Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Play a role in corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

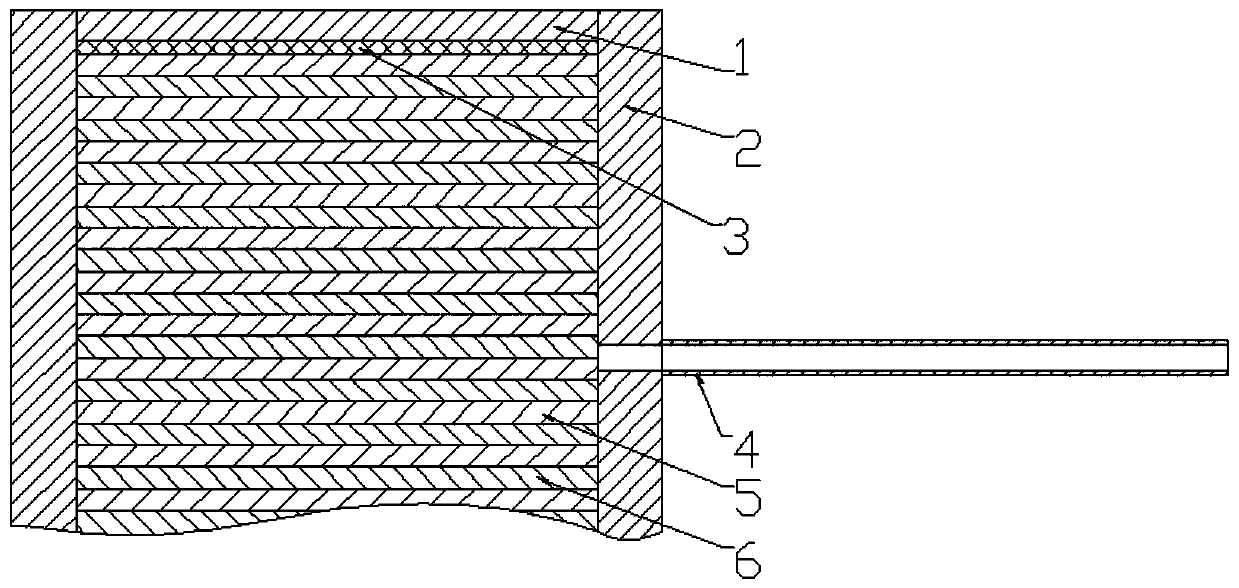

Energy-saving aluminum alloy door and window with high compression resistance and corrosion resistance

ActiveCN107989515APlay a role in corrosion resistanceEffective shock absorptionClimate change adaptationWindow/door framesAdhesiveCorrosion resistant

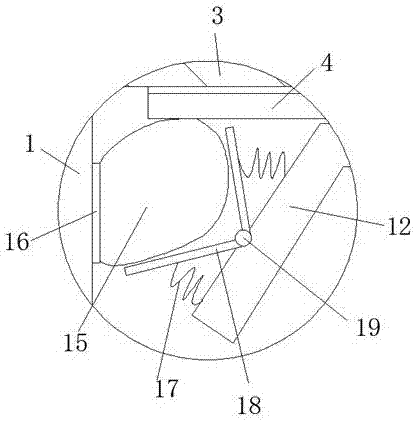

The invention discloses an energy-saving aluminum alloy door and window with high compression resistance and corrosion resistance and belongs to the field of energy-saving aluminum alloy doors and windows. The energy-saving aluminum alloy door and window with high compression resistance and corrosion resistance comprises a vacuum window body, wherein the vacuum window body is connected to a wall,the periphery of the vacuum window body is fixedly connected with connecting profiles, and connecting slots corresponding to the connecting profiles are formed in the wall. Corrosion-resistant rubbergaskets can play a corrosion-resistant role and effectively realize buffering and shock absorption to improve the wind pressure resistance, every two rotating buffer plates are connected with on oblique buffer plate through buffer springs, effective buffering and shock absorption can be realized, the wind pressure resistance effect can be improved, an inflatable buffer air bag is arranged betweenevery two rotating buffer plates and sealed and fixedly connected to the vacuum window body and the corresponding corrosion-resistant rubber gasket respectively through an adhesive, a sealed space canbe formed to surround the connecting profiles, corrosion of the connecting profiles can be effectively prevented, effective buffering and shock absorption can be realized, and the wind pressure resistance capacity of the aluminum alloy door and window can be guaranteed.

Owner:ANHUI PROVINCE JINPENG ENERGY SAVING TECH CO LTD

Biological magnesium alloy with corrosion resistant function and preparation method thereof

InactiveCN107739940AImprove corrosion resistancePlay a role in corrosion resistanceSelective laser meltingAlcohol

The invention discloses biological magnesium alloy with a corrosion resistant function. The biological magnesium alloy is prepared from a biological magnesium alloy matrix and graphene oxide, whereinthe graphene oxide is distributed on the grain boundary of the biological magnesium alloy matrix, and the graphene oxide wraps biological magnesium alloy grains so as to form a second phase of a nanohoneycomb structure. The invention further discloses a preparation method. The preparation method comprises the following steps of (1) respectively putting GO powder and biological magnesium alloy powder in absolute ethyl alcohol according to the design proportion for ultrasonic agitation so as to obtain a GO suspension and a biological magnesium alloy suspension; (2) slowly adding the GO suspension to the biological magnesium alloy suspension, continuing to perform ultrasonic agitation so as to obtain a mixed suspension, and performing vacuum filtration and drying treatment on the mixed suspension so as to obtain mixed powder with uniform dispersion; and (3) performing selective laser melting on the mixed powder in the protective atmosphere so as to prepare the biological magnesium alloywith the corrosion resistant function. According to the biological magnesium alloy with the corrosion resistant function, the second phase of the nano honeycomb structure constructed by utilizing GO can be used as a shield so as to isolate the biological magnesium alloy from body fluid, so that a galvanic corrosion effect of a conventional second phase is avoided, and the corrosion resistance is improved.

Owner:CENT SOUTH UNIV

0Cr18Ni10Ti small-diameter seamless stainless steel capillary tube and production process thereof

The invention discloses a 0Cr18Ni10Ti small-diameter seamless stainless steel capillary tube. The 0Cr18Ni10Ti small-diameter seamless stainless steel capillary tube comprises the following chemical components in percentage by mass: 0.029-0.031% of C, 0.55-0.59% of Si, 1.12-1.14% of Mn, 0.001-0.003% of S, 0.015-0.017% of P, 17.55-17.75% of Cr, 10.15-10.25% of Ni, 0.33-0.35% of Nb, 0.022-0.024% of Mo, 0.04-0.06% of N, 0.149-0.151% of Ti, 0.0013-0.0015% of Sb, 0.0007-0.0009% of Pb, 0.0012-0.0014% of Ce, 0.08-0.12% of rare earth elements and the balance of Fe and unavoidable impurities. The invention further discloses a production process of the 0Cr18Ni10Ti small-diameter seamless stainless steel capillary tube. The 0Cr18Ni10Ti small-diameter seamless stainless steel capillary tube has good flexibility, corrosion resistance, high temperature resistance, wear resistance, tensile strength and water resistance and also has excellent electromagnetic shielding performance.

Owner:WUXI XINCHANG STEEL PIPE

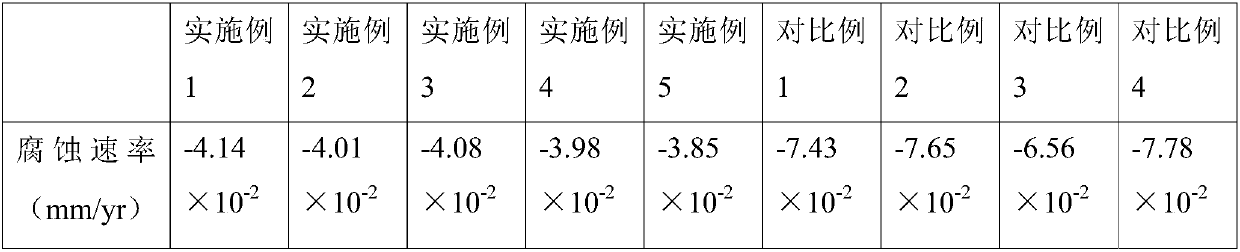

440 MPa corrosion resisting steel for ship at low temperature environment and production method of corrosion resisting steel

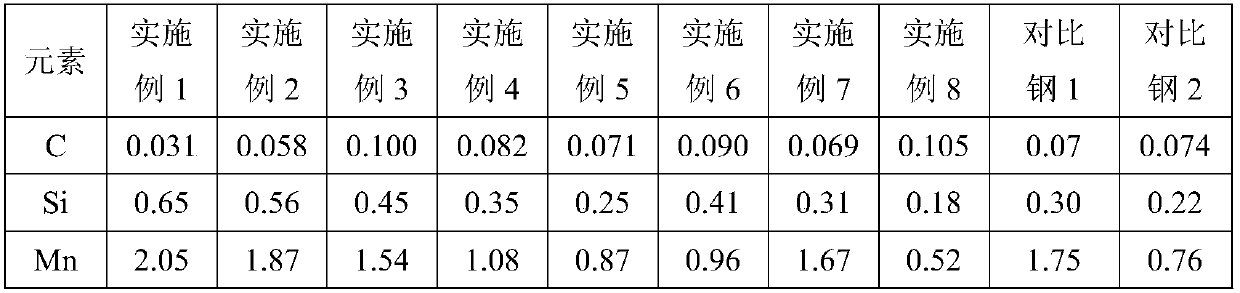

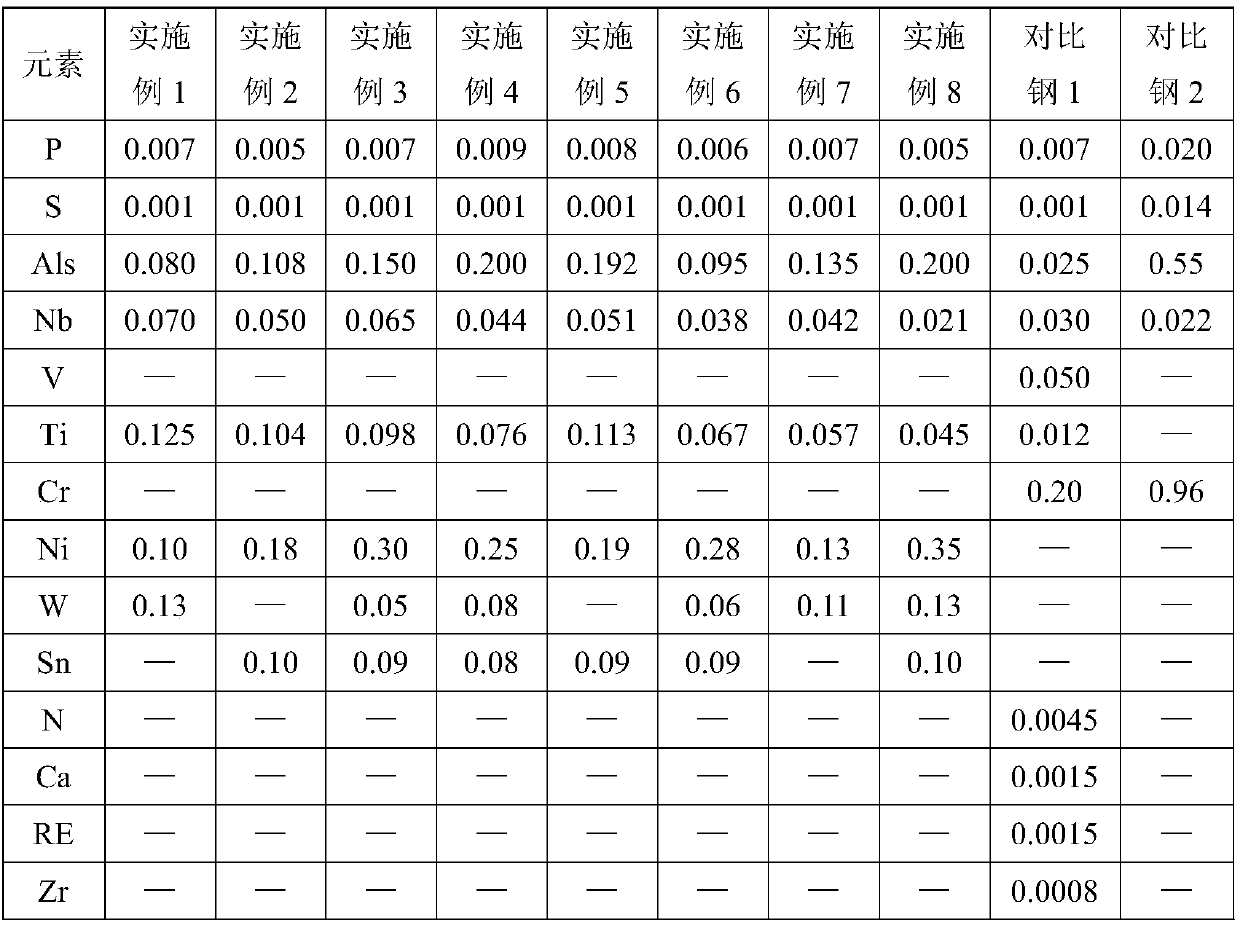

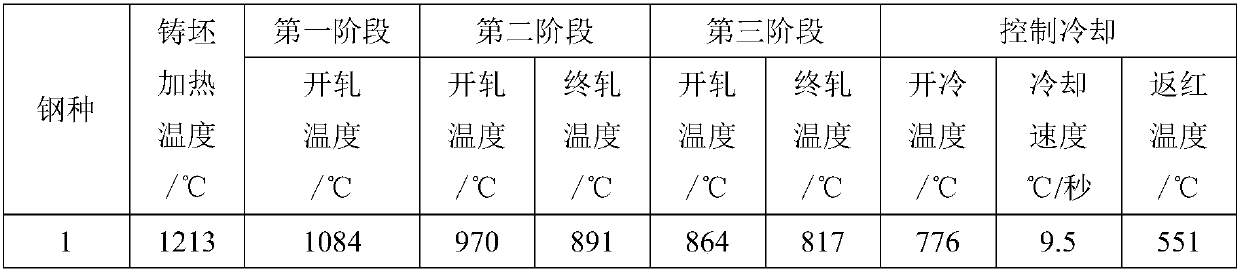

The invention discloses a corrosion-resistant steel for 440MPa ships in a low-temperature environment and a production method thereof, belonging to the technical field of material steel. It includes the following components in mass percentage: C: 0.031-0.105%, Si: 0.18-0.65%, Mn: 0.52-2.05%, P≤0.009%, S≤0.001%, Als: 0.080-0.200%, Nb: 0.021 to 0.070%, Ti: 0.045 to 0.125%, Ni: 0.10 to 0.35%, and the balance is Fe and unavoidable impurities. The production method is 1) conventional molten iron desulfurization; 2) converter smelting and RH vacuum treatment; 3) billet continuous casting and heating; 4) section rolling; 5) cooling. The prepared steel plate can be used in an extremely cold and low temperature environment of around ‑80°C. The yield strength of the steel plate is ≥440Mpa, the impact toughness KV2≥100J, and the seawater corrosion performance is better than the traditional seawater corrosion-resistant steel 10CrMoAl.

Owner:武汉钢铁有限公司

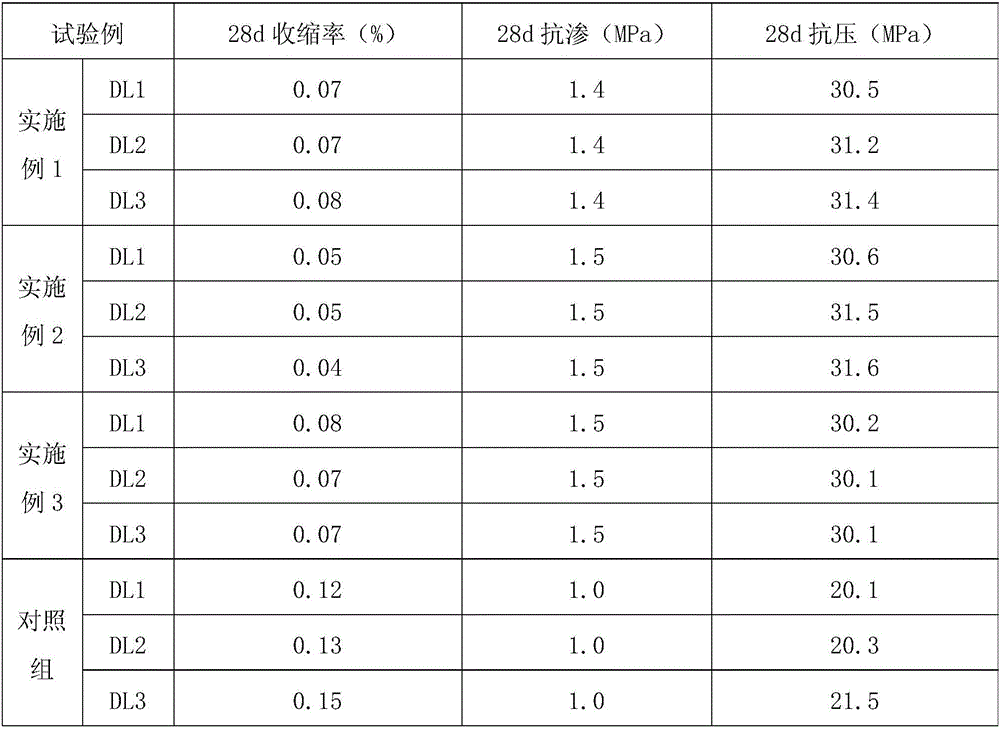

High-efficiency corrosion resistant pre-mixed mortar

The invention relates to a pre-mixed mortar material for buildings and particularly relates to high-efficiency corrosion resistant pre-mixed mortar. The mortar is prepared by mixing the following ingredients in percentages by weight: 5-20% of river sand, 10-30% of manufactured sand, 10-20% of flyash, 10-20% of granulated blast-furnace slag powder, 1-2% of polycarboxylic acid, 1-2% of sodium gluconate, 5-15% of cement, 5-15% of redispersible powder, 5-10% of kaolin and 5-10% of an electrolytic manganese slag waste. By using the pre-mixed mortar prepared at the ratio, the prepared concrete has the characteristics of being hard, corrosion-resistant and low in cost, and has wide applicability.

Owner:中山市群发建筑材料有限公司

Wood-plastic composite material preparation method

The invention belongs to the technical field of wood-plastic composite materials, and discloses a wood-plastic composite material preparation method, which comprises: (1) pre-treating wood powder, wherein wood powder, an epoxy resin, a curing agent, an accelerant, a reactive diluent and an inert diluent are uniformly mixed according to a mass ratio of (2-20):100:(20-150):(0.05-3):(5-15):(10-20), and curing treatment is performed to obtain pretreated wood powder; (2) uniformly mixing the pretreated wood powder, a resin, hollow glass microspheres, a coupling agent, a lubricant and an ultravioletabsorbent according to a mass ratio of (25-40):(20-40):(20-25):(2-4):(2-4):(2-4); and (3) carrying out extrusion molding, hot press molding or compression molding on the granules uniformly mixed in the step (2) to obtain the wood-plastic composite material. The wood-plastic composite material prepared by the method is good in interface bonding, light in weight and high in strength.

Owner:重庆泛锐科技有限公司

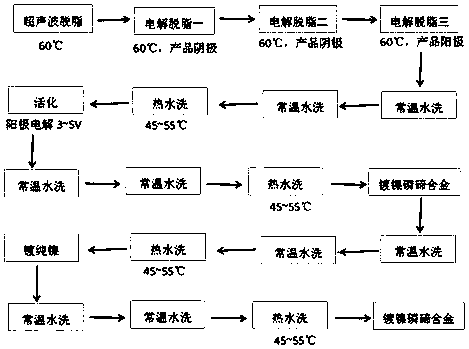

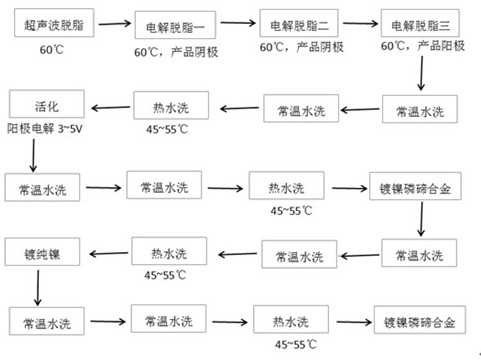

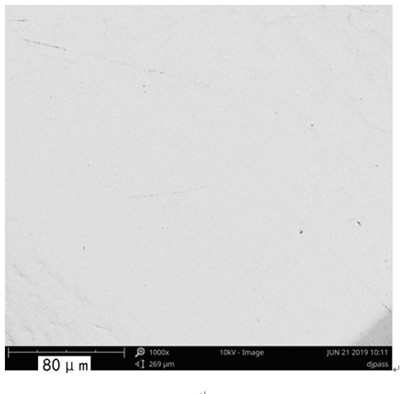

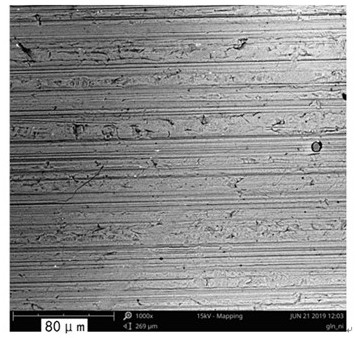

Connector electroplating process

ActiveCN110306220AFast and effective tearFast and effective impactJewelleryElectrolysisSalt spray test

The invention relates to the technical field of electronic connector electroplating, and discloses a connector electroplating process, comprising the following steps: degreasing: performing ultrasonicdegreasing, cathodic electrolytic degreasing and anodic electrolytic degreasing in sequence; water washing after degreasing; activation: performing anode electrolysis activation in a solid inorganicacid salt aqueous solution, and water washing after activation; nickel plating: plating nickel-phosphorus-tellurium multi-alloy nickel, plating semi-gloss nickel after water washing, and plating nickel-phosphorus-tellurium multi-alloy nickel again after water washing. Compared with the prior art, the process optimizes the pre-treatment, water washing and nickel plating processes, especially the design of the multi-alloy nickel layer, so that a coating is flat and has no pinhole under a 1000-fold microscope; the product can pass a salt spray test after electroplating without an organic sealingfilm, and has no quality issues such as impedance and soldering in use; after the connector is electroplated by the process, sodium chloride can be effectively prevented from entering the inside of the coating in the salt spray test, thus effectively avoiding corrosion of primary batteries.

Owner:惠州锦鑫表面处理有限公司

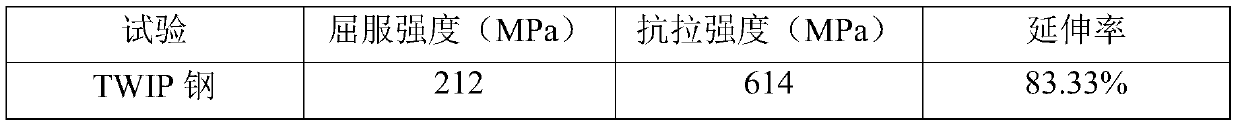

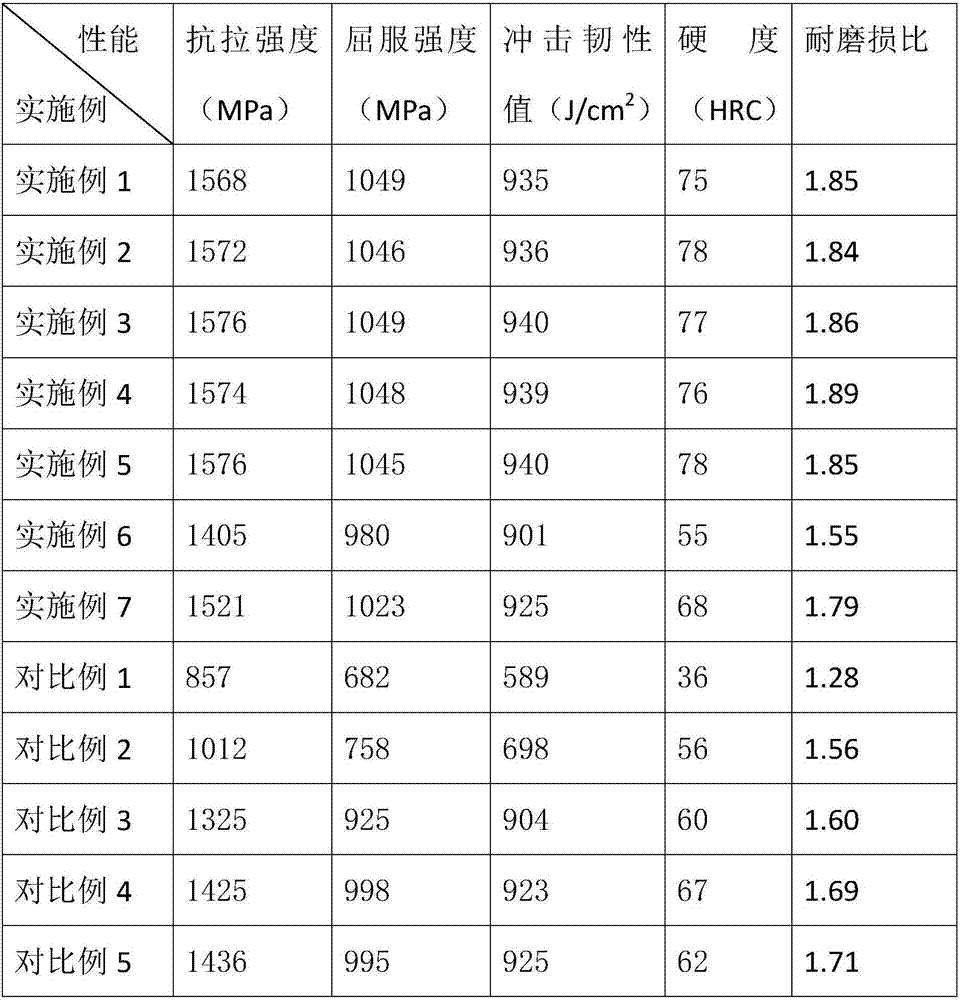

High-performance anti-corrosion TWIP/stainless steel multi-layer composite material and preparation method

ActiveCN110103530AHighlight substantive featuresHigh strengthLaminationLamination apparatusSurface layerStrength of materials

The invention discloses a high-performance anti-corrosion TWIP / stainless steel multi-layer composite material and a preparation method. The composite material comprises multiple TWIP steel material layers and multiple stainless steel material layers, the TWIP steel material layers and the stainless steel material layers are laminated alternately and rolled together, and the surface layers of the composite material are all stainless steel layers; the thickness of each material layer in the multi-layer composite material is less than or equal to 0.05 millimeter, and the number of the TWIP steelmaterial layers is one less than that of the stainless steel material layers. According to the preparation method, based on the requirements for the mechanical properties of the material, subsequent process adjustment and control such as thermal treatment or cold rolling or annealing treatment and the like are conducted, and therefore the TWIP / stainless steel multi-layer composite steel with the high yield strength and the high product of strength and elongation is obtained. The composite material is composed of thin stainless steel and TWIP steel plate materials through multi-layer lamination, the advantages of the TWIP steel can be exerted, and the corrosion resistance performance and strength requirement of the material can be ensured.

Owner:HEBEI UNIV OF TECH

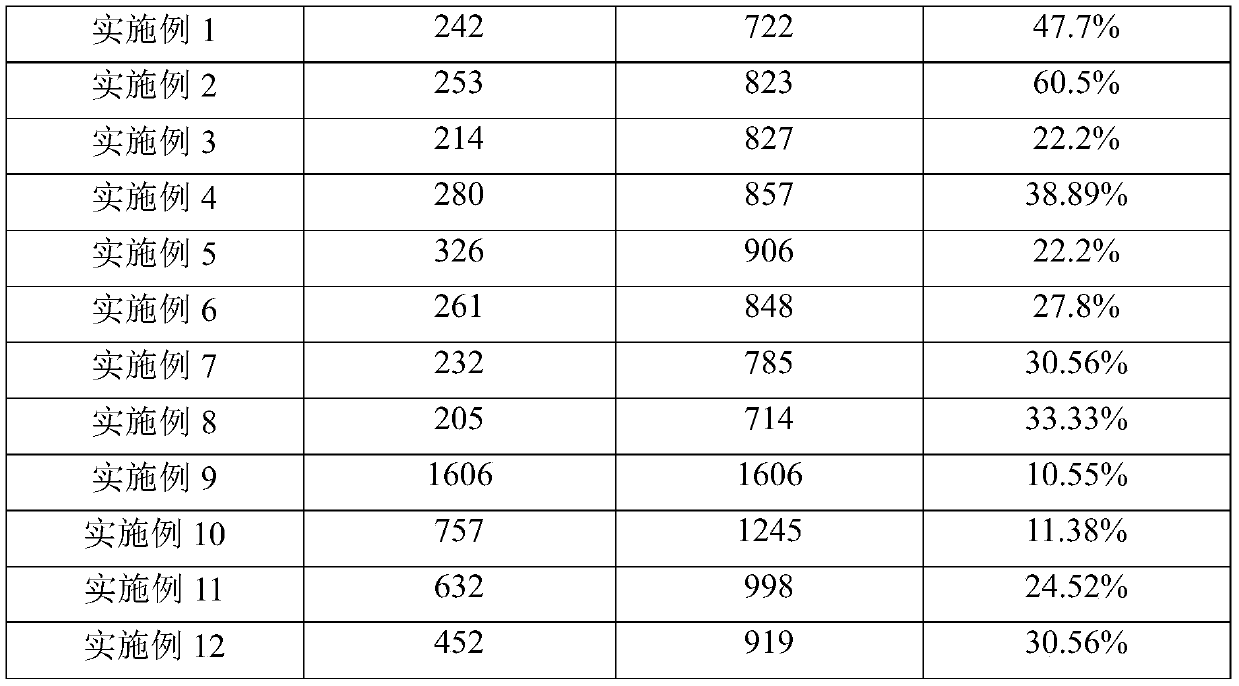

Household micro photovoltaic power generation system

InactiveCN108631712AUniform heat dissipationPlay a role in corrosion resistancePhotovoltaic supportsPhotovoltaic energy generationHeat conductingEngineering

The invention discloses a household micro photovoltaic power generation system, the system comprises a frame, a battery plate main body, a subplate and a bottom plate, wherein an inner wall of the frame is fixedly connected with the battery plate main body, the bottom of the frame is rotationally connected with a support rod, the top of the frame is fixedly connected with an upper surface of the subplate through the support rod, the back of the battery plate main body is fixedly connected with a heat conducting plate, the lower surface of the heat conducting plate is fixedly connected with a metal plate, the frame is fixedly connected with the metal plate through an insulating layer, the lower surface of the metal plate is fixedly connected with a protective plate, the lower surface of theprotective plate is fixedly connected with a heat dissipation fin, the inside of the heat dissipation fin is provided with a condensing tube, and the bottom of the subplate is fixedly connected witha sliding rod. The household micro photovoltaic power generation system is provided with the heat dissipation fin, the metal plate, the heat conducting plate, the condensing tube, an optical sensing device, a signal processor, a controller and a motor, thus, a problem that poor heat dissipation effect causes decline of power generation efficiency, failure in rotation of the solar battery plate andlimitation to optical energy absorption is solved.

Owner:南京华杰能源科技有限公司

Nickel base alloy powder used for coating and preparing method of nickel base alloy powder used for coating

InactiveCN110306095AModerate hardnessModerate intensityTransportation and packagingMetal-working apparatusAlloySilicon dioxide

The invention discloses nickel base alloy powder used for a coating. The nickel base alloy powder used for the coating comprises the following raw materials including, by weight, 1%-5% of magnesium, 35%-45% of cobalt, 7%-10% of chromium, 2%-5% of molybdenum, 2%-5% of boron, 3%-5% of silicon and 40%-50% of nickel. A preparing method of the nickel base alloy powder used for the coating includes thefollowing steps that the technological processes for preparing the base alloy powder include burdening, centrifuging, atomizing, screening, grinding, mixing, drying and screening; and in the burdeningprocess, hydrous magnesium sulfate, cobalt nitrate hexahydrate, chromic nitrate nonahydrate, erbium nitrate pentahydrate, boron powder, silicon dioxide and nickel nitrate hexahydrate with the corresponding proportions are taken, water is added for mixing, stirring is conducted for 2 min to 7 min through a stirring machine, and a mixture is obtained. By means of the nickel base alloy powder usedfor the coating and the preparing method of the nickel base alloy powder used for the coating, the anti-crack performance, the forming property, the technology stability and the component uniformity of the alloy powder in a laser cladding layer are fundamentally achieved and improved, and the requirements of urban pipelines and equipment for the comprehensive performance such as heat resistance, corrosion resistance, wear resistance and high strength of the cladding layer are met.

Owner:扬州安泰威合金硬面科技有限公司

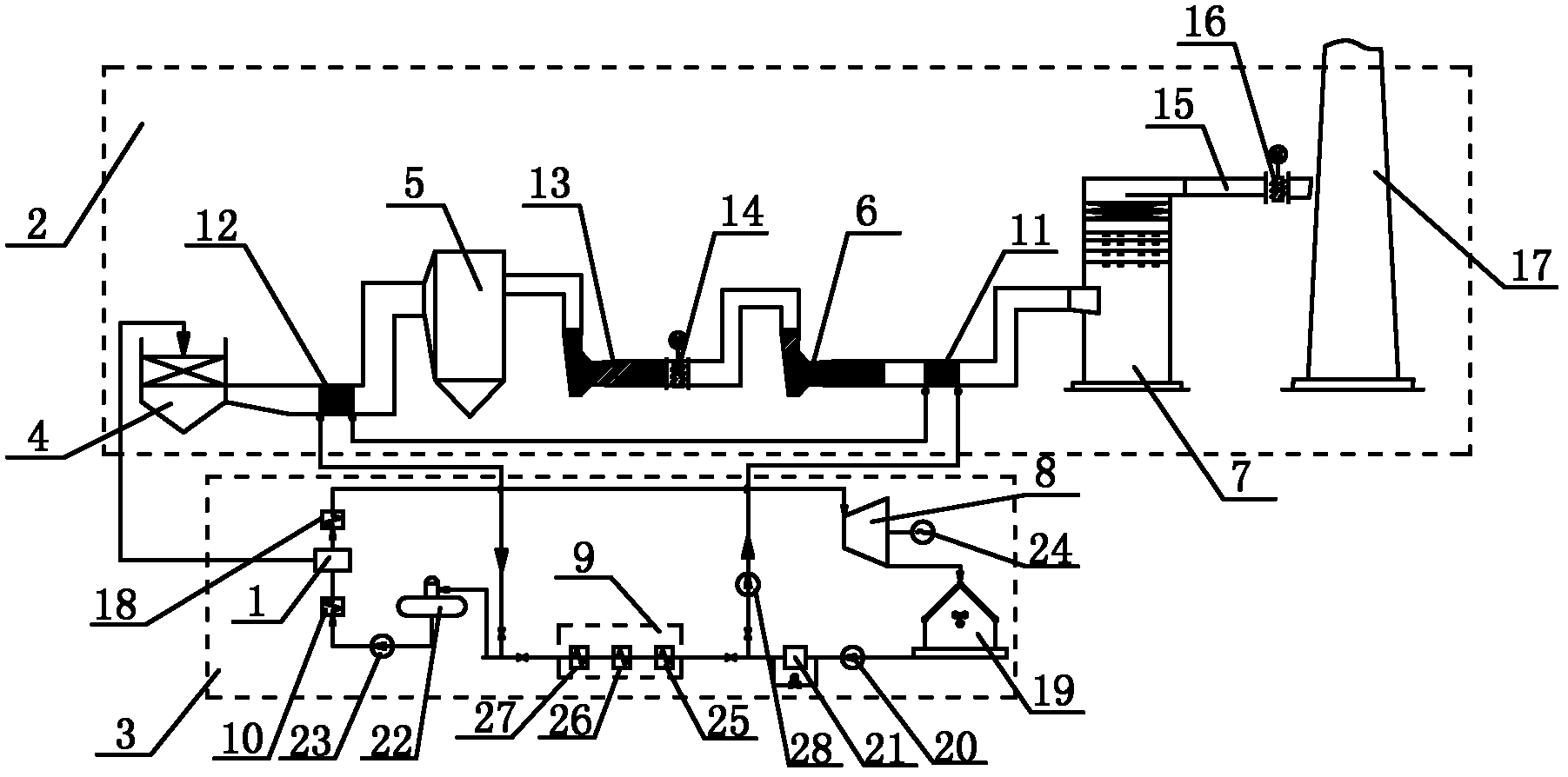

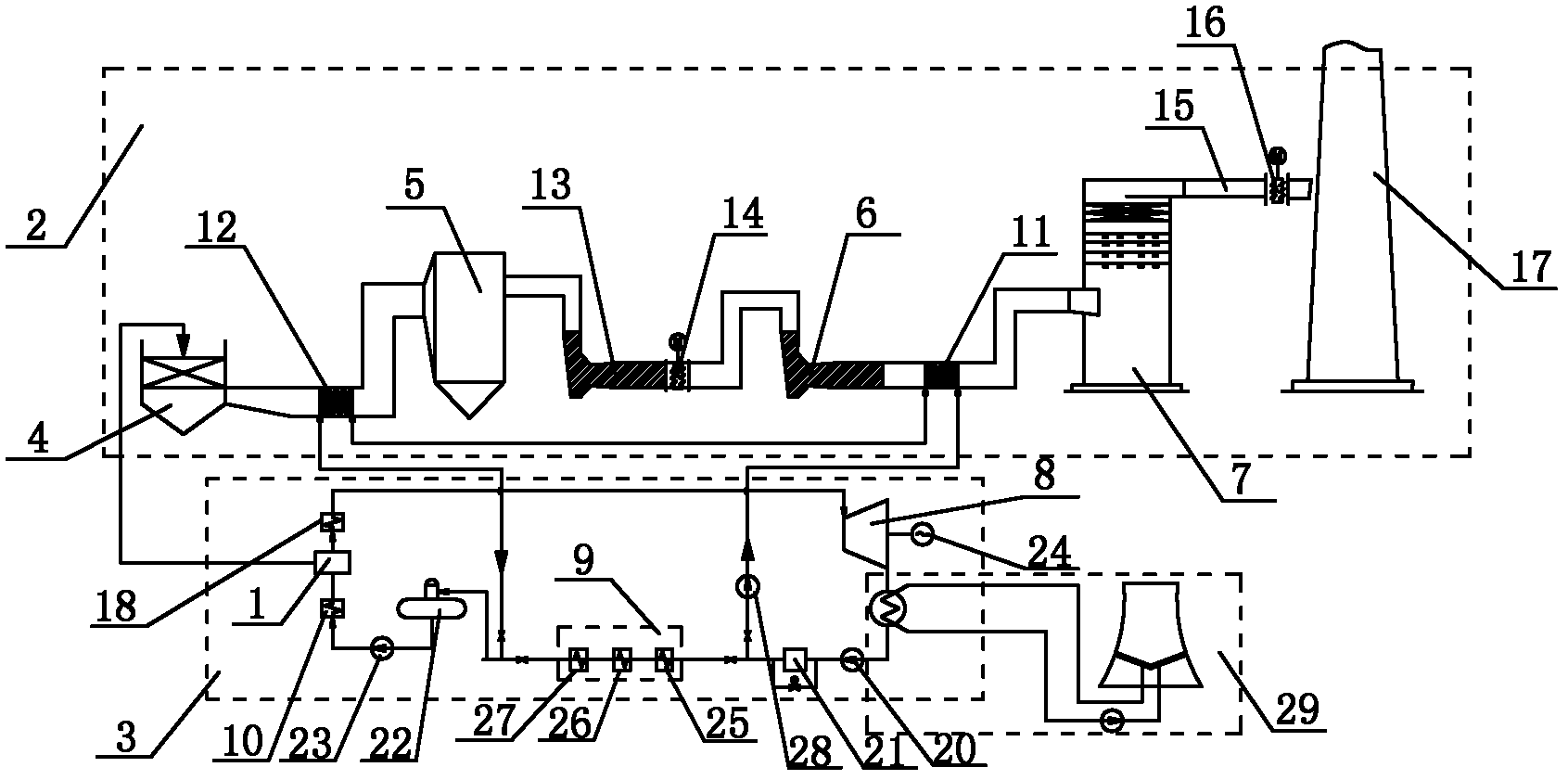

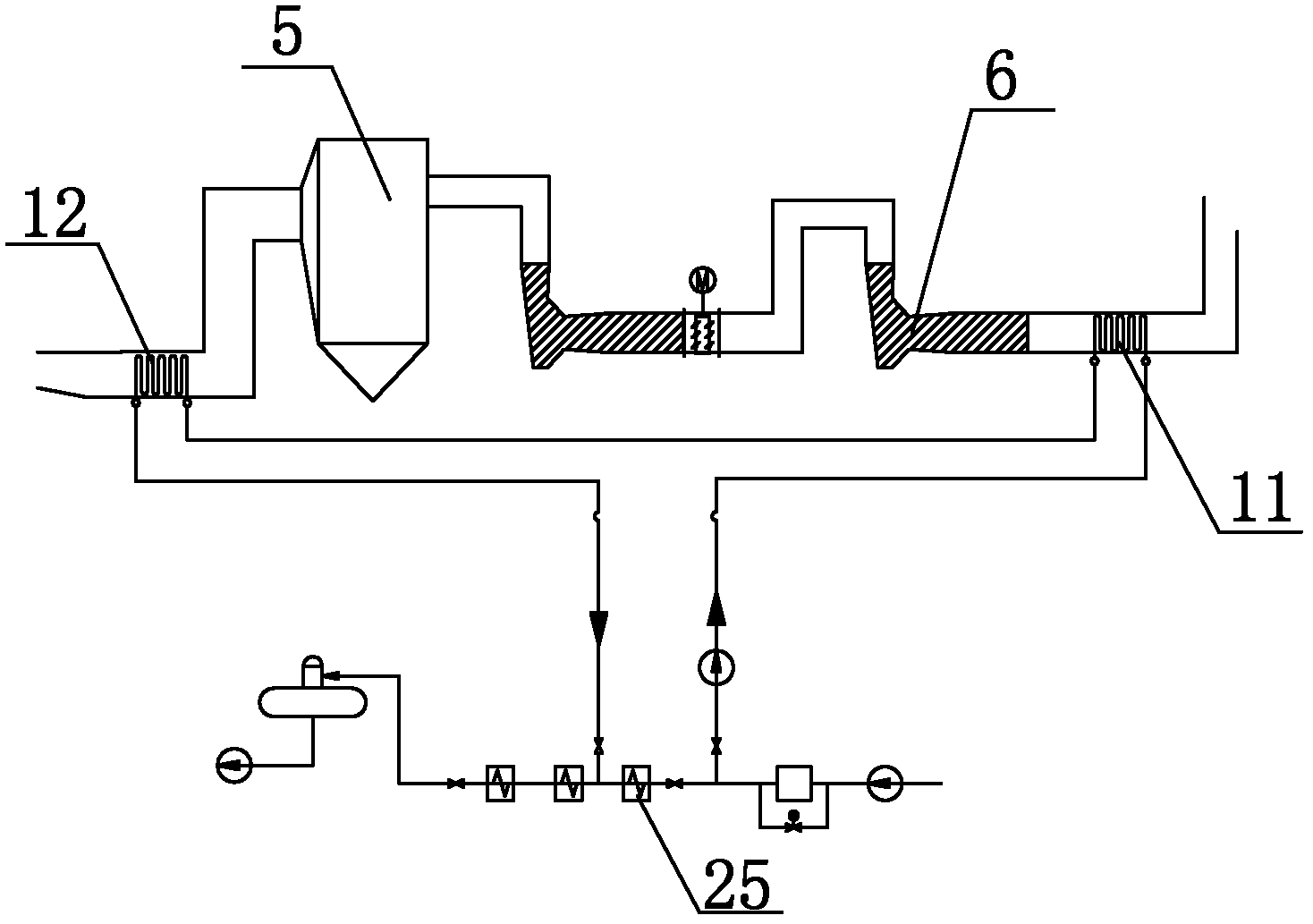

Multilevel condensation water heating system

InactiveCN103047642AAvoid excessive dust accumulation,Avoid resistanceFeed water supplyCombustion technology mitigationAir preheaterEngineering

The invention discloses a multilevel condensation water heating system which comprises a boiler, a tail smoke processing system and a smoke waste heat recycling system. The steam output end of the boiler is respectively connected with an air preheater and a turbine. The condensation water input end of the boiler is connected with a high pressure heater, a first level air water heat exchanger is arranged in a smoke channel where a booster fan is connected with an absorption tower, a second level air water heat exchanger is arranged in a smoke channel where the air preheater is connected with a dust remover, the input end of the first level air water heat exchanger is connected with the condensation water input end of a low pressure water heater, the output end of the first level air water heat exchanger is connected with the input end of the second level air water heat exchanger through a pipe, and the output end of the second level air water heat exchanger is connected with the condensation water output end of the low pressure heat exchanger. The multilevel condensation water heating system adopts multilevel heat exchange, can completely utilize smoke waste heat, and can effectively resolve the problem that a traditional low temperature heater is apt to ash blocking, easy to corrode, easy to abrade and high in construction cost.

Owner:沈兴财

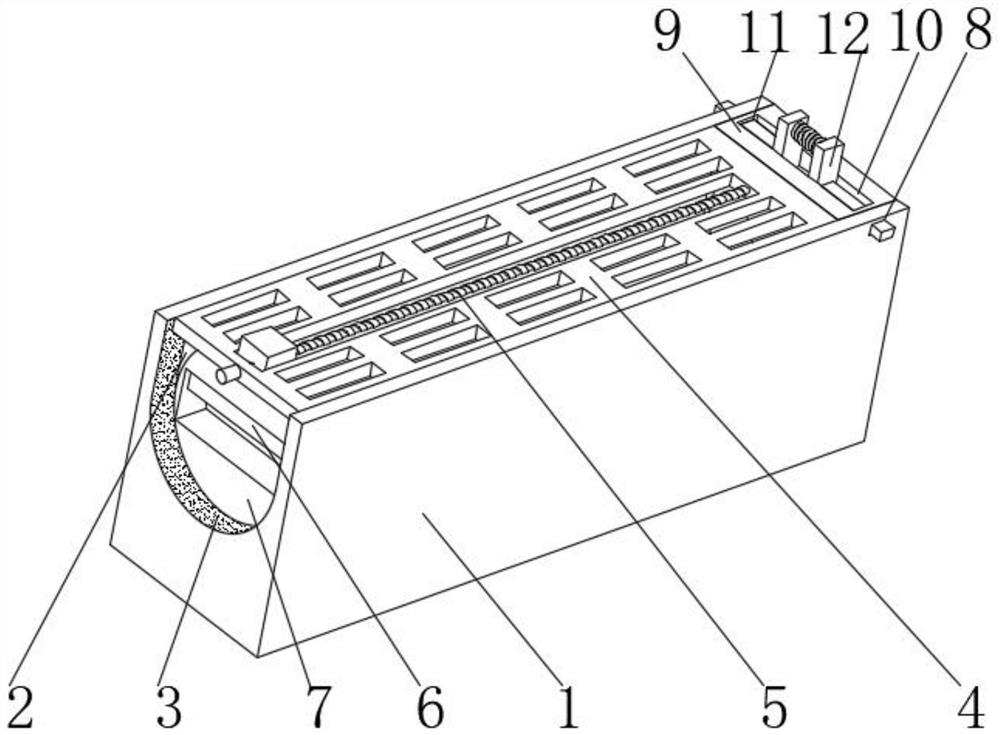

Corrosion-resistant high-strength composite resin U-shaped drainage ditch

InactiveCN111894111AEasy to take outEasy to useSewerage structuresStationary filtering element filtersEngineeringStructural engineering

The invention discloses a corrosion-resistant high-strength composite resin U-shaped drainage ditch. The corrosion-resistant high-strength composite resin U-shaped drainage ditch comprises a drainageditch body, a U-shaped groove is formed in the upper end of the drainage ditch body, a zinc coating is fixedly installed on the groove wall of the U-shaped groove, a perforated strainer device is arranged on the upper portion of the groove wall of the U-shaped groove, a sliding device is arranged in the middle of the perforated strainer device, a stretchable isolation device is arranged on the left portion of the lower end of the sliding device, a cleaning device is arranged on the left portion of the groove wall of the U-shaped groove, through grooves are formed in the upper side of the rightportion of the front end of the drainage ditch body and the upper side of the right portion of the rear end of the drainage ditch body correspondingly, a supporting plate is movably connected to theupper side of the right portion of the groove wall of the U-shaped groove, and a filtering and storing device is arranged on the groove wall of a concentric-square-shaped groove. According to the corrosion-resistant high-strength composite resin U-shaped drainage ditch, first movable plates on the two sides are manually pressed, so that a storage box is conveniently taken out of the U-shaped groove, sundries are cleared away, the sundries are prevented from being accumulated in the drainage ditch body to cause blockage, and normal use of the drainage ditch body is guaranteed.

Owner:安徽绿洲危险废物综合利用有限公司

Filter cloth with anti-corrosion function

InactiveCN109011839ACorrosion-resistantInsulation hasFiltration separationPolyesterPolyvinyl chloride

The invention discloses filter cloth with an anti-corrosion function. The filter cloth comprises a filter cloth body, wherein the filter cloth body is prepared from polypropylene fiber, polyvinyl chloride fiber, carbon fiber, polyester fiber and aramid fiber, wherein an insulation coating coats the top of the filter cloth body. Through the arrangement and the mutual matching of the insulation coating, the polypropylene fiber, the polyvinyl chloride fiber, the carbon fiber, the polyester fiber and the aramid fiber, the problem that the existing filter cloth does not have the anti-corrosion function and can be easily damaged is solved. The filter cloth body has the anti-corrosion performance, in the use process, so that the damage condition due to contact with corrosive substances is avoided, so that the service life of the filter cloth body is prolonged; the filter cloth body also has the performance of insulation, flame retardance, wear resistance, waterproof performance and the like,so that the use range of the filter cloth body is increased. Therefore the filter cloth is suitable for being popularized and used.

Owner:陈根章

Shutter door positioning bracket

InactiveCN107964640APlay a role in corrosion resistanceHigh hardnessShutters/ movable grillesSolid state diffusion coatingFiberSolid solution

The invention relates to a bracket, in particular to a shutter door positioning bracket, and belongs to the field of alloy materials. The shutter door positioning bracket is made of a magnesium alloy;the magnesium alloy specifically comprises the following components in percentage by mass: 7.5-8.0% of Al, 0.55-0.65% of Zn, 0.15-0.25% of Mn, 0.05-0.1% of Si, 0.5-0.8% of La, 0.8-1.2% of Nd, 0.6-0.85% of NiTi long fiber, and the balance of Mg; and an Al-Zn film layer with a thickness of 1.0-1.2 mm is expanded and permeated on the surface of the magnesium alloy. The Al-Zn film layer is prepared on the surface of the magnesium alloy through the surface expansion and permeation treatment; and a stable dispersion layer consisting of a surface alloy layer AlMg2Zn and a Mg-Al-Zn solid solution layer is formed to achieve a corrosion resisting effect on the shutter door positioning bracket.

Owner:宁波市鄞州隆茂冲压件厂

Nickel-based alloy powder and a preparing method thereof

InactiveCN107779674AImprove antioxidant capacityEnhanced high temperature corrosion resistanceCorrosionMagnesium sulphate heptahydrate

Nickel-based alloy powder and a preparing method thereof are disclosed. The method includes (1) preparing raw materials; (2) mixing anhydrous magnesium sulfate, cobalt nitrate hexahydrate, chromium nitrate nonahydrate, molybdenum nitrate pentahydrate and nickel nitrate hexahydrate, adding water to the mixture, and mixing the mixture; (3) heating the mixture obtained in the step (2) to 70-80 DEG C,adding aqueous ammonia under stirring into the mixture, with the weight of the aqueous ammonia being 0.01-0.02 time of the weight of the mixture, and stirring the mixture for 3-5 min; (4) centrifuging the mixture obtained in the step (3), and drying a precipitate; (5) performing ball milling; (6) smelting; (7) quenching a product obtained in the step (6) in ice water, maintaining the temperatureat 700-900 DEG C for 5-8 days, and then quenching the product in ice water; and (8) putting the product obtained in the step (7) into a ball mill, and performing ball milling at a rotating speed of 150-250 r / min for 5-8 h. The nickel-based alloy powder prepared by the method has significantly improved corrosion resistance, high-temperature strength and other mechanical properties.

Owner:XIHUA UNIV

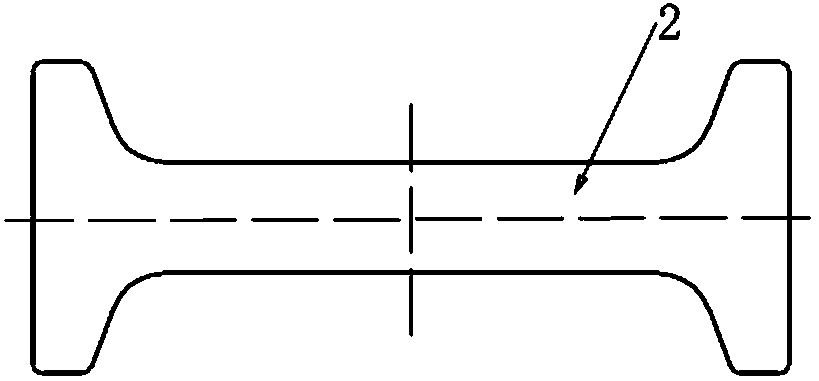

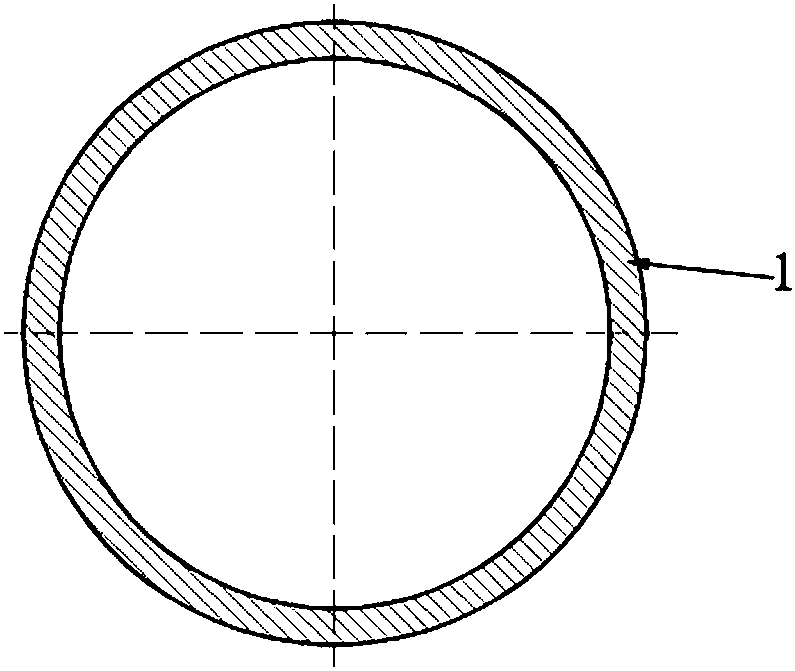

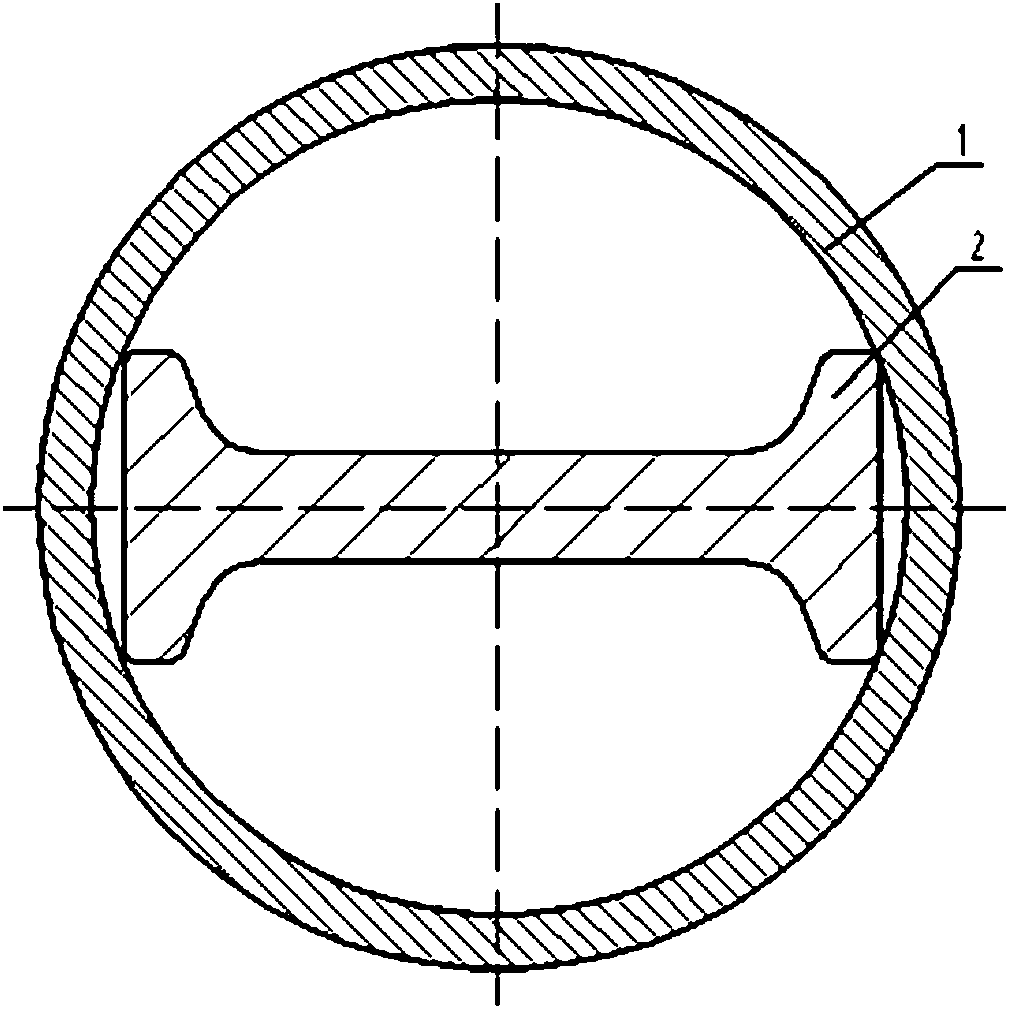

Production method of steel for corrosion-resistant structure

InactiveCN108856288AReduce manufacturing costLow priceMetal rolling arrangementsCarbon steelCorrosion resistant

The invention belongs to the technical field of corrosion-resistant steel production, and particularly relates to a production method of steel for a corrosion-resistant structure. The production method comprises the following steps that S1, composite blanks are manufactured, wherein the core steel is sleeved with the tubular steel blanks to prepare the composite blanks; S2, the composite blanks obtained in the step 1 undergo rolling combining; S3, vacuum treatment is carried out on the combined composite blank; and S4, the composite blank subjected to the vacuum treatment is rolled again. Common carbon steel is low in price, but the common carbon steel is not ideal in corrosion resistance, the corrosion-resistant steel has good corrosion resistance, but the corrosion-resistant steel is expensive in manufacturing cost, so that by adopting a mode of combining the common carbon steel and the corrosion-resistant steel, the corrosion-resistant effect can be achieved, and moreover, the production cost can be reduced; the carbon steel is used as the core steel (the base material), a corrosion-resistant steel type (the tubular steel blank) is used as a shell, the two parts are connected bymeans of extrusion and other means, and then are vacuumized to be in a vacuum state, the two ends are welded, the base material and the shell are combined into a whole by means of rolling and other means after heating, and compounding of the structural steel is realized through rolling after heating again.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Connector Plating Process

ActiveCN110306220BFast and effective tearFast and effective impactJewelleryElectrolysisSalt spray test

Owner:惠州锦鑫表面处理有限公司

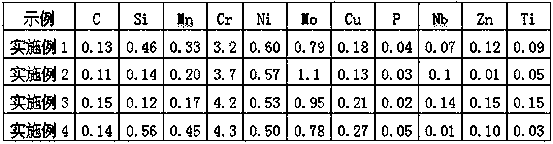

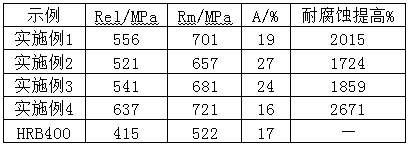

High-carbon-equivalent corrosion-resistant rebar and heat treatment method thereof

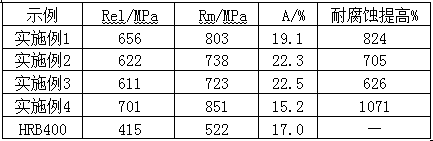

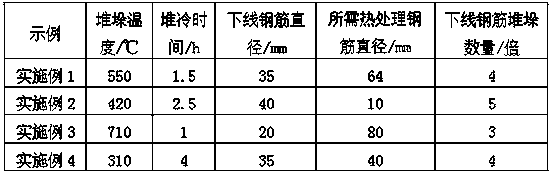

ActiveCN108441782AGood mechanical propertiesImprove performanceFurnace typesHeat treatment furnacesChemical compositionHigh carbon

The invention discloses a high-carbon-equivalent corrosion-resistant rebar and a heat treatment method thereof. The high-carbon-equivalent corrosion-resistant rebar comprises, by mass, 0.11-0.15% of C, less than or equal to 0.56% of Si, less than or equal to 0.45% of Mn, 3.2-4.3% of Cr, 0.5-0.6% of Ni, 0.78-1.1% of Mo, 0.13-0.27% of Cu, less than or equal to 0.05% of P, 0.01-0.14% of Nb, 0.01-0.15% of Zn, 0.03-0.15% of Ti and the balance Fe and inevitable impurities. According to the heat treatment method, the high-carbon-equivalent corrosion-resistant rebar needing to be subjected to heat treatment and hot-rolled rebar which is discharged recently are put in a slow cooling pit for stack cooling together, the stack cooling temperature is 310-710 DEG C, and stack cooling time is one hour orlonger. The rebar has the high corrosion resistance and excellent mechanical performance, the production cost is low, and the application prospects are wide.

Owner:HEBEI IRON AND STEEL

Corrosion-resistant surface treatment process for sunlight panel

InactiveCN109654364AImprove anti-scourabilityIncreased durabilitySheets/panelsThin layerCorrosion resistant

The invention discloses a corrosion-resistant surface treatment process for a sunlight panel, a molten corrosion-resistant thin layer is not only laid on the upper layer of a solid sunlight plate body, but also integrally formed into each hole so as to achieve a good consolidation effect, and not only a corrosion-resistant effect is achieved, the anti-scouring property and durability of the corrosion-resistant thin layer can also be greatly enhanced.

Owner:GUANGDONG GUOWEIXING PLASTIC SCI & TECHCO LTD

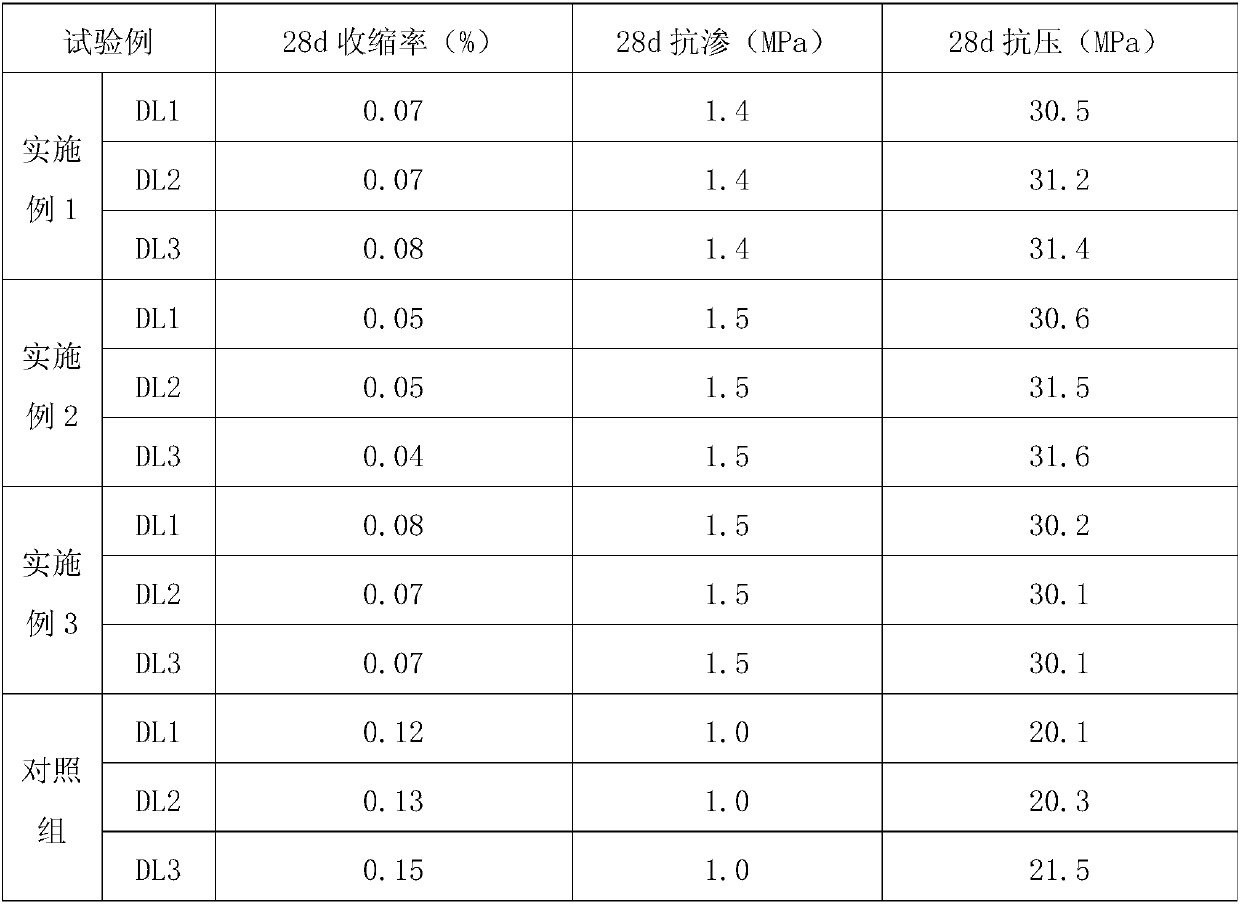

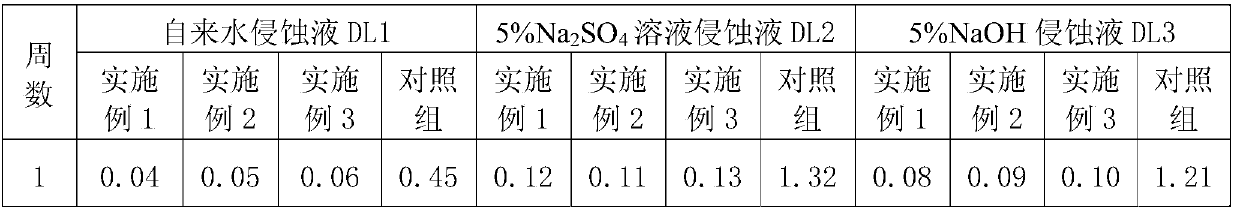

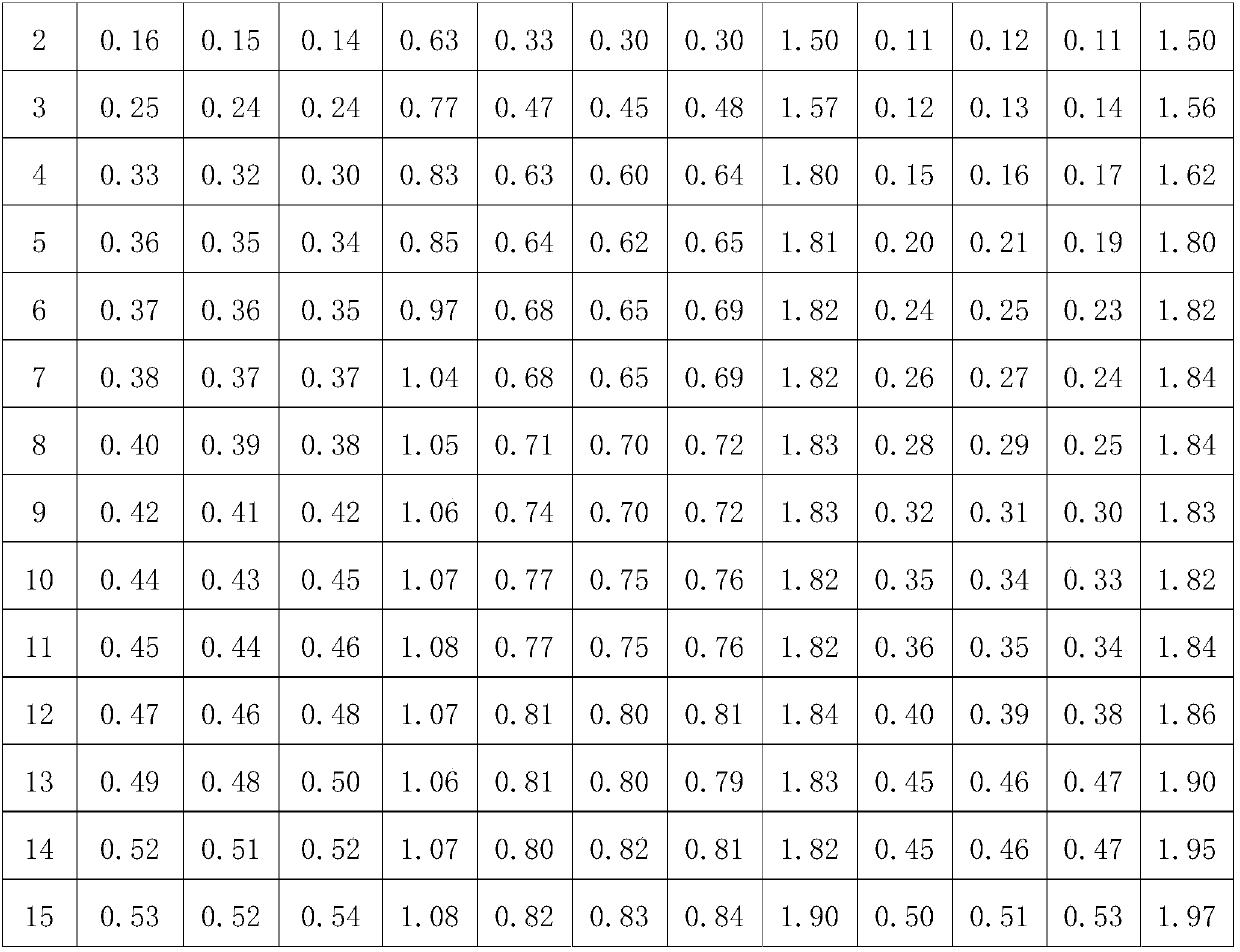

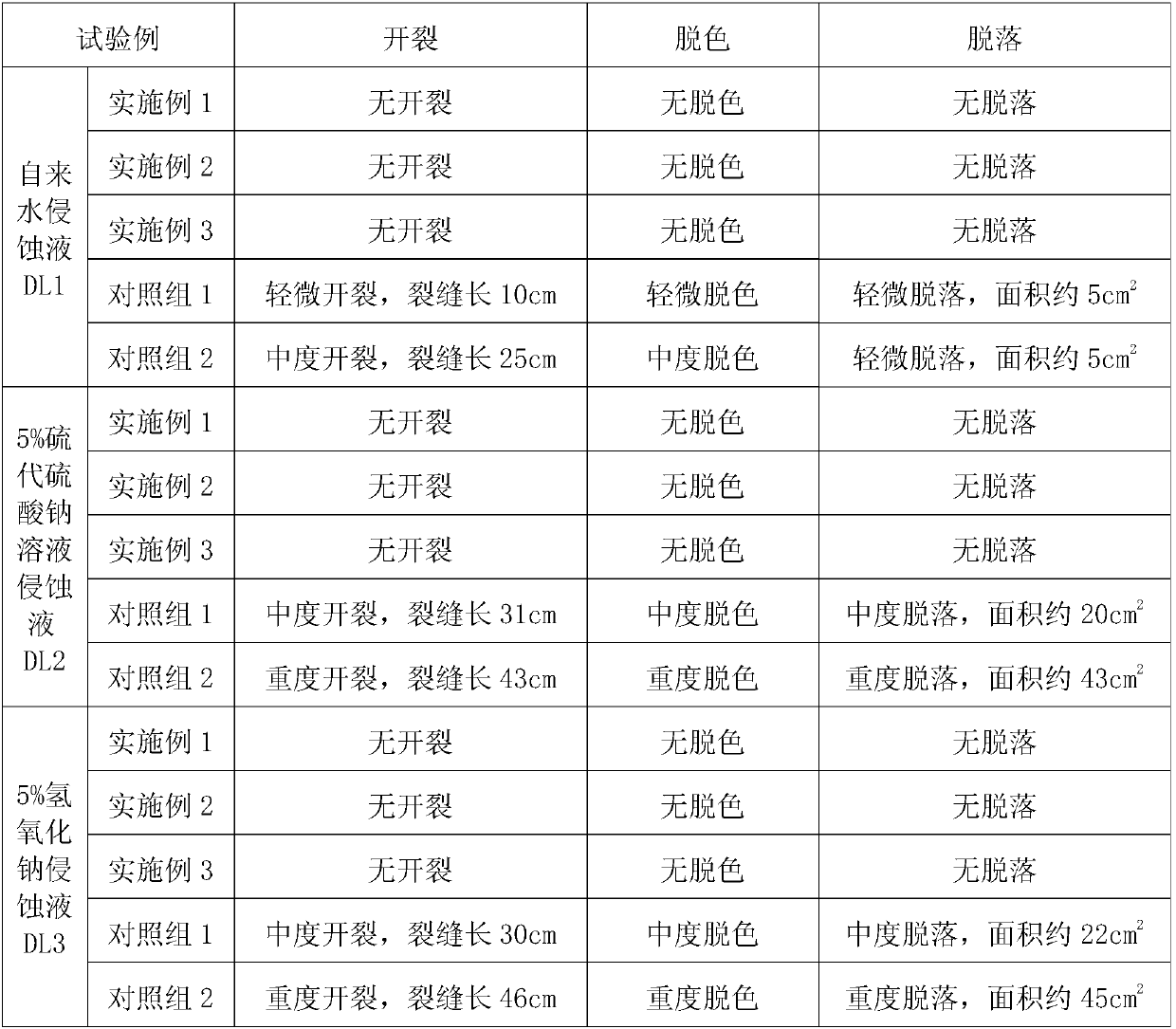

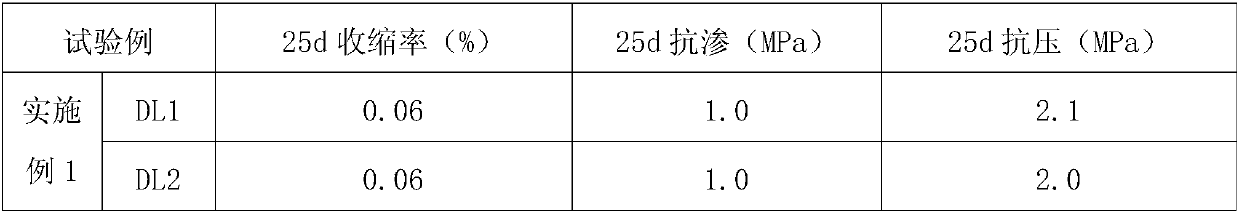

A high-efficiency corrosion-resistant ready-mixed mortar

The invention relates to a pre-mixed mortar material for buildings and particularly relates to high-efficiency corrosion resistant pre-mixed mortar. The mortar is prepared by mixing the following ingredients in percentages by weight: 5-20% of river sand, 10-30% of manufactured sand, 10-20% of flyash, 10-20% of granulated blast-furnace slag powder, 1-2% of polycarboxylic acid, 1-2% of sodium gluconate, 5-15% of cement, 5-15% of redispersible powder, 5-10% of kaolin and 5-10% of an electrolytic manganese slag waste. By using the pre-mixed mortar prepared at the ratio, the prepared concrete has the characteristics of being hard, corrosion-resistant and low in cost, and has wide applicability.

Owner:中山市群发建筑材料有限公司

A kind of high-strength corrosion-resistant steel bar and heat treatment method thereof

ActiveCN108441781BGood mechanical propertiesImprove performanceFurnace typesHeat treatment furnacesRebarCorrosion resistant

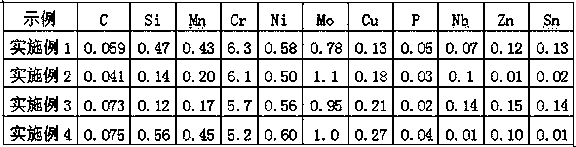

The invention discloses a high-strength and corrosion-resistant rebar and a heat treatment method thereof. The high-strength and corrosion-resistant rebar comprises, by mass, 0.041-0.075% of C, less than or equal to 0.56% of Si, less than or equal to 0.45% of Mn, 5.2-6.3% of Cr, 0.5-0.6% of Ni, 0.78-1.1% of Mo, 0.13-0.27% of Cu, less than or equal to 0.05% of P, 0.01-0.14% of Nb, 0.01-0.15% of Zn,0.01-0.14% of Sn and the balance Fe and inevitable impurities. According to the heat treatment method, the high-strength and corrosion-resistant rebar needing to be subjected to heat treatment and ahot-rolled rebar which is discharged recently are put in a slow cooling pit for stack cooling together, the stacking temperature is 200 DEG C or higher, and stack cooling time is one hour or longer. The rebar has the high corrosion resistance and excellent mechanical performance, the production cost is low, and the application prospects are wide.

Owner:HEBEI IRON AND STEEL

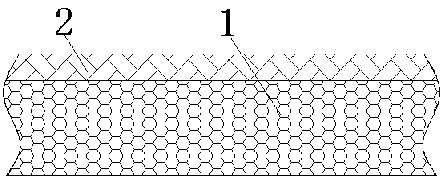

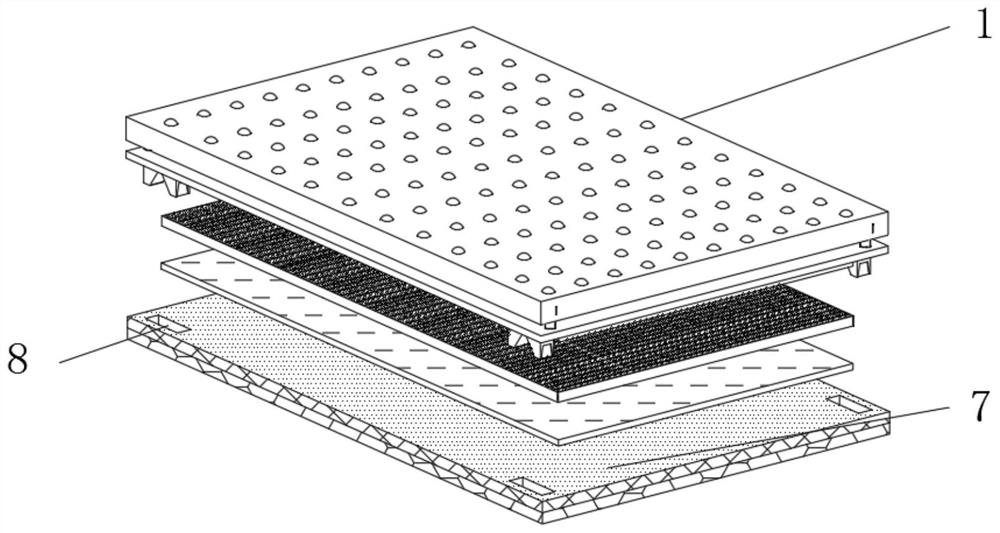

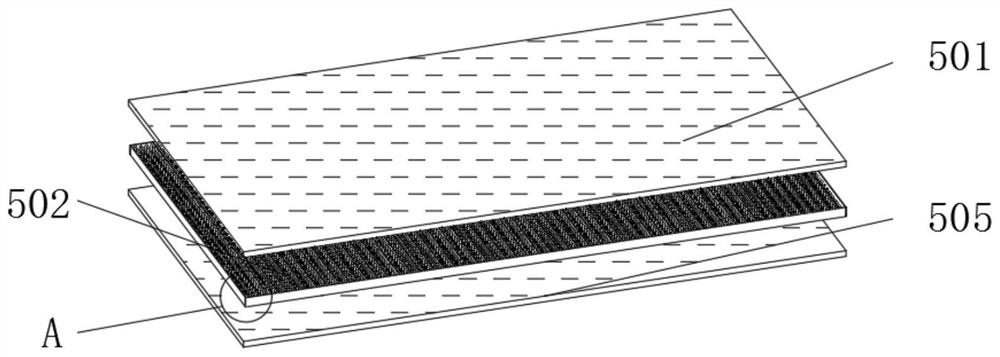

Aluminum-plastic composite panel

InactiveCN104354382AImprove noise reductionImprove sound insulationDomestic wallsMetal layered productsHoneycombAlloy

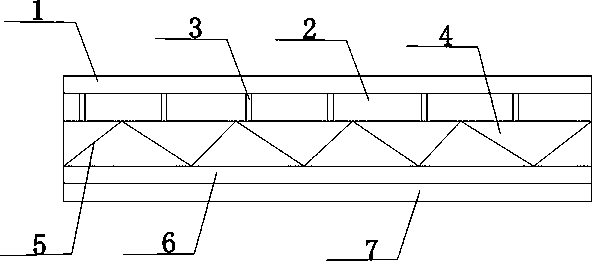

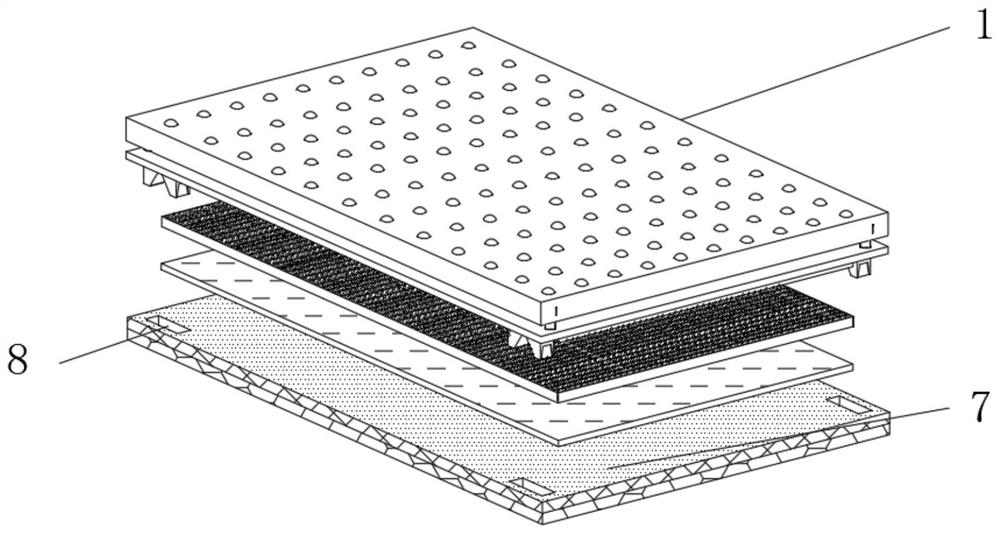

The invention discloses an aluminum-plastic composite panel. The aluminum-plastic composite panel comprises an upper aluminum alloy plate, wherein a honeycomb core veneer is arranged on the lower surface of the upper aluminum alloy plate and is thicker than the aluminum alloy plate; three or more acoustic panels are mounted in the honeycomb core veneer; the acoustic panels are fixedly connected with the honeycomb core veneer; an anti-corrosion primer layer is arranged on the lower surface of honeycomb core veneer; the anti-corrosion primer layer is thicker than the honeycomb core veneer; support devices are arranged in the anti-corrosion primer layer and serve as triangular structures; more than one support device is arranged; every two support devices are fixedly connected; a central core veneer is arranged on the lower surface of the anti-corrosion primer layer and adhered on the lower surface of the anti-corrosion primer layer; reinforced ribs are arranged inside the central core veneer. The aluminum-plastic composite panel is good in noise reduction performance, excellent in sound insulation, firm in structure, low in possibility of dropping and damage due to collision and other conditions, and in addition capable of resisting corrosion.

Owner:GUANGZHOU ALOYA RENOXBELL ALUMINUM

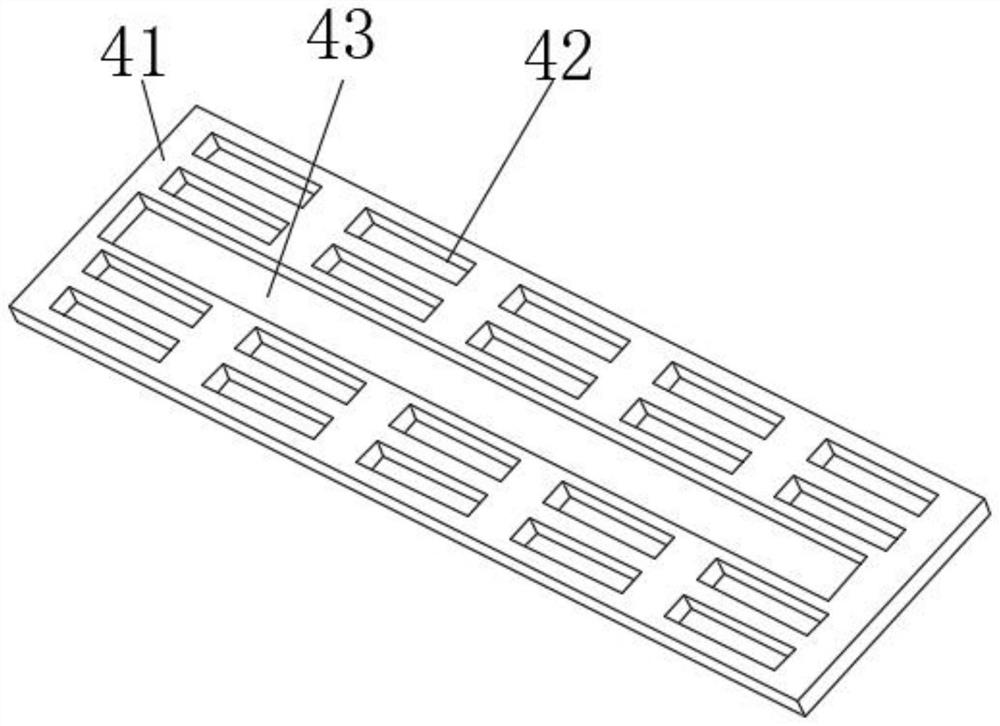

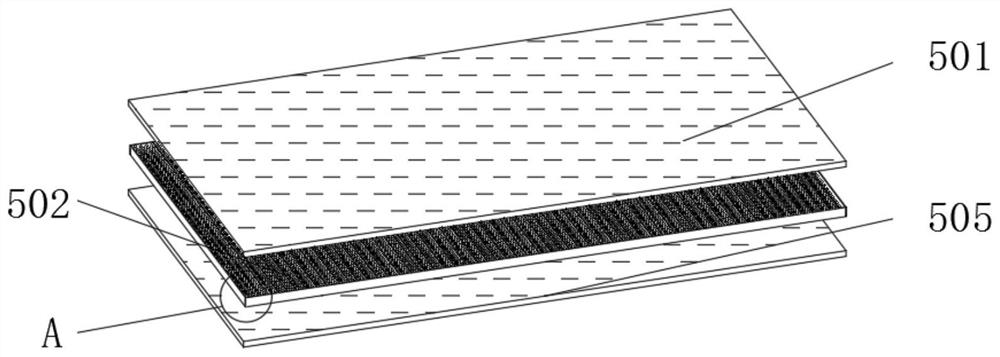

High-strength VCM film-coated plate base with impact resistance and preparation process

ActiveCN113386400ADampingGood vibration dampingMachine framesLayered productsRubber materialRubber sheet

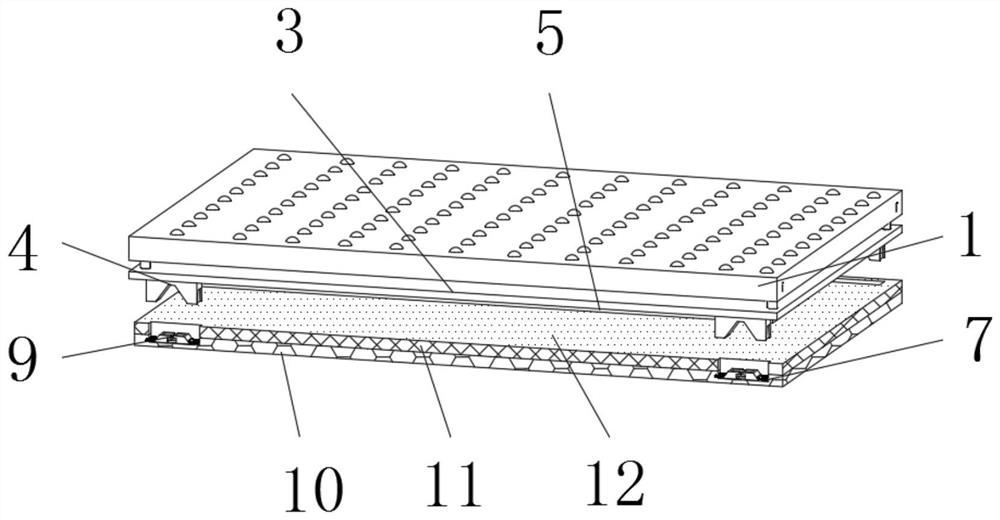

The invention discloses a high-strength VCM film-coated plate base with impact resistance and a preparation technology, and belongs to the technical field of VCM film-coated plate bases. The high-strength VCM film-coated plate base with impact resistance comprises a first film-coated top plate, wherein an adjusting mechanism is arranged at the top of the first film-coated top plate, and clamping blocks are fixedly connected to the two sides of the bottom of a first film-coated bottom plate. According to the high-strength VCM film-coated plate base with the impact resistance and the preparation process, rubber sheets are arranged, the rubber sheets and paraffin sheets are distributed in the buffer mechanism at equal intervals in a mixed mode in the buffer mechanism, the rubber sheets have good vibration reduction, impact isolation and sound insulation performance, have certain damping performance and can absorb energy, meanwhile, due to the fact that the rubber material and the metal surface can be firmly bonded, and the paraffin sheets and the rubber sheets are distributed at equal intervals in a mixed mode, the rubber sheets can be well protected through the paraffin sheets, the service life of the rubber sheets is prolonged, and then the service life of the device is prolonged.

Owner:JIANGSU LIBA ENTERPRISE JOINT STOCK

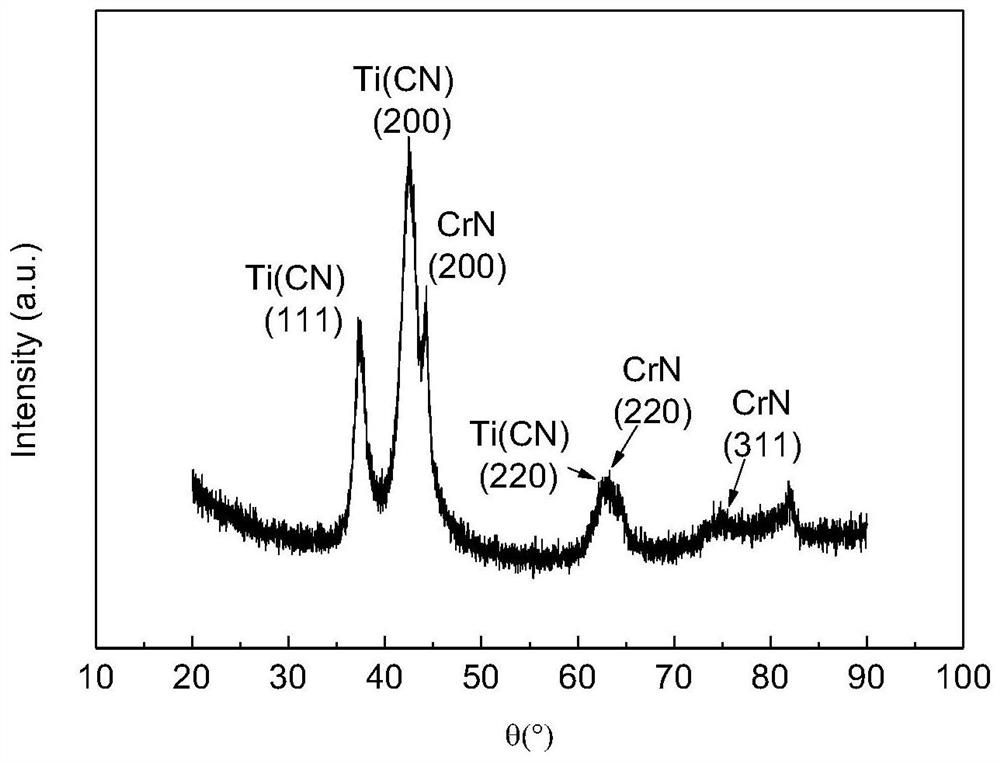

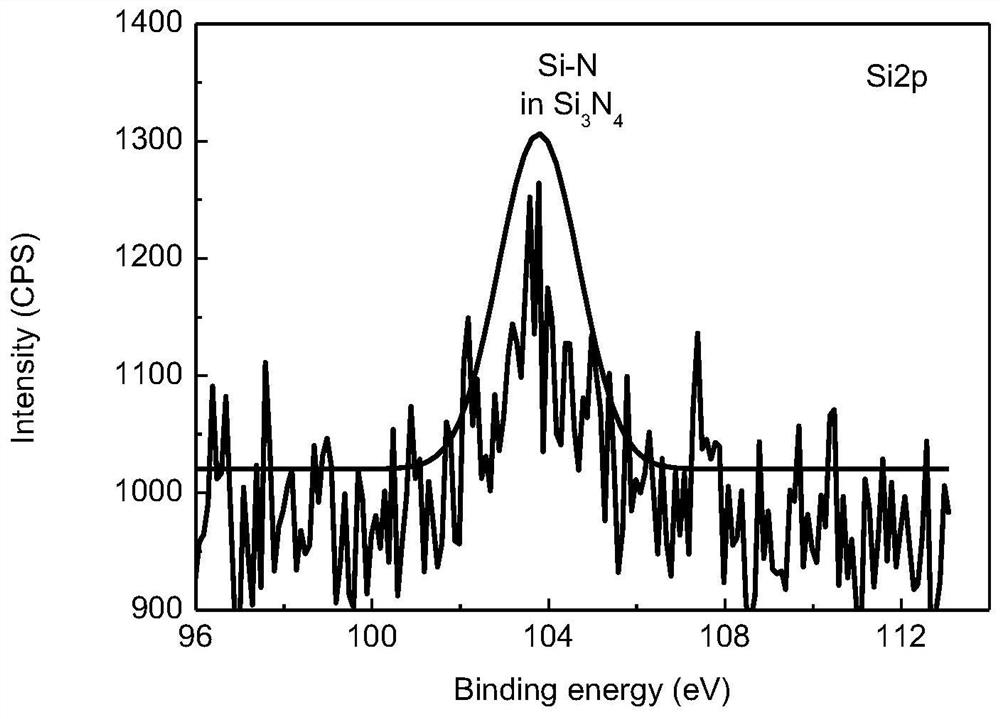

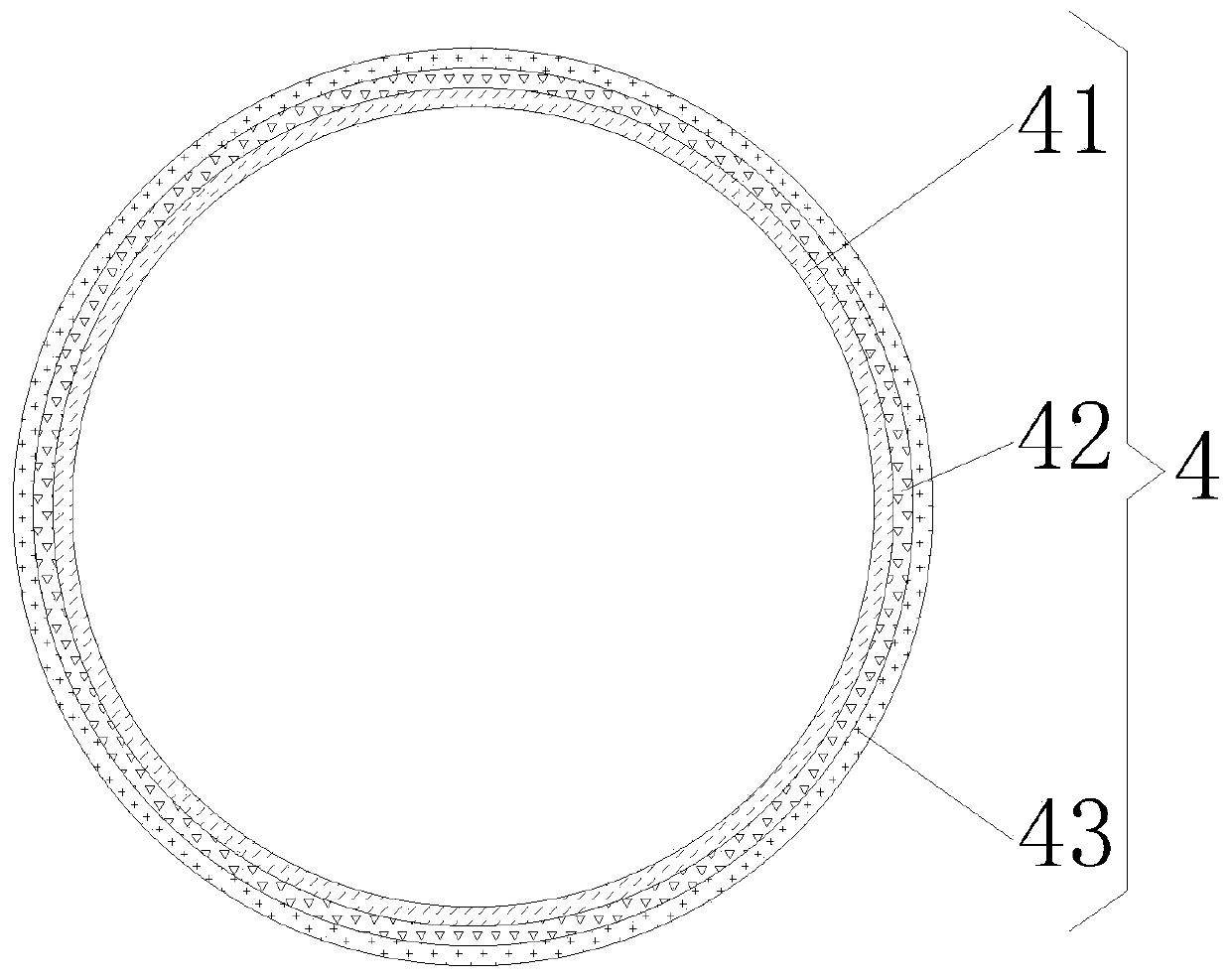

TiSi-based nano-composite multilayer water-erosion-resistant film of turbine blade and application of TiSi-based nano-composite multilayer water-erosion-resistant film

PendingCN112853280AExtended service lifeHigh bonding strengthVacuum evaporation coatingSputtering coatingSteam turbine bladeAmorphous phase

The invention discloses a TiSi-based nano-composite multilayer water-erosion-resistant film of a turbine blade and application of the TiSi-based nano-composite multilayer water-erosion-resistant film. The TiSi-based nano-composite multilayer water-erosion-resistant film comprises a metal Cr bottom layer, a TiSi transition layer, a TiSiN oxidation-resistant transition layer and a TiCrSiCN water-erosion-resistant film layer which are sequentially deposited on the surface of the turbine blade. The TiCrSiCN water-erosion-resistant film layer is of a nano-composite structure of Ti(CN), CrN nanocrystals, Si3N4 and C amorphous phases. The surface of the turbine blade is cleaned, then the turbine blade is placed on a rotating device in a vacuum chamber to rotate, plasma cleaning is conducted, then the metal Cr bottom layer, the TiSi transition layer, the TiSiN oxidation-resistant transition layer and the TiCrSiCN water-erosion-resistant film layer are sequentially deposited on the surface of the turbine blade through a multi-arc ion plating physical vapor deposition method, and thus the TiSi-based nano-composite multilayer water-erosion-resistant film of the turbine blade is prepared. The TiSi-based nano-composite multilayer water-erosion-resistant film is simple to operate, low in cost and environmentally friendly.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Preparation process of high-strength VCM film-coated plate base

InactiveCN114474875ADampingGood vibration dampingLayered productsNon-rotating vibration suppressionRubber materialRubber sheet

The invention discloses a preparation technology of a high-strength VCM film-covered plate base, and belongs to the technical field of VCM film-covered plate bases. The VCM film-covered plate base comprises a first film-covered top plate, an adjusting mechanism is arranged at the top of the first film-covered top plate, clamping blocks are fixedly connected to the two sides of the bottom of the first film-covered bottom plate, and the clamping blocks are fixedly connected to the two sides of the first film-covered bottom plate; according to the high-strength VCM film-coated plate base with the impact resistance and the preparation technology, rubber sheets are arranged, the rubber sheets and paraffin sheets are distributed in the buffer mechanism in a mixed mode at equal intervals, and the rubber sheets have good vibration reduction, impact isolation and sound insulation performance, have certain damping performance and can absorb energy; meanwhile, due to the fact that the rubber material and the metal surface can be firmly bonded, and the paraffin pieces and the rubber pieces are distributed in a mixed mode at equal intervals, the rubber pieces can be well protected through the paraffin pieces, the service life of the rubber pieces is prolonged, and therefore the service life of the device is prolonged.

Owner:JIANGSU LIBA ENTERPRISE JOINT STOCK

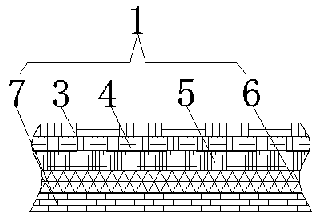

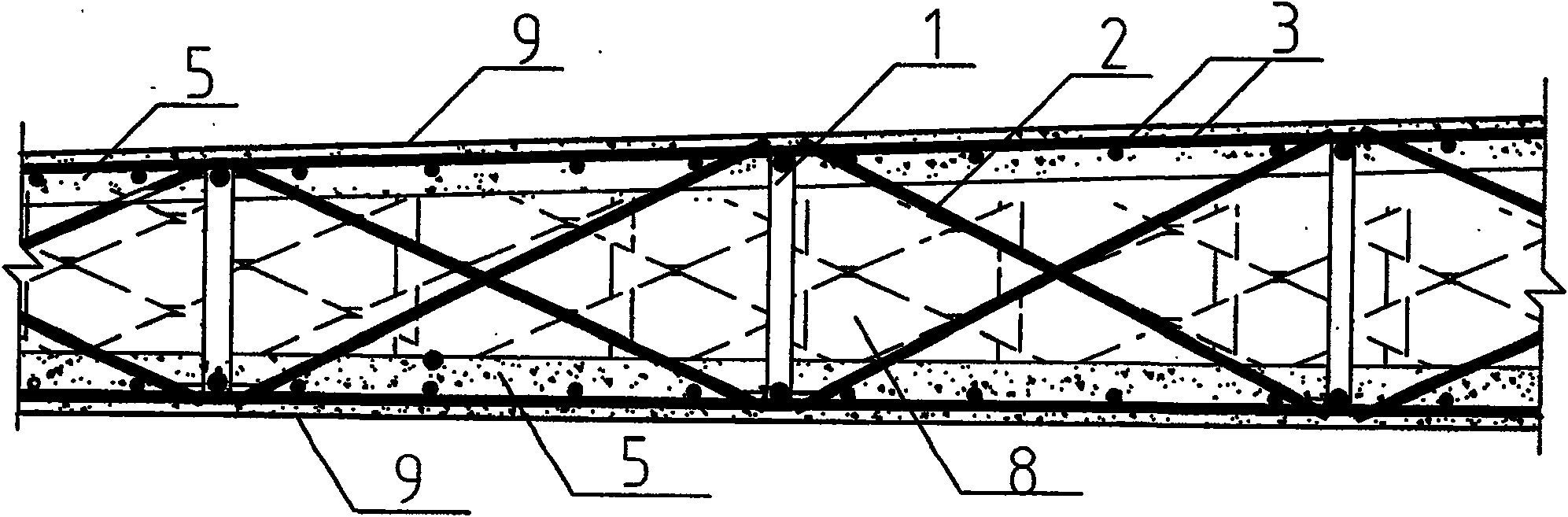

Insulation roof slab and method for making same

InactiveCN100567675CHigh tensile strengthEven by forceRoof covering using slabs/sheetsEarthquake resistanceGlass fiber

The invention relates to a panel for thermal insulation room, which is characterized in that the steel wire mesh frame is used as the skeleton frame; a plurality of concrete layers (5) are fixedly connected with both sides of the steel wire mesh frame; an empty cavity is formed between the concrete layers (5); the thermal insulation material is filled in the empty cavity to form the insulation layer (8); the thermal insulation material must be tightly closed to the internal walls of the concrete layer on both sides; an alkali resistant glass fiber mesh cloth (9) is embedded in the outer side of the concrete layer (5). The construction method comprises four steps: making the skeleton frame of the steel wire mesh frame, preparing the concrete material, making the concrete layer and forming the insulation layer. The panel for thermal insulation room has the advantages of earthquake resistance, light weight, high strength, impermeability, endurance, sound insulation, fire resistance, energy conservation, thermal insulation and higher efficiency of construction, and is more particularly suitable for construction engineering.

Owner:山东深科保温板墙开发股份有限公司

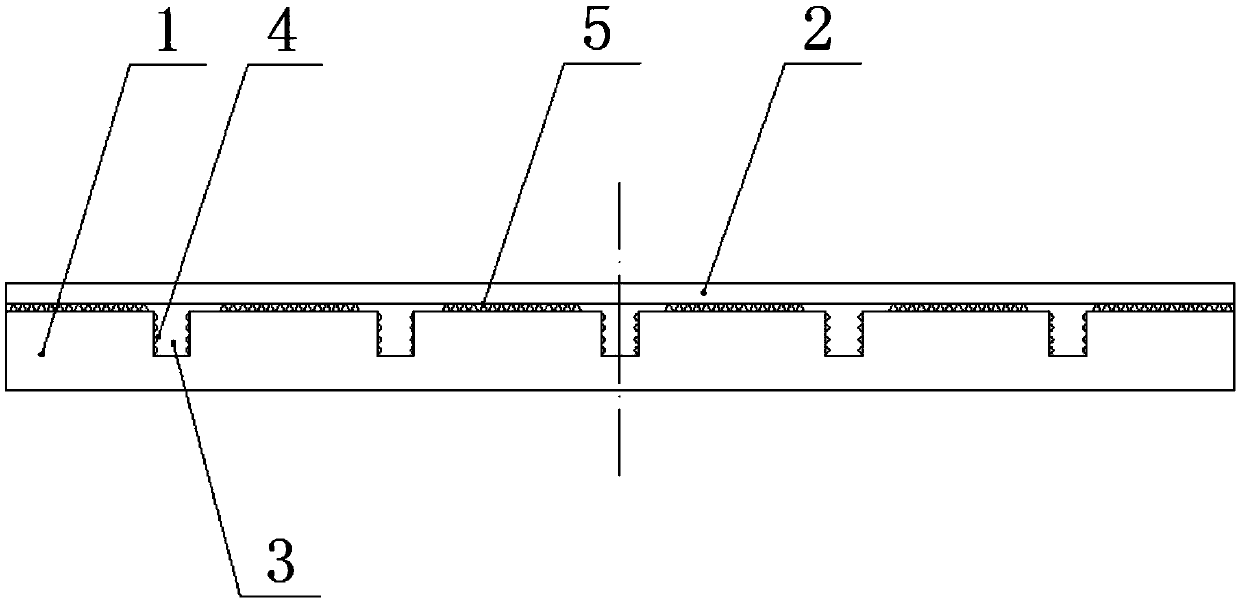

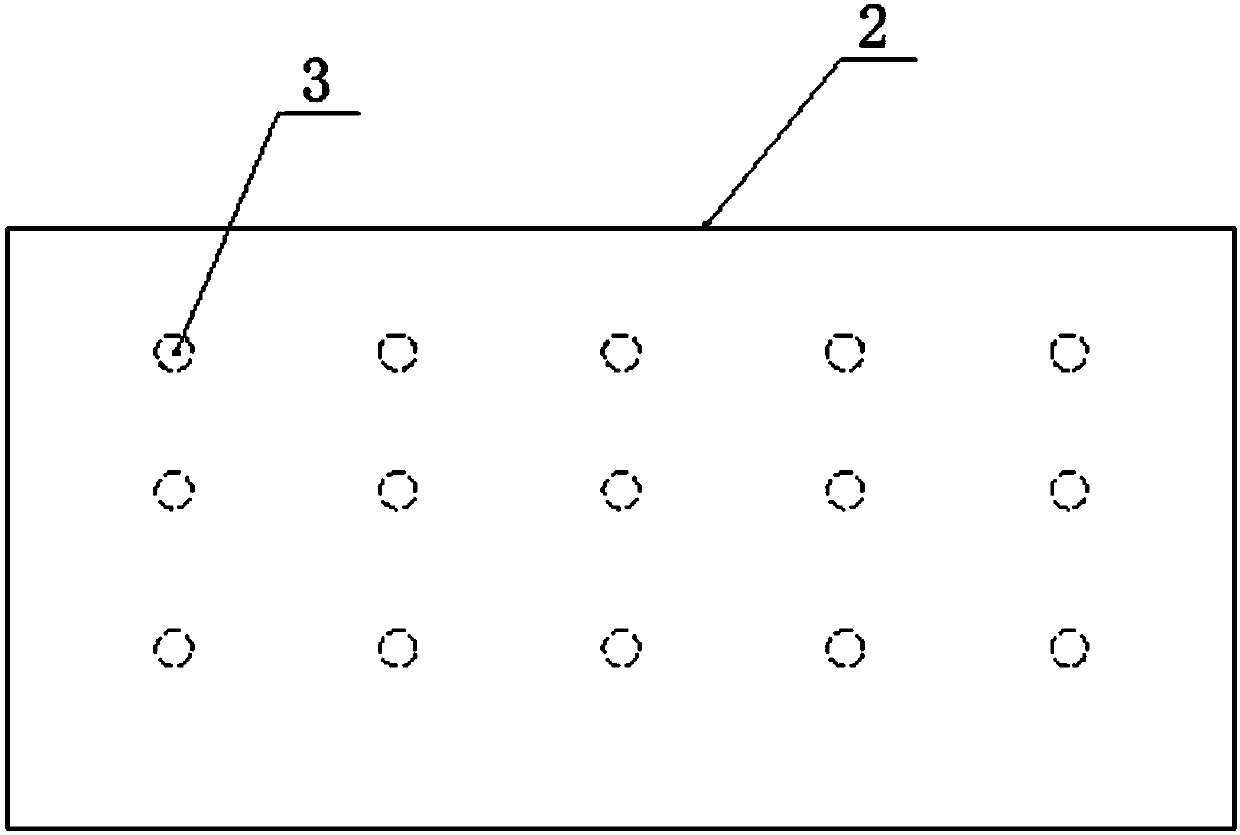

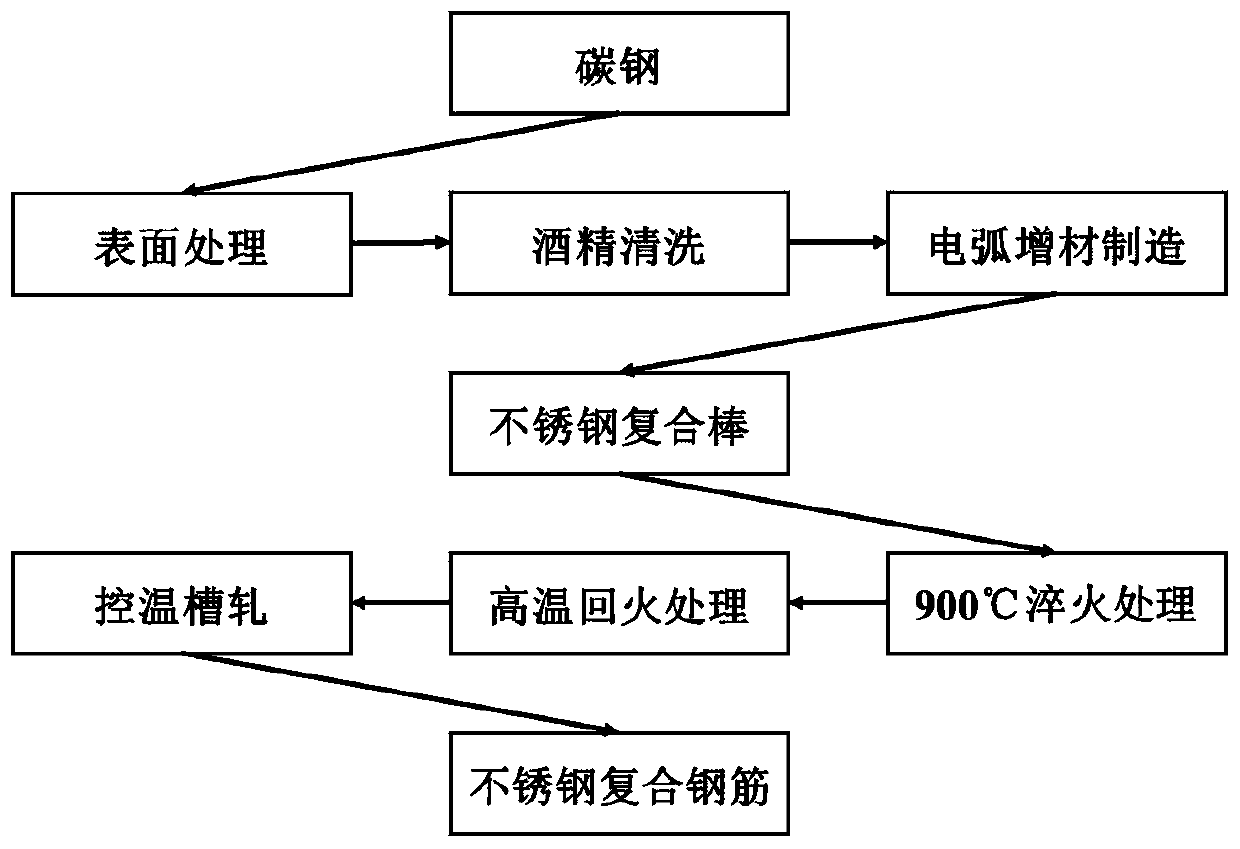

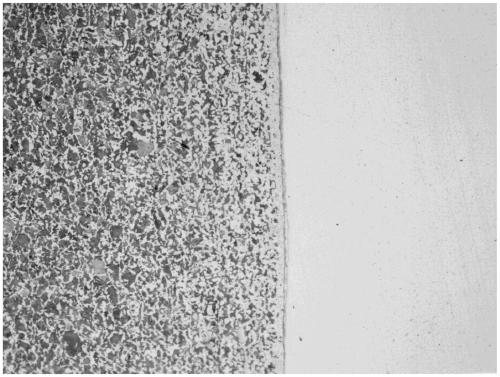

A method of additive manufacturing-temperature-controlled slot rolling for preparing stainless steel composite steel bars

InactiveCN110014051BHigh strengthSolving the Strength-Toughness Inversion PhenomenonTemperingSS - Stainless steel

The invention discloses a method for preparing a stainless steel composite reinforcing steel bar through additive-manufacturing and temperature-controlled slot rolling. The method comprises the following steps: pre-treating a carbon-steel surface and then performing electric-arc additive manufacturing, and surfacing a layer of stainless steel with a thickness of 2.5-5mm at the periphery of the carbon-steel surface; using straight-line welding to perform welding filling on four edges until carbon steel is completely coated by stainless steel, thereby obtaining a stainless steel composite rod; performing quenching and tempering treatment, and finally performing multi-pass slot rolling and forming on a slot rolling mill for coating stainless steel onto a carbon-steel base body, obtaining a relatively good inter-layer interface junction state and a nano-scale crystalline grain dimension, thereby realizing the purposes of resisting corrosion, strengthening and toughening. Through electric-arc additive-manufacturing, very strong interface bonding strength can be obtained, tensile property can reach 800-1000 MPa, and impact toughness can be 120-150J / cm<2>.

Owner:HEBEI UNIV OF TECH

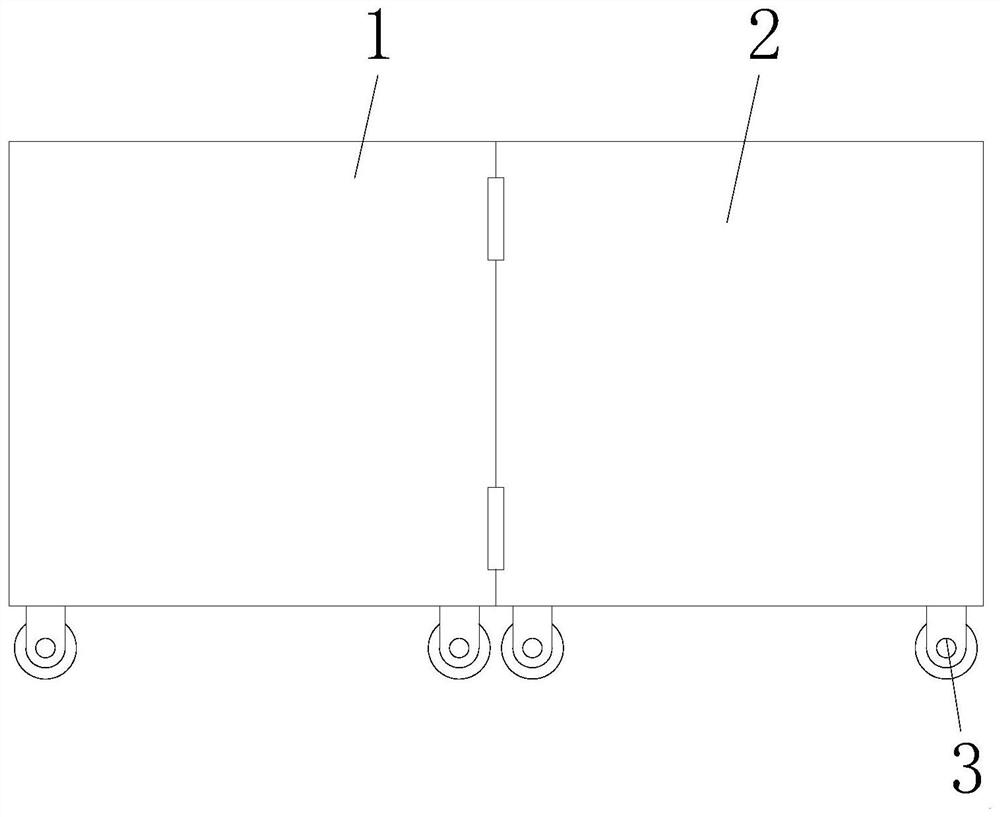

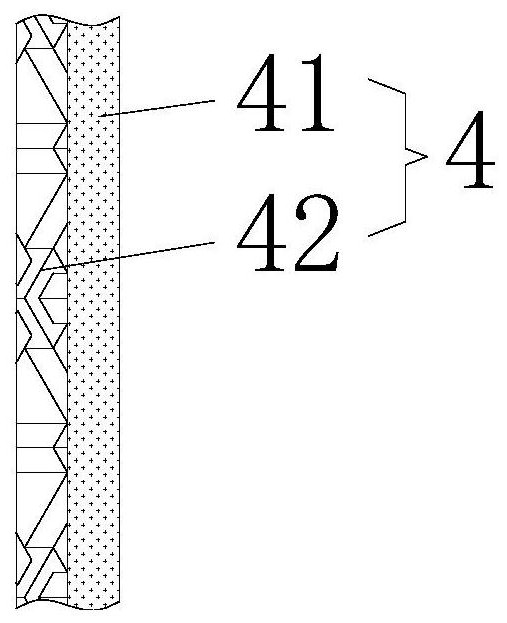

Movable retractable glass curtain wall

The invention discloses a movable retractable glass curtain wall which comprises a first wall plate. The right side of the first wall plate is movably connected with a second wall plate through a hinge, the first wall plate comprises a coating layer, a first high-strength layer, a sound insulation layer, a heat preservation layer and a second high-strength layer, and the outer surface of the firsthigh-strength layer is coated with the coating layer. The first high-strength layer is located on the outer surface of the sound insulation layer, the sound insulation layer is located on the outer surface of the heat preservation layer, the heat preservation layer is located on the outer surface of the second high-strength layer, the coating layer comprises an ultraviolet-proof coating and a corrosion-resistant coating, and the ultraviolet-proof coating is arranged on the outer surface of the corrosion-resistant coating in a coating manner; and the ultraviolet-proof coating is efficient elastic acrylic waterproof paint. According to the movable retractable glass curtain wall, through mutual cooperation of the ultraviolet-proof coating, the corrosion-resistant coating, the first high-strength layer, the sound insulation layer, the heat preservation layer and the second high-strength layer, the problems that an existing movable retractable glass curtain wall is not high in strength andpoor in heat preservation and sound insulation effect are solved.

Owner:南通市金鑫窗业有限公司

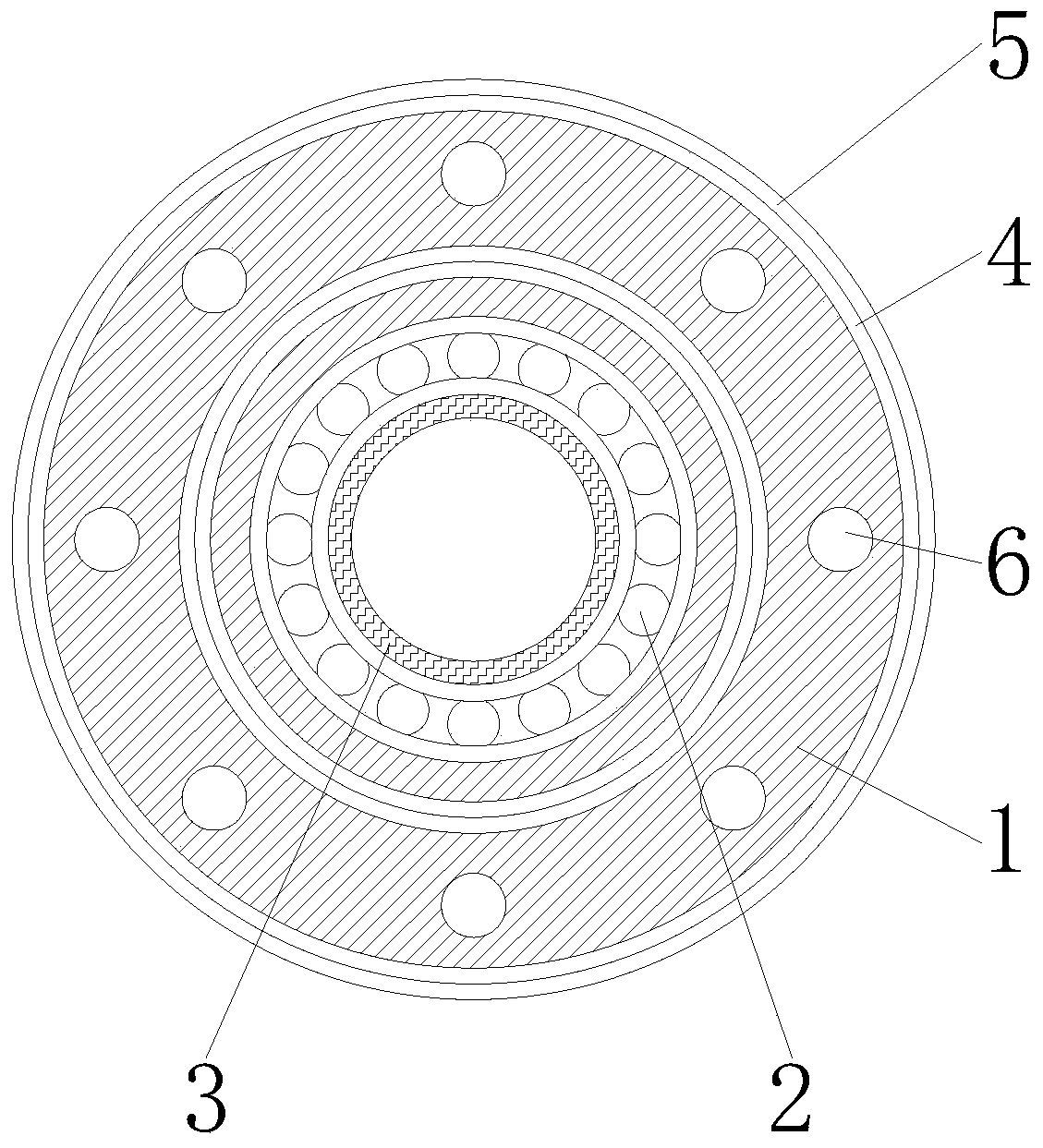

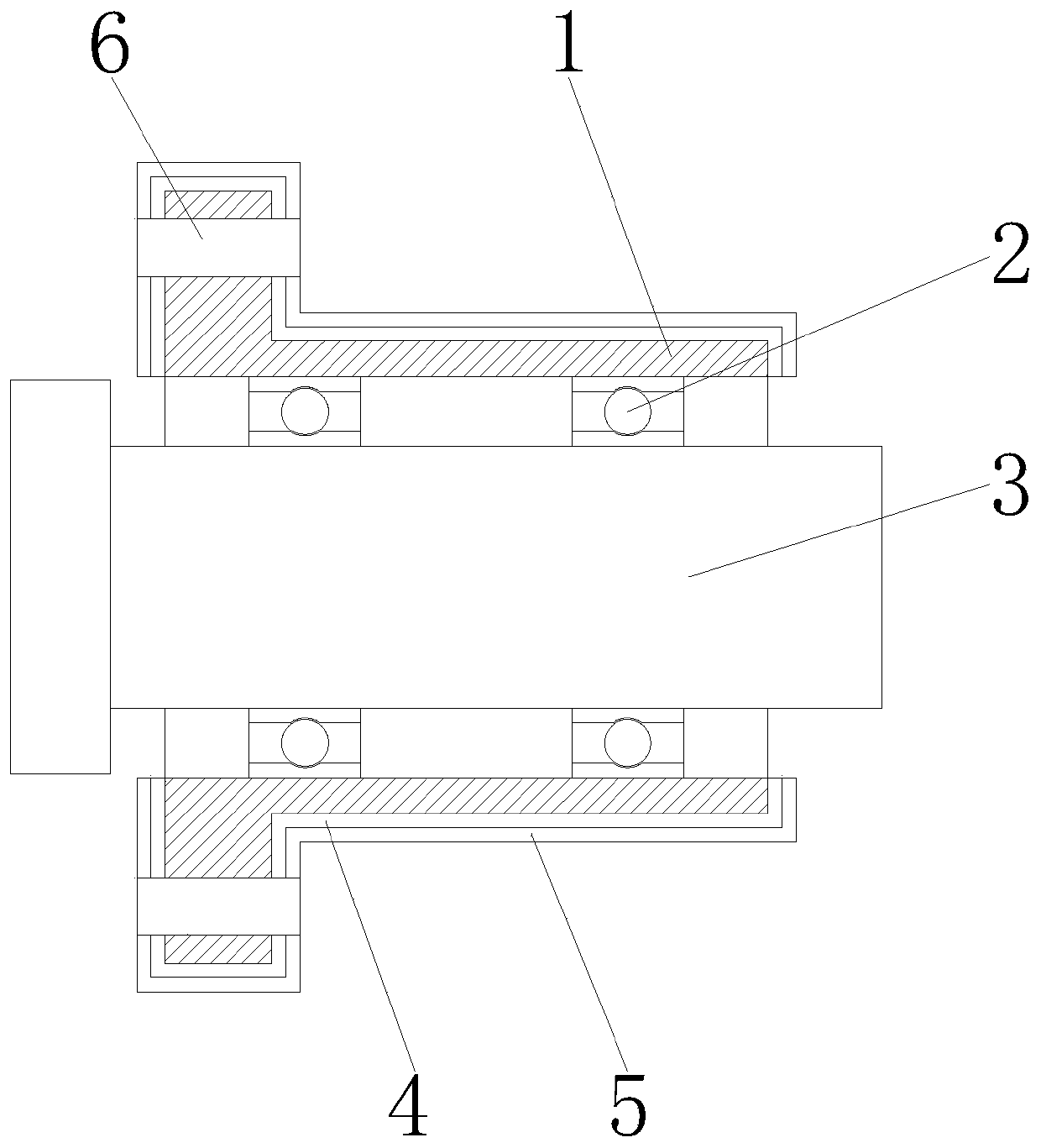

Optical fiber slip ring for optical communication equipment

InactiveCN111045159AEffective insulationCorrosion effectiveCoupling light guidesEpoxyColloidal silica

The invention discloses an optical fiber slip ring for optical communication equipment, which comprises a slip ring stator, wherein bearings are fixedly connected to the front end and the rear end ofthe inner wall of the slip ring stator, the inner walls of the bearings are fixedly connected with a slip ring rotor, the surface of the slip ring stator is provided with an insulating layer, and a corrosion-resistant layer is arranged on the side, which is away from the slip ring stator, of the insulating layer. According to the invention, the advantages of insulation and corrosion resistance ofthe optical fiber slip ring are achieved through mutual cooperation of the bearings, the insulating layer, an insulating plastic layer, an insulating rubber layer, an insulating silica gel layer, thecorrosion-resistant layer, a phenolic resin paint layer, an epoxy resin coating layer and an inorganic zinc-rich paint layer; when the optical fiber slip ring is in contact with a power supply, the optical fiber slip ring can be effectively insulated, the problem that the optical fiber is short-circuited and even damaged due to the fact that electricity is conducted into the optical fiber is prevented, the service life of the optical fiber is prolonged, the corrosion resistance of the optical fiber slip ring is improved, the optical fiber slip ring is prevented from being corroded and damaged,and the service life of the optical fiber slip ring is prolonged.

Owner:深圳市国扬通讯有限公司 +1

A waterproof and anti-corrosion colored ready-mixed mortar

The invention relates to a pre-mixed mortar material for construction, in particular to waterproof anticorrosive colorized pre-mixed mortar. The pre-mixed mortar is prepared by mixing the following materials in percentage by weight: 5-10% of river sand, 10-20% of quartz sand, 5-10% of fly ash, 5-10% of granulated blast furnace slag powder, 1-2% of polycarboxylic acid, 1-2% of sodium gluconate, 5-20% of organic pigment, 5-15% of re-dispersible latex powder, 10-20% of kaolin, 1-5% of electrolytic manganese residue wastes, and 5-10% of cement. The colorized pre-mixed mortar prepared by use of the above proportions has the characteristics of easy coloration, water resistance, and corrosion resistance when applied to decoration of wall bodies.

Owner:长兴欧立亚新型建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com