Wind turbine generator combined type blades and installation method

A wind turbine, combined technology, applied in wind turbine components, wind power generation, wind turbines, etc., can solve the problems of high cost, difficult to realize, inconvenient transportation, etc., and achieve low cost, reduced difficulty and cost, and fast installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention provides a wind turbine combined blade and its installation method. In order to make the technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific implementation methods and accompanying drawings.

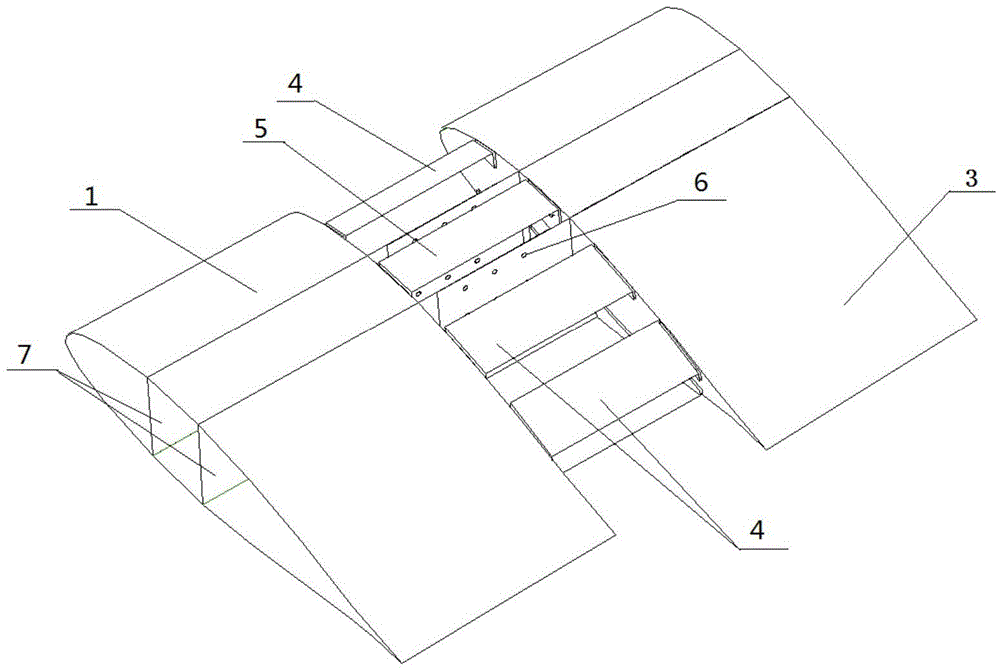

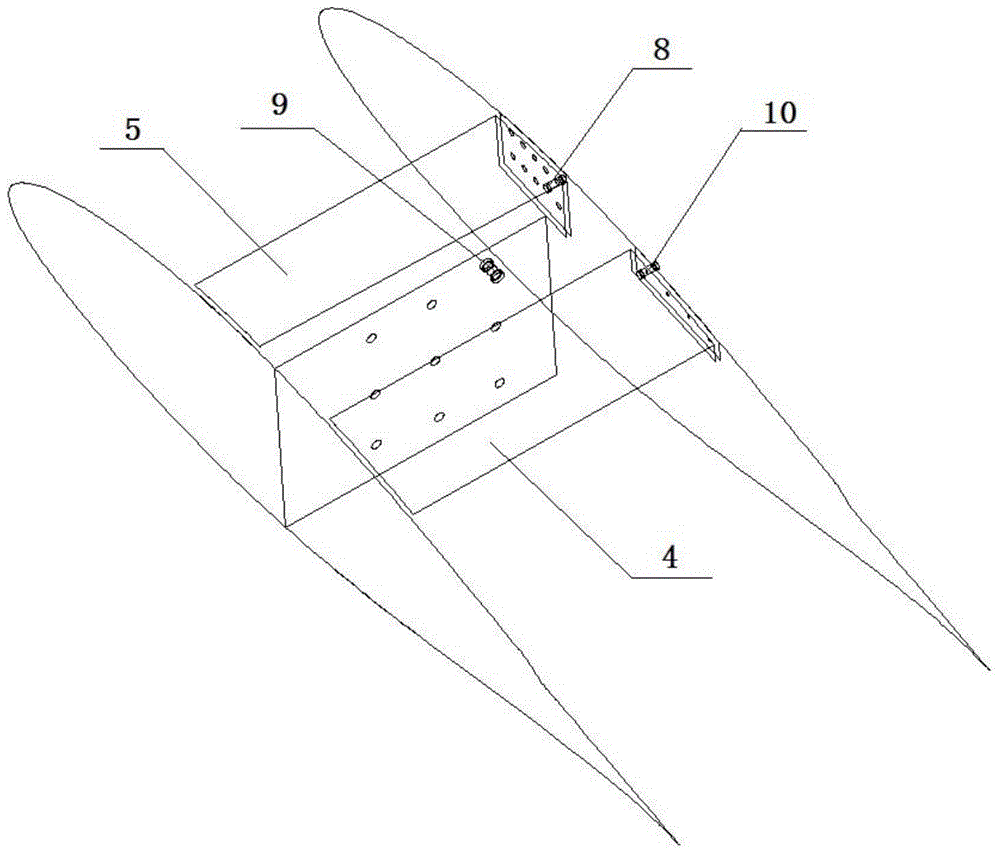

[0027] Such as figure 1 As shown, the wind turbine blade at least includes two parts: the blade root section 1 and the blade tip section 3, and the blade root section 1 and the blade tip section 3 are connected through the blade connecting section 2; figure 2 It is a structural diagram of the connection area of the present invention, the connection ends of the blade root section 1 and the blade tip section 3 are closed, and the web protrudes; the blade connection section 2 includes a skin joint 4, a spar cap joint 5, and a web joint 6; The corresponding webs of the blade root section 1 and the blade tip section 3 are connected by a web joint 6; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com