Backup type semiconductor laser based on reconstructing-equivalent chirp technology

An equivalent chirp, laser technology, applied in the field of optoelectronics, can solve problems such as poor single-mode performance of lasers

- Summary

- Abstract

- Description

- Claims

- Application Information

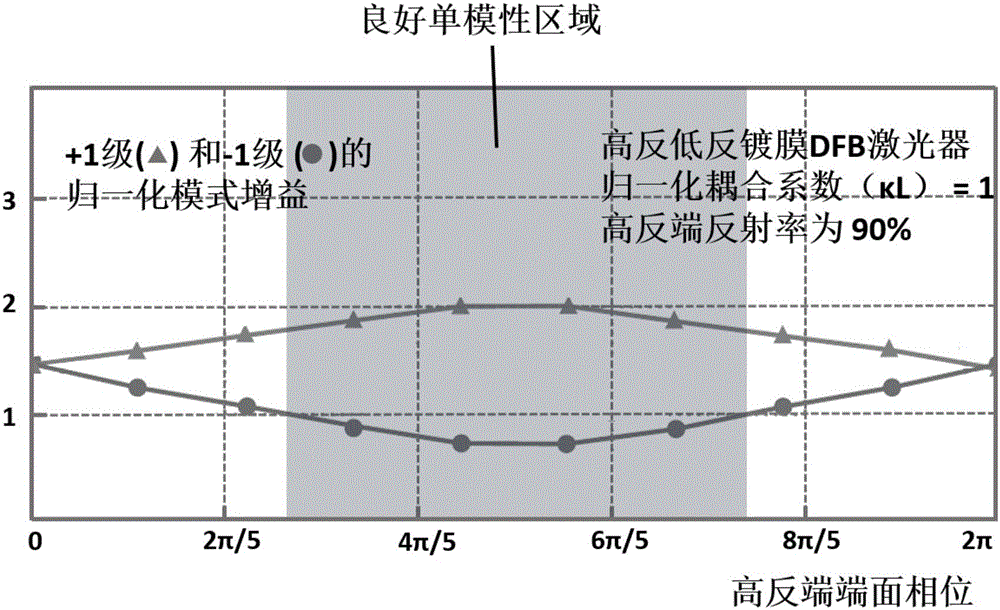

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

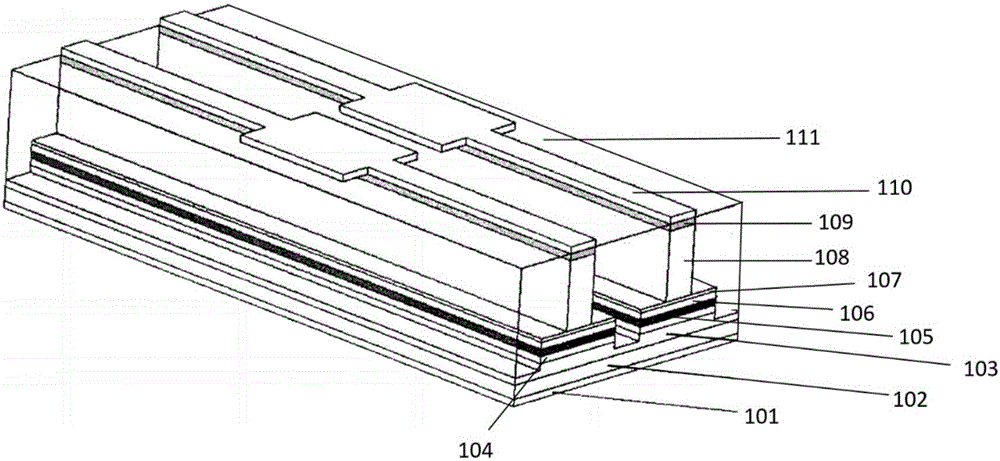

Embodiment Construction

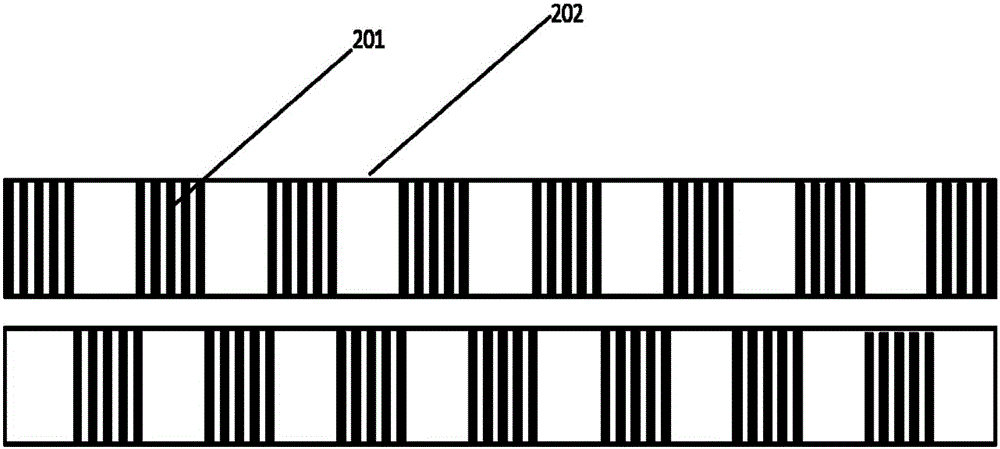

[0036] 1. Production of sampling grating

[0037] The DFB semiconductor laser in the present invention generally uses III-V compound semiconductor materials, such as GaAlAs / GaAs, InGaAs / InGaP, GaAsP / InGaP, InGaAsP / InP, InGaAsP / GaAsP, etc.). At the same time, it can also be applied to various ternary compounds and quaternary compound semiconductor materials such as II-VI compound semiconductor materials and IV-VI compound semiconductor materials. In addition, the present invention can also be applied to aluminum-doped semiconductor materials (for example, AlGaInAs) for manufacturing semiconductor lasers without refrigeration and with good temperature characteristics. In order to reduce the influence of laser end face reflection, an anti-reflection coating can be coated on both end faces. Laser of the present invention manufactures key is to do sampling grating structure, and its concrete manufacturing method is:

[0038] (1) First design and make the grating pattern of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com