Tread sweeper

A tread cleaning and end face technology, which is applied in vehicle cleaning, vehicle cleaning equipment, vehicle exterior cleaning devices, etc., can solve problems such as abnormal heating of wheel treads, eccentric wear of brake shoes, and affecting the service life of brake shoes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

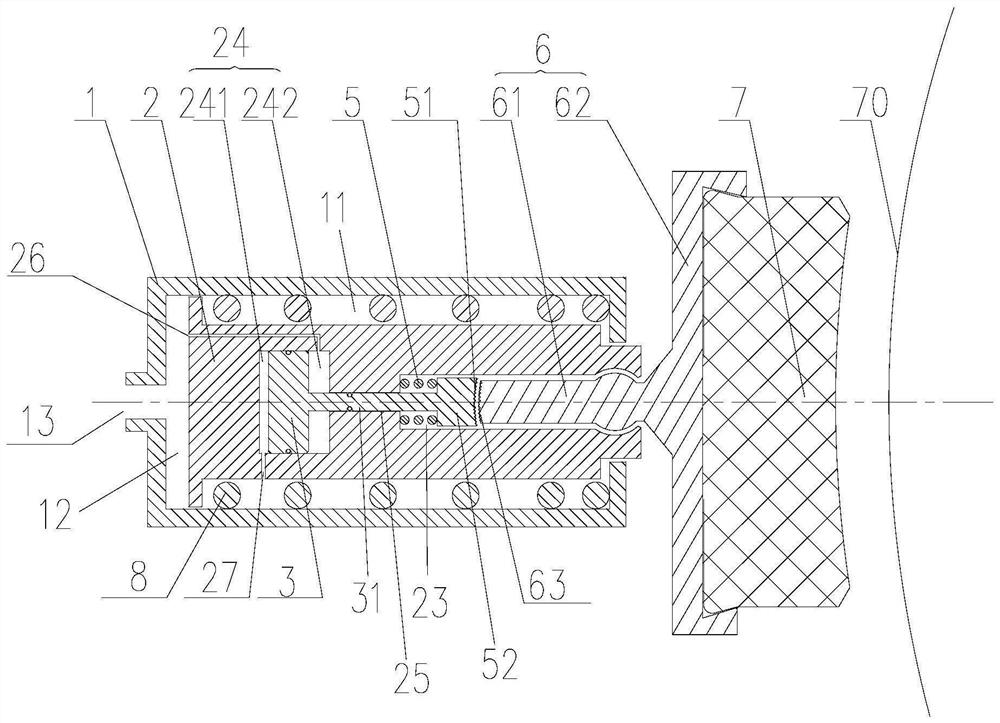

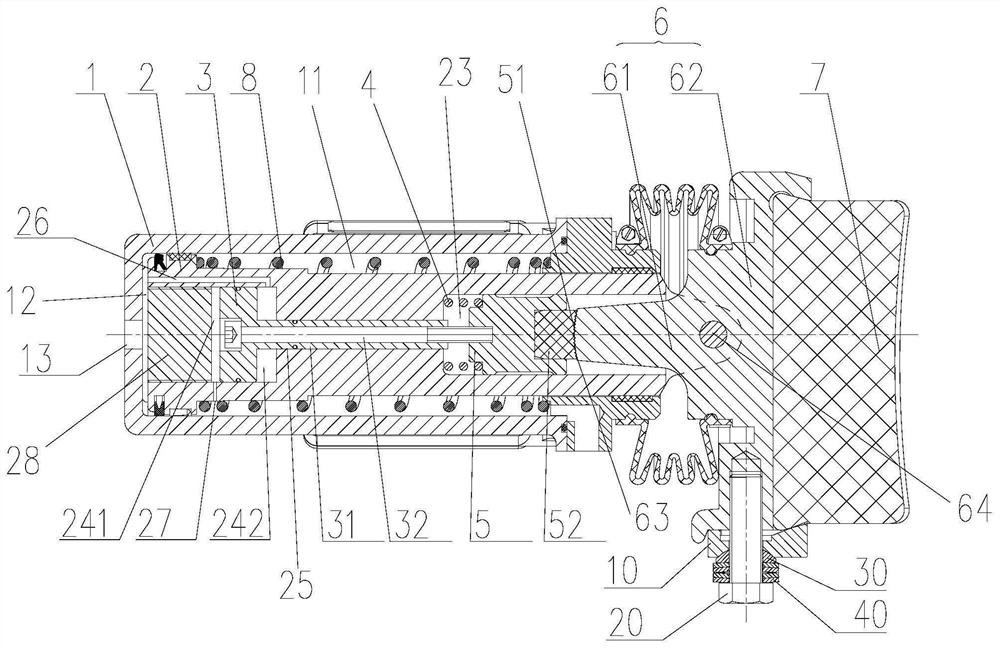

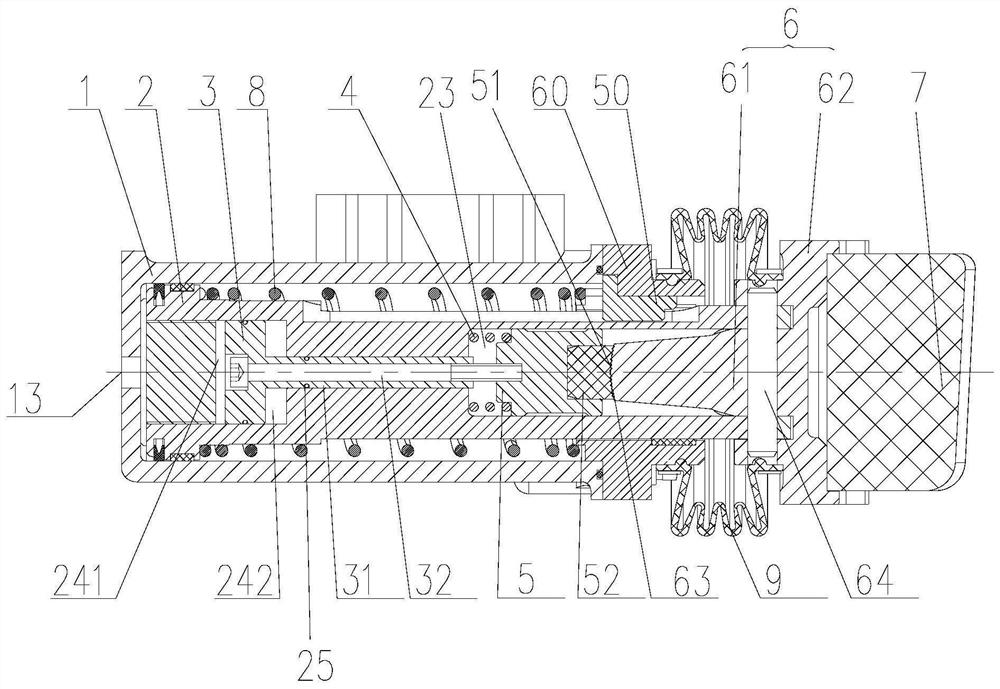

[0032] Figure 1 image 3 As shown, the tread cleaner of this embodiment includes a brake shoe holder 6, a cylinder 1 and a piston rod 2.

[0033] The piston rod 2 has one end of the piston 21 sealed and slidably installed in the cylinder 1. The piston 21 divides the inner cavity of the cylinder 1 into a rod cavity 11 and a rodless cavity 12. The inner wall of the cylinder 1 is provided with an inlet connected to the rodless cavity 12. Stoma13. Wherein, the section of the piston rod 2 located in the rod chamber 11 is pierced with a return spring 8 for pushing the piston 2 back to the initial position during relief.

[0034] The brake shoe holder 6 has a connection end 61 and an installation end 62, and the brake shoe 7 is installed on the installation end 62. The brake shoe 7 is tightly pressed on the brake shoe holder 6 by the pressure block 10, the mounting screw 20, the arc block 30 and the disc spring 40, and the arc block 30 makes the pre-tightening force of the mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com