Anti-wear energy-saving agent, and preparation method and application thereof

A technology of energy-saving agent and mixture, which is applied in the direction of additives, petroleum industry, lubricating composition, etc. It can solve the problems of destroying the excellent performance of graphene, affecting the effect of lubrication and anti-wear, and the difficult-to-control lattice of graphene, etc., to achieve excellent tribochemical properties , excellent physical properties, the effect of overcoming metallographic defects and processing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

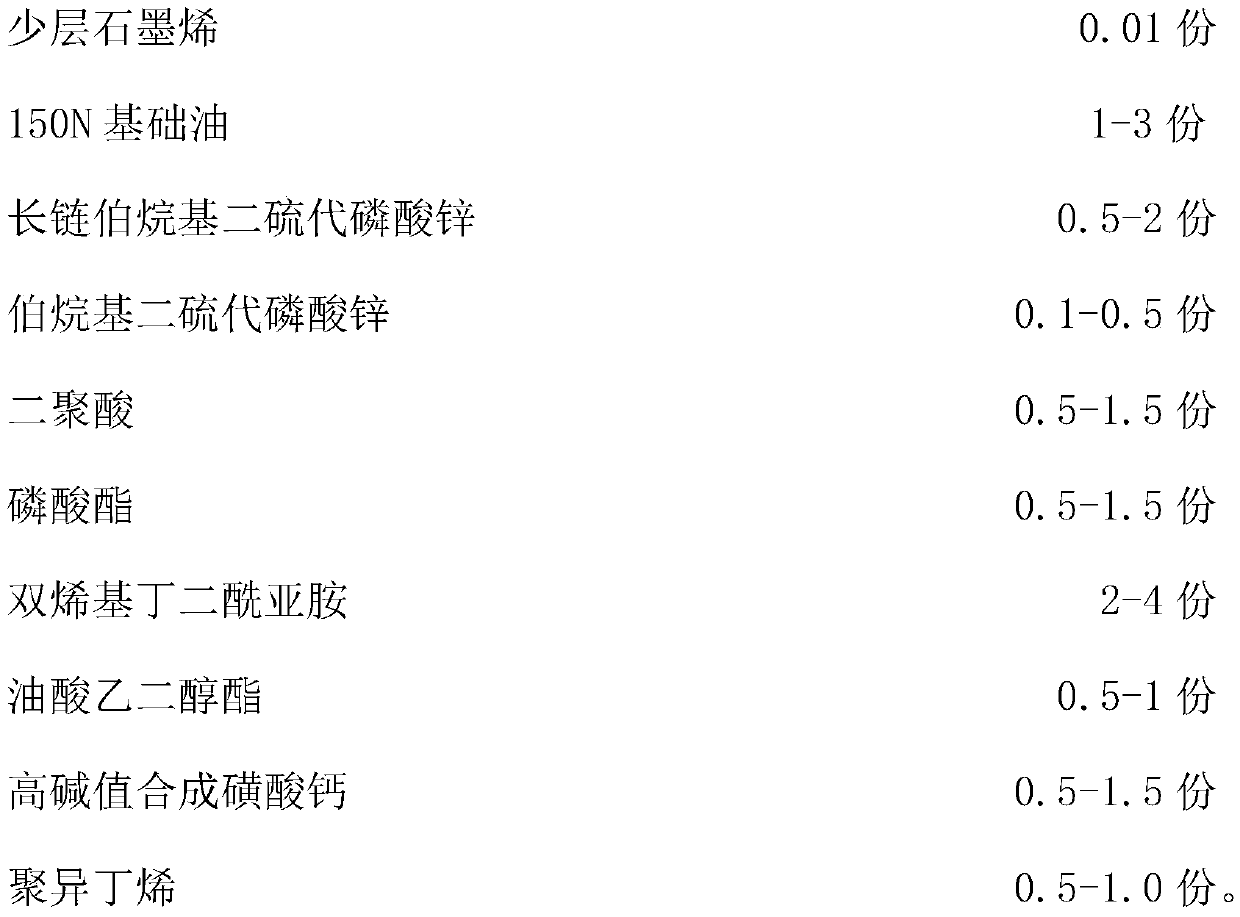

[0074] An anti-wear energy-saving agent is made of the following components:

[0075]

[0076] The specific surface area of the few-layer graphene is 150m 2 / g.

[0077] The preparation method of above-mentioned a kind of anti-wear energy-saving agent, concrete steps are as follows:

[0078] (1) First mix long-chain primary alkyl zinc dithiophosphate, ethylene glycol oleate and 150N base oil after destaticizing treatment at 50°C for 30 minutes to obtain mixture A;

[0079] (2) In addition, dienyl succinimide was mixed with dimer acid and phosphoric acid ester, primary alkyl zinc dithiophosphate and polyisobutylene at 50°C for 30 minutes to obtain mixture B;

[0080] (3) Finally, mix mixture A and mixture B, then add high base value synthetic calcium sulfonate and few-layer graphene, heat to 80°C, stir and mix for 30 minutes, and release it after cooling to 50°C, which is the finished product.

[0081] In step (1), the destaticizing treatment condition for the 150N base...

Embodiment 2

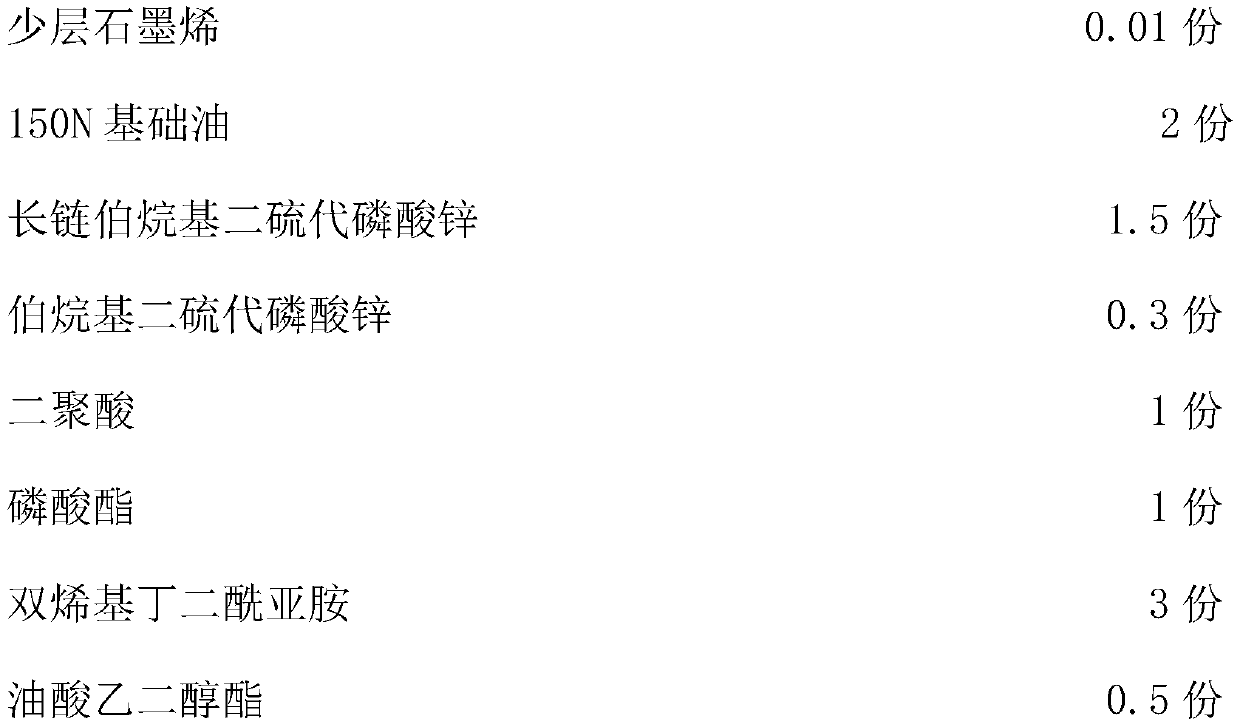

[0083] An anti-wear energy-saving agent is made of the following components:

[0084]

[0085] The specific surface area of the few-layer graphene is 120m 2 / g.

[0086] The preparation method of above-mentioned a kind of anti-wear energy-saving agent, concrete steps are as follows:

[0087] (1) First mix long-chain primary alkyl zinc dithiophosphate, ethylene glycol oleate and 150N base oil after destaticizing treatment at 100°C for 10 minutes to obtain mixture A;

[0088] (2) In addition, dienyl succinimide was mixed with dimer acid and phosphoric acid ester, primary alkyl zinc dithiophosphate and polyisobutylene at 90°C for 10 minutes to obtain mixture B;

[0089] (3) Finally, mix mixture A and mixture B, then add high base value synthetic calcium sulfonate and few-layer graphene, heat to 90°C, stir and mix for 10 minutes, and release it after cooling to 50°C, which is the finished product.

[0090] In step (1), the destaticizing treatment condition for the 150N bas...

Embodiment 3

[0092] An anti-wear energy-saving agent is made of the following components:

[0093]

[0094] The specific surface area of the few-layer graphene is 130m 2 / g.

[0095] The preparation method of above-mentioned a kind of anti-wear energy-saving agent, concrete steps are as follows:

[0096] (1) First, mix long-chain primary alkyl zinc dithiophosphate, ethylene glycol oleate, 2,6-di-tert-butyl-p-cresol with destaticized 150N base oil at 80°C for 20 minutes, Obtain mixture A;

[0097] (2) In addition, dienyl succinimide was mixed with dimer acid and phosphoric acid ester, primary alkyl zinc dithiophosphate and polyisobutylene at 80° C. for 20 minutes to obtain mixture B;

[0098] (3) Finally, mix mixture A and mixture B, then add high base value synthetic calcium sulfonate and few-layer graphene, heat to 85°C, stir and mix for 20 minutes, and release it after cooling to 50°C, which is the finished product.

[0099] In step (1), the destaticizing treatment condition for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com