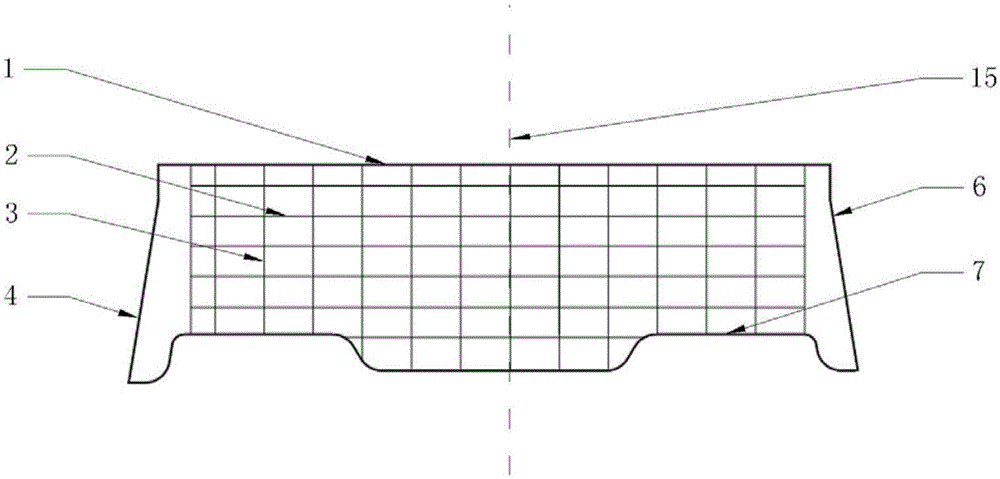

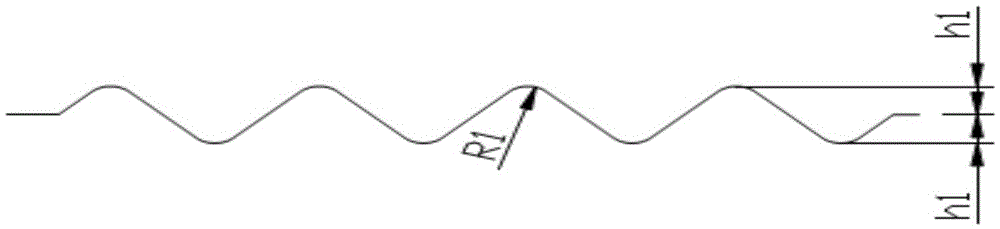

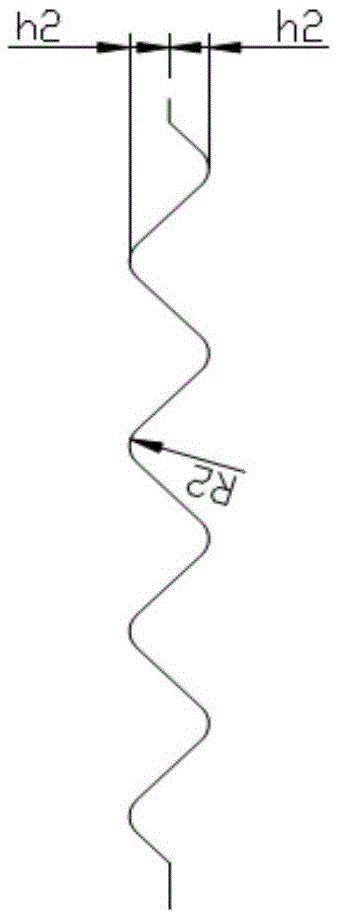

Steel disc for truck and bus tires and tire manufactured by using the same

InactiveCN105539018AReduce rigidityIncrease contact areaRoad vehicle tyresRoad vehiclesThree-dimensional spaceEngineering

A steel disc for truck and bus tires is integrally a three-dimensional design, which is reflected in a three-dimensional space of length, width and thickness; the steel disc is designed as wavy curved planes in both two vertical directions of a length direction and a width direction of the steel disc; in the width direction, the wavy curved plane extends to a position which is 2-5 mm from the edge of the steel disc; in the length direction, the wavy curved plane is arranged at a middle part and accounts for 70-95 % of the whole length; two end parts of the steel disc are designed as planes; in the length direction of the steel disc, each part is designed with unequal length; and in the width direction of the steel disc, each part is designed with unequal width. In a tire tread manufactured by using the steel disc, a plurality of three-dimensional grooves, which are manufactured by using the steel disc as a mold, are formed in each side pattern block and each should pattern block; and angles between the three-dimensional grooves and the central line of the tire tread are 35-90 DEG. According to the invention, as the snow coefficient of a tire manufactured by using the steel disc is 1.25-2.43, excellent braking and driving performances of the truck and bus tires on ice snow covered pavements or snow slush pavements are ensured.

Owner:SAILUN GRP CO LTD

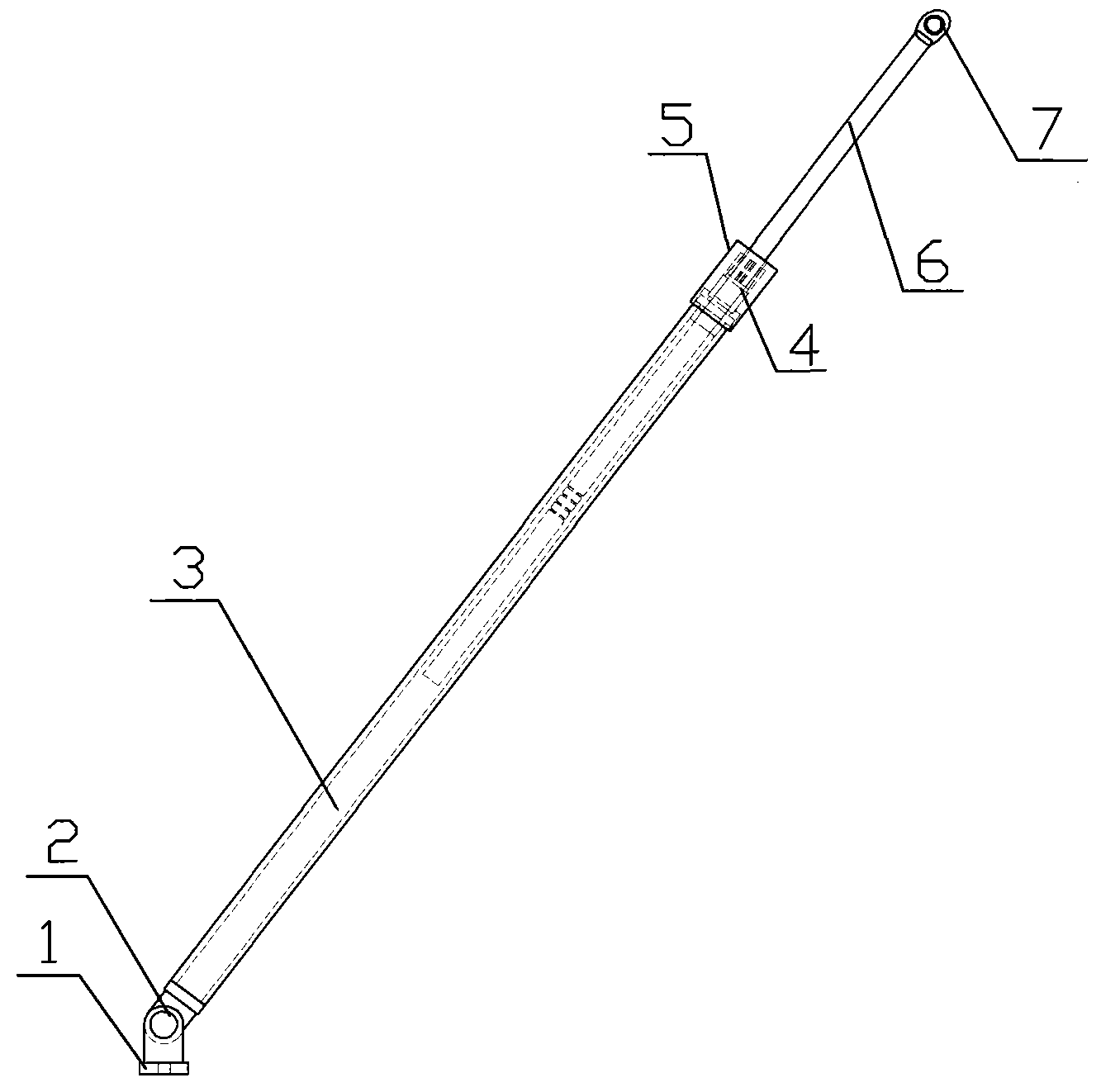

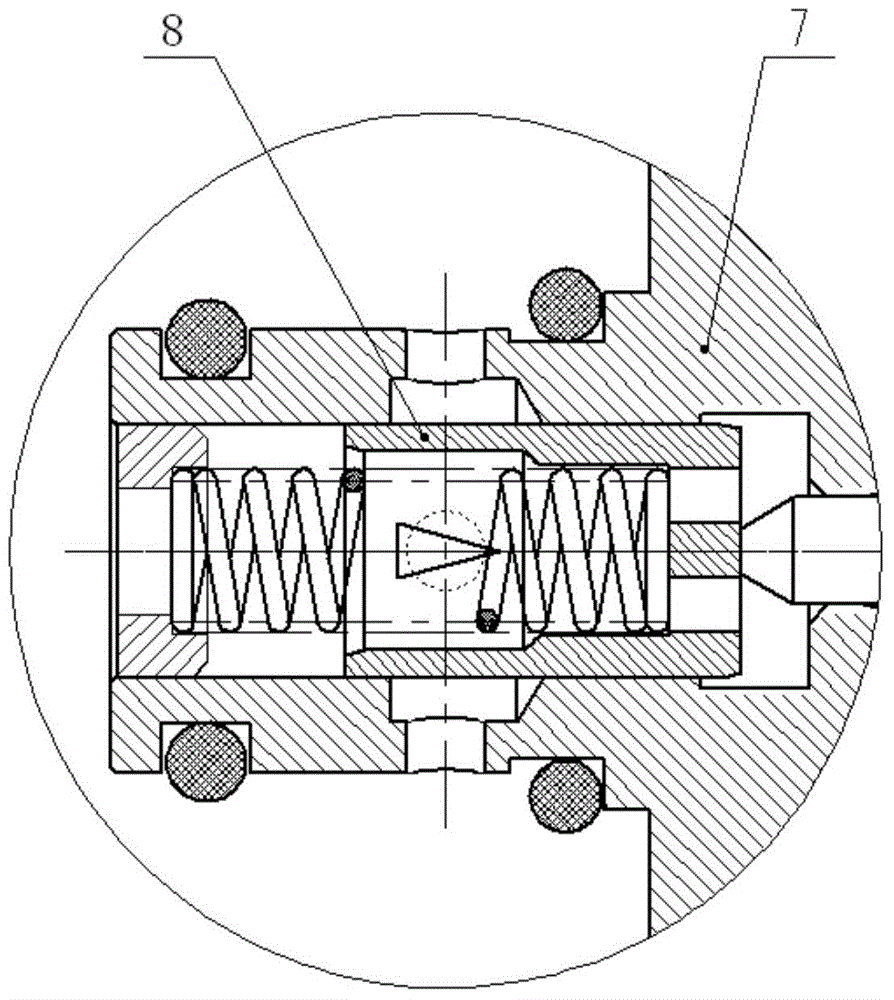

Hand-locking type support rod of tip-up door

The invention discloses a hand-locking type support rod of a tip-up door. A support is connected with a sliding cylinder through a lower hinge pin; a locking jaw is integrally fixed with the sliding cylinder; a hand locking nut on the locking jaw is connected with the locking jaw; a sliding rod is mounted in the sliding cylinder; a positioning groove is arranged at the tail end of the sliding rod in the sliding cylinder; and an upper hinge pin is connected with the sliding rod. The hand-locking type support rod of a tip-up door provided by the invention adopts a full-mechanical structure, is manually operated and saves all pneumatic and hydraulic elements; as the locking jaw is made from a hard material, the concentricity between the sliding rod and the sliding cylinder is ensured, eccentric wear between the sliding rod and a guide cylinder is reduced to a great degree, the service life of the easily-damaged parts is prolonged, and the failure of the support rod caused by a sealing element is eliminated; and moreover, the hand-locking type support rod has the characteristics of light weight, low cost, good shape and the like, and is convenient to install and adjust and to replace the components.

Owner:天津凯德实业有限公司

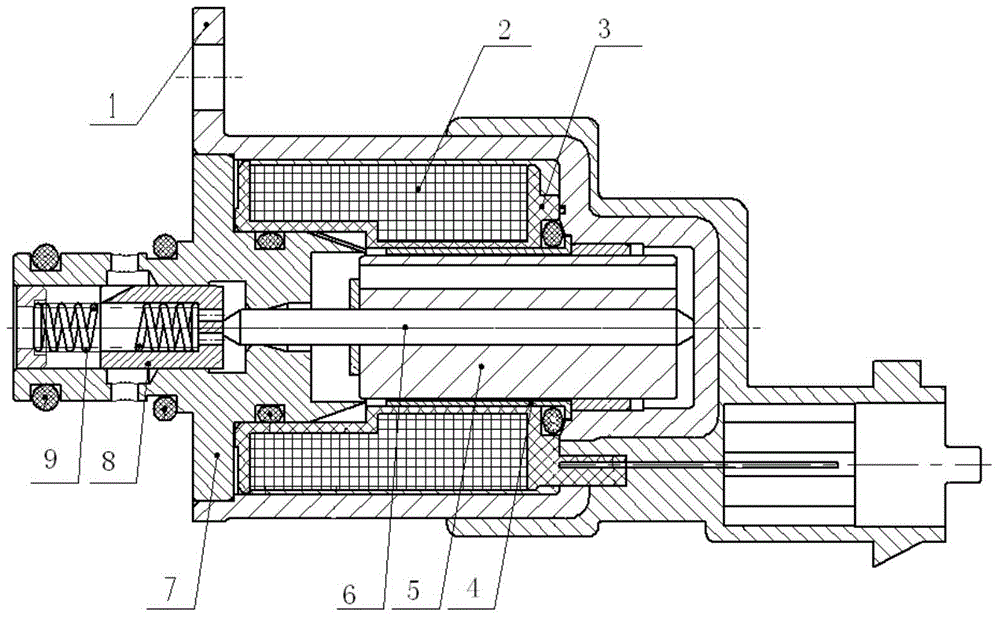

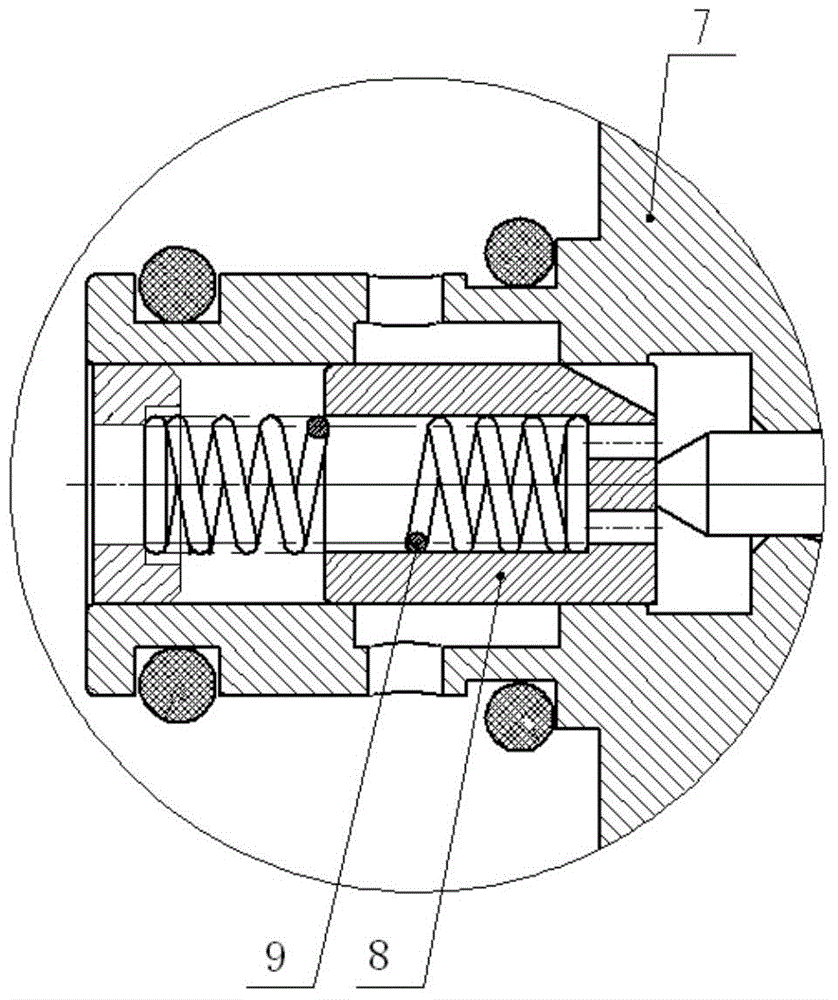

Valve element of proportional electromagnetic valve and proportional electromagnetic valve with valve element

ActiveCN104455655AImprove flowCircumferential force balanceOperating means/releasing devices for valvesEngineeringHigh pressure

The invention discloses a valve element of a proportional electromagnetic valve. The valve element is installed in an inner hole of a static iron valve seat of the proportional electromagnetic valve. The axial position of the valve element is adjusted through the effect between a push rod and an adjusting spring. Two or more evenly-distributed flow adjusting grooves are formed in the outer circumferential wall of one end of the valve element and are axial flow passing grooves, and the notch sectional area of each flow adjusting groove is the largest at the end of the valve element and gradually reduced to zero along the outer circumferential wall of the valve element. The invention further provides the proportional electromagnetic valve with the valve element. By the axial flow passing flow adjusting grooves, liquid directly flows to a high-pressure pump oil channel through the flow adjusting grooves, the environment of a flow field is improved, the interaction effect between liquid pulsation and valve element final motion is reduced, the evenly-distributed flow adjusting grooves are good in alignment, the flow direction of the liquid is better optimized, and eccentric wear caused by long time work of the valve element is reduced. The valve element is reasonable in structural design and easy to machine, and the wall thickness of the valve element is increased, so that deformation of the valve element is not likely to happen.

Owner:北油电控燃油喷射系统(天津)有限公司

Crankless piston type stepless speed change engine and design method

InactiveCN101781997ALight weightImprove work efficiencyEngine componentsReciprocating piston enginesGear driveDrive shaft

The invention provides a crankless piston type stepless speed change engine and a design method. Air cylinder assemblies are oppositely arranged on the same axis, a swing arm is arranged between the air cylinder assemblies, one end of the swing arm is fixed, the other end of the swing arm is provided with an arc-shaped step rack, a slide slot is vertically arranged in the middle of the swing arm, a swing arm slide block is arranged in the slide slot, the oppositely arranged air cylinder assemblies are connected together via a connection rod, the swing arm slide block is arranged in the middle of the connection rod to drive the swing arm to swing left and right and further drive the arc-shaped step rack to swing left and right so as to drive a group of one-way gears to rotate, the rotation of the one-way gears drives a transmission shaft to rotate continuously to output kinetic energy outwards, an air cylinder shell is adjusted by a synchronous ascending and descending mechanism arranged at the outer part of the air cylinder shell to move up and down along a slideway, and because the air cylinder assemblies are arranged in the air cylinder shell, the vertical movement of the air cylinder shell drives the swing arm slide block to move up and down in the slide slot of the swing arm, and the moment of the swing arm slide block driving the swing arm is changed via the change of the position of the swing arm slide block in the slide slot so as to change the swing amplitude of the arc-shaped step rack, the rotate speed of the transmission shaft is changed along with the change of the position of the swing arm slide block on the swing arm, and stepless speed change is realized.

Owner:钱戈

Follow-up type automatic compensation polished rod sealing device

InactiveCN105971544AUniform and stable penetrationAvoid corrosionSealing/packingOil fieldEngineering

The invention provides a follow-up type automatic compensation polished rod sealing device and belongs to the technical field of oil field machinery. The follow-up type automatic compensation polished rod sealing device comprises a sealing cover, a sealing shell, a pressure adjusting spring, a translation pressing plate, an upper follow-up platform, a follow-up packing box, a lower follow-up platform and a sealing foundation support; the follow-up packing box is in close contact with a polished rod, parallel movement in any direction in the horizontal plane is conducted by means of the upper follow-up platform and the lower follow-up platform, and the problem of eccentric wear is effectively solved; the follow-up packing box is provided with compensation packing and centralization packing, close contact with the polished rod can be achieved under continuous pressure, the sealing effect is improved, and packing wear can be compensated continuously; an annular cavity formed by a sealing cover retaining ring and the sealing shell is filled with lubricating oil and can provide continuous lubrication and oil seal for the upper follow-up platform, the lower follow-up platform, the polished rod and even the packing, radial and axial friction is reduced, meanwhile multiple purposes of saving energy, sealing, prolonging the service life and the like are achieved, and the follow-up type automatic compensation polished rod sealing device can be widely applied to wellhead sealers of oil field pumping units with rods.

Owner:HARBIN UNIV OF SCI & TECH +1

Middle-and-long distance guide wheel tire pattern

ActiveCN106427406AImprove cooling effectImprove gripTyre tread bands/patternsRolling resistance optimizationEngineering

Owner:AEOLUS TIRE

Tread sweeper

ActiveCN111824074APrevents sticking to wheel treadsLow rotational resistanceCleaning apparatus for vehicle exteriorsEngineeringAxial thrust

The invention discloses a tread sweeper. The sweeper comprises a brake head, a cylinder and a piston rod. The brake head is provided with a connecting end and a mounting end; a brake shoe is installedat the mounting end, one end, provided with a piston, of the piston rod is arranged in the cylinder in a sealed and sliding mode, an inner cavity of the cylinder is divided into a rod cavity and a rodless cavity through the piston, an air inlet hole connected with the rodless cavity is formed in the inner wall of the cylinder, and an extending end of the piston rod is movably connected with the brake head; and a sliding groove is formed in the end surface of the extending end, an connecting end extends towards the piston end and extends into the sliding groove, and a pre-tightening mechanismfor applying an axial thrust to the connecting end is arranged between the bottom surface of the sliding groove and the end surface of the connecting end. The brake head is pressed through thrust of the pre-tightening mechanism, a friction resistance is provided for rotation of the brake head, and therefore the brake head is locked in a relieving state, gaps between the upper end and the lower endof the brake shoe and a wheel set tread are kept uniform, and the brake shoe is prevented from being attached to the wheel set tread.

Owner:QINGDAO SRI TECH CO LTD

Adjustable internal curve hydraulic pump or motor

PendingCN107575378AChange outputReduce eccentric wearRotary piston pumpsRotary piston liquid enginesReciprocating motionWave shape

The invention relates to an adjustable internal curve hydraulic pump or motor comprising a stator and a rotor which are coaxially connected and can be rotated relatively. The inner wall of the statoris composed of a plurality of concave curved surfaces and a plurality of convex curved surfaces which are spaced; and the rotor is provided with a piston hole which is internally provided with a piston assembly of which one end comes into contact with the inner wall of the stator, and the other end of the piston assembly reciprocates in the piston hole in the axial direction of the piston hole. Inthe direction vertical to the axial direction of the stator, the section of one end of the inner wall of the stator is circular, and the section of the other end of the inner wall is undulant; the undulant degree of the section of the inner wall gradually increases from one end to the other end, and the inner wall is provided with a plurality of guide slots which undulate along the wave shape; and one end of the piston assembly is located in the guide slots, and matched with the shape of the guide slots. An included angle is formed between the axis of the piston hole and the radial directionof the rotor in a plane defined by that the axis of the piston hole intersects with the axis of the rotor.

Owner:常熟市海虞镇志宏五金厂

A Metering Pump with Integral Eccentric Wheel Stroke Adjusting Mechanism

The invention discloses a metering pump with an entire solid eccentric wheel travel adjustment mechanism. The metering pump comprises an amount adjustment lead screw, a moving shaft, a hollow shaft, a connection rod, the entire eccentric wheel, a worm gear, a worm and a slide rod, wherein one end of the amount adjustment lead screw is connected with the moving shaft in a mode of coaxial relative motion, the moving shaft is sleeved in the hollow shaft, a chute is formed in the moving shaft, a slide block is arranged in the chute, the entire eccentric wheel is sleeved on the hollow shaft and fixed with the connection rod, the connection rod is connected with the slide rod, and the worm wheel is in cup joint to the hollow shaft and is meshed with the worm. The metering pump is large in bearing capacity, high in metering precision and long in service life.

Owner:DEPAMU HANGZHOU PUMP TECH

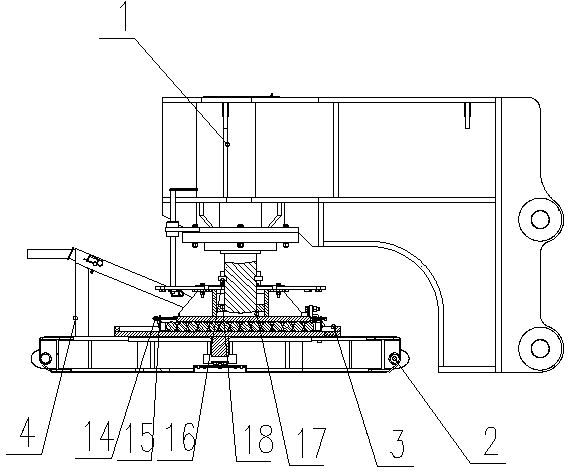

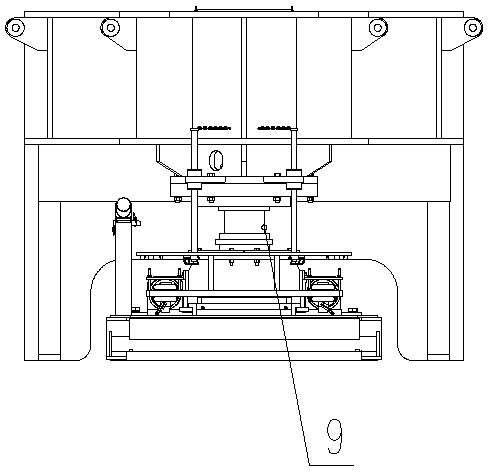

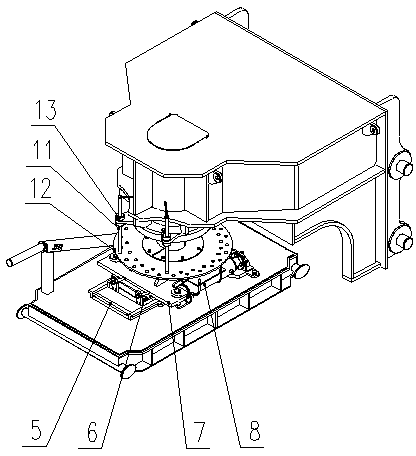

Roller row type omni-directional drilling rig whole step-by-step moving device

ActiveCN104373051ARotate in placeImprove adaptabilityDerricks/mastsDrilling machines and methodsOmni directionalSubstructure

Provided is a roller row type omni-directional drilling rig whole step-by-step moving device. A support is fixed to a cluster well rig substructure through connecting pin shafts, and a reversing rotating mechanism and a trolley are installed on a skid. The trolley is composed of a tray, an upper trolley base, a roller row and horizontal movement oil cylinders. The roller row is formed by installing 14 rollers on a frame, the horizontal movement oil cylinders are connected with the upper trolley base through pin shafts, piston rods of the horizontal movement oil cylinders are connected with the tray through bolts, guide rolling wheels are installed on the two sides of the front end of the upper trolley base, lug plates are installed at the two ends of the roller row, the roller row is connected with the upper trolley base through an adjusting rod, the trolley is connected with a jacking oil cylinder through a spherical surface tray and a clamping plate set, the jacking oil cylinder is installed on the support through bolts, and the spherical surface tray is installed on the upper trolley base. A limiting ring is installed on the spherical surface tray. Through the roller row type omni-directional drilling rig whole step-by-step moving device, on-site rotation of a whole drilling rig can be achieved, well site adaptability of the moving device is improved, the same moving device can be shared by multiple drilling rigs, and investment is saved.

Owner:中石化四机石油机械有限公司 +1

Gasoline engine

ActiveCN103867296AImprove mechanical efficiencyReduce friction workValve arrangementsInternal combustion piston enginesGasolineEngineering

The invention relates to a gasoline engine, which comprises a piston, a combustion chamber and a fuel-oil supplying system, wherein the piston is formed by a piston top, a head, a pin seat and a skirt, wherein the ratio of the height of the skirt to the total height formed by the head and the skirt is 0.6 to 0.7, and the ratio of the chord length of the projection of the molded line of the skirt on a plane on the piston top to the diameter of a cylinder is 0.5 to 0.6; the combustion chamber is hemispheric and is jointly formed by a cylinder head, the piston top, a cylinder-head gasket and one part of a box body, and the surface-to-volume ratio delta of the combustion chamber is 0.15 to 0.25; the fuel-oil supplying system comprises a gasoline pump, a ventilating pipe and a negative-pressure pipe, wherein a negative-pressure impulse-type gasoline pump is adopted as the gasoline pump, the ventilating pipe is arranged on a cylinder head cover, one end of the negative-pressure pipe is connected with the ventilating pipe of the cylinder head cover, and the other end of the negative-pressure pipe is connected with the negative-pressure impulse-type gasoline pump. Through the improvement on structures, such as the piston, a connecting rod, a rocker and the like, the frictional work is reduced, and therefore the mechanical efficiency of the gasoline engine is greatly enhanced.

Owner:ZHEJIANG YAOFENG POWER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com