Method and device for producing a translucent multilayer composite building element with integrated facade panels

A multi-layer composite and manufacturing method technology, which is applied in the direction of building components, buildings, building structures, etc., can solve problems such as difficulty in alignment of light guide rods, difficulty in connecting external wall panels and surface layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

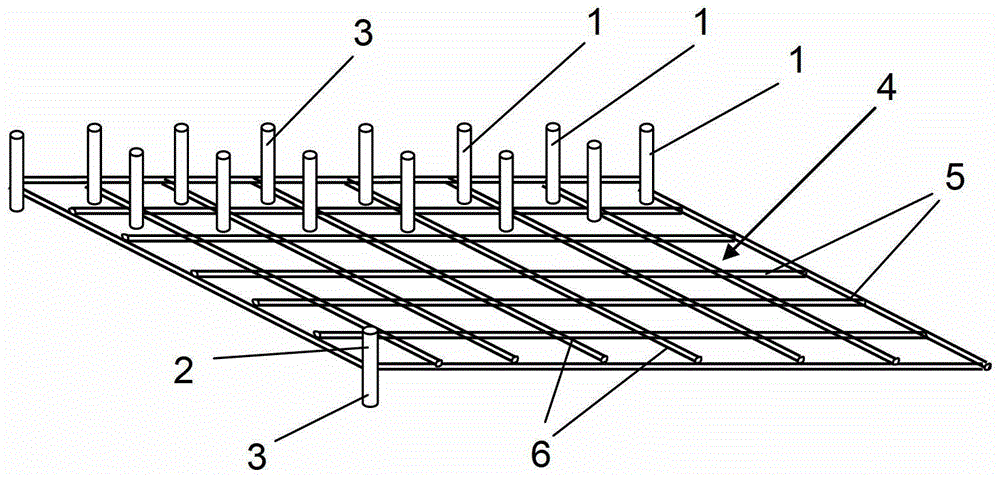

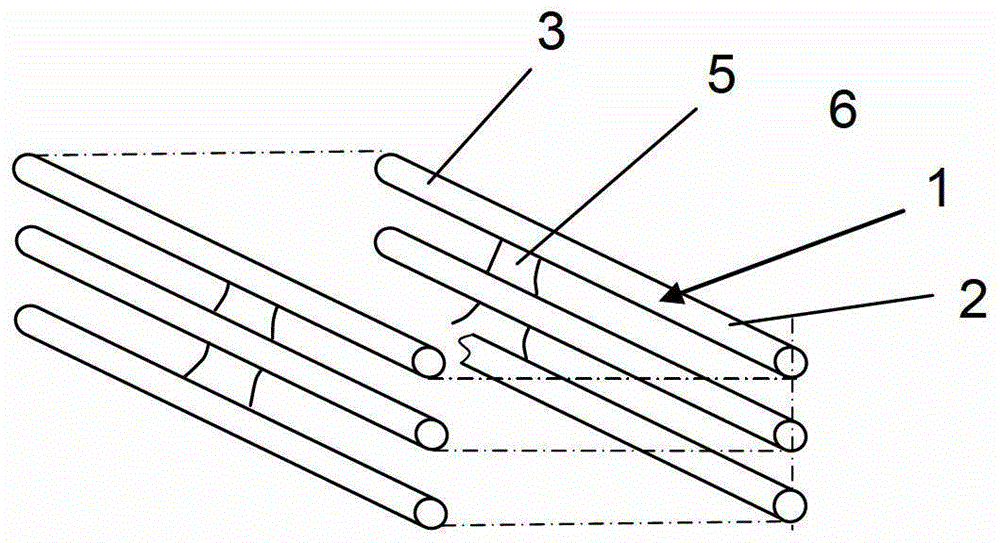

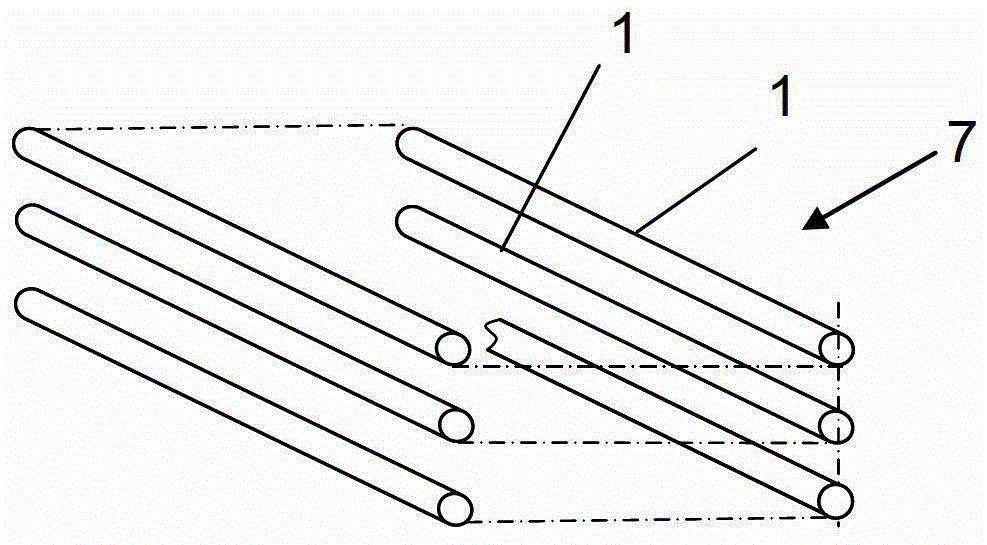

[0056] like figure 1 , 2 As shown, the light guide rods 1 can have any shape, composition and cross section, and the distance between each light guide rod is maintained by an additional fixing element.

[0057] In the illustrated embodiment, each light guiding bar is formed of a light guiding plastic material, such as polycarbonate or the like. Each light guide rod 1 has an upper end 2 and a lower end 3, and the upper end and the lower end can have any contour.

[0058] according to figure 1 , 2 The embodiment of the present invention shows that the light guide rod 1 is injected at the intersection of a grid mat 4 comprising interconnected longitudinal beams 5 and cross beams 6.

[0059] The longitudinal beams 5 and crossbeams 6 are also formed of light-guiding plastic materials, which benefit from the good uniform light distribution across the surface of the grid pad 4 generated by the light-guiding beams and stringers, and are arranged on the grid pad 4 The light distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com