Back passivating method and preparation method of crystalline silicon solar cell

A technology for solar cells and crystalline silicon, applied in the field of solar cells, can solve the problems of poor passivation effect, high cost, and difficulty in increasing the back passivation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

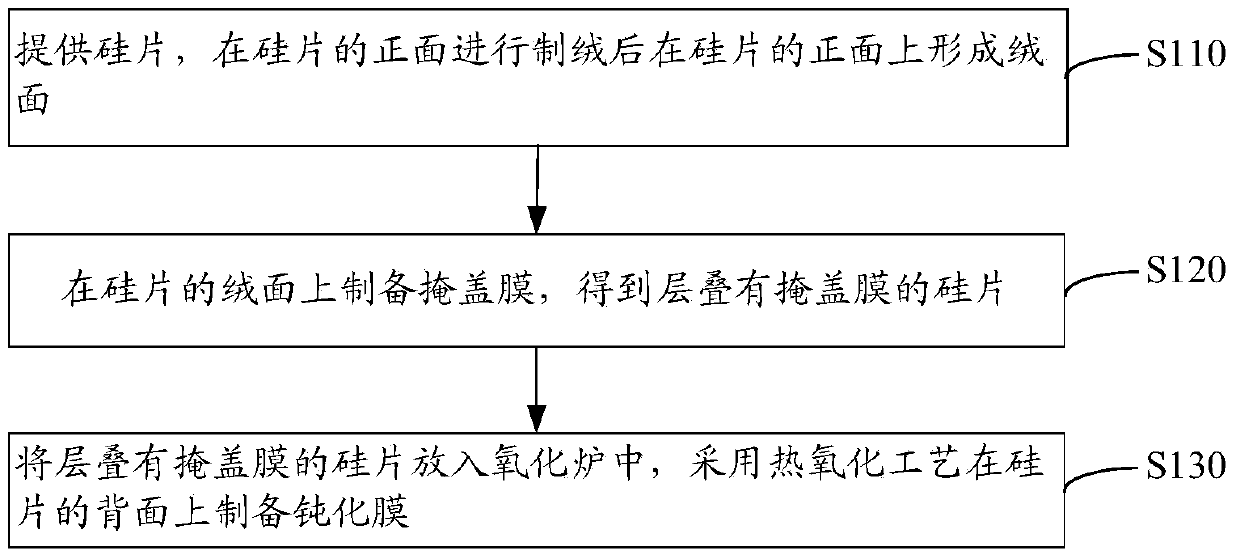

[0044] Further, a method for preparing a crystalline silicon solar cell is provided. The preparation method of the crystalline silicon solar cell includes the above step S110, step S120 and step S130, and also includes the following step S140.

[0045] Step S140: forming a positive electrode and a back electrode on the mask film and the passivation film respectively to obtain a crystalline silicon solar cell.

[0046] In one embodiment, the corrosive paste is first printed on the mask film by screen printing process, then placed at room temperature for 5 minutes, then ultrasonically cleaned for 2 minutes, and dried, and the back surface of the silicon wafer is cut out. Point contact pattern. After cleaning the sample, use the screen printing process to print the electrode paste on the masking film and the passivation film respectively, and sinter at 780 ° C to 810 ° C for 5 seconds to 10 seconds to form a positive electrode on the front side of the silicon wafer. A back elec...

Embodiment 1

[0052] Preparation of crystalline silicon solar cells

[0053] 1. Provide P-type monocrystalline silicon wafers, use acid method to make texture, and form a textured surface on the front side of P-type monocrystalline silicon wafers;

[0054] 2. Put the textured silicon wafer into a diffusion furnace, and carry out phosphorus diffusion at 860°C, and the square resistance of phosphorus diffused to the silicon wafer is 70Ω / □;

[0055] 3. Remove phosphosilicate glass with hydrofluoric acid, and perform edge etching by wet method;

[0056] 4. Coating a layer of silicon nitride film on the front side of the silicon wafer by plasma enhanced chemical vapor deposition method to obtain a silicon wafer laminated with a masking film, the thickness of the silicon nitride film is 80nm;

[0057] 5. Put the silicon wafer laminated with the mask film into the oxidation furnace, and use the wet oxygen thermal oxidation process to perform thermal oxidation at 800°C to form a silicon dioxide fi...

Embodiment 2

[0061] Preparation of crystalline silicon solar cells

[0062] 1. Provide P-type monocrystalline silicon wafers, use acid method to make texture, and form a textured surface on the front side of P-type monocrystalline silicon wafers;

[0063] 2. Put the textured silicon wafer into a diffusion furnace, and carry out phosphorus diffusion at 830°C, and the square resistance of phosphorus diffused to the silicon wafer is 60Ω / □;

[0064] 3. Remove phosphosilicate glass with hydrofluoric acid, and perform edge etching by wet method;

[0065] 4. Coating a layer of silicon nitride film on the front side of the silicon wafer by plasma enhanced chemical vapor deposition method to obtain a silicon wafer laminated with a masking film, the thickness of the silicon nitride film is 90nm;

[0066] 5. Put the silicon wafer laminated with the mask film into the oxidation furnace, and use the wet oxygen thermal oxidation process to perform thermal oxidation at 650°C to form a silicon dioxide fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com