Hand-locking type support rod of tip-up door

A technology of support rod and hand lock, which is applied in the direction of building fasteners, wing fan fasteners, buildings, etc., can solve the problems of gas spring opening and closing failure, gas spring gas leakage, seal failure and other problems, Achieve the effect of eliminating failures, facilitating installation and adjustment, and reducing eccentric wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

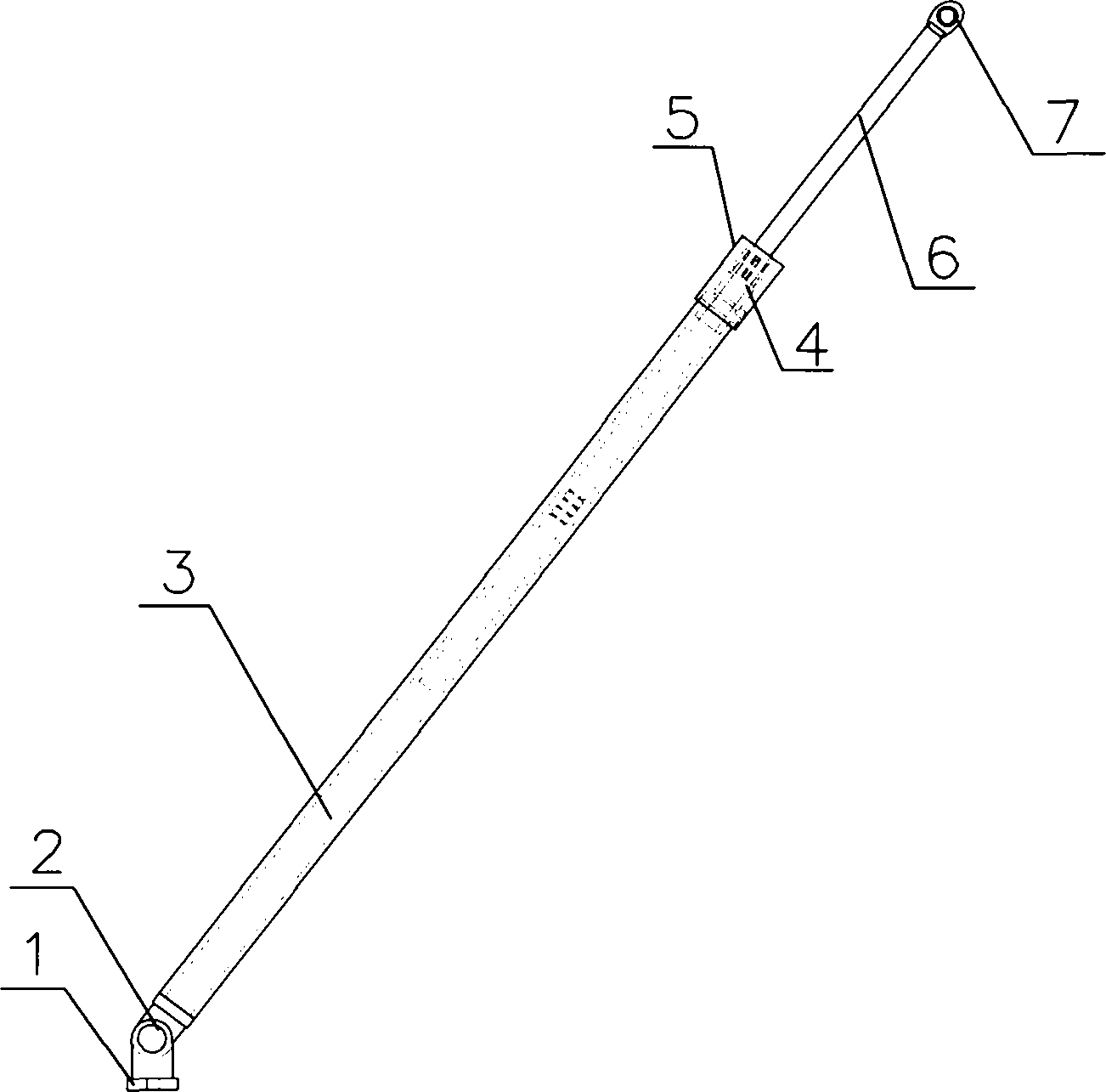

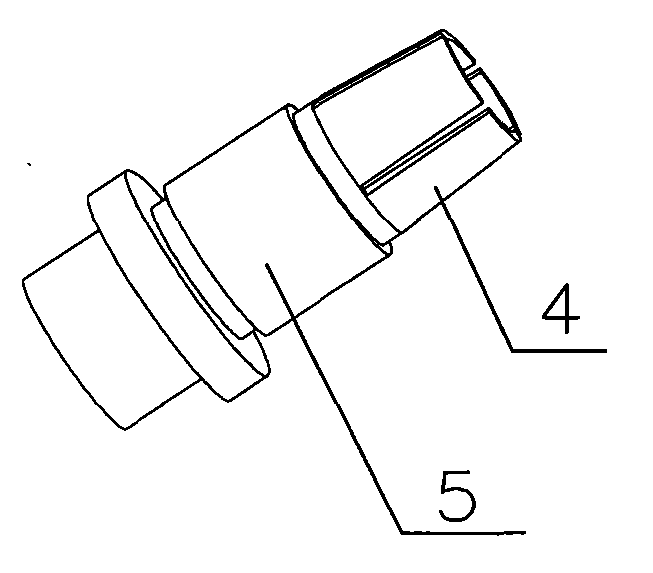

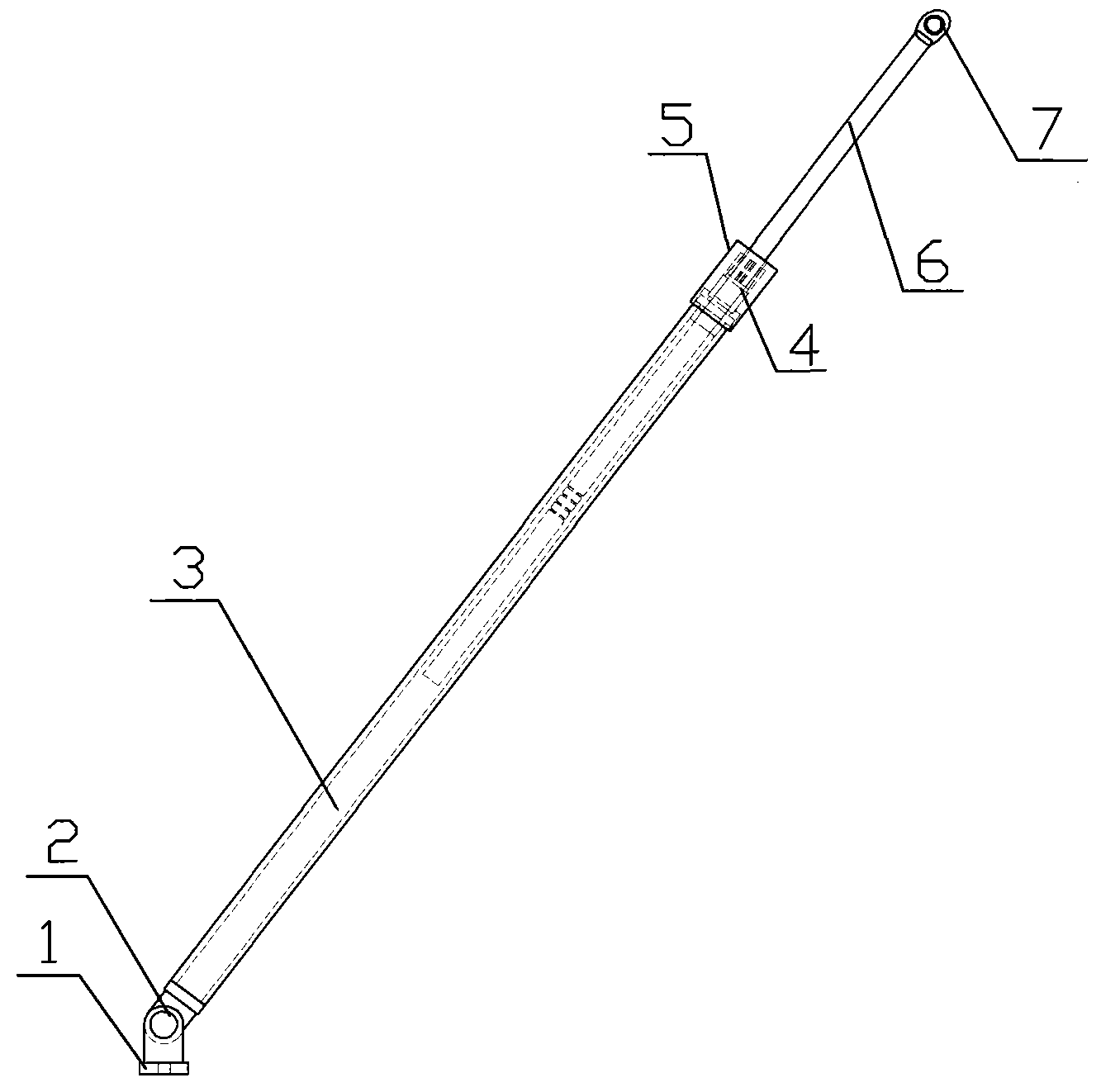

[0008] Such as figure 1 and figure 2 As shown in the figure, it is a hand-locked support rod with an upturned door. The support 1 is connected to the sliding cylinder 3 through the lower pin shaft 2. The locking claw 4 and the sliding cylinder 3 are fixed as a whole. The manual locking nut on the locking claw 4 5 is connected with it, the slide bar 6 is installed in the slide tube 3, the end of the slide bar 6 in the slide tube 3 has a positioning groove, and the upper pin shaft 7 is connected with the slide bar 6. The locking pawl 4 is composed of four locking pieces with gaps between them.

[0009] The working principle of the present invention is as follows: bearing 1 is fixed on the door frame of the upward turning door, and the upper bearing pin 7 connects the slide bar 6 with the upward turning door.

[0010] When it is necessary to open the upper flap door, the hinges at the lower pin shaft 2 and the upper pin shaft 7 will make the upper flap door support rod automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com