Preparation method of modified expanded graphite plant-based lubricating grease

An expanded graphite, plant-based technology, used in lubricating compositions, petroleum industry, etc., can solve the problems of poor thermal conductivity, poor lubricity, and poor high temperature resistance, and achieve the effect of easy transfer and improved lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

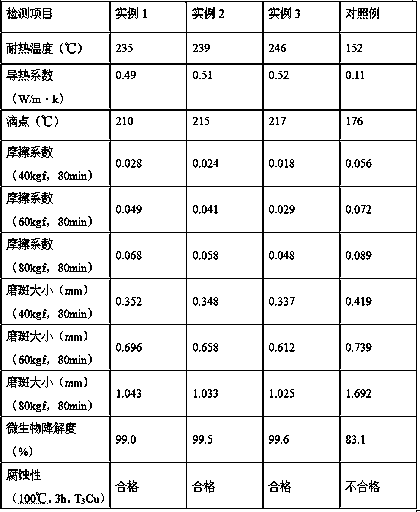

Examples

example 1

[0021] Mix concentrated sulfuric acid solution with a mass fraction of 85% and acetic anhydride at a volume ratio of 4:1 and stir for 4 minutes to obtain a mixed solution, then weigh 32 g of graphite and put it into a grinder for 12 minutes to obtain graphite powder. : 3:1 Mix and stir graphite powder, mixed liquid and potassium permanganate for 35 minutes to obtain the reactant, put the reactant in a high-temperature furnace, expand for 1 hour at a temperature of 950°C, cool and discharge the material, and obtain the modified Expanded graphite; Weigh 0.2kg of soybeans and 0.1kg of peanut seeds, mix them in a beaker with 2L of deionized water, stir and soak for 35min, take out the soybeans and peanut seeds, and dry them in a constant temperature drying oven at 65°C After 16 minutes, the dried product was obtained, and then the dried product was ground in a pulverizer for 1 hour to obtain an oily product; continue to mix the oily product and cyclohexane at a material-to-liquid r...

example 2

[0023] Mix concentrated sulfuric acid solution with a mass fraction of 85% and acetic anhydride at a volume ratio of 4:1 and stir for 5 minutes to obtain a mixed solution, then weigh 36 g of graphite and put it into a grinder to grind for 13 minutes to obtain graphite powder. : 3:1 Mix and stir graphite powder, mixed solution and potassium permanganate for 40 minutes to obtain the reactant, put the reactant in a high-temperature furnace, expand for 2 hours at a temperature of 975°C, cool and discharge the material, and obtain the modified Expandable graphite; Weigh 0.3kg of soybeans and 0.1kg of peanut seeds, mix them in a beaker with 3L of deionized water, stir and soak for 40min, take out the soybeans and peanut seeds, and dry them in a constant temperature drying oven at a temperature of 70°C After 18 minutes, the dried product was obtained, and then the dried product was put into a pulverizer and ground for 1.5 hours to obtain an oily product; continue to mix the oily produ...

example 3

[0025] Mix and stir concentrated sulfuric acid solution with a mass fraction of 85% and acetic anhydride at a volume ratio of 4:1 for 6 minutes to obtain a mixed solution, then weigh 40 g of graphite and put it into a grinder to grind for 15 minutes to obtain graphite powder with a mass ratio of 7 : 3:1 Mix and stir graphite powder, mixed solution and potassium permanganate for 45 minutes to obtain the reactant, put the reactant in a high-temperature furnace, expand for 3 hours at a temperature of 1000°C, cool and discharge the material, and obtain the modified Expandable graphite; Weigh 0.4kg of soybeans and 0.2kg of peanut seeds, mix them in a beaker with 4L of deionized water, stir and soak for 45min, take out the soybeans and peanut seeds, and dry them in a constant temperature drying oven at a temperature of 75°C After 20 minutes, the dried product was obtained, and then the dried product was put into a pulverizer and ground for 2 hours to obtain an oily product; continue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com