Bracket-free floating air pressure caliper disc brake

A caliper-disc brake without bracket technology, which is applied in the direction of brake type, axial brake, brake parts, etc., can solve the problems of complex assembly, easy to occur eccentric wear, poor rigidity, etc., to improve deformation, reduce Small frictional resistance, promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

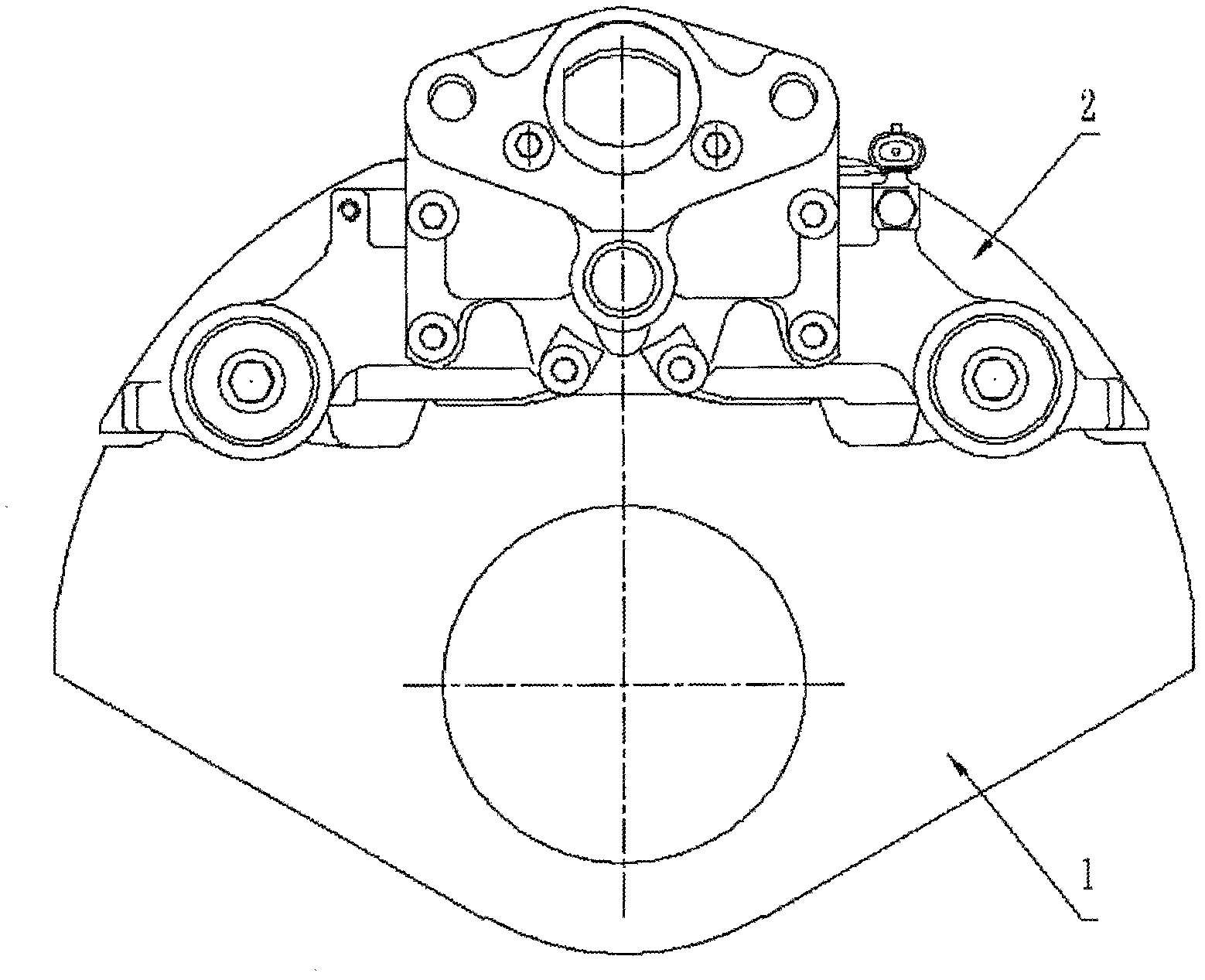

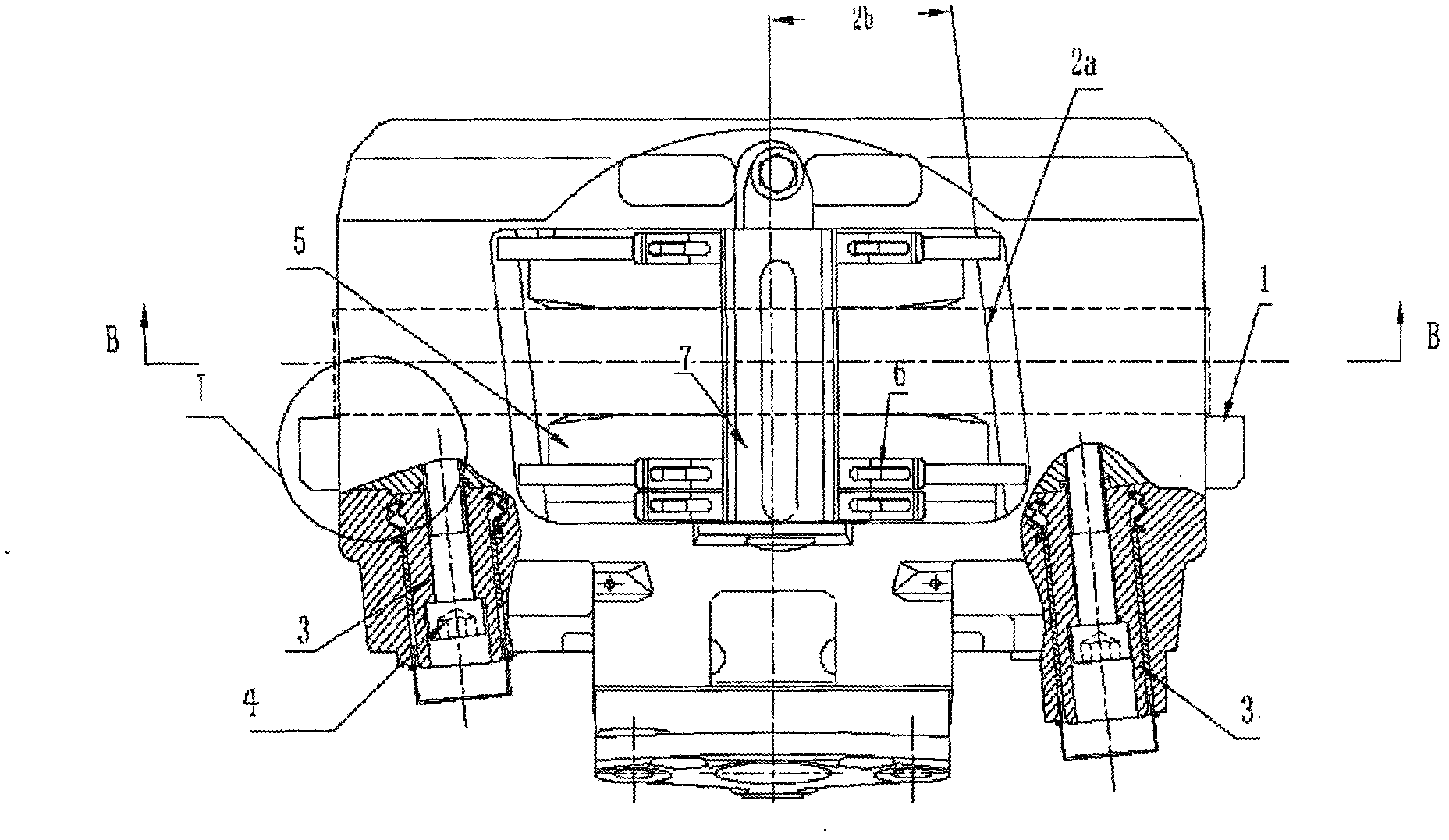

[0031] See Figure 1-2 , Shows the bracketless floating air pressure caliper disc brake of the present invention. The brake includes a mounting plate 1, a brake caliper assembly 2, two guide pins 3, a screw 4, a friction plate 5, a compression spring 6 and a pressure plate 7.

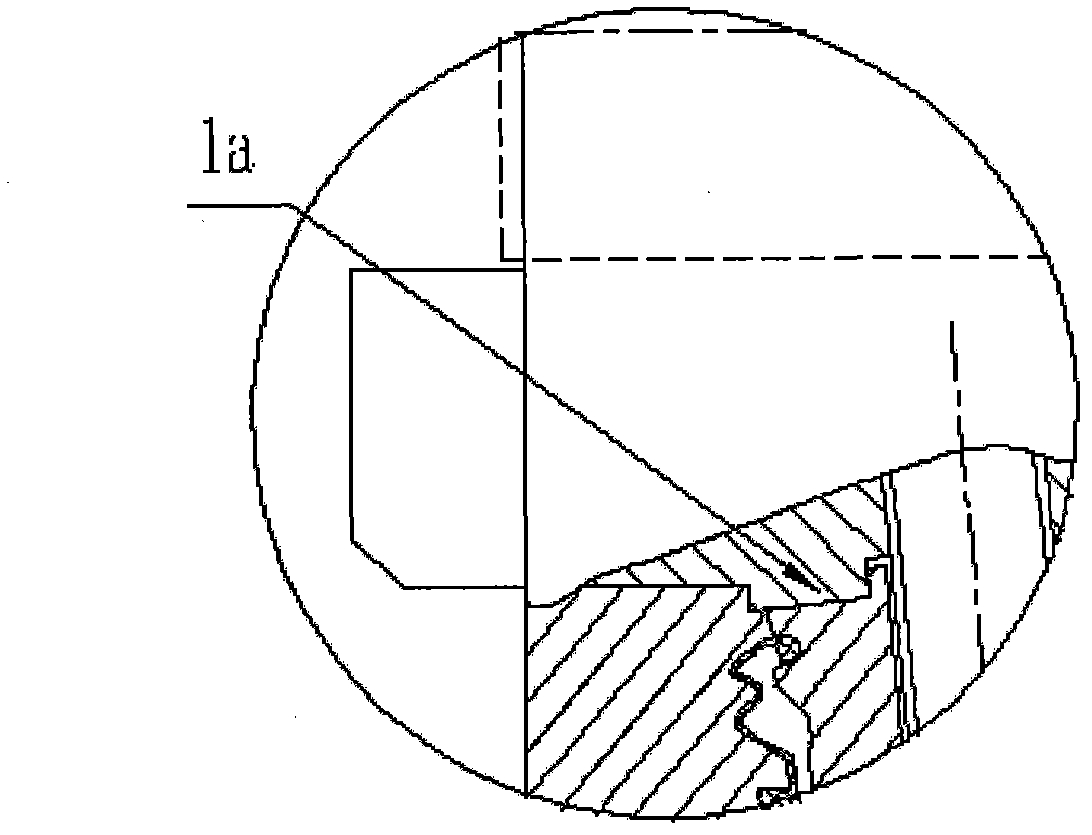

[0032] Among them, on the non-steer wheels, the mounting plate is a plate-like structure as shown; on the steering wheels, the mounting plate is integrated on the steering knuckle, and the mounting plate 1 has a central through hole, which is used for the non-steer vehicle For centering on the bridge, optionally, the form of the mounting plate 1 is not limited to this. For the steering wheel brake, the form of the mounting plate is similar to that of the steering knuckle. Mounting holes (not shown) are also provided on both sides of the mounting plate 1. The mounting hole is for fixing the guide pin 3.

[0033] Wherein, both sides of the brake caliper assembly 2 are provided with pin holes, and the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com