High-carbon-equivalent corrosion-resistant rebar and heat treatment method thereof

A heat treatment method and high carbon equivalent technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of insufficient strength, low Ni content, increased production costs, etc., and achieve excellent mechanical properties and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

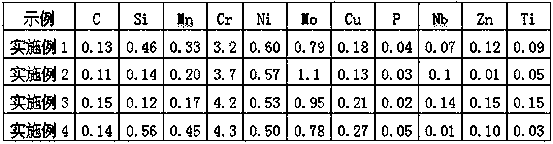

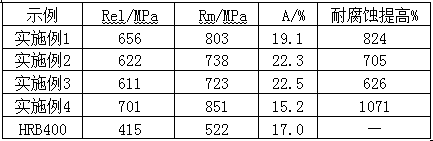

[0030] The chemical composition and mass percentage of the high carbon equivalent corrosion-resistant steel bars in this example are shown in Table 1, and the performance test results are shown in Table 3.

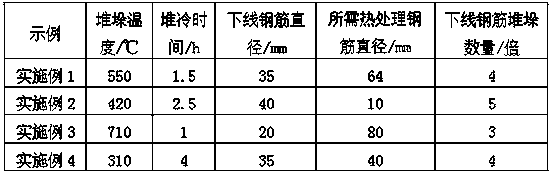

[0031] The heat treatment method of high carbon equivalent corrosion-resistant steel bars is as follows: put the high carbon equivalent corrosion-resistant steel bars that need heat treatment together with the hot-rolled steel bars that have just come off the line into the slow cooling pit for stacking, and the stack of hot-rolled steel bars (diameter 35mm) The stacking temperature is 550°C, and the total mass of off-line hot-rolled steel bars is 4 times that of the required heat-treated steel bars (diameter 64mm); when stacking, a layer of off-line steel bars with the same number of required heat-treated steel bars should be laid in advance at the bottom of the slow cooling pit Hot-rolled steel bars, and then mix the required heat-treated steel bars with the hot-rolled ste...

Embodiment 2

[0033] The chemical composition and mass percentage of the high carbon equivalent corrosion-resistant steel bars in this example are shown in Table 1, and the performance test results are shown in Table 3.

[0034] The heat treatment method of high carbon equivalent corrosion-resistant steel bars is as follows: put the high carbon equivalent corrosion-resistant steel bars that need heat treatment together with the hot-rolled steel bars that have just come off the line into the slow cooling pit for stacking, and the stack of hot-rolled steel bars (diameter 40mm) The stacking temperature is 420°C, and the total mass of off-line hot-rolled steel bars is 5 times that of the required heat-treated steel bars (diameter 10mm); when stacking, a layer of off-line steel bars with the same number of required heat-treated steel bars should be laid in advance at the bottom of the slow cooling pit Hot-rolled steel bars, and then mix the required heat-treated steel bars with the hot-rolled ste...

Embodiment 3

[0036] The chemical composition and mass percentage of the high carbon equivalent corrosion-resistant steel bars in this example are shown in Table 1, and the performance test results are shown in Table 3.

[0037] The heat treatment method of high carbon equivalent corrosion-resistant steel bars is as follows: put the high carbon equivalent corrosion-resistant steel bars that need heat treatment together with the hot-rolled steel bars that have just come off the line into the slow cooling pit for stacking, and the stack of hot-rolled steel bars (diameter 20mm) The stacking temperature is 710°C, and the total mass of off-line hot-rolled steel bars is three times that of the required heat-treated steel bars (diameter 80mm); when stacking, lay a layer of off-line steel bars with the same number of required heat-treated steel bars in advance at the bottom of the slow cooling pit Hot-rolled steel bars, and then mix the required heat-treated steel bars with the hot-rolled steel bars...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com