Pumping well anti-eccentric device based on ball face abrasion-proof body

A technology for anti-eccentric wear and pumping wells, which is applied to drilling equipment, earthwork drilling, drill pipes, etc., can solve problems such as increased maintenance costs for oil well operations, affecting normal production of pumping wells, and ineffective anti-eccentric wear effects. Simple, long anti-wear time, and the effect of increasing crude oil output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in combination with specific embodiments.

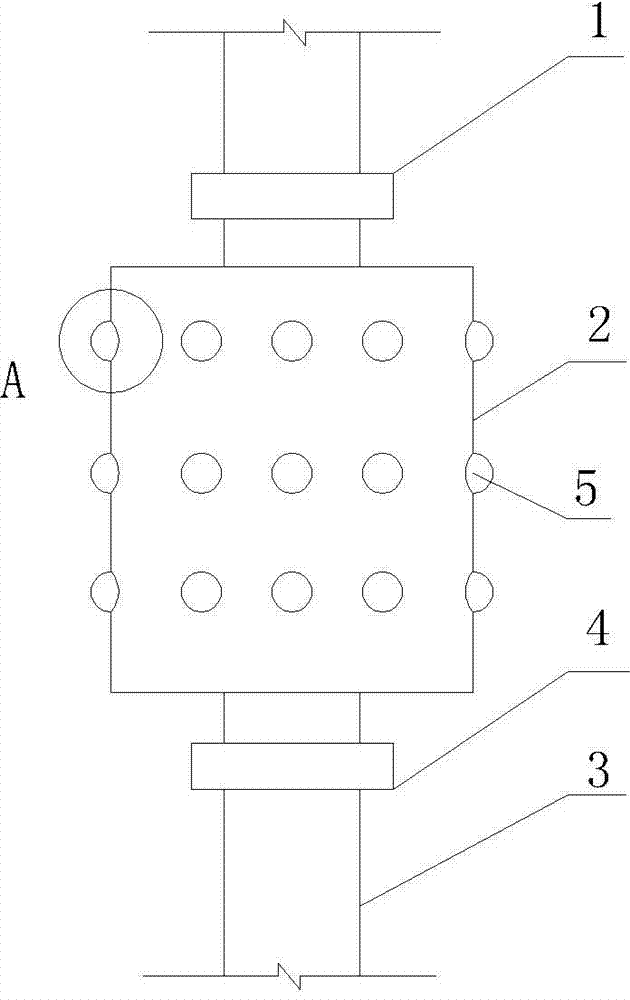

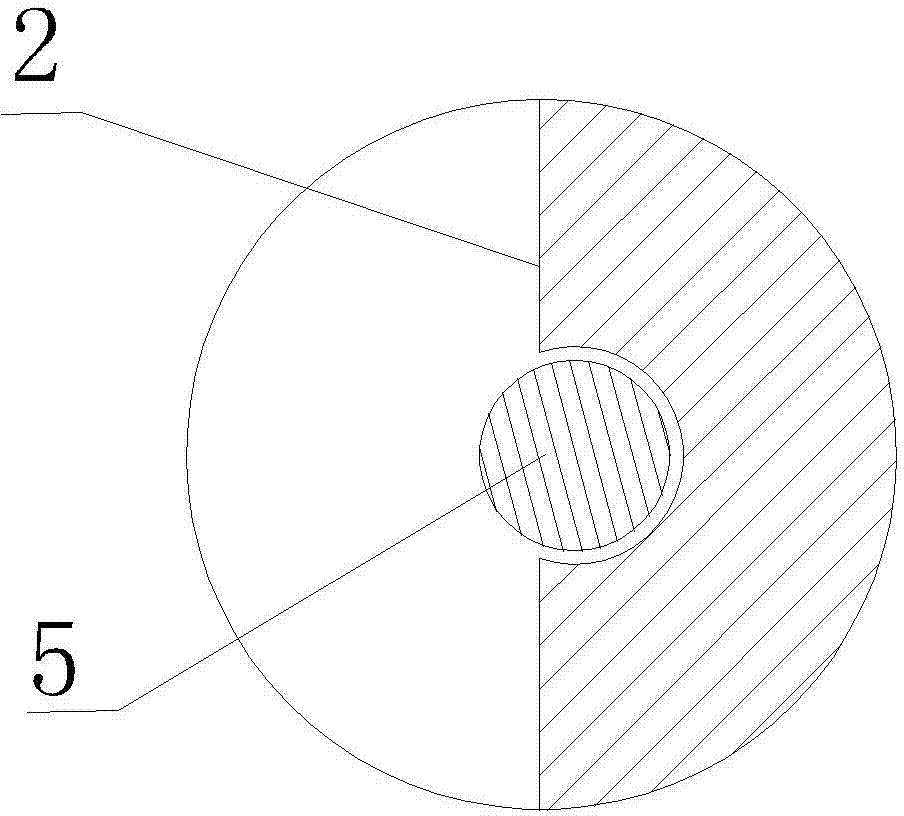

[0014] The invention relates to an anti-eccentric wear device for pumping wells based on a ball surface anti-wear body, which is provided with a central rod 3, on which a cylindrical anti-wear body 2 is sheathed, and the outer wall of the anti-wear body 2 is evenly provided with several spherical In the groove, a spherical ball 5 is embedded in the spherical groove, and a small part of the spherical crown of the ball 5 is located outside the spherical groove. The upper and lower sides of the center rod 3 and the upper and lower sides of the wear-resistant body 2 are respectively provided with an upper limit ring 1 and a lower limit ring 4 fixed on the center rod 3, between the upper limit ring 1 and the lower limit ring 4 and the wear-resistant body 2 There are gaps.

[0015] When the sucker rod encounters eccentric wear, the ball 5 hits the oil pipe and rotates, and cau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com