Sulfide catalyst with palladium on nitrogen doped mesoporous carbon, and application of sulfide catalyst

A nitrogen-doped mesoporous carbon and sulfide technology is used in physical/chemical process catalysts, chemical/physical processes, preparation of organic compounds, etc. The effect of improving activity, not easy to be deactivated, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

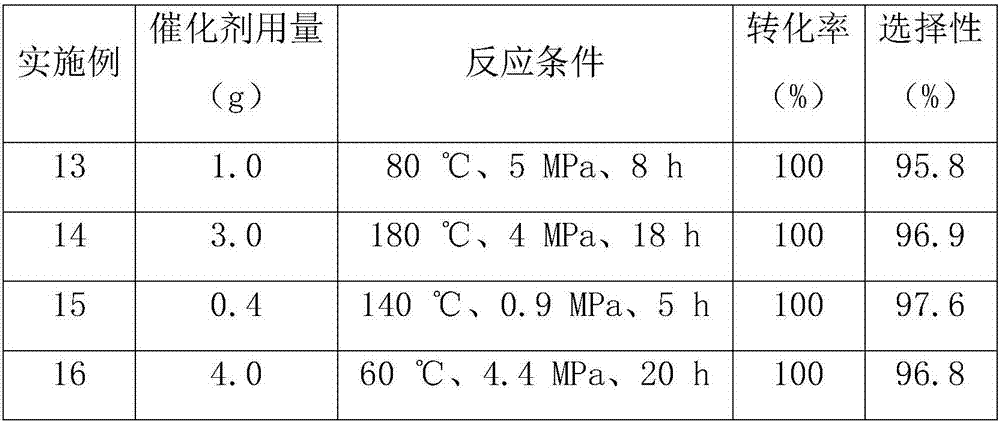

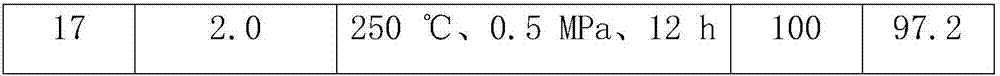

Examples

Embodiment 1

[0041] (1) Weigh 10g of mesoporous carbon, the particle size of mesoporous carbon is 1000 mesh, and the specific surface area is 1300m 2 / g, the average pore diameter is 3nm, mix it with 2g of urea evenly, and treat it at 800°C for 8h under nitrogen atmosphere to obtain 10g of nitrogen-doped mesoporous carbon;

[0042] (2) Prepare 10 g of nitrogen-doped mesoporous carbon obtained in step (1) in 100 ml of deionized water to prepare a slurry at a temperature of 25 ° C, and slowly add 10 ml of H 2 PdCl 4 Solution (the Pd content is 0.05g / ml, namely 0.47mmol / ml), stirred for 0.5h; the pH value of the solution was adjusted to 8 with 10wt% KOH solution, and the temperature was lowered to room temperature, filtered, and the filter residue was washed with deionized water until Neutral to get filter cake;

[0043] (3) The filter cake obtained in step (2) is configured into 80ml slurry at 80°C, 0.9g of 85wt% hydrazine hydrate solution (23.9mmol) is added dropwise, stirred for 2.5h, fi...

Embodiment 2

[0046] (1) Weigh 10g of mesoporous carbon, the particle size of mesoporous carbon is 800 mesh, and the specific surface area is 1500m 2 / g, the average pore size is 2nm, put it in NH 3 , the gas flow rate is 1L / h, and the treatment is at 200°C for 50h to obtain 9.9g of nitrogen-doped mesoporous carbon;

[0047] (2) Prepare 9.9 g of nitrogen-doped mesoporous carbon obtained in step (1) in 100 ml of deionized water to form a slurry at a temperature of 100 ° C, and slowly add 10 ml of Na 2 PdCl 4 solution (Pd content is 0.01g / ml, namely 0.094mmol / ml), stirred for 2h; the pH value of the solution was adjusted to 8.5 with 10wt% NaOH solution, and the temperature was lowered to room temperature, filtered, and the filter residue was washed with deionized water to medium sex;

[0048] (3) The filter cake obtained in step (2) is configured into a 50ml slurry at 100°C, 14g of 40wt% formaldehyde (186.7mmol) is added dropwise, stirred for 0.5h, filtered, and the filter cake is washed w...

Embodiment 3

[0051] (1) Weigh 10g of mesoporous carbon, the particle size of mesoporous carbon is 100 mesh, and the specific surface area is 1600m 2 / g, with an average pore diameter of 10nm, mix it with 14g of melamine evenly, and treat it at 1500°C for 0.5h under a helium atmosphere to obtain 10.0g of nitrogen-doped mesoporous carbon;

[0052] (2) Prepare 10.0 g of nitrogen-doped mesoporous carbon obtained in step (1) in 100 ml of deionized water to prepare a slurry at a temperature of 40° C., and slowly add 5 ml of Pd(NO 3 ) 2 Solution (the Pd content is 0.2g / ml, namely 1.88mmol / ml), stirred for 10h; the pH value of the solution was adjusted to 9 with ammonia water, and the temperature was lowered to room temperature, filtered, and the filter residue was washed with deionized water until neutral to obtain a filter cake ;

[0053] (3) The filter cake is then configured into a 100ml slurry at 20°C, 30g of 30wt% formic acid (195.7mmol) is added dropwise, stirred for 50 hours, filtered, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com