A kind of diesel antiwear agent and preparation method thereof

A technology of anti-wear agent and diesel oil, which is applied in the field of anti-wear agent to achieve the effect of improving synergistic effect, best performance and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

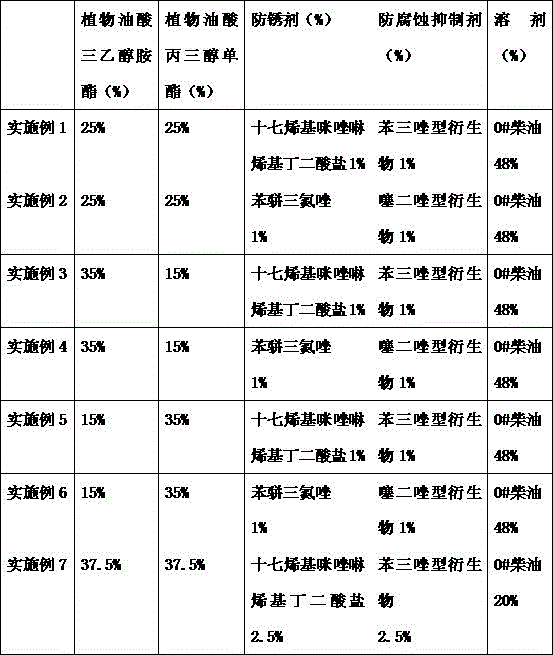

Image

Examples

Embodiment Construction

[0021] Preparation of Vegetable Triethanolamine Oleate

[0022] First, vegetable oleic acid (ricinoleic acid is used as raw material in this example) and triethanolamine are added into the reactor at a molar ratio of 1:1.01~1.25, nitrogen gas is introduced and the temperature is raised to reach 130°C within 2~3 hours. After the heat preservation reaction for 30 minutes, continue to heat up to 140~160°C, hold the heat preservation reaction for a certain period of time, stop heating when it is determined that there is no longer moisture generated and carried out, and cool with cooling water until it cools below 50°C, stop the flow of nitrogen, and release materials and collect products.

[0023] Preparation of Vegetable Glycerol Oleate

[0024] First, it will be produced by the process of esterification under the catalysis of vegetable oleic acid (ricinoleic acid is used as raw material in this embodiment) and glycerol acid. Add vegetable oleic acid and glycerol to the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com