Multilevel condensation water heating system

A technology for heating systems and condensed water, applied in lighting and heating equipment, preheating, supplementary water supply, etc., can solve the problems of increasing pipe spacing, long desulfurization flue space, pipe fitting corrosion, etc., to increase flue gas resistance, Avoid the effect of excessive dust accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

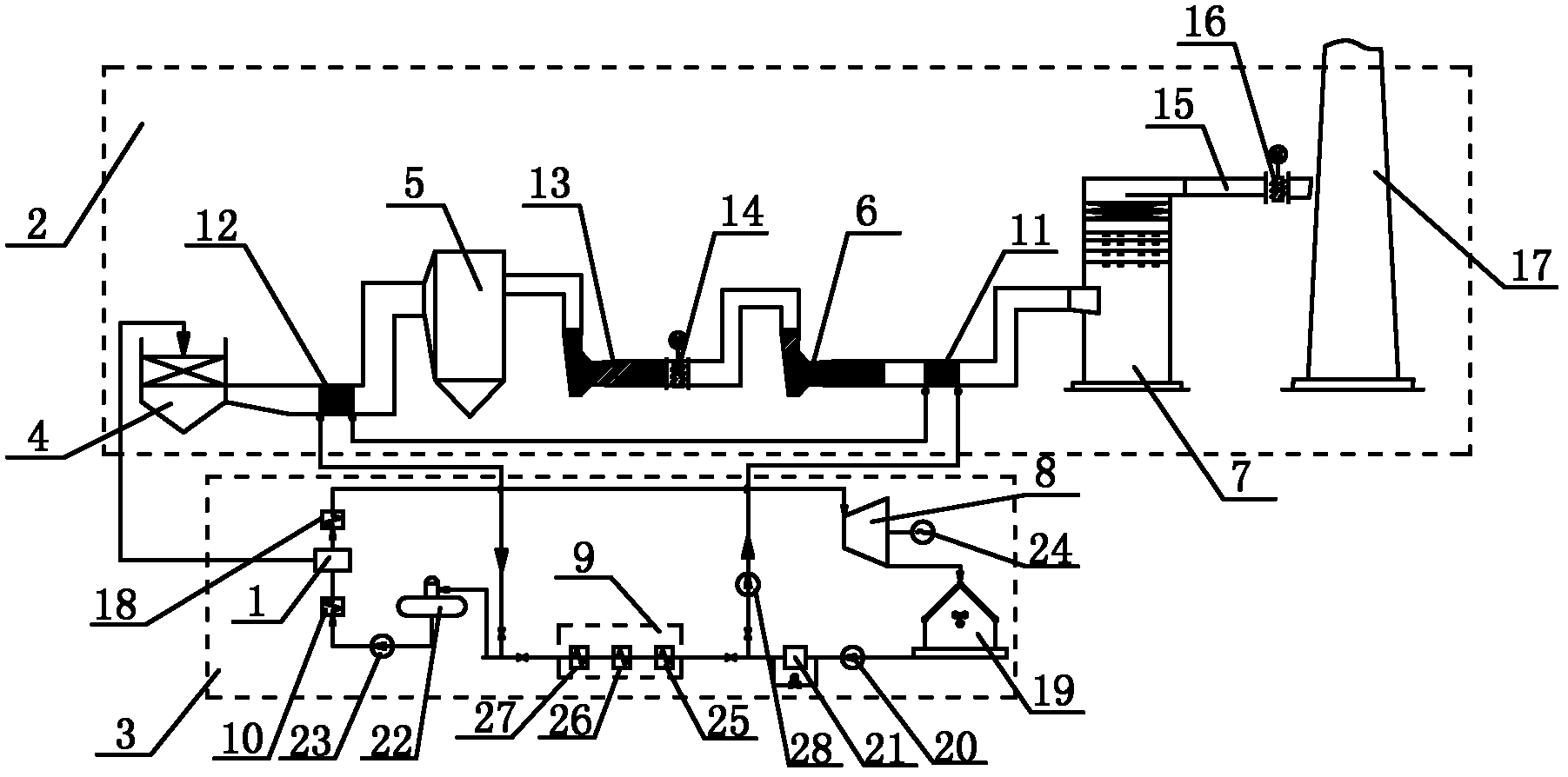

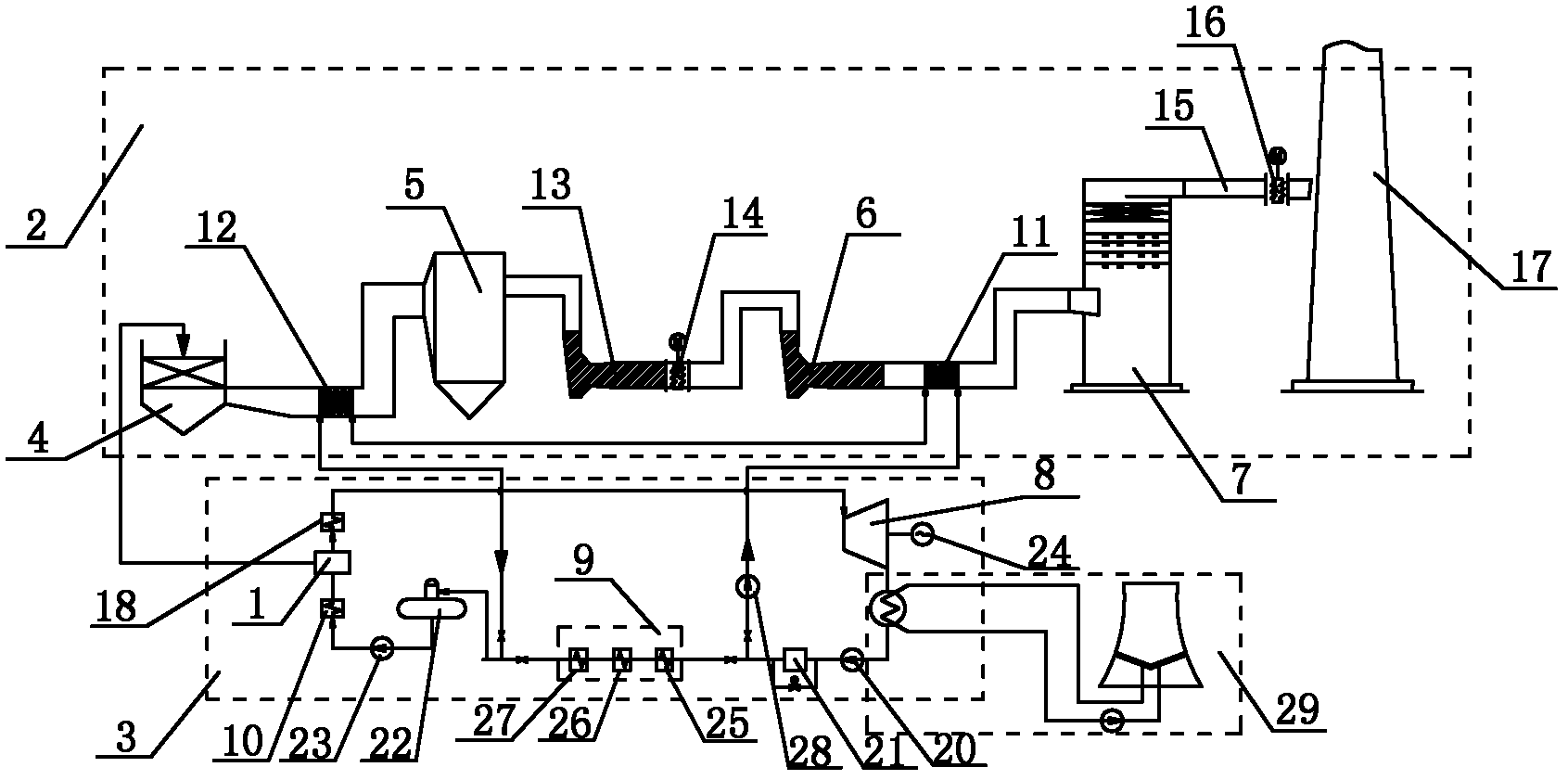

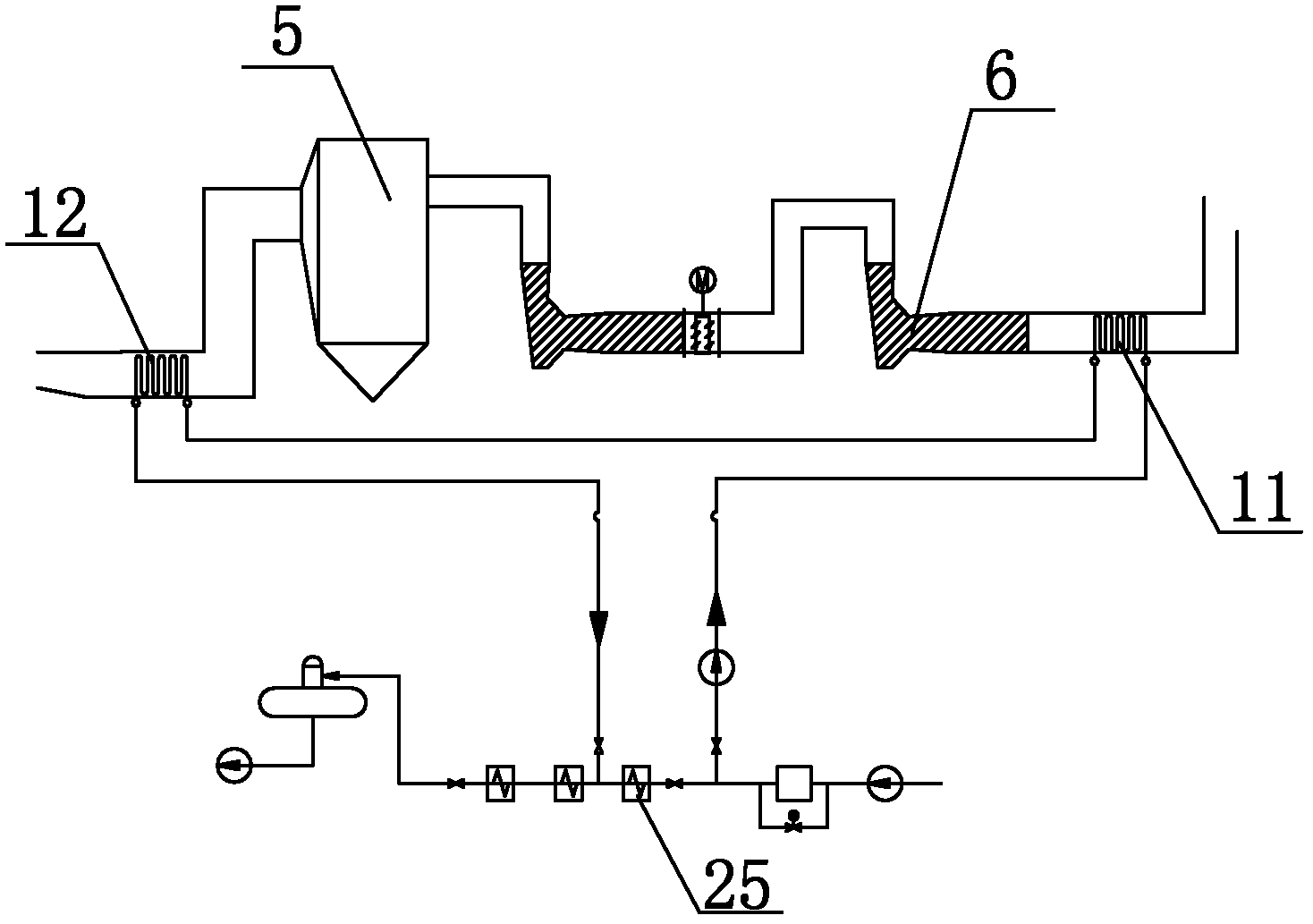

[0031] Embodiment 1 of the present invention: as figure 1As shown, a multi-stage condensate heating system includes a boiler 1, a tail flue gas treatment system 2 and a flue gas waste heat recovery system 3, and the tail flue gas treatment system 2 includes an air preheater 4, a dust collector 5, and a booster fan 6. Absorption tower 7, induced draft fan 13, induced draft fan outlet baffle 14, clean flue 15, clean flue gas baffle 16 and chimney 17, one end of induced draft fan 13 is connected with dust collector 5, and the other end of induced draft fan 13 is set There is an induced draft fan outlet baffle 14, and the induced draft fan outlet baffle 14 is connected with the absorption tower 7 through the original flue, and the absorption tower 7 is connected with one end of the clean flue gas baffle 16 through the clean flue 15, and the clean flue baffle 16 The other end is connected to the chimney 17; the flue gas waste heat recovery system 3 includes a steam turbine 8, a lo...

Embodiment 2

[0034] Embodiment 2 of the present invention: as figure 1 As shown, a multi-stage condensate heating system includes a boiler 1, a tail flue gas treatment system 2 and a flue gas waste heat recovery system 3, and the tail flue gas treatment system 2 includes an air preheater 4, a dust collector 5, and a booster fan 6. Absorption tower 7, induced draft fan 13, induced draft fan outlet baffle 14, clean flue 15, clean flue gas baffle 16 and chimney 17, one end of induced draft fan 13 is connected with dust collector 5, and the other end of induced draft fan 13 is set There is an induced draft fan outlet baffle 14, and the induced draft fan outlet baffle 14 is connected with the absorption tower 7 through the original flue, and the absorption tower 7 is connected with one end of the clean flue gas baffle 16 through the clean flue 15, and the clean flue baffle 16 The other end is connected to the chimney 17; the flue gas waste heat recovery system 3 includes a steam turbine 8, a l...

Embodiment 3

[0037] Embodiment 3 of the present invention: as figure 1 As shown, a multi-stage condensate heating system includes a boiler 1, a tail flue gas treatment system 2 and a flue gas waste heat recovery system 3, and the tail flue gas treatment system 2 includes an air preheater 4, a dust collector 5, and a booster fan 6. Absorption tower 7, induced draft fan 13, induced draft fan outlet baffle 14, clean flue 15, clean flue gas baffle 16 and chimney 17, one end of induced draft fan 13 is connected with dust collector 5, and the other end of induced draft fan 13 is set There is an induced draft fan outlet baffle 14, and the induced draft fan outlet baffle 14 is connected with the absorption tower 7 through the original flue, and the absorption tower 7 is connected with one end of the clean flue gas baffle 16 through the clean flue 15, and the clean flue baffle 16 The other end is connected to the chimney 17; the flue gas waste heat recovery system 3 includes a steam turbine 8, a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com