High-performance anti-corrosion TWIP/stainless steel multi-layer composite material and preparation method

A multi-layer composite material and composite material technology, applied in the field of design metal calendering, can solve the problems of low strength, uneven deformation, different stress, etc., and achieve the effects of good corrosion resistance, high elongation, corrosion resistance, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

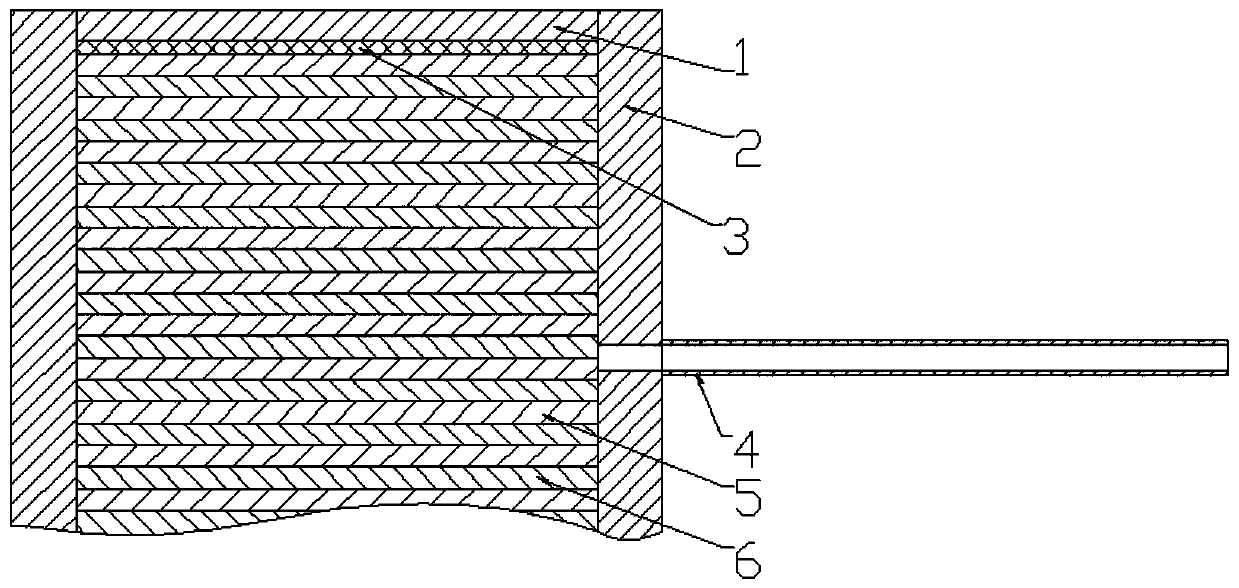

[0031] The preparation method of the above materials is as follows: by cutting stainless steel and TWIP steel material sheets and laminating them in multiple layers, in the lamination process, it is necessary to ensure that the stainless steel plate is located on the surface layer of the billet to ensure the corrosion resistance of the material, and then four seals are used to surround the lamination. The TWIP / stainless steel material forms a groove, and the upper and lower ends are sealed with lids to form a box body, which is welded by argon arc welding to obtain a sealed group blank, which is sealed and then vacuumized. Multi-pass hot rolling is carried out on the hot rolling mill to ensure that the total rolling reduction is 90%.

[0032] After hot rolling, the heat treatment process (heat preservation and quenching or annealing treatment, cold rolling and annealing treatment) can be continued to obtain better interlayer interface bonding and micron layer thickness scale, a...

Embodiment 1

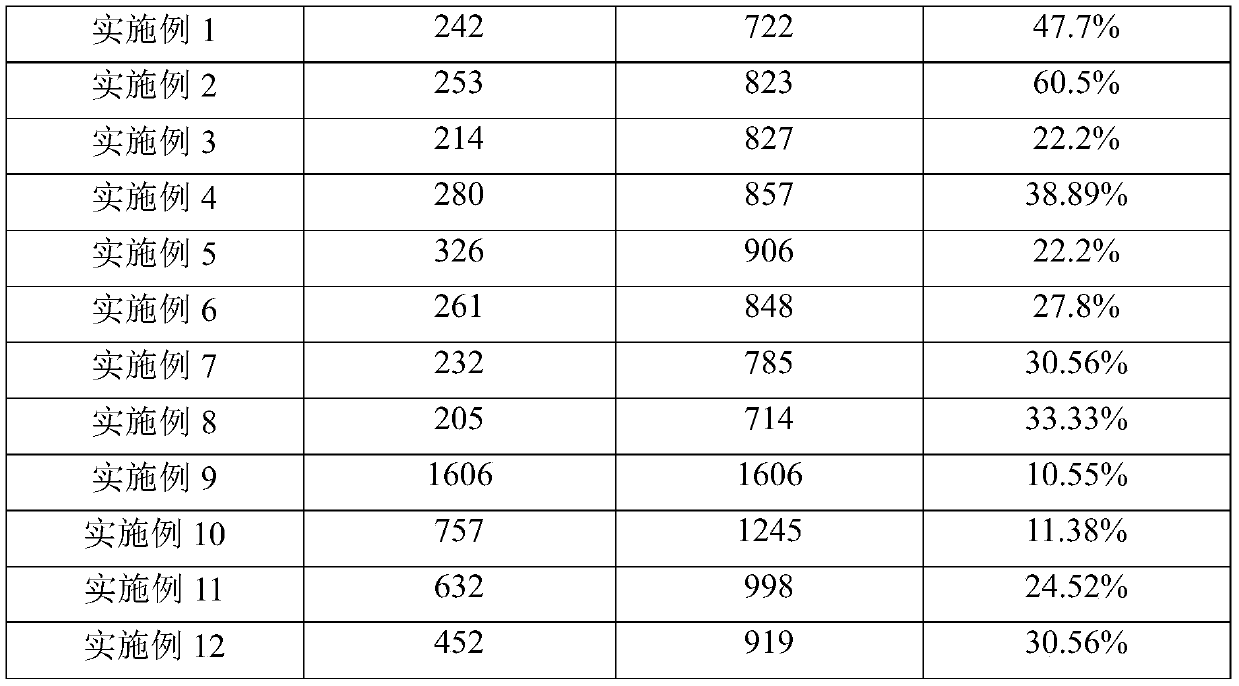

[0047] The stainless steel material specifically used in this embodiment is SUS304 austenitic stainless steel, the total number of stacked layers of TWIP steel and SUS304 stainless steel is 61, and the layer thickness ratio of stainless steel and TWIP steel is 1:1.

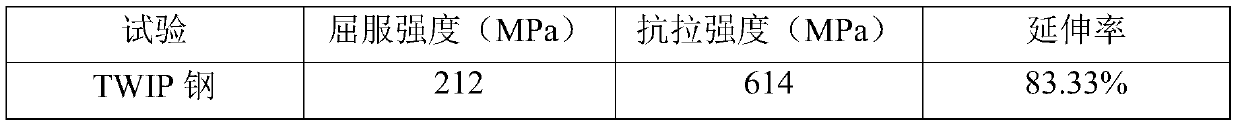

[0048] The TWIP steel involved in this embodiment is a well-known material widely used in the field. The main components are: Mn: 31.48% Si: 2.83% Al: 2.88% C: 0.0046%. The toughness of TWIP steel is very high and the elongation can reach 83.33%, but the tensile strength is relatively low and can only reach 600MPa. SUS304 austenitic stainless steel is a well-known material widely used in the field. Main components: Cr: 18.5% Ni: 8.5% Mn: 2% Si: 2% P: 0.025% S: 0.001%. It has high strength but low elongation.

[0049] The specific preparation process is:

[0050] 1: Take 31 pieces of SUS304 austenitic stainless steel and 30 pieces of TWIP steel with a thickness of 0.5mm, put them in 95% alcohol for ultrasonic cle...

Embodiment 2

[0059] On the basis of Example 1, the material was subjected to a heat treatment process, and the material was kept at 1050° C. for 6 minutes and then quenched.

[0060] The tensile test of the material yielded a yield strength of 253MPa, a tensile strength of 824MPa, and an elongation of 60.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com