Sensor with contact-pressing and ultrasonic functions

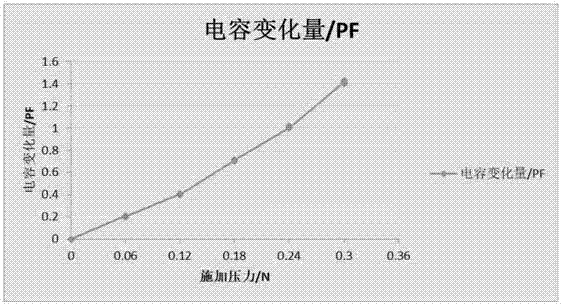

A sensor and touch pressure technology, applied in the field of sensors, can solve problems such as poor sensitivity, achieve good practicability, improve sensitivity, and increase complexity and difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

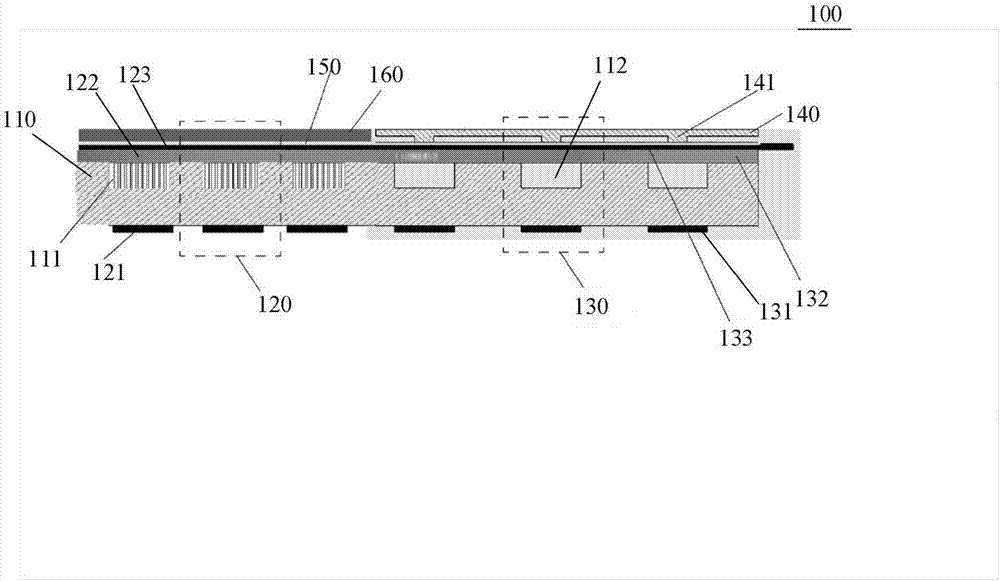

[0061] refer to figure 1, the present invention relates to a sensor 100 with touch pressure and ultrasonic functions, the sensor 100 includes a substrate 110 and an ultrasonic detection unit 120 and a touch pressure detection unit 130 formed on the substrate 110 .

[0062] The ultrasonic detection unit 120 includes a first ultrasonic detection electrode layer 121 formed on the lower surface of the substrate 110 and a first elastic film 122 and a second ultrasonic detection electrode layer 123 sequentially formed on the upper surface of the substrate 110 .

[0063] The touch detection unit 130 includes a first touch detection electrode layer 131 formed on the lower surface of the substrate 110, a second elastic film 132 and a second touch detection electrode layer sequentially formed on the upper surface of the substrate 110. electrode layer 133 .

[0064] Wherein, the above-mentioned sensor 100 further includes a contact layer 140, the contact layer 140 corresponds to the to...

Embodiment 2

[0104] see Figure 6 , the present invention also discloses the preparation method of the sensor described in Example 1, specifically, including the following steps:

[0105] The first step is to prepare the upper plate.

[0106] For the upper plate, for example, a 4-inch SOI double-sided polished first silicon wafer 123 with a thickness of 300 μm is selected to make the upper plate part.

[0107] Through reverse coating, photolithography, and development of graphics, through the deep silicon etching process, etching penetrates the entire first silicon wafer to form alignment marks for bonding the upper plate during the bonding process.

[0108] The second step is to prepare the lower plate.

[0109] The lower plate is prepared, and the lower plate is, for example, a 4-inch second silicon wafer 110 with a thickness of 300 μm and polished on both sides. The lower plate is formed by the following steps:

[0110] Form an oxide layer of about 0.8 μm by thermal oxygen on both s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com