Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "No difficulty increase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulfide catalyst with palladium on nitrogen doped mesoporous carbon, and application of sulfide catalyst

InactiveCN106902845AHigh activityIncreased electron cloud densityPhysical/chemical process catalystsThiol preparationPalladium catalystSulfidation

The invention discloses a sulfide catalyst with palladium on nitrogen doped mesoporous carbon, and application of the sulfide catalyst. The sulfide catalyst is prepared through the following steps: uniformly mixing mesoporous carbon with a nitrogen-containing compound to obtain nitrogen doped mesoporous carbon; enabling the obtained nitrogen doped mesoporous carbon to be made into seriflux; slowly dropwise adding a soluble palladium-containing solution according to the palladium loading capacity; performing thorough uniform stirring; adding an alkaline solution to regulate the pH value of the solution; lowering the temperature to room temperature; performing filtering to obtain a filter cake I and filter residues; performing washing until the filter residues are neutral; enabling the filter cakes I to be made into seriflux; dropwise adding a liquid-phase reduction agent; performing stirring; performing filtering to obtain a filter cake II; washing the filter cake II until the filter cake II is neutral; performing drying. Under inert atmosphere, high-temperature sulfidation is performed on the catalyst with palladium on nitrogen doped mesoporous carbon by adopting a sulphur-containing substance to obtain the sulfide catalyst with palladium on nitrogen doped mesoporous carbon. The sulfide catalyst with palladium on nitrogen doped mesoporous carbon, which is disclosed by the invention, is used for synthesizing sulfo-arylamine through catalytic hydrogenation.

Owner:ZHEJIANG UNIV OF TECH

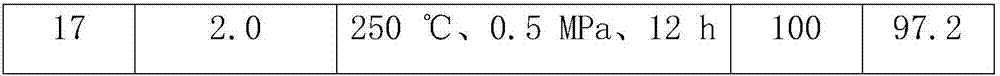

Method for recycling sludge of sewage plant to produce cement

InactiveCN101376573AQuality assuranceAvoid it happening againSludge treatmentCement productionChemical LinkageClay minerals

The invention relates to a method which is used for directly applying the settled sludge of a wastewater treatment plant to the cement production after treatments of iron removing, sterilization and deodorization, dehydration and drying. The method comprises the following steps: firstly, the iron of the sludge is removed; secondly, the sludge is sterilized and deodorized; thirdly, the sludge is dehydrated and dried; fourthly, the mixture amount of the sludge is determined; fifthly, the sludge enters a kiln system for calcining; and sixthly, the clinker obtained by the incineration and gypsum are mixed and made into cement by a cement grinding mill. The method adopting the invention has the following advantages: firstly, the resource utilization of the sludge is realized, a large amount of clay mineral is economized, and the precious land resource is saved; secondly, the abundant heat value of the sludge can be effectively utilized, and the coal resource can be economized; thirdly, the harmless treatment is carried out to the sludge at the temperature higher than 1450 DEG C, both the organic matters and the inorganic matters in the municipal sludge can be cracked and calcined into harmless matters, and the possibilities of producing poisonous gases and waste residues are avoided during the low temperature treating process; fourthly, the heavy metals in the municipal sludge are dissolved in the portland cement clinker minerals in a solid way, and are tightly combined with the cement ingredients by chemical bonds, and the heavy metal pollution phenomenon cannot happen under the usual conditions; and fifthly, the mixed and burnt sludge does not increase the clinker calcination difficulty and does not reduce the cement strength, but also has a certain mineralization promoting effect on the cement clinker calcination to a certain extent.

Owner:ZHENGZHOU UNIV

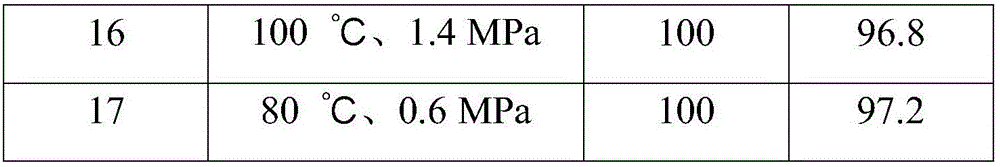

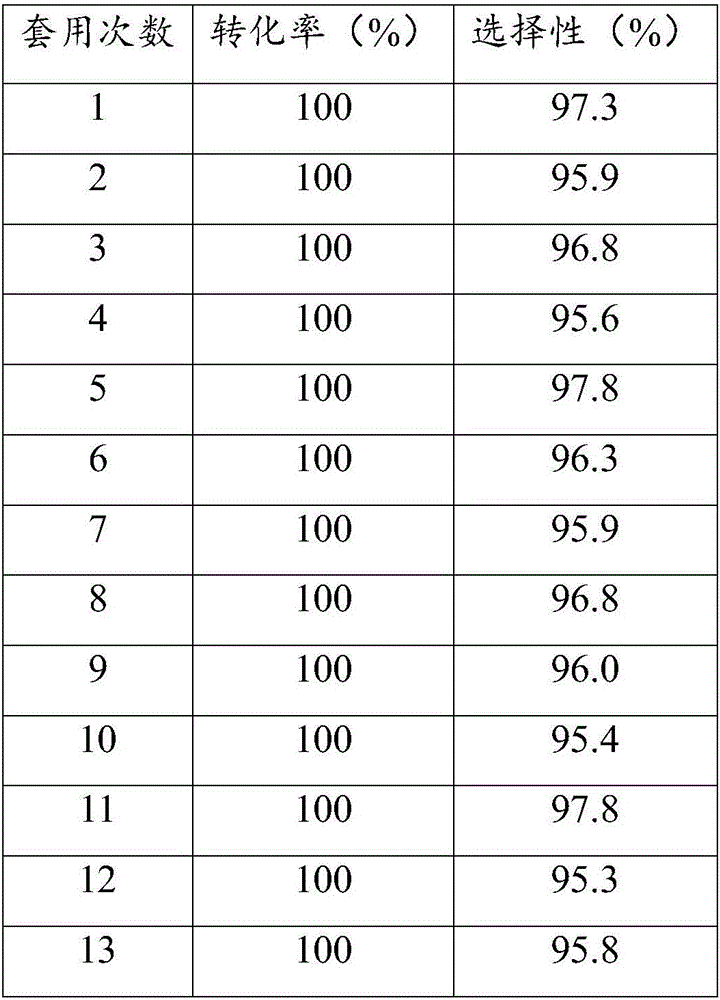

Synthetic method of N,N'-dibenzyl-1,2-ethanediamine

ActiveCN106748813AHigh selectivityAvoid PolymerizationOrganic compound preparationAmino compound preparationHydrogenation reactionBenzyl-EDTA

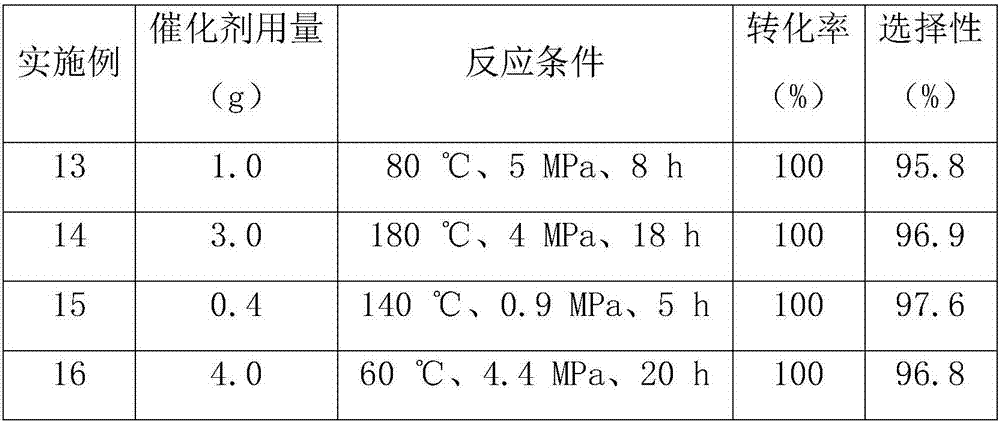

The invention discloses a synthetic method of N,N'-dibenzyl-1,2-ethanediamine. The synthetic method comprises the following components: in a reaction vessel, a liquid phase catalytic hydrogenation reaction is carried out for N,N'-dibenzylidene-1,2-ethanediamine in the effects of a nitrogen doped meso pore carbon loaded precious metal catalyst in order to prepare and obtain N,N'-dibenzyl-1,2-ethanediamine. In the nitrogen doped meso pore carbon loaded precious metal catalyst, the precious metal is Pd or Pt, and the load capacity of the precious metal is 1-10wt%. The synthetic method has the advantage of high selectivity of target products.

Owner:ZHEJIANG UNIV OF TECH

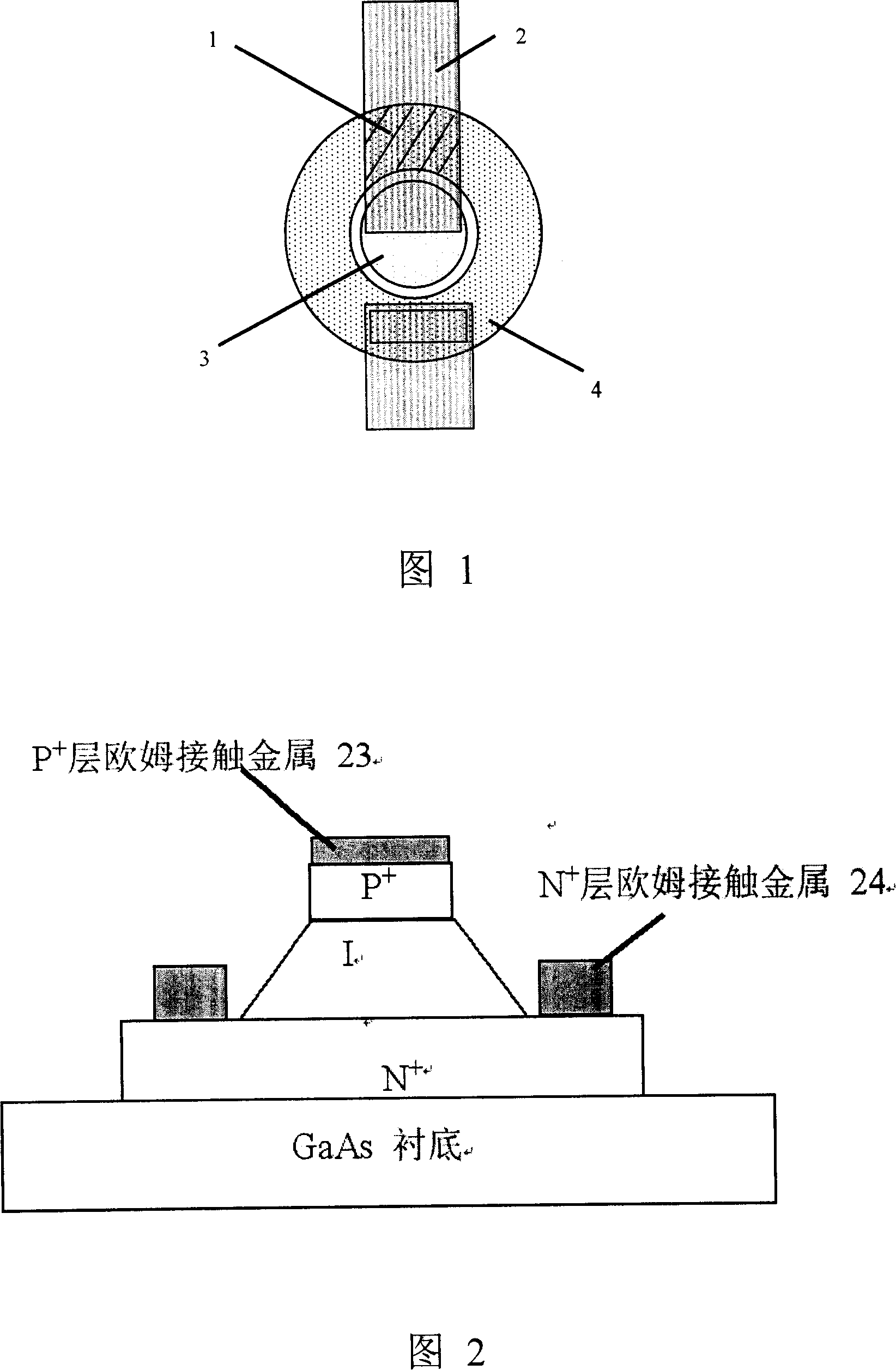

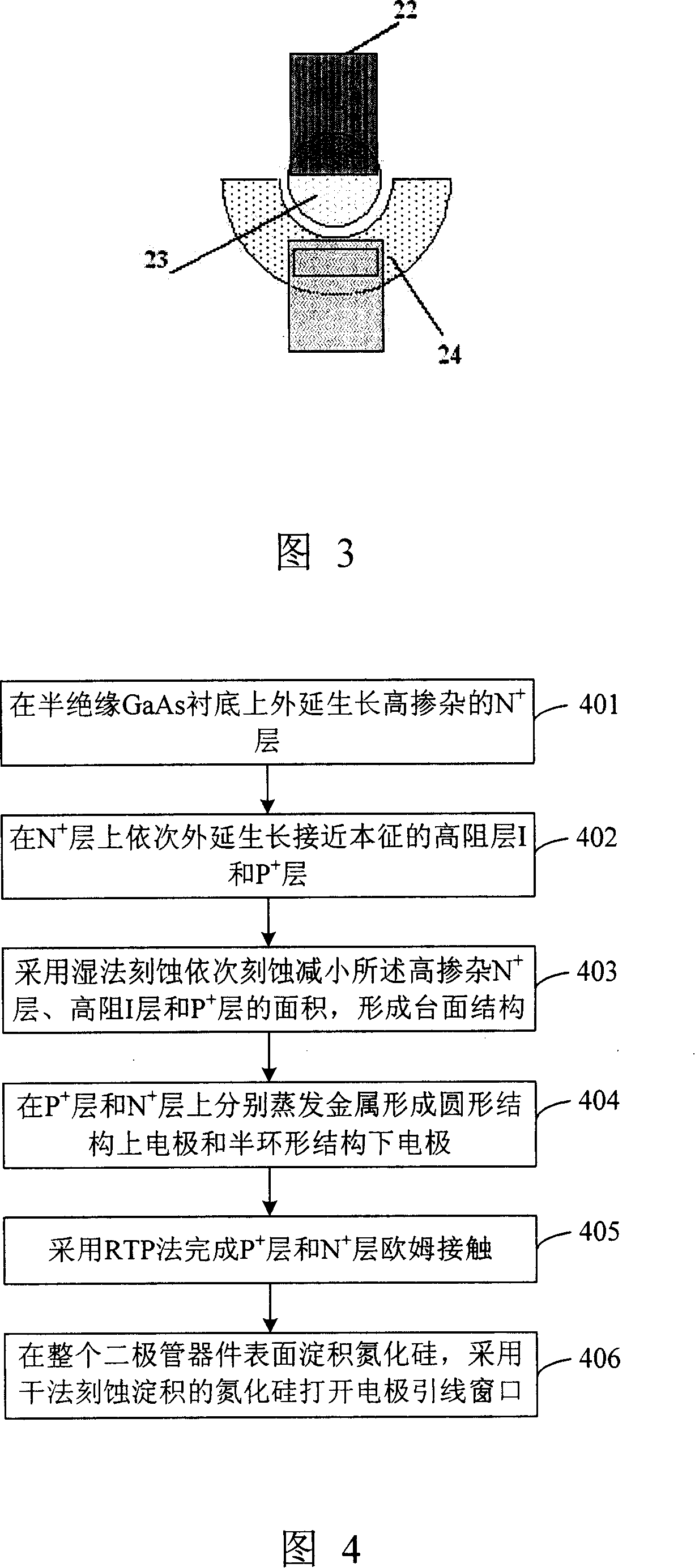

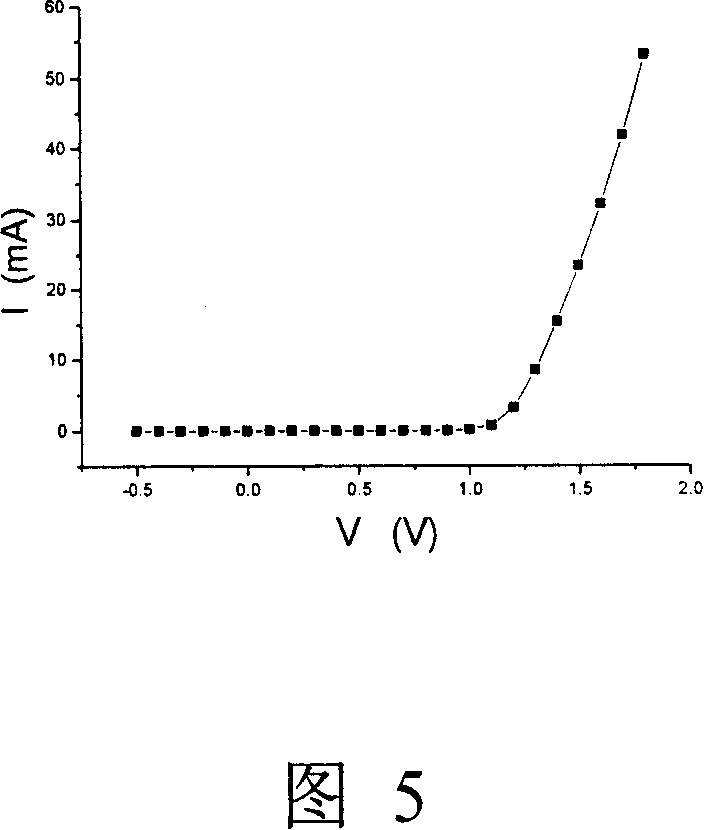

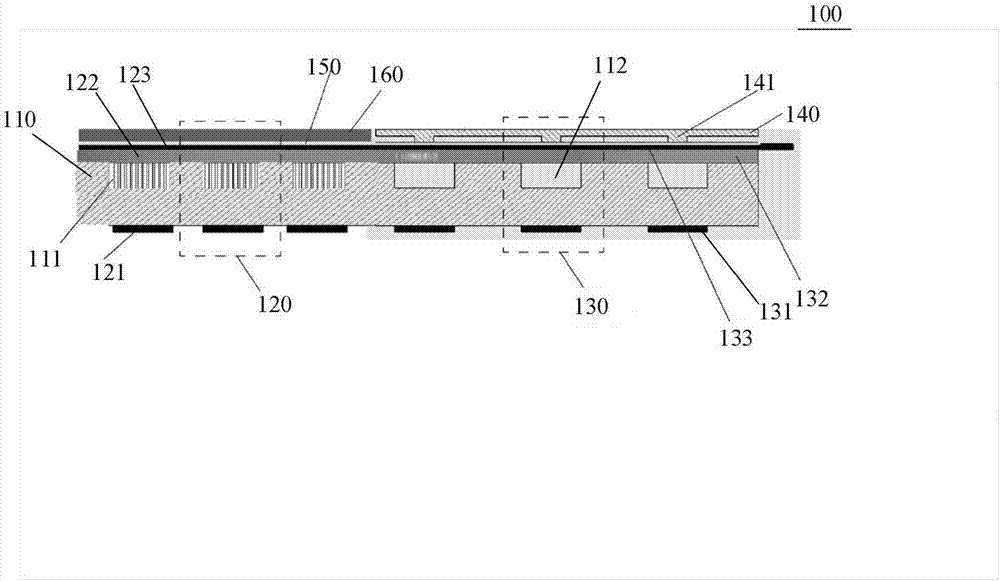

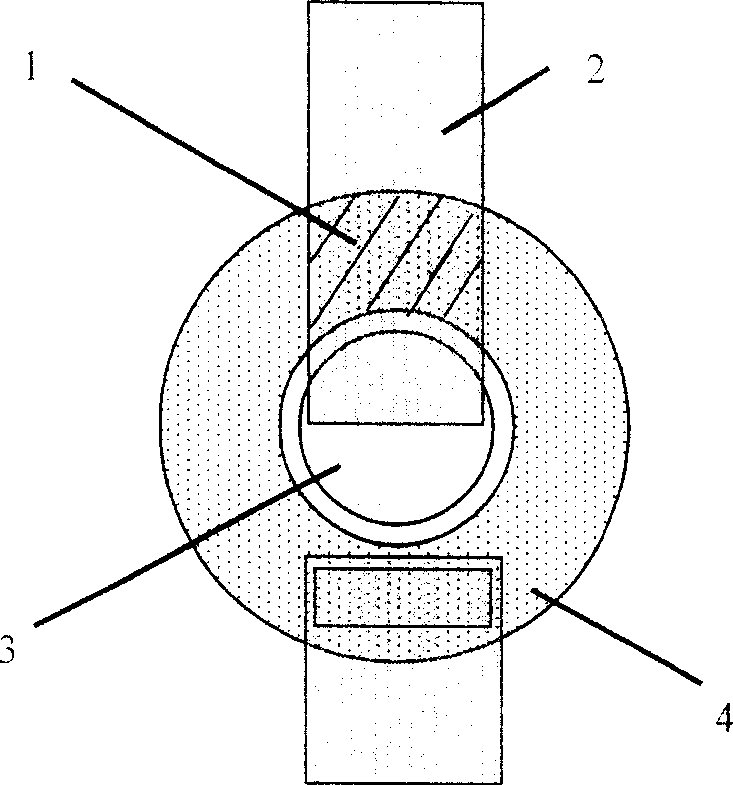

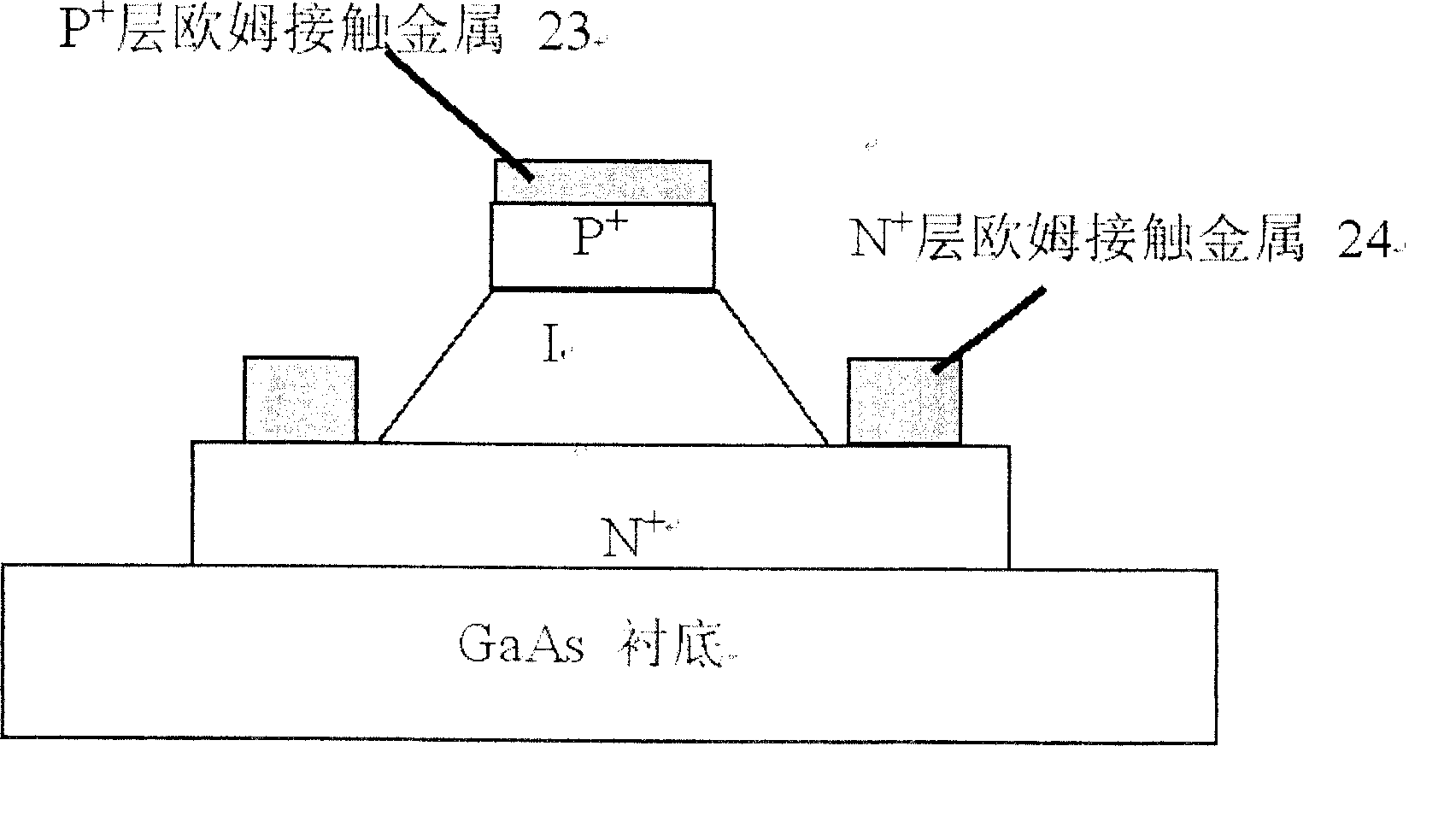

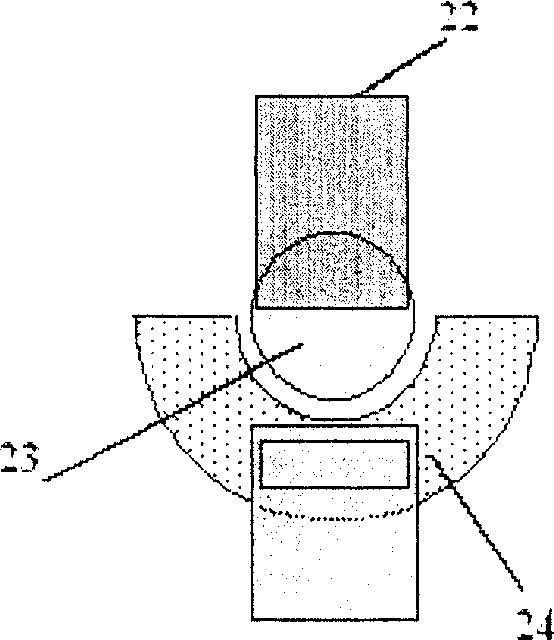

Gallium arsenide PIN diode and preparation method thereof

ActiveCN101140955AReduce parasitic capacitanceRealize the process is simpleSemiconductor/solid-state device manufacturingSemiconductor devicesMaterials scienceAir bridge

The invention discloses a GaAs PIN diode, which comprises: a semi-insulating GaAs underlay for supporting the whole GaAs diode; a high doped layer N growing in extension on the semi-insulating GaAs underlay, resistive formations I and P close to eigen growing in extension in turn on the high doped layer N; By wet process and etching, the areas of the said high doped layer N, resistive formations I and P reduced in turn to form a mesa structure; a top electrode of the round structure formed by metal evaporator on layer P; a semi-orbicular bottom electrode formed by metal evaporator on layer N. The invention also discloses a manufacturing method of GaAs PIN diode. The invention efficiently lowers the parasitic capacitance of the PIN diode without increasing the difficulty of the process and simultaneously greatly shortens the microstrip line connected with the top electrode. The spurious inductance brought by the invention can be greatly reduced or even omitted without using the air-bridge process. The invention has the advantages of easy making, better high frequency characteristic, which is easy to realize the single scale integration.

Owner:北京中科微投资管理有限责任公司

Device and method for compacting/consolidating a part made of a composite material having a thermoplastic matrix reinforced by continuous fibers, in particular fibers of natural origin

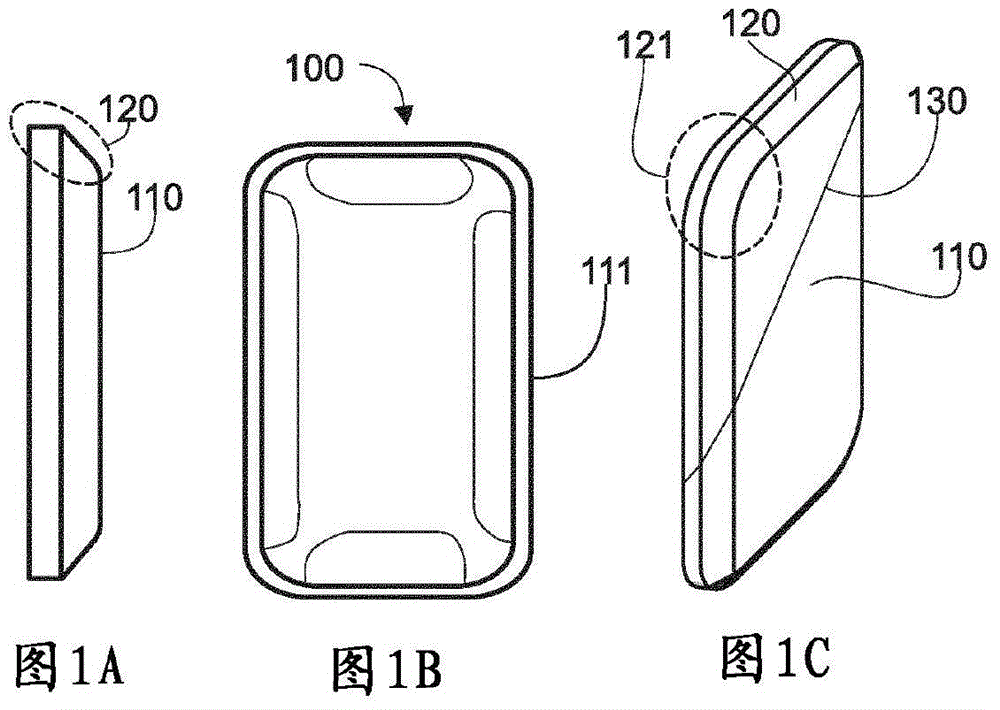

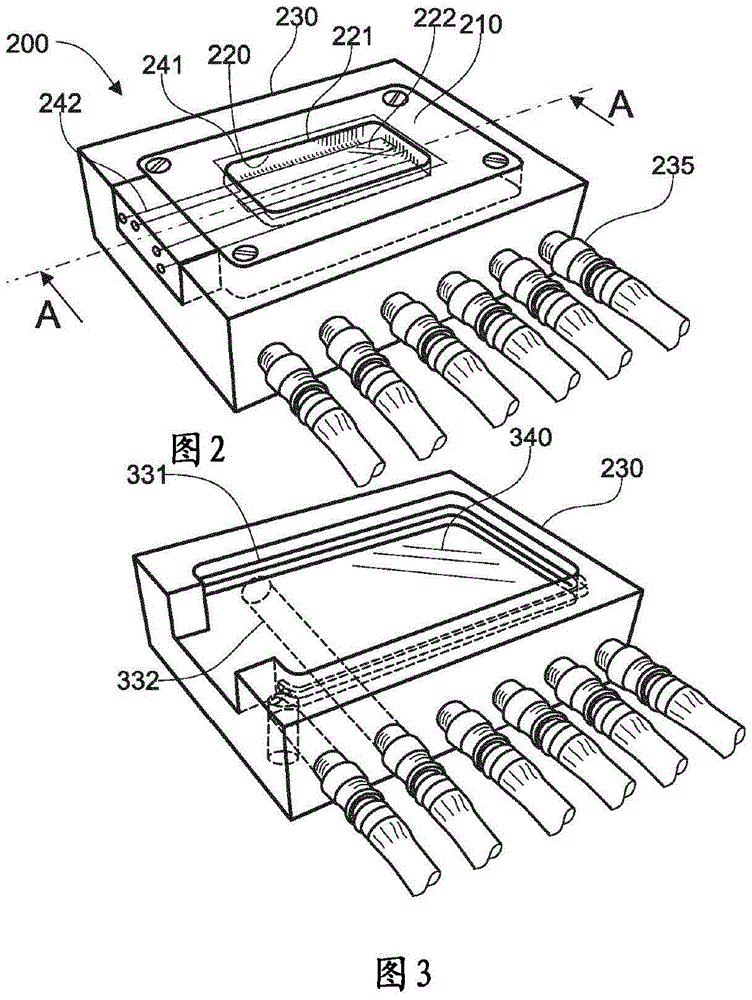

ActiveCN103459130AGuaranteed pressureGuaranteed to be inDomestic articlesTelephone set constructionsInductorThermoplastic matrix

The invention relates to a device for forming and consolidating a textile preform (600) comprising continuous fibers impregnated with a thermoplastic resin, characterized in that it includes: i) a die (200) including a former (210) comprising a cavity (220) corresponding to the shape of the part, the depth of said former extending between an inlet plane and a bottom, and said former being inserted into a mold base (230); ii) means (241, 242) for the induction-heating of the former (210), including two inductors which extend into recesses of the former (210), and each of which forms a turn in a plane substantially parallel to the inlet plane of the cavity (220) and located between said inlet plane and the bottom of the former; and iii) a means (235) for cooling the die.

Owner:ROCTOOL SAS

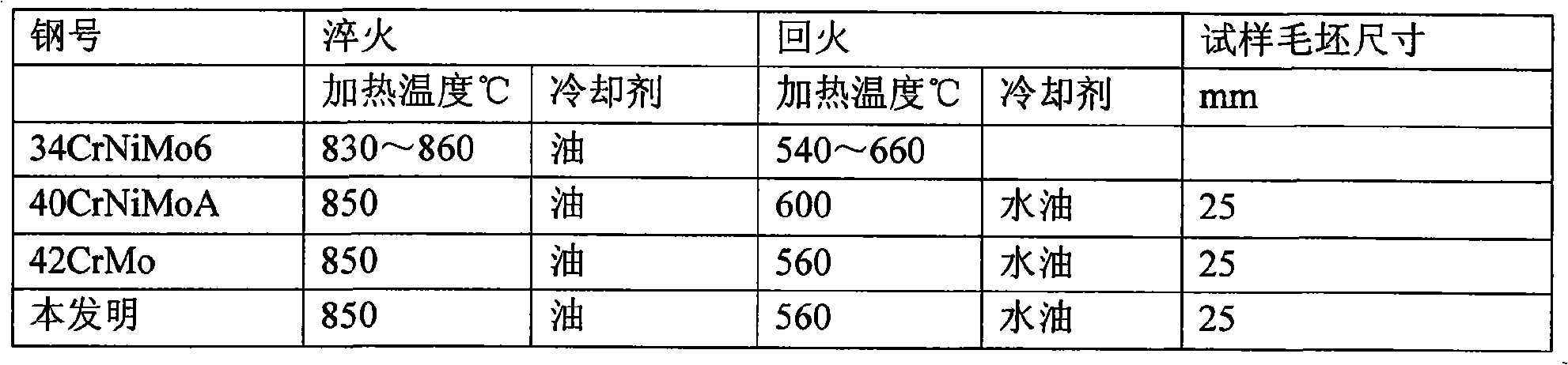

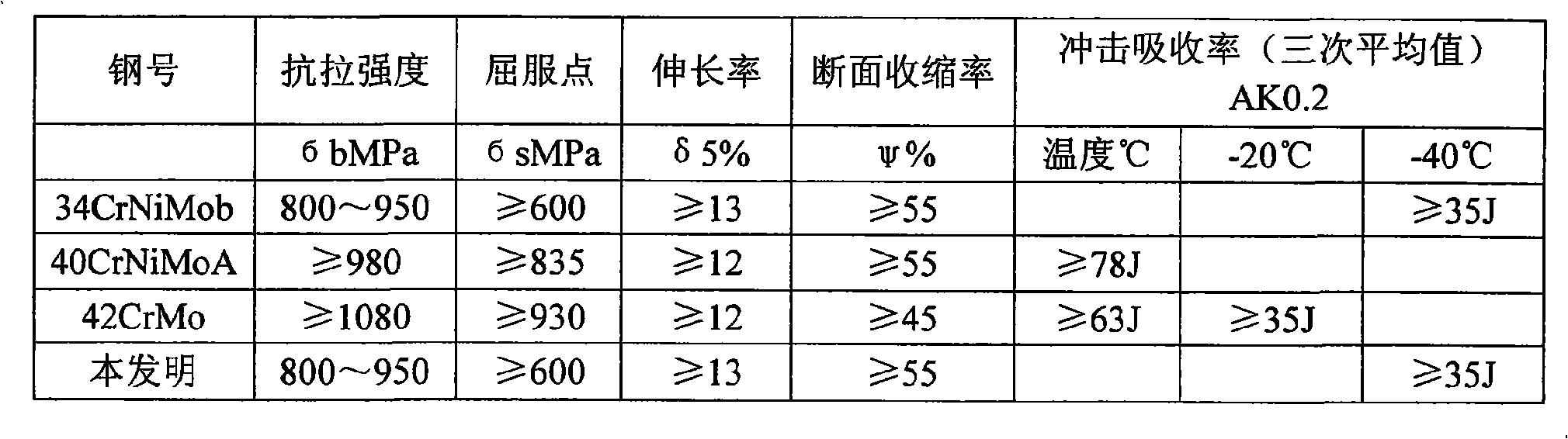

Alloy constructional steel for large-scale wind power principal axis

InactiveCN101294261AImprove low temperature impact toughnessImprove impact toughnessChemical compositionMechanical property

The invention relates to structural alloy steel used on a large-scale wind-power main shaft. The structural alloy steel mainly comprises the chemical compositions by weight percentage as follows: C is 0.38 to 0.45 percent, Si is 0.17 to 0.37 percent, Mn is 0.50 to 0.80 percent, Cr is 0.90 to 1.20 percent, Ni is 0.30 percent, Mo is 0.15 to 0.25 percent, P is less than or equals to 0.035 percent, S is less than or equals to 0.035 percent, and other weight percentage is composed of Fe and ineluctable impurities. Ni alloying element, which is used for improving the low-temperature impact property of the steel and is 0.30 percent, is added in 42CrMo structural alloy steel, so that the special requirement of ultralow temperature (that is lower than minus 40 DEG C) performance of the wind-power main shaft can be satisfied on the premise that the mechanical property of the 42CrMo structural alloy steel is not changed.

Owner:JIANGYIN LEGAO ENERGY EQUIP

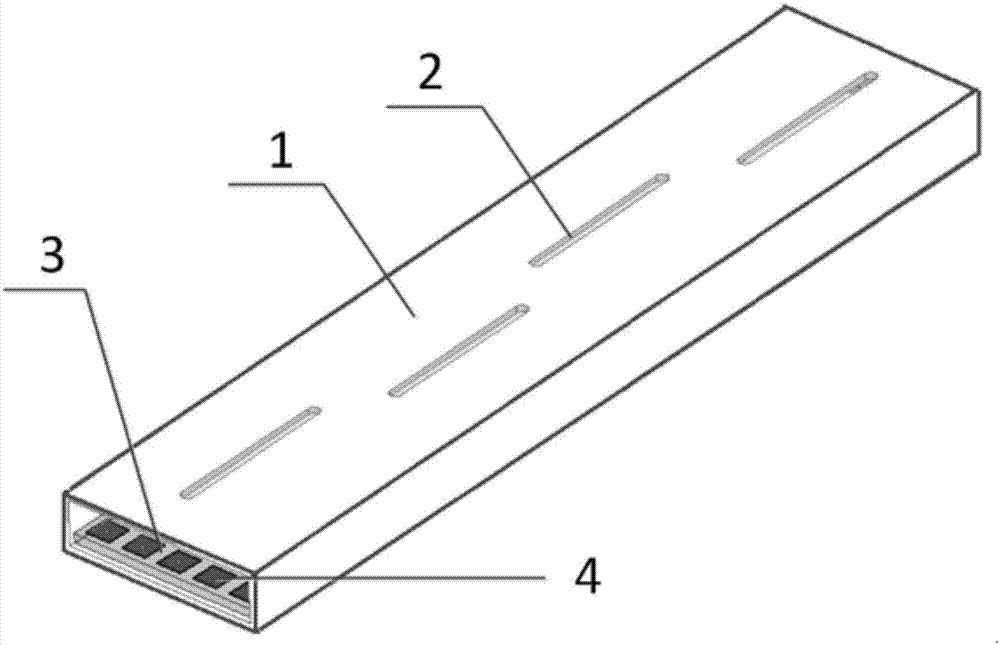

High-resistance surface metamaterial waveguide slot antenna

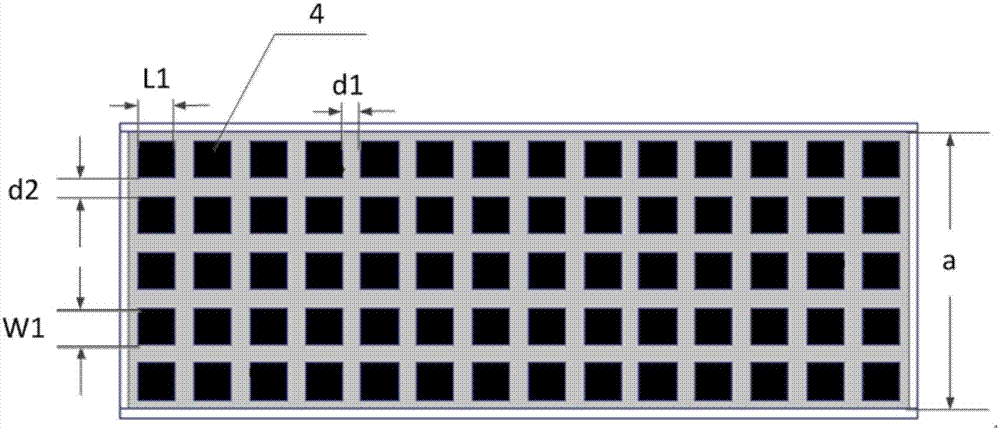

ActiveCN107317116AEMI suppressionNo difficulty increaseAntennas earthing switches associationSlot antennasHigh resistanceLow frequency band

The invention discloses a high-resistance surface metamaterial waveguide slot antenna. The metamaterial waveguide slot antenna comprises a metamaterial waveguide tube and a radiation gap, wherein the metamaterial waveguide tube comprises a metal waveguide tube and a dielectric plate, the metal waveguide tube is a through tube with a rectangular cross section, the radiation gap is arranged in an upper surface of the metal waveguide tube, one end of the metal waveguide tube is opened and is used as a signal input port, the other end of the metal waveguide tube is closed and is in a short-circuit state, the dielectric plate is arranged on a wide edge of a lower part of an inner wall of the metal waveguide tube along a length direction, a periodic pattern is etched on a surface of the dielectric plate. By the antenna, low-loss radiation can be achieved in a working frequency band, and the antenna is high in efficiency; and by the antenna, dual-band suppression outside the working frequency band can be achieved, the characteristic of the antenna is equivalent to that of a high-pass filter when electromagnetic interference of a low frequency band is suppressed, and the characteristic of the antenna is equivalent to that of a band rejection filter when electromagnetic interference of a high frequency band is suppressed.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

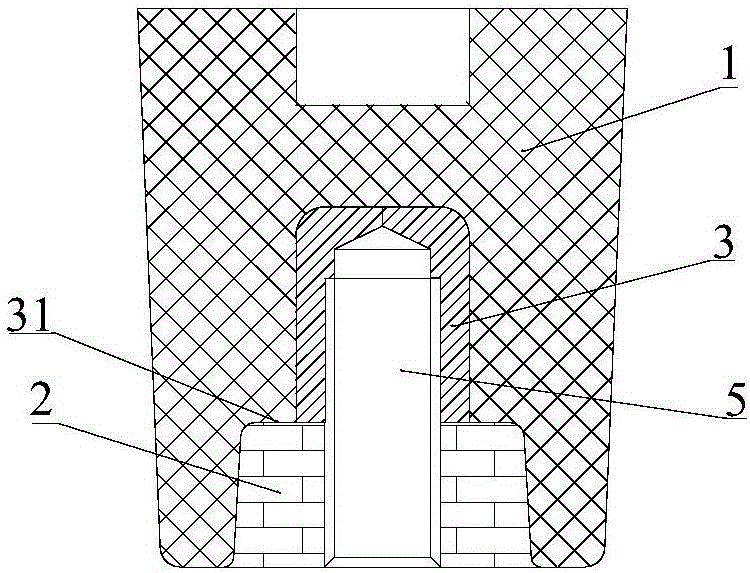

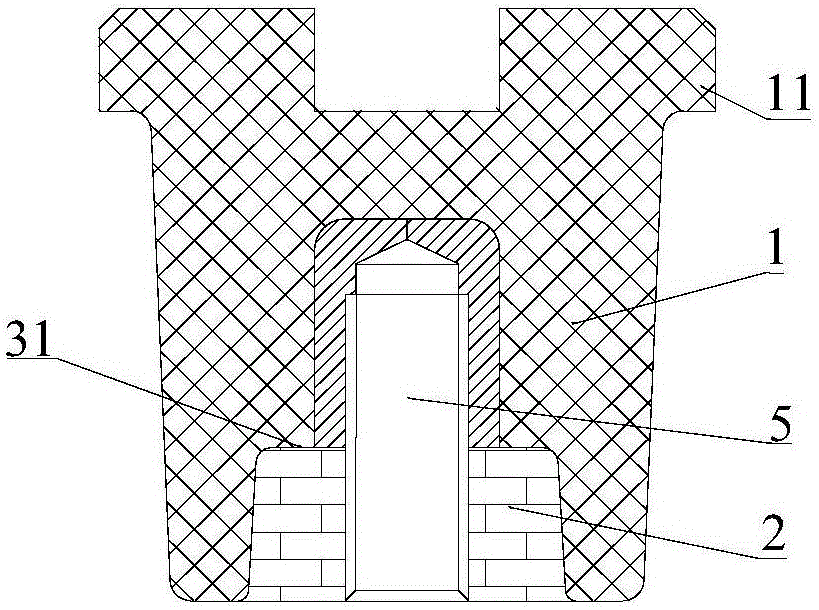

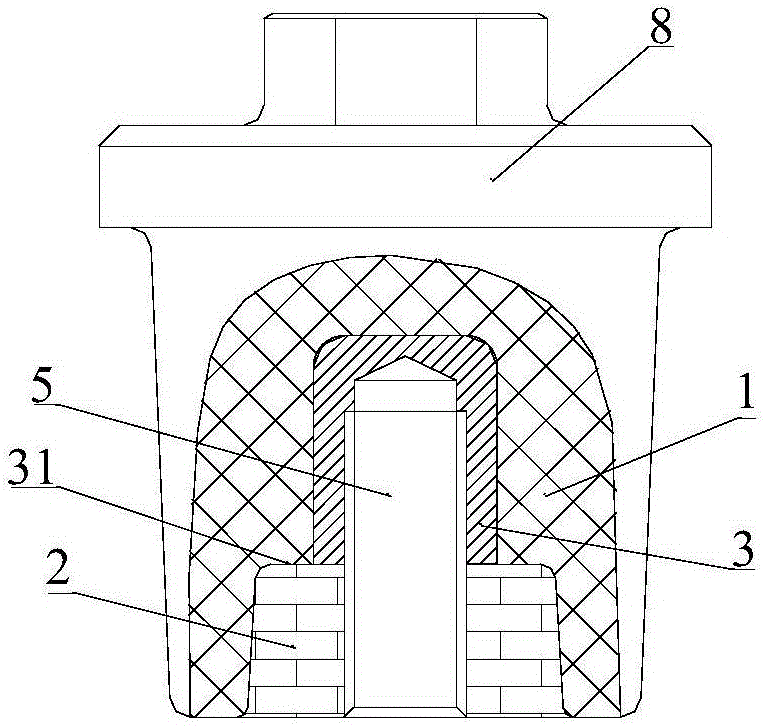

Temperature measurement device of cable joint and cable joint

PendingCN106595899ATemperature reflexEasy to fixCoupling device detailsThermometers using physical/chemical changesElectricityRadio frequency

The present invention relates to a temperature measurement device of a cable joint and a cable joint. The temperature measurement device comprises a rear plugging cover and a temperature measurement sensing device; a metal insert is embedded into one end of the rear plugging cover; the wiring terminal of the cable joint is fixedly connected with the metal insert; the temperature measurement sensing device is crimped between the wiring terminal and the metal insert; and the temperature measurement sensing device is an SAW temperature sensor or a radio frequency identification sensor or a radio frequency sensor which obtains electricity through an electric field. According to the temperature measurement device of the cable joint of the invention, the temperature measurement sensing device directly contacts with a heat emitting point in the cable joint, so that the temperature of a cable connection point in the cable joint can be reflected effectively and authentically.

Owner:廊坊芳远新合电气股份有限公司 +1

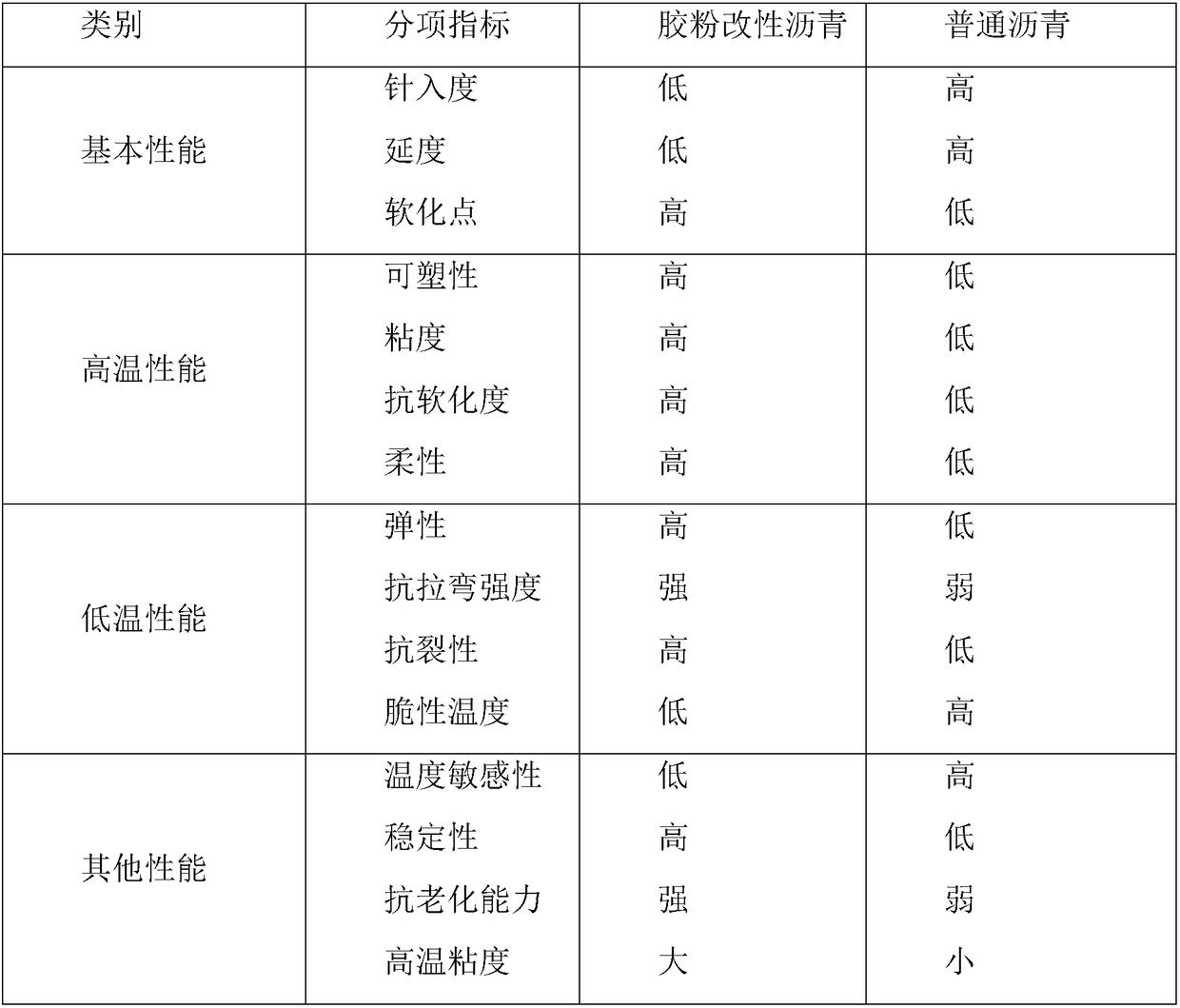

Production process for rubber powder modified asphalt

The invention discloses a production process for rubber powder modified asphalt, and relates to asphalt roads. The invention is to solve the following problems in the prior art: rubber powder enablesa cementing material to be thickened at a high temperature; a mixed material has small thickness; an aggregate material in the mixed material is coarse; a stone material is difficult to be compacted due to direct contact; and constructed pavements easily generate distresses like loosening and potholes. The production process comprises the following steps: step 1, selecting the rubber powder, wherein rubber powder particles with a particle size of 60 to 100 meshes and a desulfurization content of 60% are selected; step 2, selecting a dispersant; step 3, selecting an additive, wherein the additive is prepared from dithioether alcohol, butyl octyl salt, AEO3, barium sulfate and AEO9 according to a weight ratio of 30: 20: 30: 10: 10; and step 4, heating matrix asphalt, adding the rubber powder, a matrix asphalt modifier, the dispersant and the additive, carrying out swelling under stirring for 120 minutes, pumping an obtained material into a colloid mill, carrying out grinding, beating theground material into a reaction tank, carrying out stirring at a low speed, and adding a stabilizer. The process provided by the technical scheme of the invention can maintain a viscosity at a high temperature.

Owner:QINGHAI HONGCHUAN XINYUAN INDAL

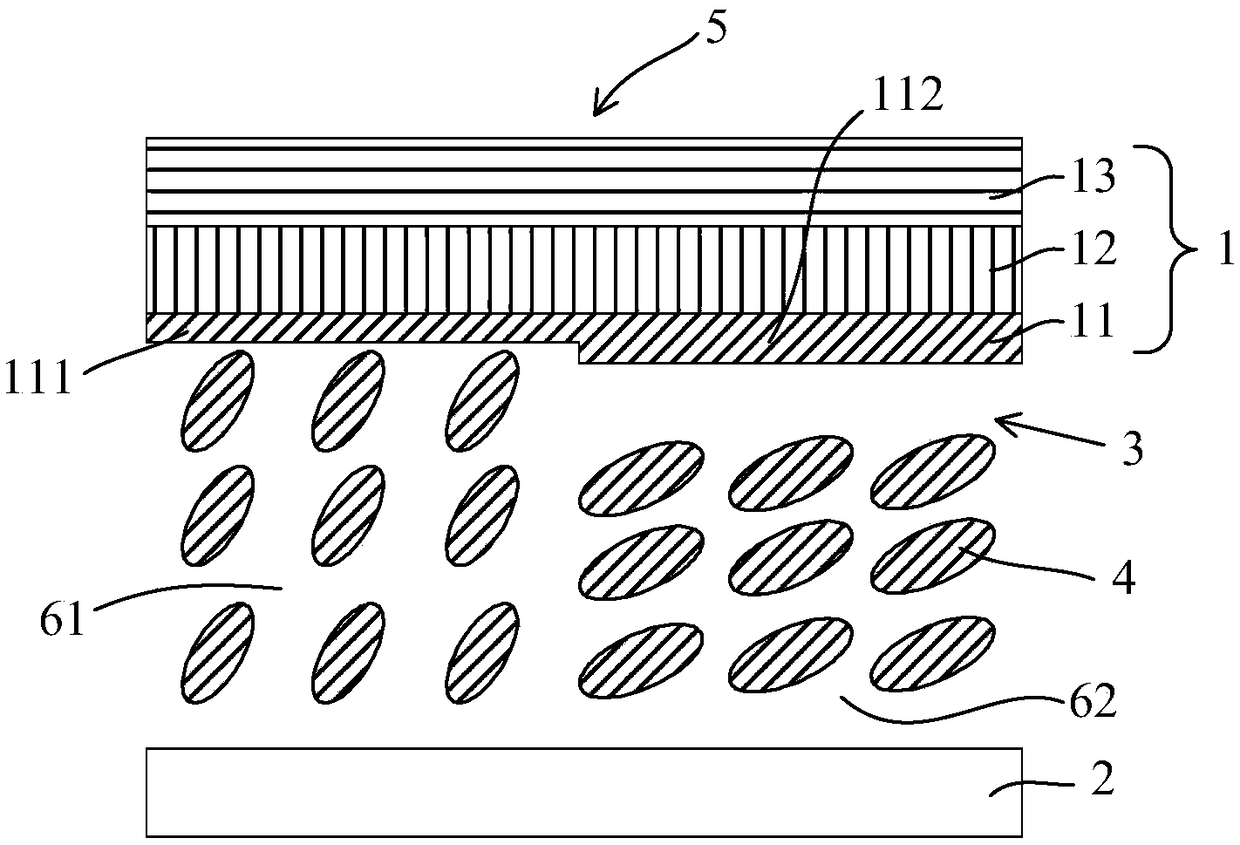

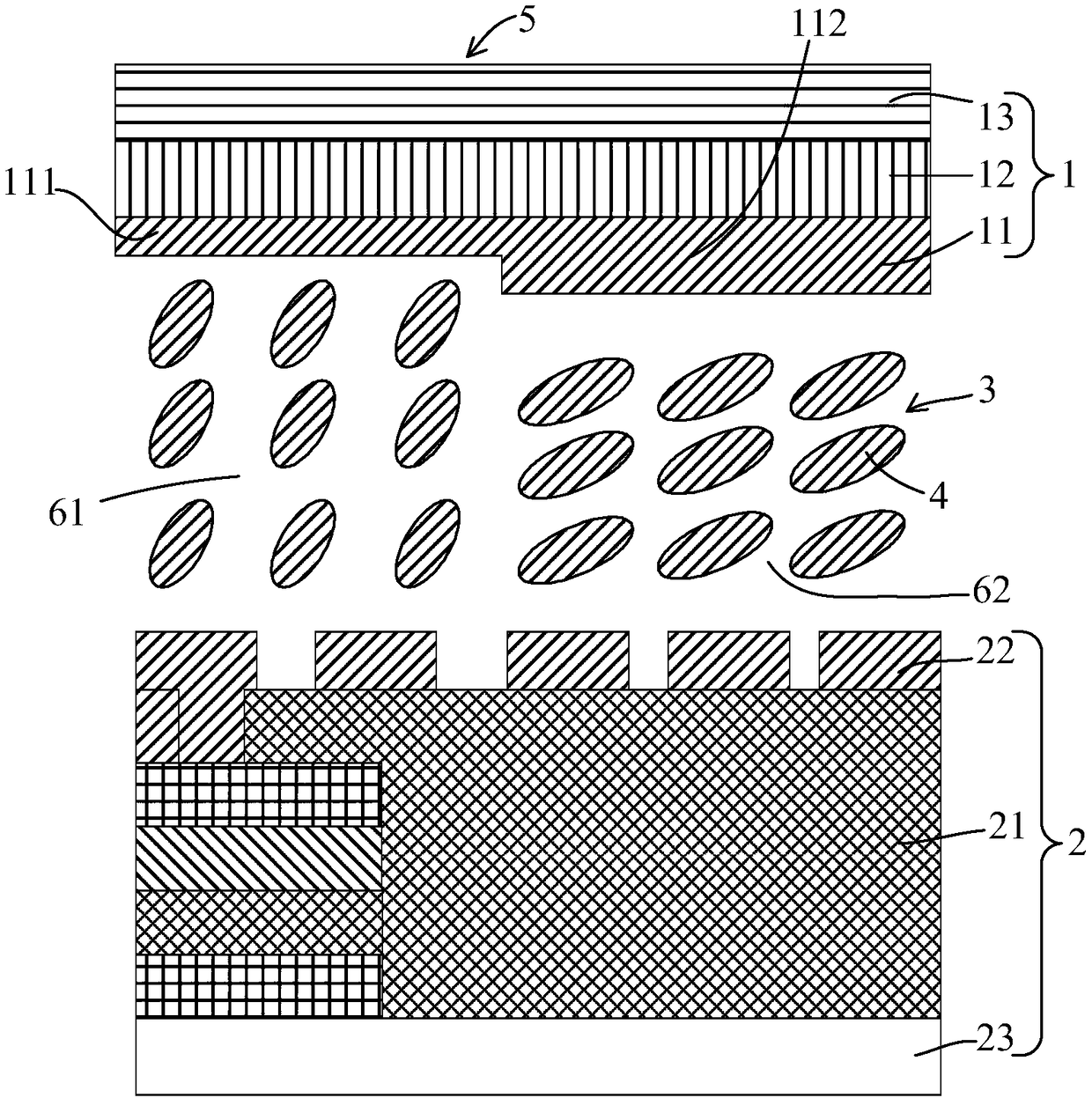

Display panel and display device

InactiveCN109343266AImprove satisfactionImprove the problem of big screen role deviationNon-linear opticsLiquid-crystal displayColor film

The invention discloses a display panel and a display device, wherein the display panel comprises a color film substrate and an array substrate arranged opposite to the color film substrate. A gap isformed between the color film substrate and the array substrate, the gap is filled with liquid crystal, the color film substrate defines a plurality of pixel areas, the color film substrate comprisesa transparent photoresist, the transparent photoresist is provided with a first photoresist layer and second photoresist layer corresponding to each pixel area, the first photoresist layer and the second photoresist layer divide the pixel areas into a first domain area and a second domain area, and the gap in the first domain area is larger than the gap in the second domain area. According to theinvention, liquid crystal gaps of different domain areas are formed in each pixel area through different photoresist layer thicknesses, so that the problem of large visual color cast is solved.

Owner:HUIZHOU CHINA STAR OPTOELECTRONICS TECHNOLOGY CO LTD

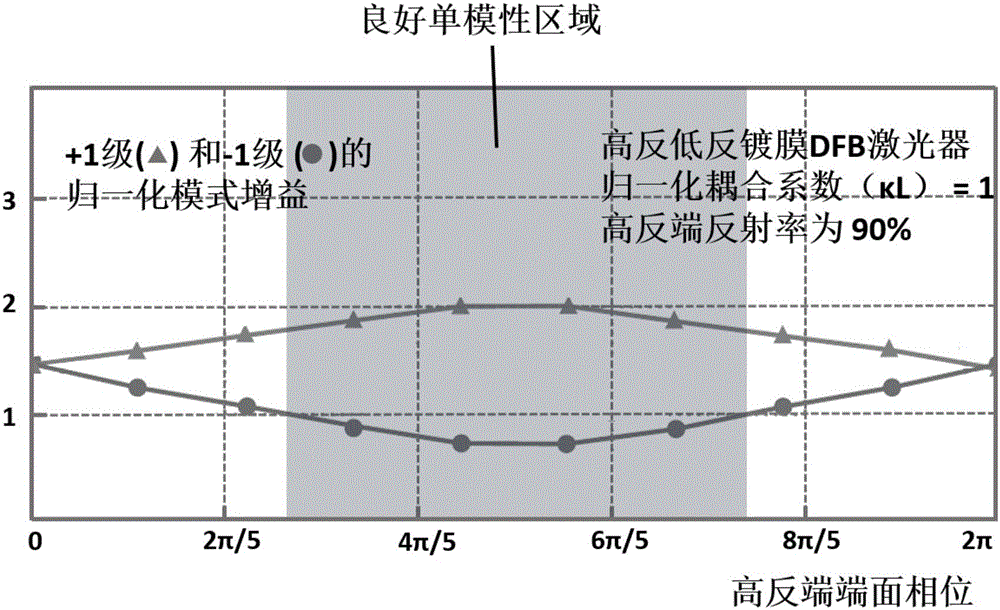

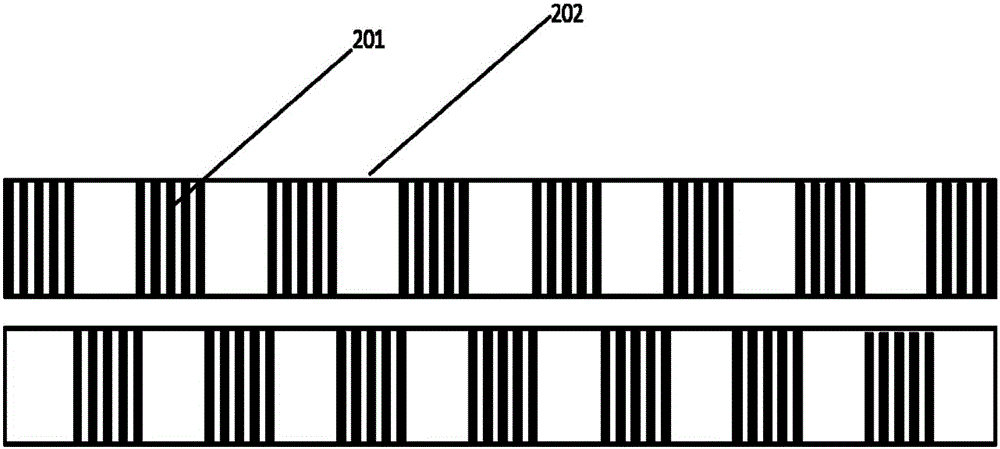

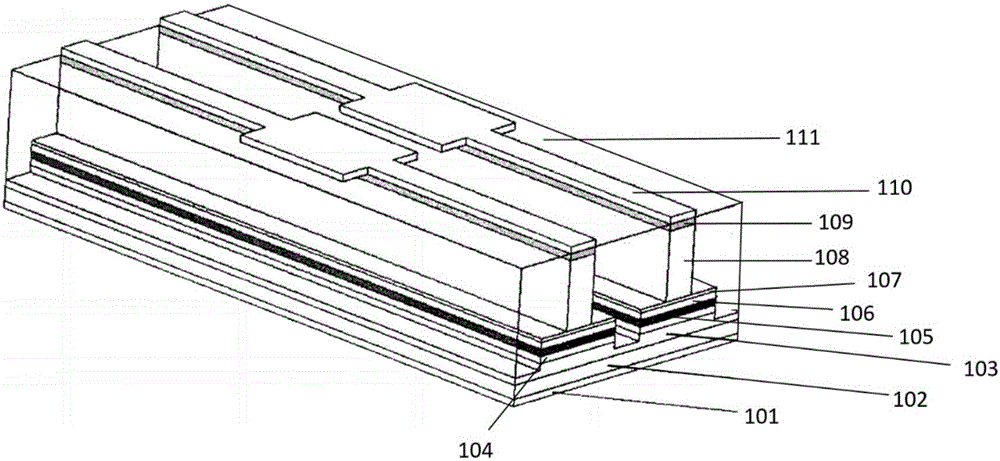

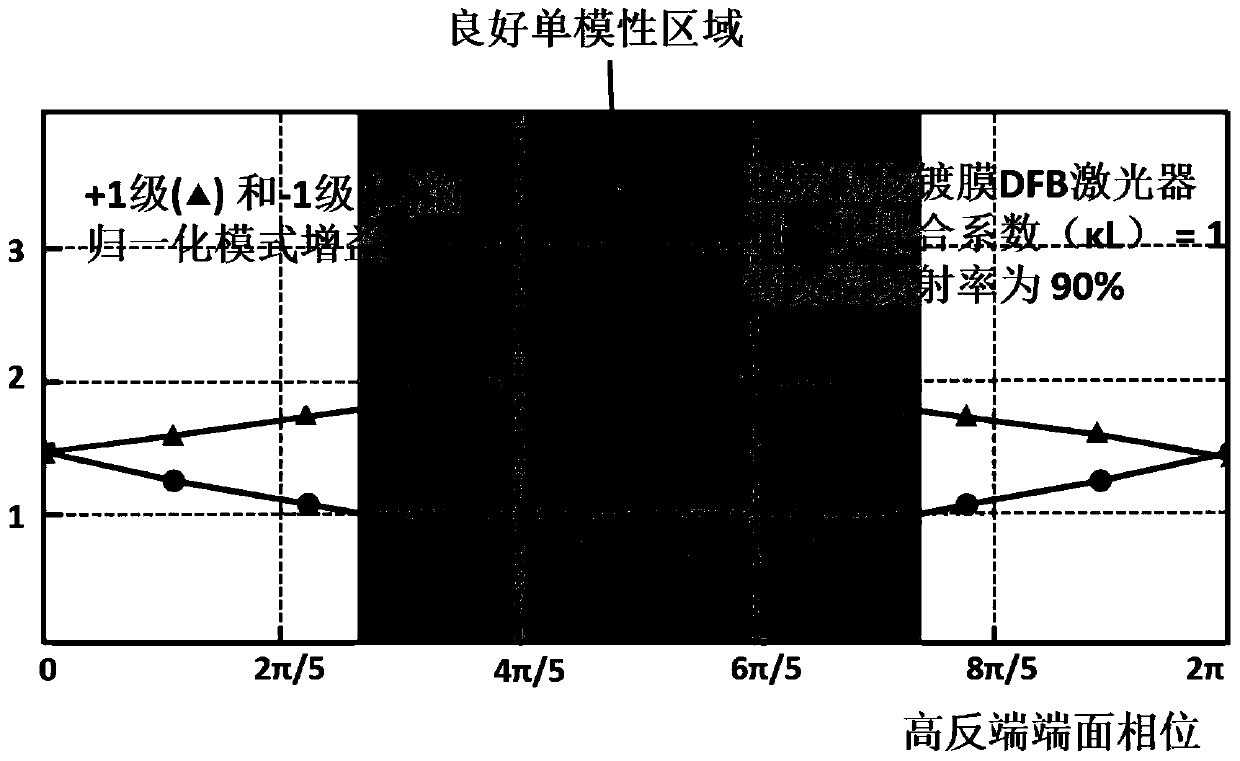

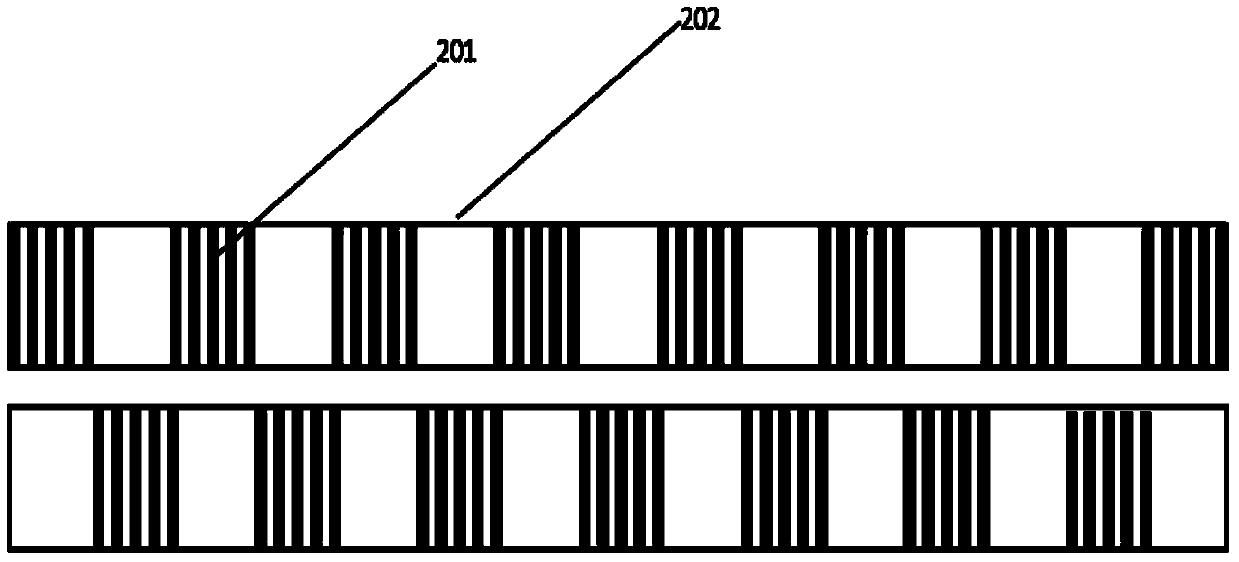

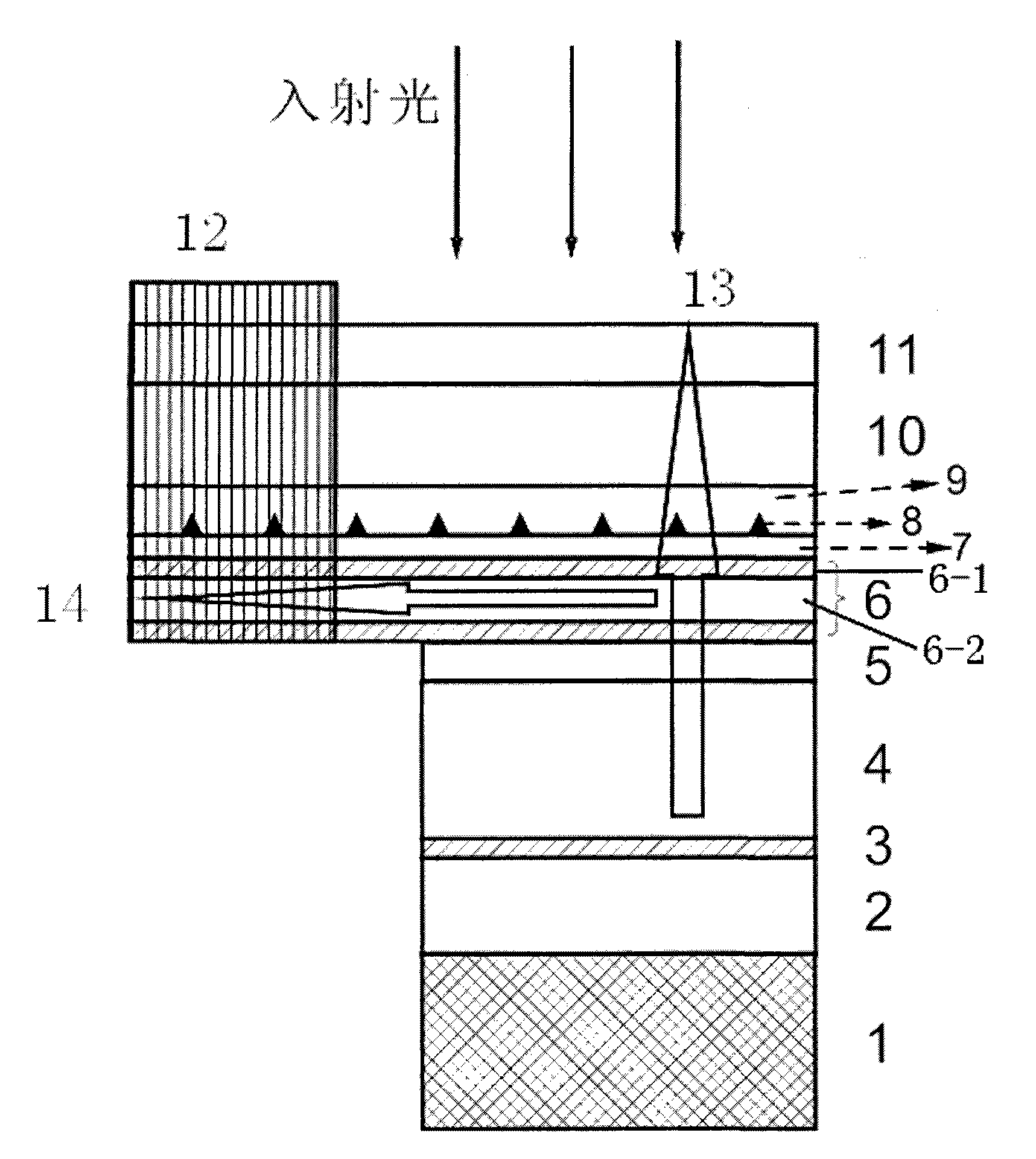

Backup type semiconductor laser based on reconstructing-equivalent chirp technology

ActiveCN105140779AEliminate the problem of low single-mode yieldIncreased single-mode yieldLaser optical resonator constructionSemiconductor laser arrangementsPhase shiftedGrating

The invention discloses a backup type semiconductor laser based on a reconstructing-equivalent chirp technology, wherein the backup type laser comprises two parallel semiconductor DFB lasers; the semiconductor DFB lasers are distributed parallelly and the interval distance is within the range of 15 micrometer to 50 micrometer; each of the leasers is utilized to add equivalent phase shift to a sampling bragg grating structure based on the reconstructing-equivalent chirp technology; and a lasing channel used by each of the lasers is provided by plus 1 level sub-grating or minus 1 level sub-grating of the sampling bragg grating. By adopting the laser provided herein, one laser of the two parallel lasers must be in the single model working state, thus eliminating the problem of low yield of high reflection-low reflection coated laser single models on the basis of not adding technology cost.

Owner:NANJING UNIV

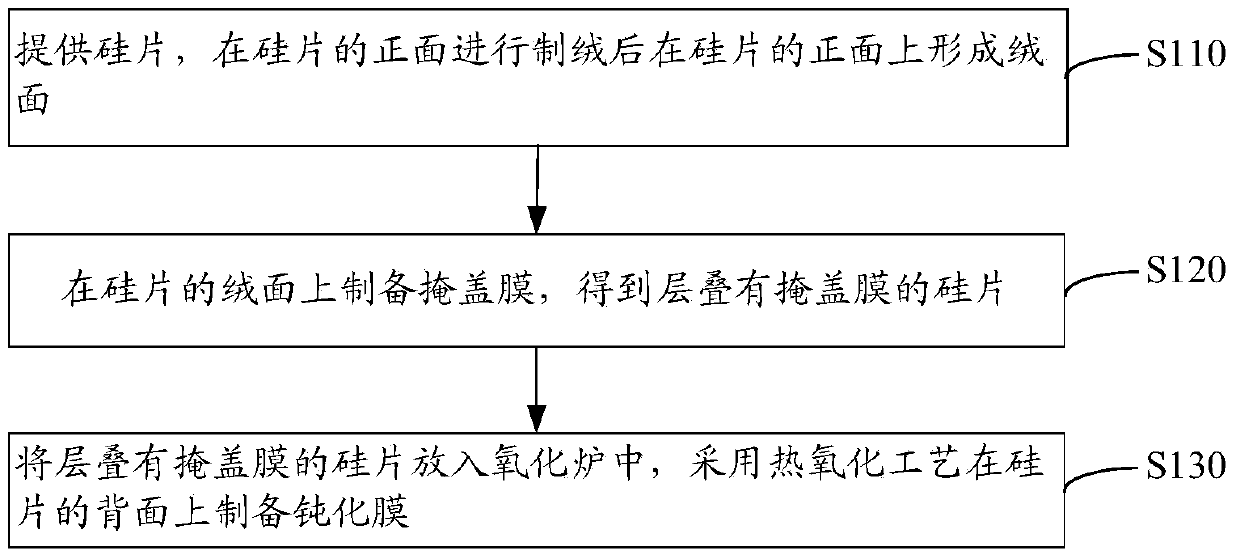

Back passivating method and preparation method of crystalline silicon solar cell

InactiveCN103746039ADoes not affect the frontNo difficulty increaseFinal product manufacturePhotovoltaic energy generationCrystalline siliconSilicon chip

The invention relates to a back passivating method and a preparation method of a crystalline silicon solar cell. The back passivating method of the crystalline silicon solar cell comprises the steps of providing a silicon chip, and forming a suede surface on the front surface of the silicon chip after sueding the front surface of the silicon chip; preparing a covering film on the suede surface of the silicon chip, and obtaining the silicon chip which is laminated with the covering film; putting the silicon chip which is laminated with the covering film in an oxidation furnace, and preparing a passivating film on the back surface of the silicon chip by adopting a thermal oxidation technology. According to the back passivating method of the crystalline silicon solar cell, disclosed by the invention, the covering film physical property of the covering film is utilized, and the passivating film is prepared on the back surface of the silicon chip by adopting the thermal oxidation technology; the advantages of a deposition method and the thermal oxidation technology are integrated, the front surface of the silicon chip can not be influenced by a growing process of the passivating film on the back surface of the silicon chip, the difficulty of a back passivating technology is not increased, the technology is simpler, and the passivating effect is good.

Owner:CSG PVTECH

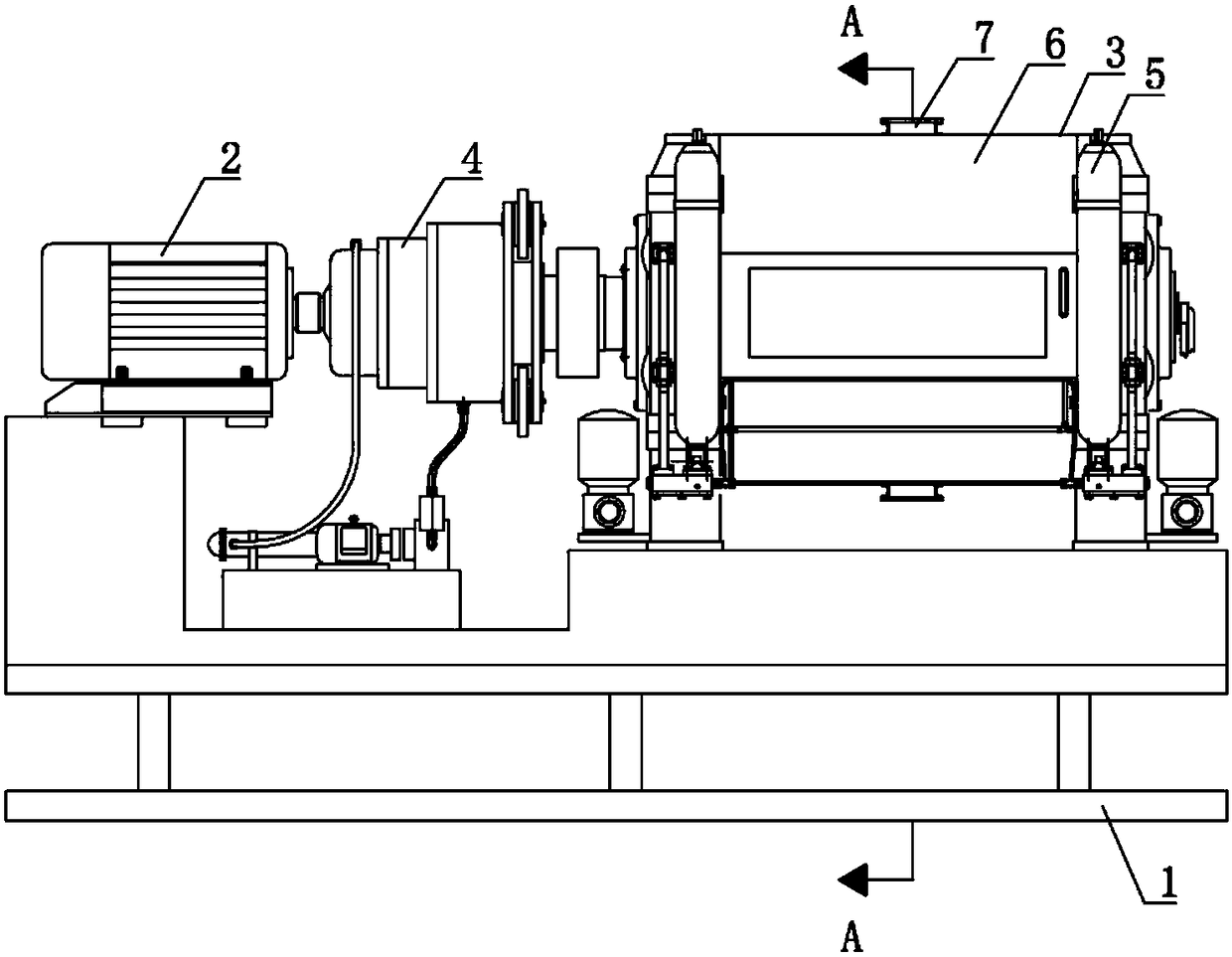

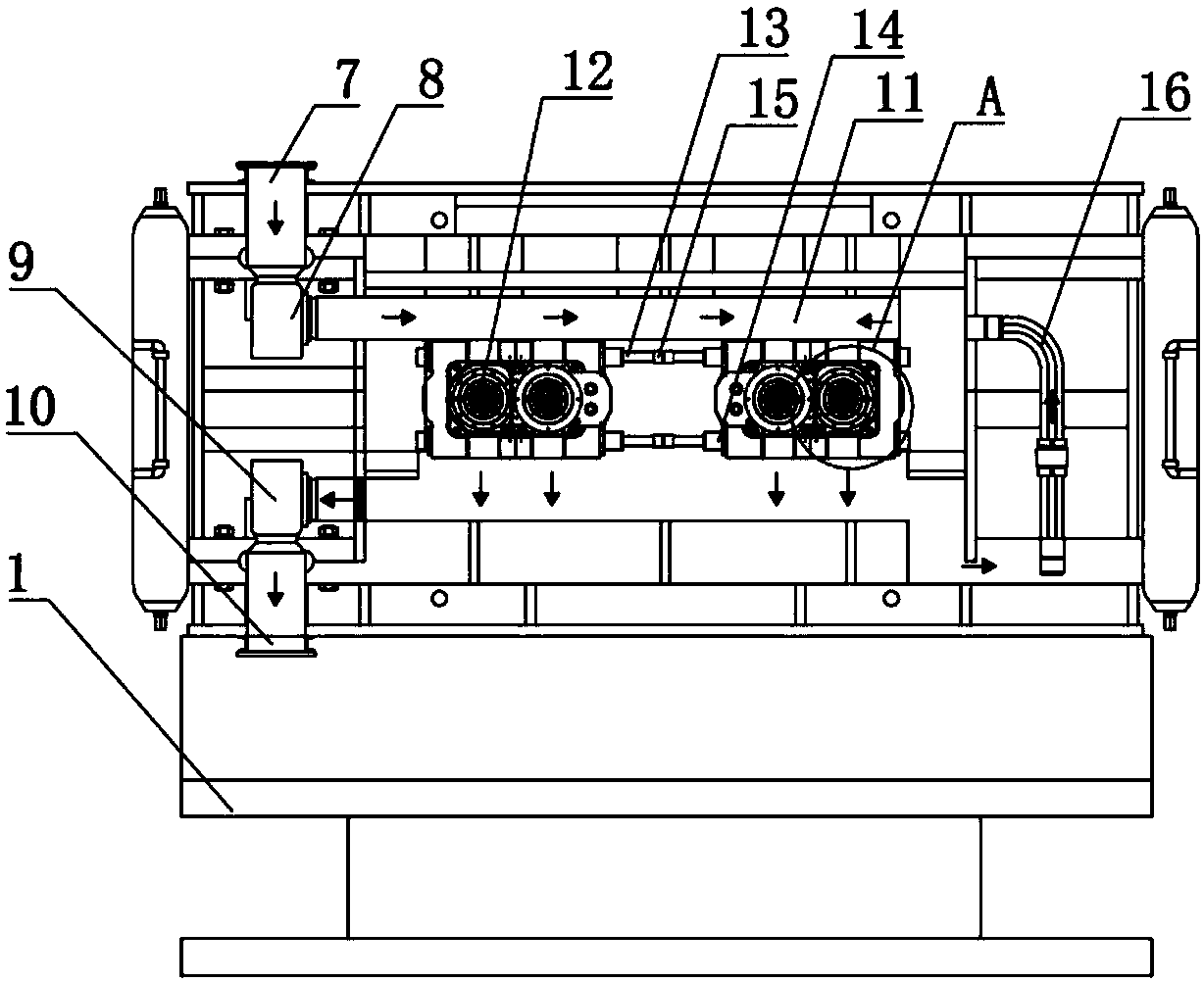

Processing device for modified asphalt and application method thereof

PendingCN108165032AQuality improvementReduce manufacturing costBuilding insulationsState of artCross-link

The invention discloses a processing device for modified asphalt, and relates to asphalt roads. The invention is to solve the following problems in the prior art: matrix asphalt containing rubber powder and auxiliary agents are incompletely ground, so a cross-linking reaction is incomplete; and onstructed pavements easily generate distresses like loosening and potholes. The processing device comprises a rubber grinding machine which comprises a mounting support seat, a horizontal motor located at the left part of the mounting support seat, a grinding device located at the right part of the mounting support seat, a motor rotating shaft and cooling water pipe joints, wherein the grinding device and the horizontal motor are connected through the motor rotating shaft; the left and right sidesof the grinding device are respectively connected with a cooling water pipe joint; and the grinding device comprises: a grinding disc shell; a feeding inlet, a feeding channel and a discharge channel,which are located above the grinding disc shell; a discharge outlet and a mixing cavity, which are located below the grinding disc shell; and a grinding structure, which is arranged in the interior of the mixing cavity. With a technical scheme of the invention, the matrix asphalt containing 15 to 20% of rubber powder and the auxiliary agents are completely ground, so the cross-linking reaction iscomplete.

Owner:QINGHAI HONGCHUAN XINYUAN INDAL

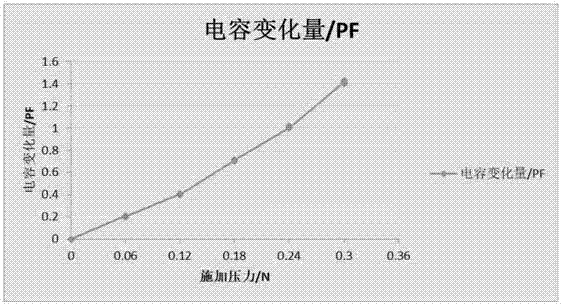

Sensor with contact-pressing and ultrasonic functions

PendingCN107957273AHigh sensitivityLarge deformationDiagnostics using pressureOrgan movement/changes detectionUltrasonic testingContact layer

The invention discloses a sensor with contact-pressing and ultrasonic functions. The sensor comprises a substrate as well as an ultrasonic detection unit and a contact-pressing detection unit which are formed on the substrate; the ultrasonic detection unit comprises a first ultrasonic detection electrode layer formed on the lower surface of the substrate as well as a first elastic film and a second ultrasonic detection electrode layer which are formed on the upper surface of the substrate sequentially; the contact-pressing detection unit comprises a first contact-pressing detection electrode layer formed on the lower surface of the substrate as well as a second elastic film and a second contact-pressing detection electrode layer which are formed on the upper surface of the substrate sequentially; the sensor further comprises a contact layer; the contact layer corresponds to the contact-pressing detection unit and is formed on one side, far away from the substrate, of the second contact-pressing detection electrode layer; the contact layer comprises a contact bulge; the contact bulge faces to the second contact-pressing detection electrode layer. When an external force acts on the sensor, the contact bulge can transmit the external force to the second elastic film well, so that the second elastic film generate greater deformation and the sensitivity of the sensor is improved.

Owner:BEIJING SINO CANBRIDGE MED TECH CO LTD

Nitrogen-doped palladium-carbon catalyst, preparation method thereof and application of nitrogen-doped palladium-carbon catalyst in CFC-113 hydrodechlorination

ActiveCN112206801AIncrease binding energyGood dispersionPreparation by dehalogenationCatalyst activation/preparationPalladium on carbonActivated carbon

The invention provides a nitrogen-doped palladium-carbon catalyst and a preparation method thereof, and an application of the nitrogen-doped palladium-carbon catalyst in a reaction for synthesizing chlorotrifluoroethylene by taking 1, 1, 2-trifluorotrichloroethane as a raw material. In the catalyst carrier nitrogen-doped activated carbon, nitrogen is mainly graphite nitrogen, and nitrogen doping can increase the binding energy of metal and carbon so that the dispersion of metal is facilitated, the fixation and stability of metal in the reaction process are improved, the operation is simple, and the obtained catalyst is easy to recycle.

Owner:ZHEJIANG UNIV OF TECH

Gallium arsenide PIN diode and preparation method thereof

ActiveCN100485971CReduce parasitic capacitanceRealize the process is simpleSemiconductor/solid-state device manufacturingSemiconductor devicesPhysicsAir bridge

The invention discloses a GaAs PIN diode, which comprises: a semi-insulating GaAs underlay for supporting the whole GaAs diode; a high doped layer N growing in extension on the semi-insulating GaAs underlay, resistive formations I and P close to eigen growing in extension in turn on the high doped layer N; By wet process and etching, the areas of the said high doped layer N, resistive formations I and P reduced in turn to form a mesa structure; a top electrode of the round structure formed by metal evaporator on layer P; a semi-orbicular bottom electrode formed by metal evaporator on layer N. The invention also discloses a manufacturing method of GaAs PIN diode. The invention efficiently lowers the parasitic capacitance of the PIN diode without increasing the difficulty of the process and simultaneously greatly shortens the microstrip line connected with the top electrode. The spurious inductance brought by the invention can be greatly reduced or even omitted without using the air-bridge process. The invention has the advantages of easy making, better high frequency characteristic, which is easy to realize the single scale integration.

Owner:北京中科微投资管理有限责任公司

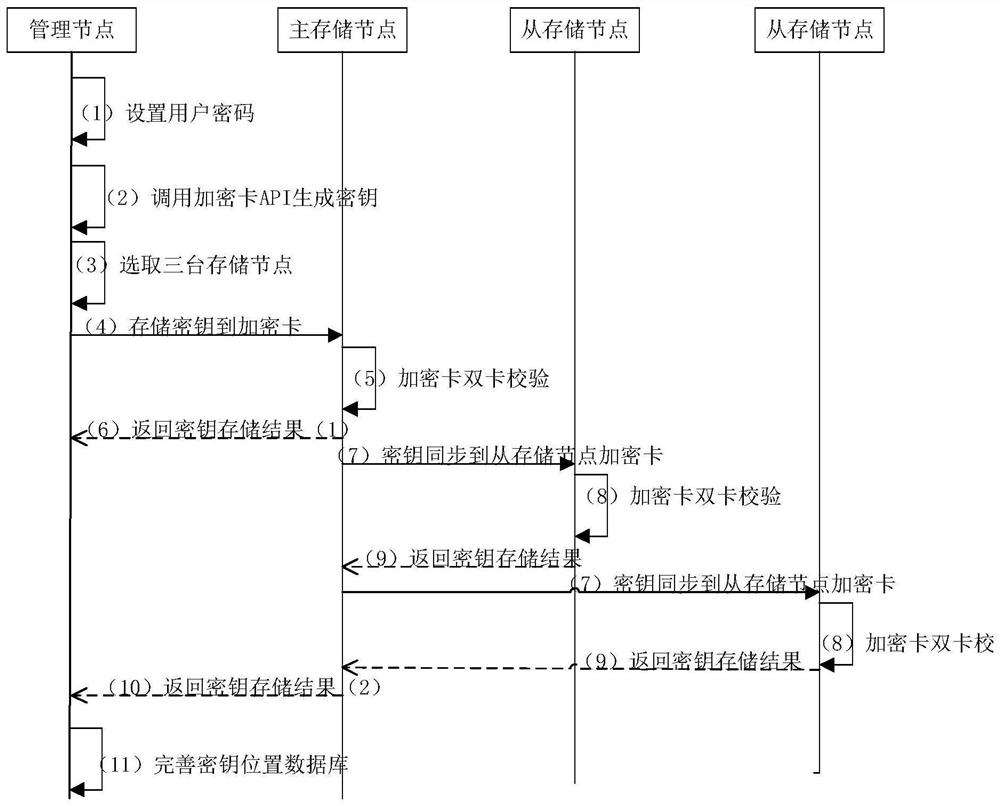

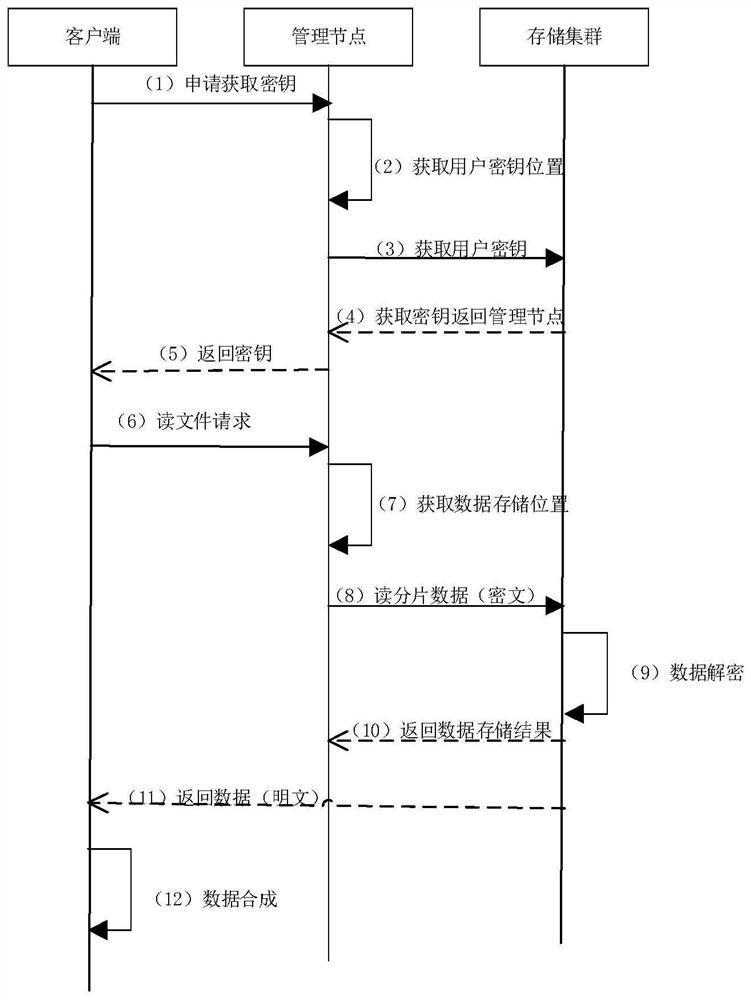

Hardware encryption method, system and device based on distributed storage

PendingCN113568568AIntegrity guaranteedGuaranteed reliabilityInput/output to record carriersDigital data protectionEmbedded systemData security

The invention discloses a hardware encryption method, system and device based on distributed storage, and belongs to the field of data security. The method comprises the following steps of: obtaining a key through an encryption card API, slicing user data, encrypting, performing hardware encryption on the data according to a user identity, and storing a ciphertext on a disk. According to the technical scheme, data leakage caused by the fact that the hard disk is stolen can be avoided due to the fact that the ciphertext data exist on the disk, meanwhile, logic isolation and encryption isolation of user data are provided by adopting different strategies of different user passwords, and establishment of a safer encryption mechanism is facilitated.

Owner:苏州海加网络科技股份有限公司

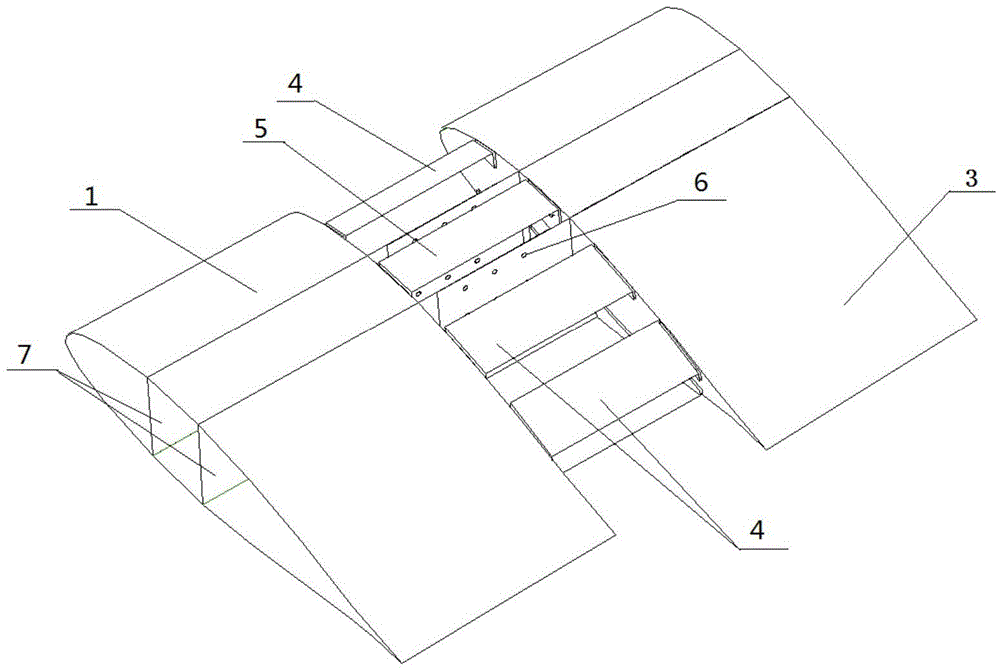

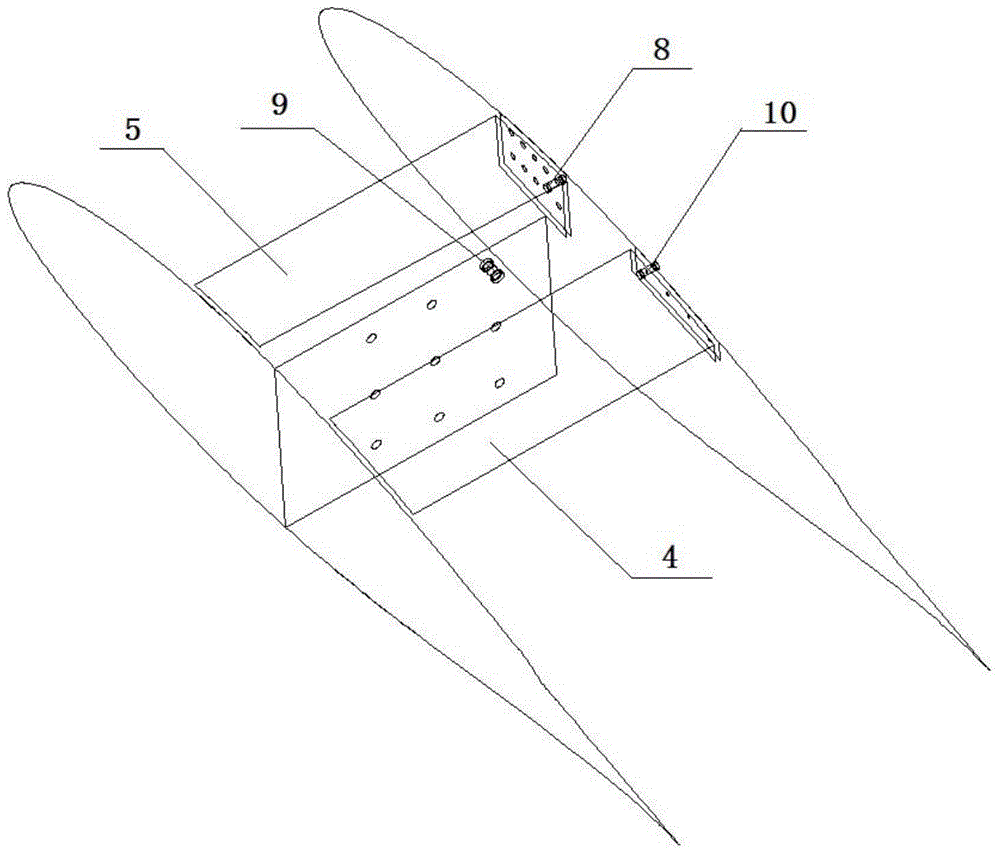

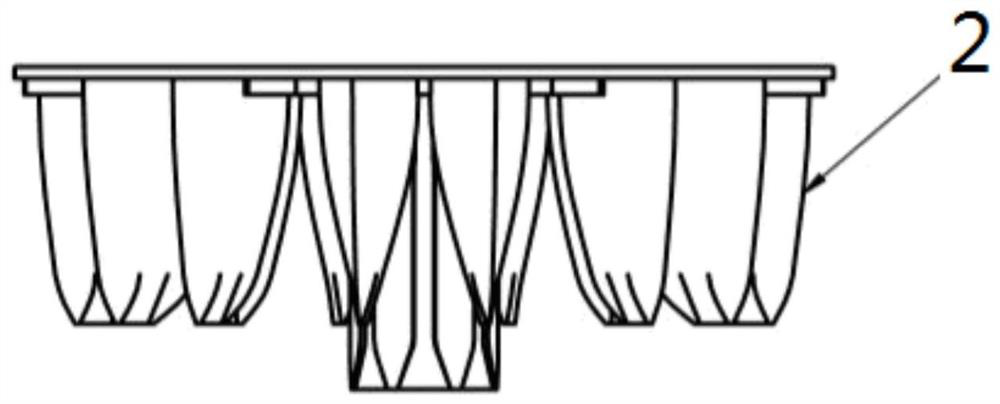

Wind turbine generator combined type blades and installation method

InactiveCN104612907AFacilitate segmented manufacturingRealize segmented manufacturingFinal product manufactureMachines/enginesFiberElectricity

The invention belongs to the technical field of wind turbine generator blades, and particularly relates to wind turbine generator combined type blades and an installation method. Each combined type blade comprises two or more segments of blades, the connection end of each segment of the blades is closed, and web plates of the segment of the blades extend out; web plates corresponding to the connection ends of two adjacent segments of blades are connected with each other through web plate connectors; a plurality of beam cap connectors are arranged between two adjacent web plates to connect the two segments of the blades; a plurality of skin connectors are arranged at the outer sides of the web plates respectively to connect the two segments of the blades; each portion of connection segments of the blades is connected with corresponding segment of the blades through titanium alloy bolts. When installation is conducted, a carbon fiber reinforced layer is paved at the connector position of each segment of the blades, and bolt holes are punched; the two segments of the blades are connected with each other through flange self-lock pins and bolts; finally, the blades are lifted and mounted on a wind turbine generator according to conventional lifting and mounting procedures. By means of the wind turbine generator combined type blades and the installation method, on the premise of not changing blade aerodynamic performance, the segmented manufacture, the segmented transportation and the rapid installation of the blades are convenient to achieve, the sufficient strength and rigidity are guaranteed, and the difficulties and the cost of manufacture and transportation are reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Preparation method and application of carbon-doped coated platinum catalyst

ActiveCN114308024AImprove defectsIncrease resistanceOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsCarbon layerPtru catalyst

The invention discloses a preparation method and application of a carbon-doped coated platinum catalyst. The preparation method of the doped carbon-coated platinum catalyst comprises the following steps: weighing a supported metal platinum catalyst, adding water into the supported platinum catalyst, uniformly mixing, adding hydrogen peroxide with the concentration of 2-5wt%, stirring for 0.5-4 hours at the temperature of 30-50 DEG C, adding a soluble carbon source compound and a soluble heteroatom-containing compound, dipping for 0.5-10 hours at room temperature, and carrying out vacuum drying until moisture is dried, so as to obtain the doped carbon-coated platinum catalyst. And then carrying out high-temperature roasting for 2-10 hours at the temperature of 400-1000 DEG C in an inert protective atmosphere, a hydrogen atmosphere or a vacuum state to prepare the doped carbon-coated platinum catalyst. The catalyst provided by the invention has a complete carbon layer wrapping metal active component with a proper structure and thickness, so that the stability of the reaction process is ensured, and the catalyst has better activity and selectivity. The catalyst is used for a reaction for preparing p-aminophenol through nitrobenzene catalytic hydrogenation rearrangement, and has high stability and high target product yield.

Owner:ZHEJIANG UNIV OF TECH

Device and method for compression-consolidation of parts made of composite materials having a thermoplastic matrix reinforced with continuous fibers, especially of natural origin

ActiveCN103459130BGuaranteed pressureGuaranteed to be inDomestic articlesTelephone set constructionsInductorThermoplastic matrix

The invention relates to a forming and consolidating device for a textile preform (600) comprising impregnation with a thermoplastic polymer, a method carried out by said device and parts obtained by this method continuous fiber, said device comprising: i. a die (200) comprising a mold (210) comprising a mold cavity (220) corresponding to the shape of the part, said mold between the inlet plane and the bottom The space extends along the depth direction and is inserted into the mold chassis (230); ii The induction heating mechanism (241, 242) of the model (210) includes two inductors, and the two inductors extend to the model (210) Coils are formed in the cavities and each in a plane substantially parallel to the entry plane of the cavity (220) and between said entry plane and the bottom of the mould; iii cooling mechanism (235) of the cavity.

Owner:ROCTOOL SAS

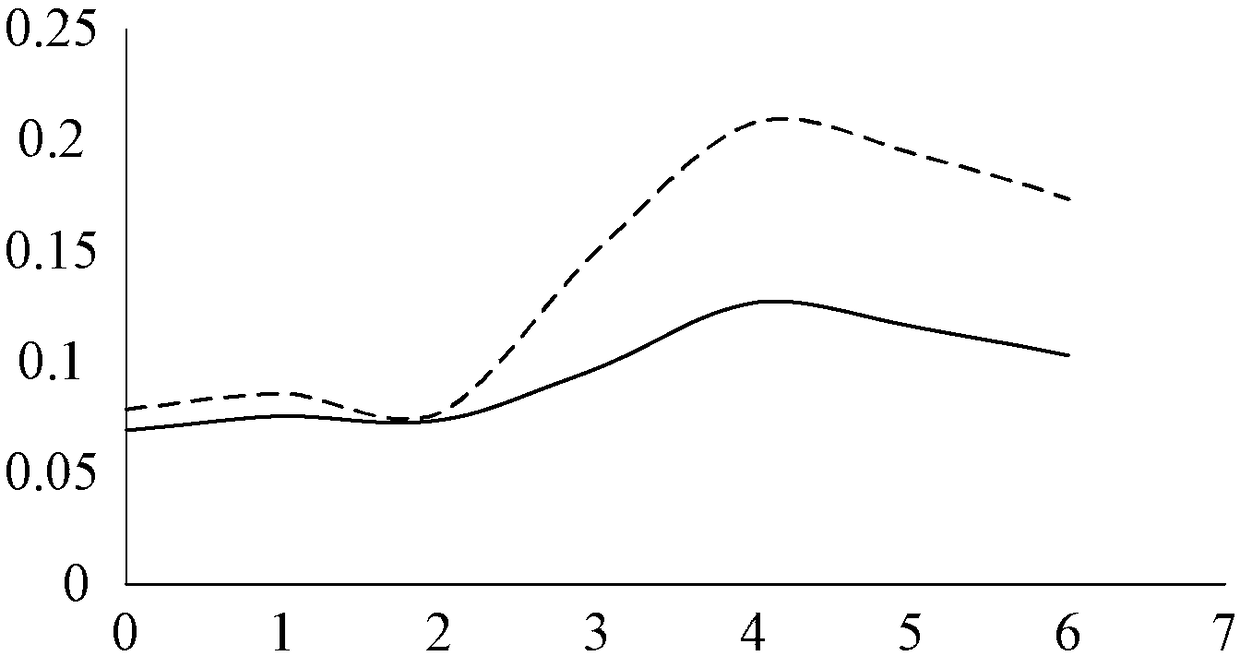

Method of processing in-band unevenness caused by DAC preprocessing

InactiveCN109474285AGood in-band flatnessGet easyTransmissionUltrasound attenuationDigital-to-analog converter

The invention relates to a method of processing in-band unevenness caused by DAC preprocessing, belonging to the technical field of digital communication. A zero-order retainer is adopted for a digital-to-analog converter (DAC), consequently, inherent attenuation in amplitude-frequency characteristic causes poor amplitude consistency in a bandwidth signal. In the method, a compensation method forpredistortion processing through a digital filter solves the inherent attenuation of the DAC, so that in-band evenness of a broadband signal is improved. Simulation results show that the method effectively relieves in-band unevenness of the broadband signal caused by DAC attenuation.

Owner:SPACE STAR TECH CO LTD

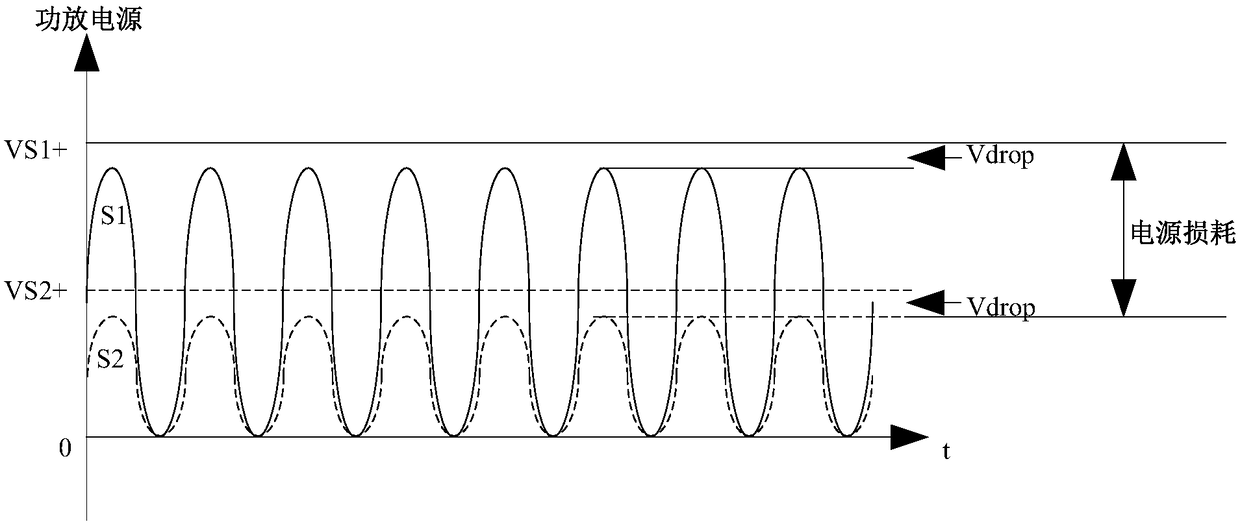

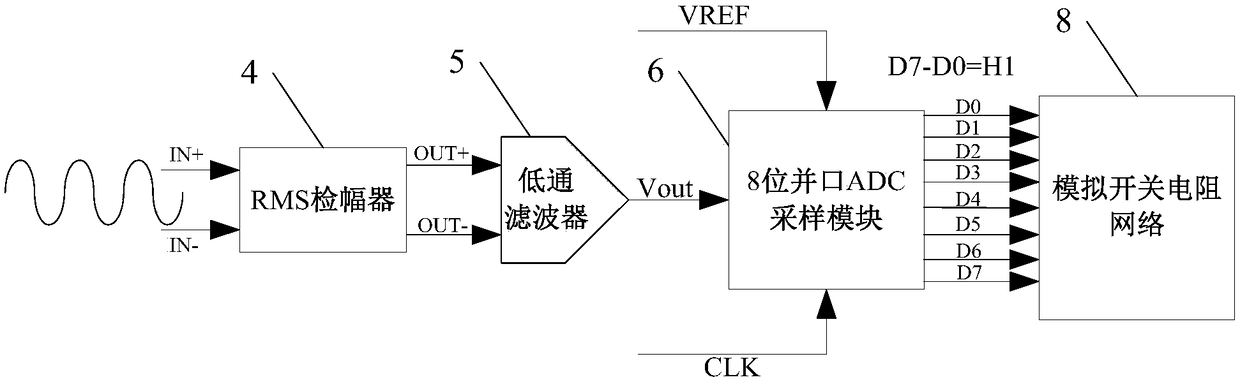

A self-adaptive adjustment device for power amplifier of well logging instrument

ActiveCN107066013BReduce lossReduce power consumptionElectric variable regulationEngineeringHeat losses

The invention discloses an adaptive adjustment device for the power amplifier power supply of a well logging instrument. By detecting the magnitude of the transmitted signal amplitude in real time, the effective value of the transmitted signal amplitude is converted into a DC voltage, and then an 8-bit parallel-port ADC sampling module performs sampling and analog-to-digital conversion. Finally, the parallel port output is realized, and the analog quantity of the transmitted signal amplitude is converted into an 8-bit binary digital quantity, which is reflected on the output voltage value of the switching power supply. Through reasonable circuit parameter matching, the non-linear error of switching power supply and power amplifier output is eliminated, so that the change of the transmitted signal is linearly proportional to the input voltage of the power amplifier, that is, the output voltage of the switching power supply, and the power amplifier always works in a state close to full load output. It reduces the heat loss of the power supply, improves the efficiency of the power amplifier, and reduces the power consumption of the system. At the same time, the present invention can automatically select whether the power amplifier is powered by the switching power supply or by the total system power supply according to the size of the transmitted signal.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

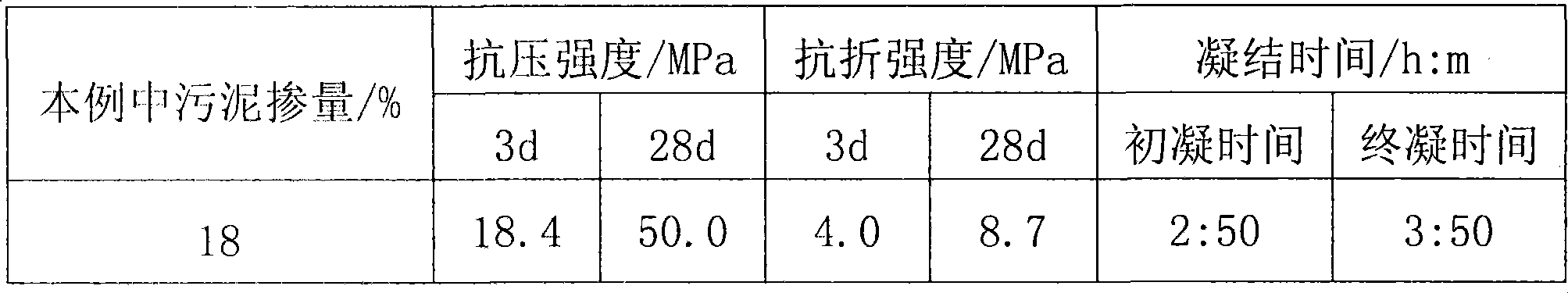

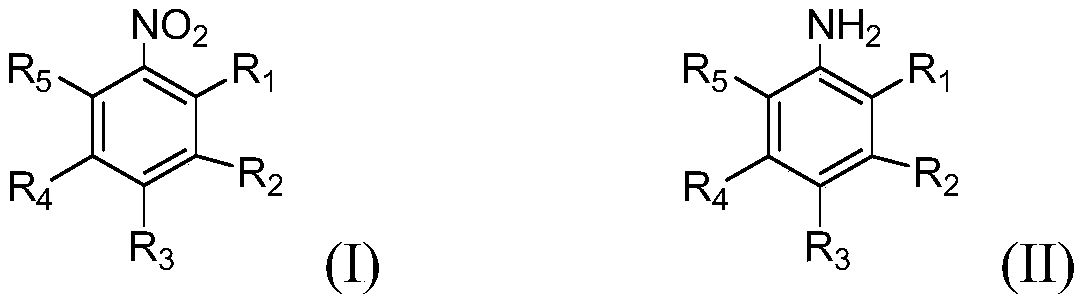

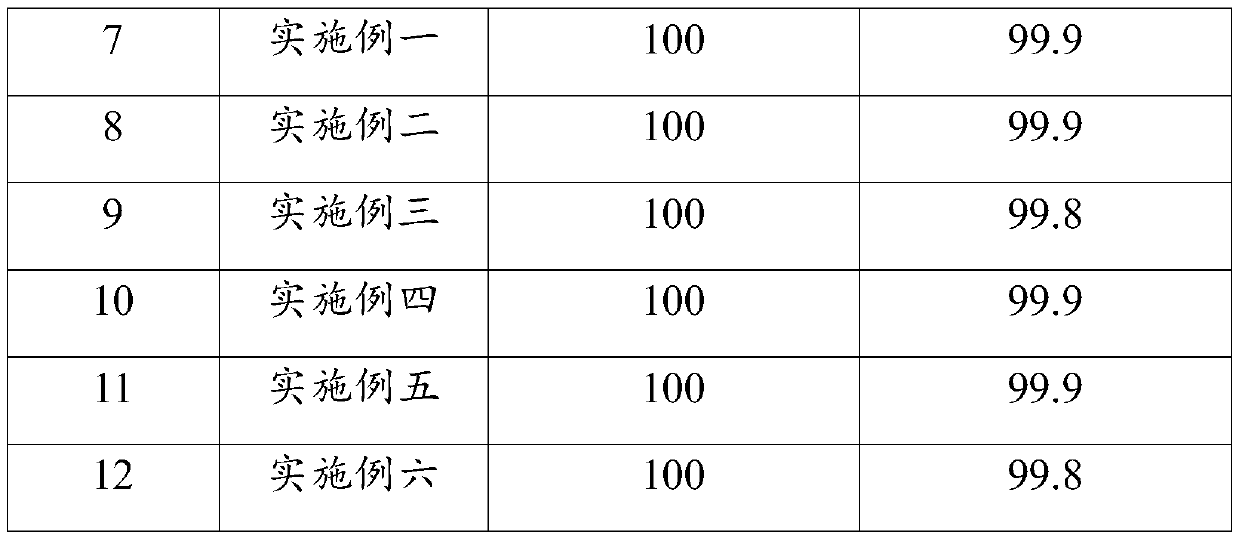

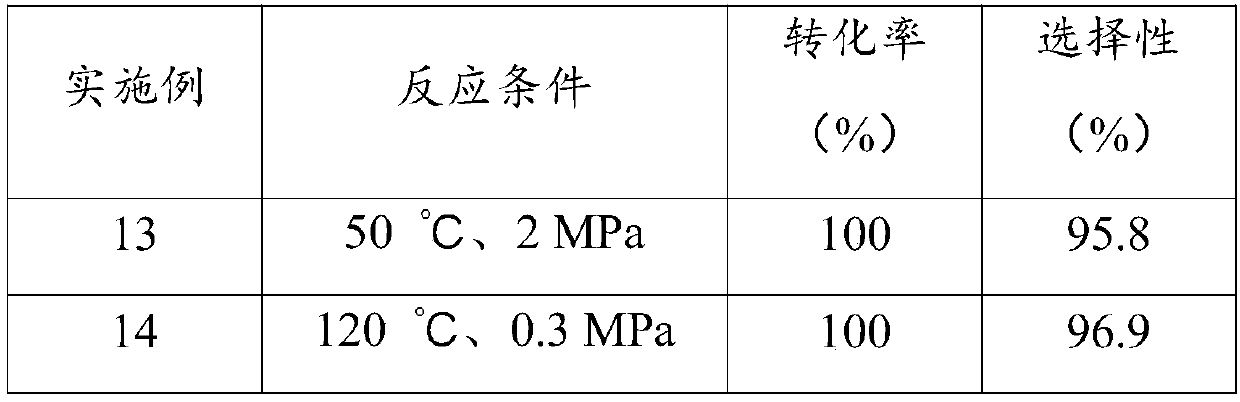

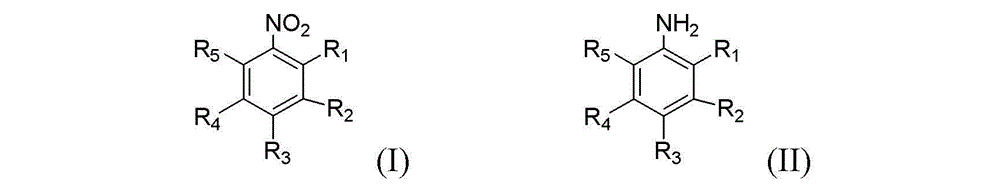

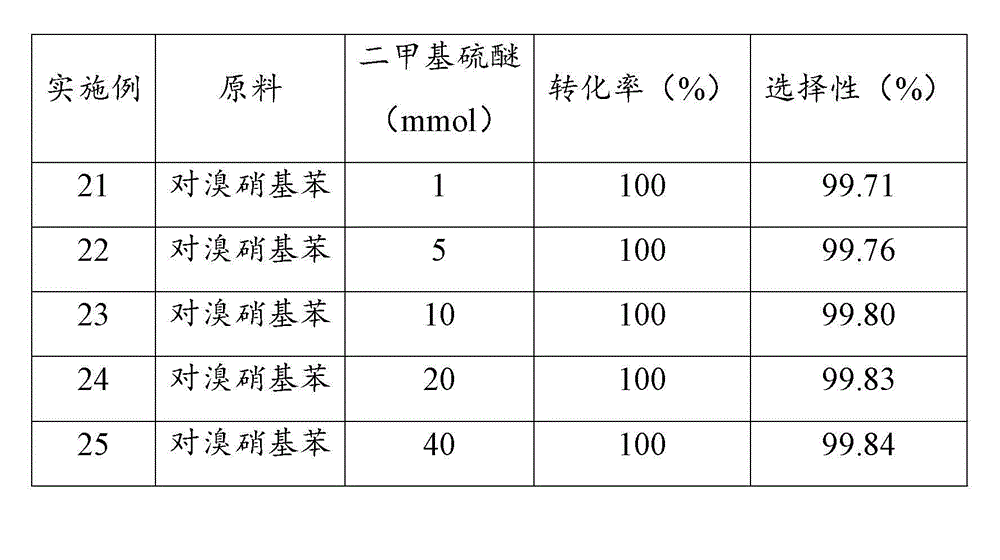

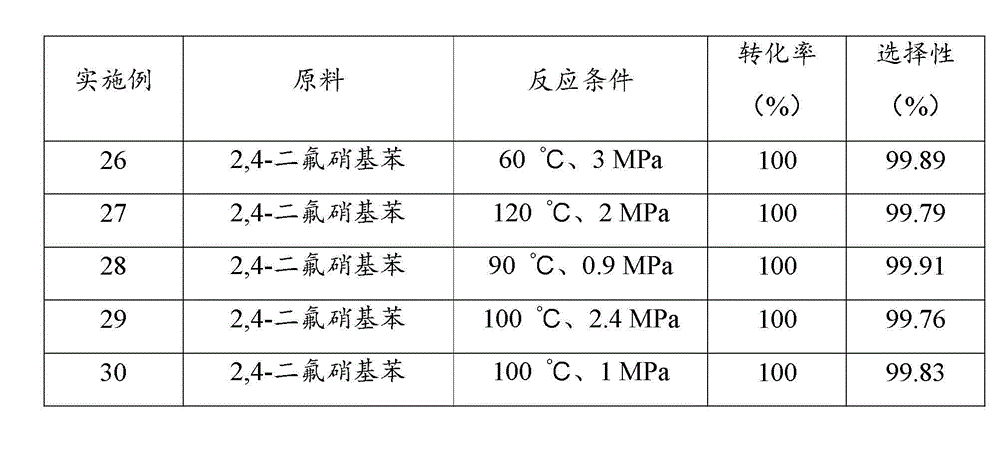

A kind of method preparing halogenated aniline by catalytic hydrogenation of halogenated nitrobenzene

ActiveCN106905167BNot easy to loseImprove stabilityOrganic compound preparationCatalyst activation/preparationHalogenHydrogenation reaction

The invention discloses a method for preparing halogenated aniline from halogenated nitrobenzene through catalytic hydrogenation. The method comprises the following steps: in a reaction kettle, performing liquid phase catalytic hydrogenation reaction to halogenated nitrobenzene under the action of a sulfur-doped carbon material loaded noble metal catalyst, to obtain halogenated aniline shown in the formula (II), wherein the loading quantity of noble metal in the sulfur-doped carbon material loaded noble metal catalyst is 0.1-5wt%. In the method, the catalyst has good stability, the hydrogenation halogen removal side effect can be effectively inhibited under the condition of having no added halogen removal inhibitor, and the product selectivity is high.

Owner:ZHEJIANG UNIV OF TECH

Backup semiconductor laser based on reconstruction-equivalent chirp technology

ActiveCN105140779BEliminate the problem of low single-mode yieldIncreased single-mode yieldLaser optical resonator constructionSemiconductor laser arrangementsPhase shiftedGrating

The invention discloses a backup type semiconductor laser based on a reconstructing-equivalent chirp technology, wherein the backup type laser comprises two parallel semiconductor DFB lasers; the semiconductor DFB lasers are distributed parallelly and the interval distance is within the range of 15 micrometer to 50 micrometer; each of the leasers is utilized to add equivalent phase shift to a sampling bragg grating structure based on the reconstructing-equivalent chirp technology; and a lasing channel used by each of the lasers is provided by plus 1 level sub-grating or minus 1 level sub-grating of the sampling bragg grating. By adopting the laser provided herein, one laser of the two parallel lasers must be in the single model working state, thus eliminating the problem of low yield of high reflection-low reflection coated laser single models on the basis of not adding technology cost.

Owner:NANJING UNIV

Method for enhancing dynamic range of quantum dot resonance tunneling diode photodetector

InactiveCN101335309BProlonged rapid thermal annealing timeExtended thermal annealing timeFinal product manufactureSemiconductor devicesPhotodetectorAbsorption layer

The invention discloses a method for increasing the dynamic range of a quantum dot resonance tunneling diode photodetector, and the hardcore of the structure thereof comprises a GaAs or InGaAs incident photon absorption layer, InAs self-assembly quantum dots with order of magnitude being 10<10>cm<-2> to 10<11>cm<-2> and an AlGaAs / GaAs double-potential-barrier structure layer; the core of the technology thereof is improved to extend the annealing time of the technique of the crisscross bridge resonance tunneling diode device so as to lead ohmic contact to diffuse to the double-potential-barrier structure layer; the core inventive point of the detecting approach thereof is that a longitudinal current branch of an original tunneling diode which is sensitive to small photons is kept, simultaneously, another transverse current which consists of two-dimensional electron gas is educed from a quantum well and can reflect the continuous variation of incident light intensity when suffering intensive modulation from a quantum dot electric field. The device of the invention has the advantages that the improvement of both the structure and the technology of the device can be compatible with the original equipment while the multiphoton detection sensitivity is greatly improved compared with the original device.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

A kind of synthetic n, the method for n'-dibenzylethylenediamine

ActiveCN106748813BHigh selectivityAvoid PolymerizationOrganic compound preparationAmino compound preparationHydrogenation reactionBenzyl-EDTA

The invention discloses a synthesis method of N,N'-dibenzylethylenediamine. The synthesis method is: in a reaction kettle, N,N'-dibenzylethylenediamine is added to nitrogen-doped mesopores. N,N'-dibenzylethylenediamine is prepared through a liquid phase catalytic hydrogenation reaction under the action of a carbon-supported precious metal catalyst; in the nitrogen-doped mesoporous carbon-supported precious metal catalyst, the precious metal is Pd or Pt, and the precious metal is The amount is 1~10wt%. The synthesis method of the present invention has the advantage of high selectivity of target products.

Owner:ZHEJIANG UNIV OF TECH

Packaging bag opening supporting device

PendingCN113371268ADispensing is safe and reliableEliminate cross-contaminationPackagingEngineeringMechanical engineering

The invention discloses a packaging bag opening supporting device. The packaging bag opening supporting device comprises a packaging bag frame and an opening supporting frame. A plurality of packaging bag inner guide blocks are arranged on the opening supporting frame, the packaging bag frame comprises a packaging bag frame top plate and a plurality of outer guide units, a plurality of packaging bag holding openings are formed in the packaging bag frame top plate, and the packaging bag holding openings are connected with the outer guide units; wherein a packaging bag can enter the containing cavities of the outer guiding units and can extend to the outer portions of the packaging bag holding openings; and the packaging bag inner guide blocks can enter the containing cavities, and an annular gap can be formed between the packaging bag inner guide blocks and the containing cavities so that the packaging bag can move up and down in the annular gap. The packaging bag opening supporting device solves the technical problem of cross contamination existing in a packaging bag opening supporting device in the prior art.

Owner:北京和利康源医疗科技有限公司

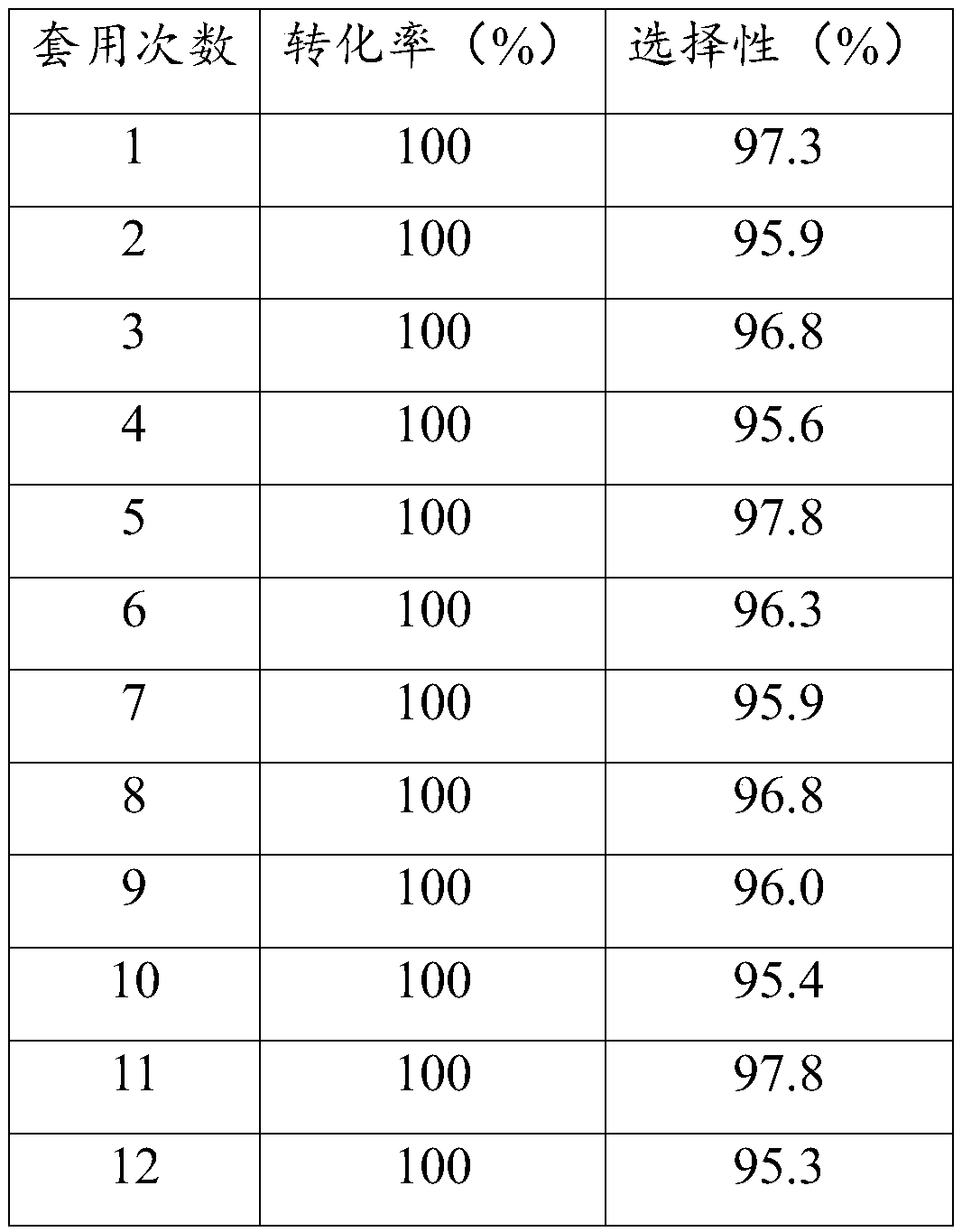

A method for synthesizing diphenylmethanol by catalytic hydrogenation of benzophenone

ActiveCN109053380BHigh activityModerately alkalinePhysical/chemical process catalystsOrganic compound preparationPtru catalystPalladium catalyst

A method for synthesizing diphenylmethanol by catalytic hydrogenation of benzophenone, the method uses a nitrogen-doped mesoporous carbon-supported palladium catalyst, and the nitrogen-doped mesoporous carbon-supported palladium catalyst consists of a nitrogen-doped mesoporous carbon support and metal palladium on the load carrier; the particle size of the nitrogen-doped mesoporous carbon is 100-1000 mesh, and the specific surface area is 600-1800m 2 / g, the average pore diameter is 2.0-20nm, the nitrogen element in the nitrogen-doped mesoporous carbon is directly doped into the carbon skeleton or connected with the carbon material by N-C bonds, and the nitrogen element content is 0.5-10wt%; The loading amount of palladium in the nitrogen-doped mesoporous carbon-supported palladium catalyst is 2-8 wt%. The nitrogen-doped mesoporous carbon-supported palladium catalyst used in the present invention exhibits high catalytic activity, high product selectivity and high stability in the catalytic hydrogenation of benzophenone to synthesize diphenylmethanol.

Owner:ZHEJIANG UNIV OF TECH

Method for preparing halogenated aniline from halogenated nitrobenzene by catalytic hydrogenation

InactiveCN102898263BLow dehalogenation rateThe effect of inhibiting dehalogenation is obviousOrganic compound preparationAmino group formation/introductionHalogenVulcanization

The invention discloses a method for preparing halogenated aniline from halogenated nitrobenzene by catalytic hydrogenation, which comprises the following step: carrying out liquid-phase catalytic hydrogenation reaction on halogenated nitrobenzene disclosed as Formula (I) under the action of a supported noble metal catalyst subjected to vulcanization treatment, thereby obtaining the halogenated arylamine disclosed as Formula (II), wherein in the Formula (I) or Formula (II), one or more of -R1, -R2, -R3, -R4 and -R5 are independently selected from -F, -Cl or -Br, and other groups are respectively independently selected from -H, -CH3, -CH2CH3, -OH, -NH2, -OCH3, -COOCH3, -NHCH2CH3 or -N(CH3)2. The method disclosed by the invention can effectively inhibit the hydrogenation dehalogenation side reaction on the premise of not adding any halogen removal inhibitor, and has the advantage of high product selectivity.

Owner:ZHEJIANG CENWAY MATERIALS CO LTD

Long pipe with safety cover

The invention belongs to the field of packaging bottles, and particularly discloses a long pipe with a safety cover. The long pipe with the safety cover comprises a pipe body and the safety cover, thelower portion of the pipe body is arranged in a sealed mode, a connecting section is arranged on the upper portion of the pipe body, an opening is formed in the upper end of the connecting section and communicates with the pipe body, the safety cover comprises a cover body and a sealing element, the sealing element is located at the top of the interior of the cover body and is fixedly connected to the top wall of the cover body, a plurality of groups of clamping parts are arranged in the circumferential direction of the connecting section, each group of clamping parts comprises an inclined groove and two protruding parts, a clamping groove is formed between every two protruding parts, the lower ends of the inclined grooves communicate with the lower ends of the clamping grooves, the upperends of the inclined grooves are flush with the upper end of the connecting section, a plurality of protrusions are arranged on the inner wall of the cover body, the number of the protrusions is thesame as the number of the clamping parts, and the protrusions can be clamped into the clamping grooves and can slide along the inclined grooves. The long pipe has the advantage that the safety cover is arranged, so that the phenomenon that a child opens a safety cover and eats other objects by mistake can be avoided.

Owner:宁波纽莱国际贸易有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com