Heat-resistant capacitor and working method

A capacitor and heat-resistant technology, applied in the field of capacitors, can solve the problems of reduced withstand voltage, breakdown damage of capacitors, and reduced insulation performance of metallized polypropylene films, so as to ensure normal service life, reduce heat dissipation, and prevent dust. accumulate too many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

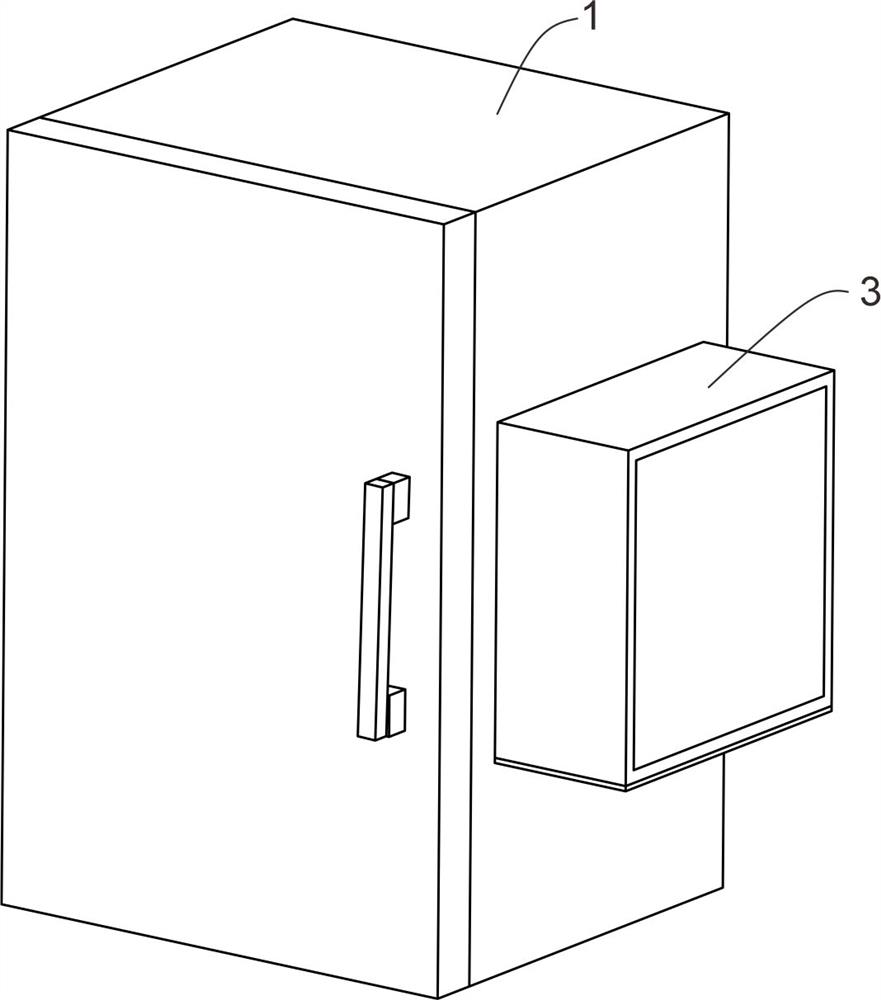

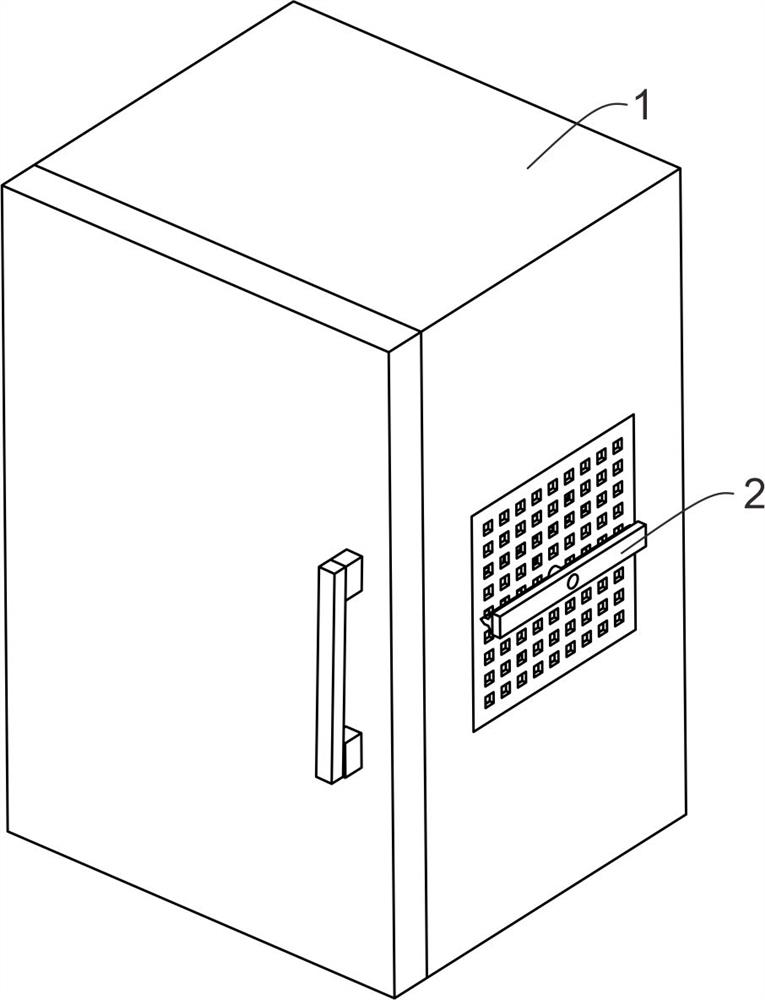

[0029] see Figure 1 to Figure 5 , the present invention provides a heat-resistant capacitor, including a casing 1 for protecting the capacitor; a dust-proof plate 11 for preventing dust from sticking to the fan blades 216; a heat dissipation unit 2 for discharging the heat inside the casing 1; The heat sink 21 for discharging the heat inside the casing 1; the cleaning member 22 for cleaning the surface of the dustproof plate 11; the protection unit for protecting the object (3) the air inlet 12 for easy entry of air; The exhaust port 13 for expelling heat; the through slot 14 for air flow; the wire hole 15 for easy installation of lead wires; the sliding door 16 for opening the casing 1;

[0030] Among them, the casing 1 for protecting the capacitor includes a dustproof plate 11 provided on both sides to prevent dust from sticking to the fan blades 216 ; a heat dissipation unit 2 for discharging the heat inside the casing 1 ; The cooling element 21 for discharging and the cl...

Embodiment 2

[0034] see Image 6 , the present invention provides a heat-resistant capacitor, which is used for installing the fixing seat 211 of the mounting seat 213; the bracket 212 for fixing the fixing seat 211; the mounting seat 213 for fixing the motor 214; A rotating motor 214 ; a mounting ring 215 that drives the fan blade 216 to rotate; a fan blade 216 that drives the air flow to discharge the hot air from the exhaust port 13 ; the first rotating rod 217 that drives the mounting ring 215 to rotate.

[0035] Further, the heat sink 21 includes a fixing seat 211 for installing the mounting seat 213 provided in the air outlet 13, and brackets 212 for fixing the fixing seat 211 are arranged around the fixing seat 211. The seat 211 is fixedly connected, and the other ends of the brackets 212 provided around are respectively fixedly connected to the inner wall of the air outlet 13 .

[0036]Further, the mounting seat 213 is fixedly connected with the fixing seat 211, the mounting seat ...

Embodiment 3

[0039] see Figure 7 , The present invention provides a heat-resistant capacitor, the second rotating rod 221 driving the fixed rod 222 to rotate; the fixed rod 222 driving the scraper 223 to rotate; the scraper 223 cleaning the surface of the dustproof plate 11 .

[0040] Further, the cleaning member 22 includes a second rotating rod 221 arranged on the other side of the mounting ring 215 and driving the fixing rod 222 to rotate. One end of the second rotating rod 221 is fixedly connected with the mounting ring 215, and the other end of the second rotating rod 221 penetrates through the mounting ring 215. The dust-proof plate 11 extends to the side of the dust-proof plate 11, and one end of the second rotating rod 221 extending to the side of the dust-proof plate 11 is provided with a fixed rod 222 that drives the scraper 223 to rotate. The fixed rod 222 and the second rotating rod 221 is fixedly connected, one side of the fixing rod 222 is symmetrically provided with a scrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com