Composite lining with metal wire screen in nanometer structure and its production process

A metal wire mesh and composite lining technology, which is applied in the direction of metal layered products, layered products, chemical instruments and methods, etc., can solve the problem that the composite lining does not have large-scale industrialization and batch application, and the surface spraying process has a thin composite thickness. , complex double-liquid casting process, etc., to achieve the effect of high yield, high production efficiency and high water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation process of the above-mentioned wire mesh composite liner 1 can be realized through the following steps:

[0038] a. Directly weave the overall wire mesh with metal wire (1);

[0039] b. Cut the wire mesh (1) according to the specification and size of the composite liner, and carry out pickling treatment;

[0040] c, prepare composite filler (2), this composite filler uses inorganic non-metal wear-resistant filler or metal wear-resistant filler;

[0041] d. Place the treated wire mesh (1) in the mold, vibrate on a three-dimensional vibration table, and inject the composite filler (2) into the wire mesh (1) under high pressure;

[0042] e. After vibration drying, curing molding, demoulding and trimming, the metal mesh composite liner is prepared.

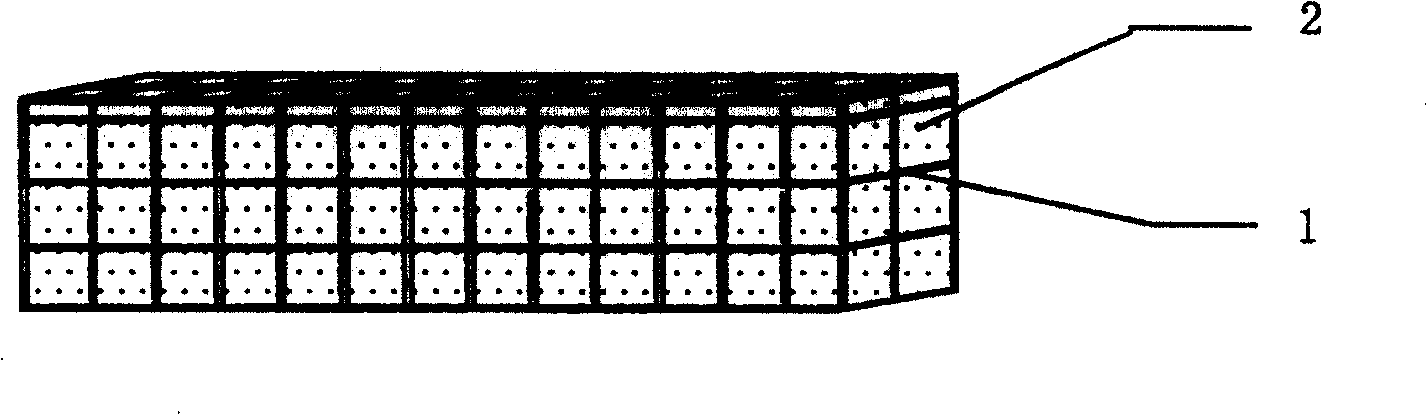

[0043] Form 2: see figure 2 . The nano-structure wire mesh composite liner 2 is composed of a wire mesh (1) and a composite filler (2), and the wire mesh (1) is composed of a single-layer wire mesh into a m...

Embodiment 1

[0055] Preparation process of nanostructure wire mesh-inorganic non-metallic wear-resistant filler composite lining

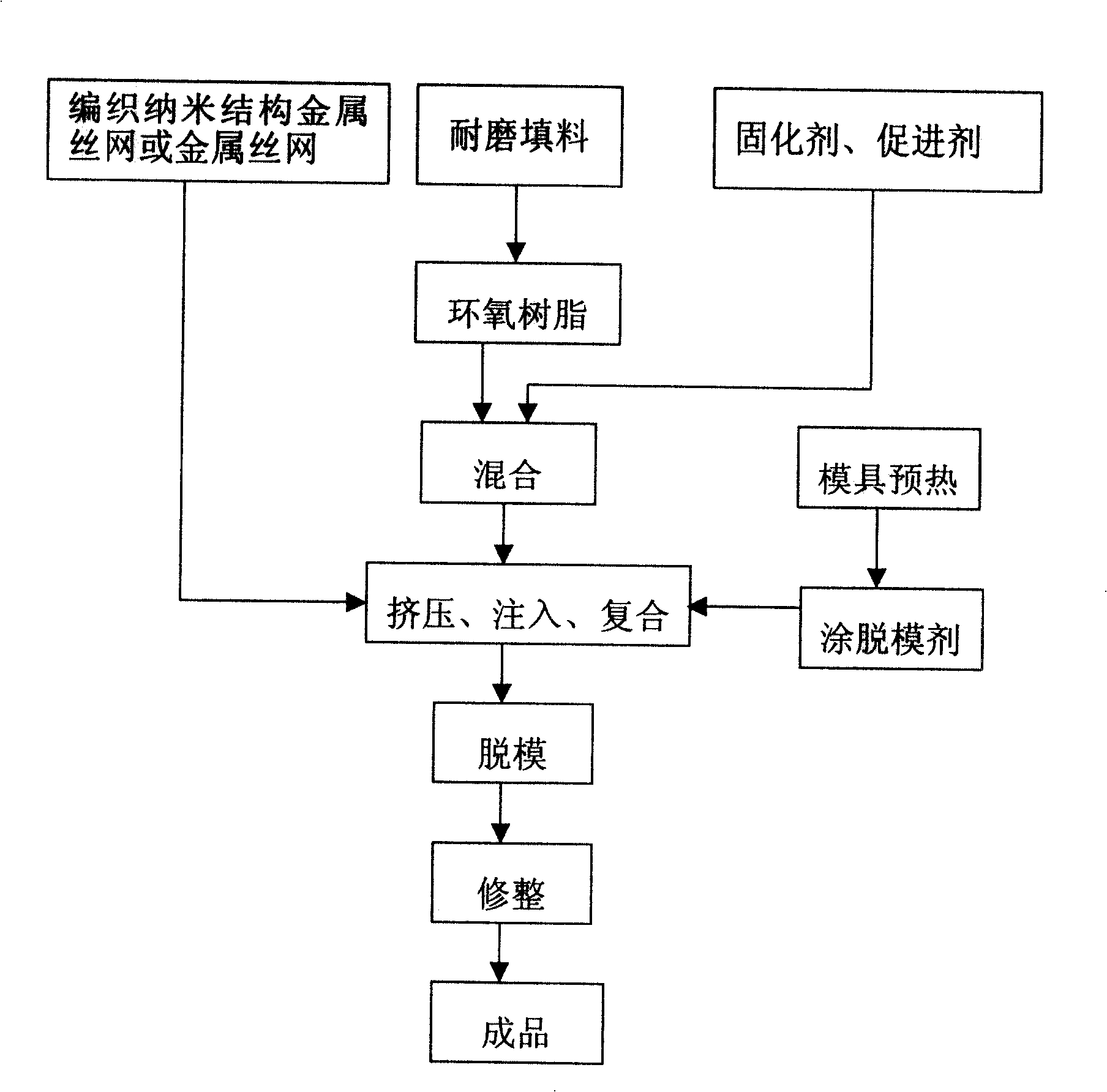

[0056] For the process flow of preparing nanostructured wire mesh-inorganic non-metallic wear-resistant filler composite liner, see image 3 .

[0057] a. First, weave nanostructured wire mesh 1 according to the size of the liner, and process it according to the process;

[0058] b. Preparation of composite filler 2, the steps are: finely grind inorganic non-metallic wear-resistant fillers with high hardness such as silicon dioxide, aluminum oxide or silicon carbide to a fine powder of about 1um, and fully mix them with epoxy resin , and then add curing agent (ethylenediamine) and accelerator (DMP-30) for mixing to prepare wear-resistant filler slurry; the mixing ratio of epoxy resin, ethylenediamine, DMP-30, and filler is: 9-11 : 2.5~3.5: 0.09~0.12: 3.5~4.5;

[0059] c. Putting together, compressing and fixing the nanostructure wire mesh 1 into the mold (co...

Embodiment 2

[0063] Preparation process of nanostructure wire mesh-metal wear-resistant filler composite liner

[0064] For the process flow of preparing nanostructured wire mesh-metal wear-resistant filler composite liner, see image 3 .

[0065] a. First, weave nanostructured wire mesh 1 according to the size of the liner, and process it according to the process;

[0066] b. Prepare composite filler 2, the steps are: finely grind metal wear-resistant fillers with high hardness such as tungsten carbide to a fine powder of about 1um, fully mix with epoxy resin, and then add curing agent (ethylenediamine) Mix with accelerator (DMP-30) to prepare wear-resistant filler slurry; the mixing ratio of epoxy resin, ethylenediamine, DMP-30, and filler is: 9~11:2.5~3.5:0.09~0.12:3.5~ 4.5; steps c, d and e are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com