Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Meet the requirements of process design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

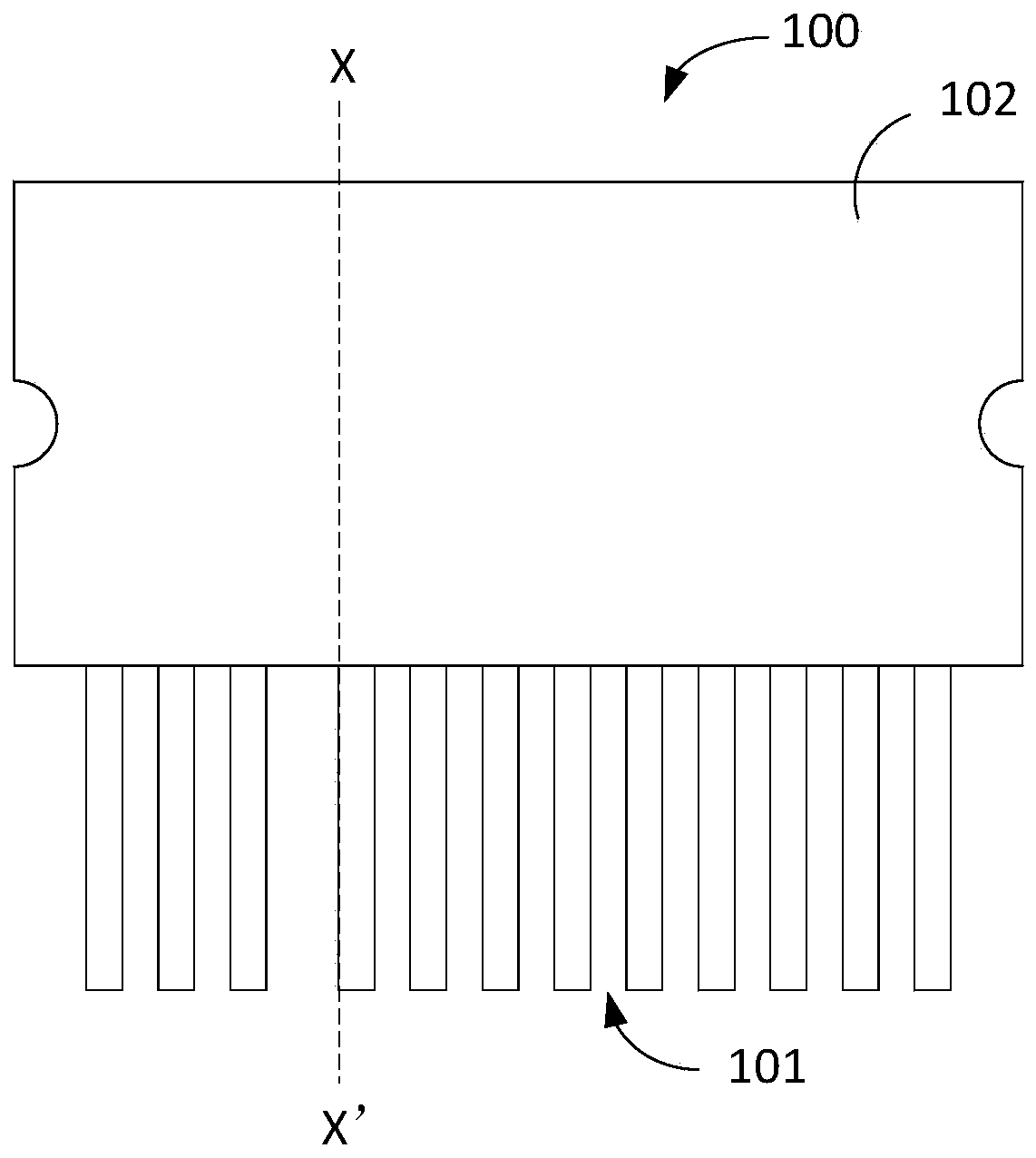

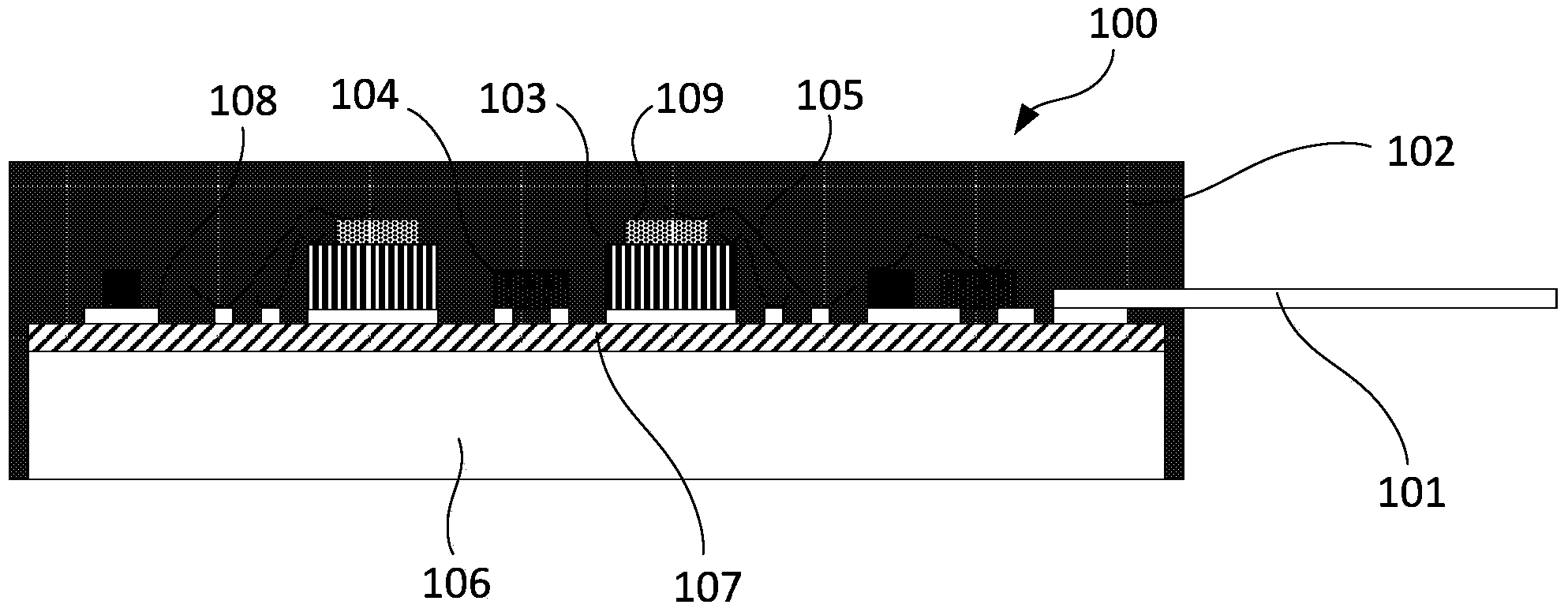

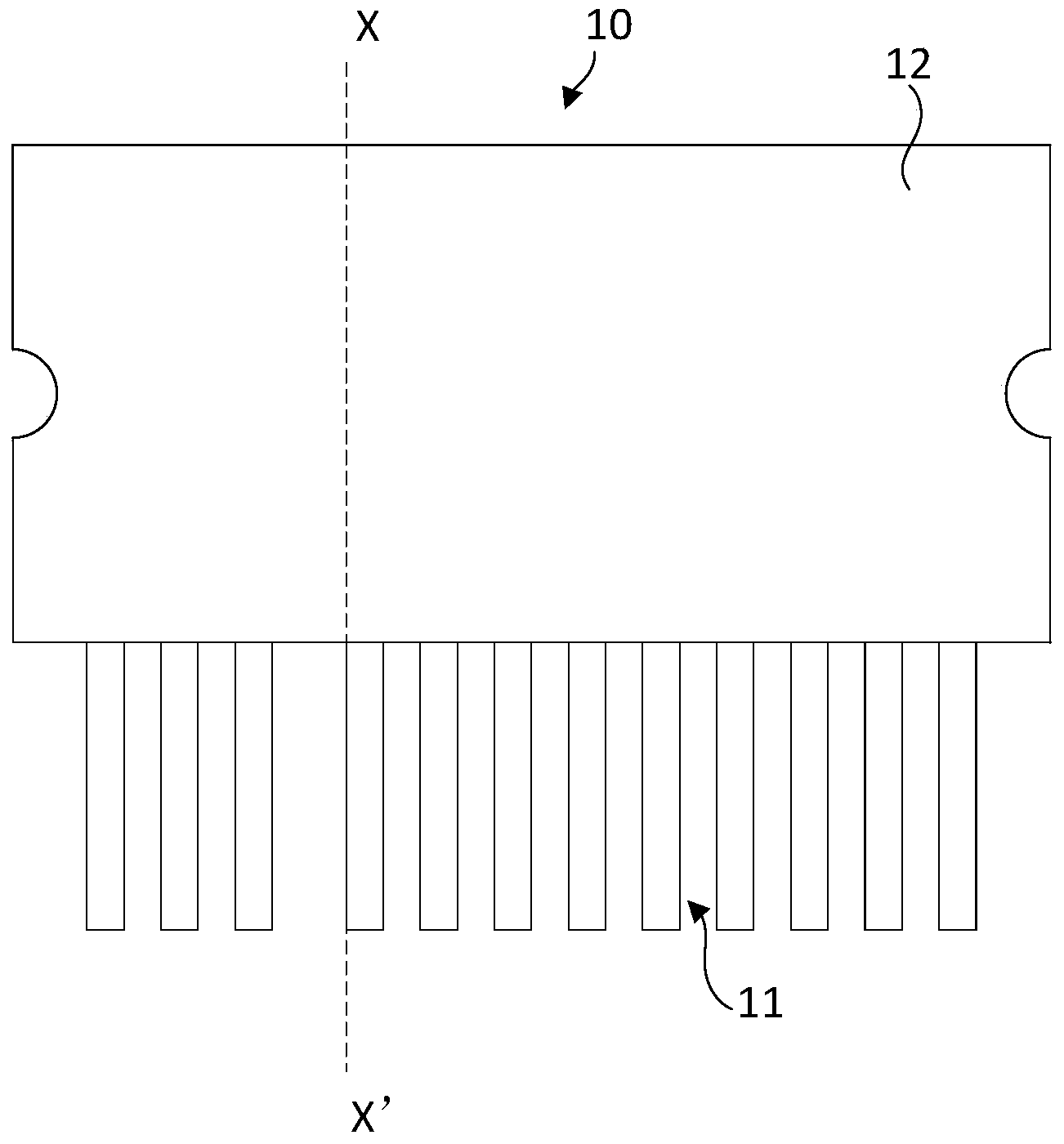

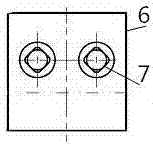

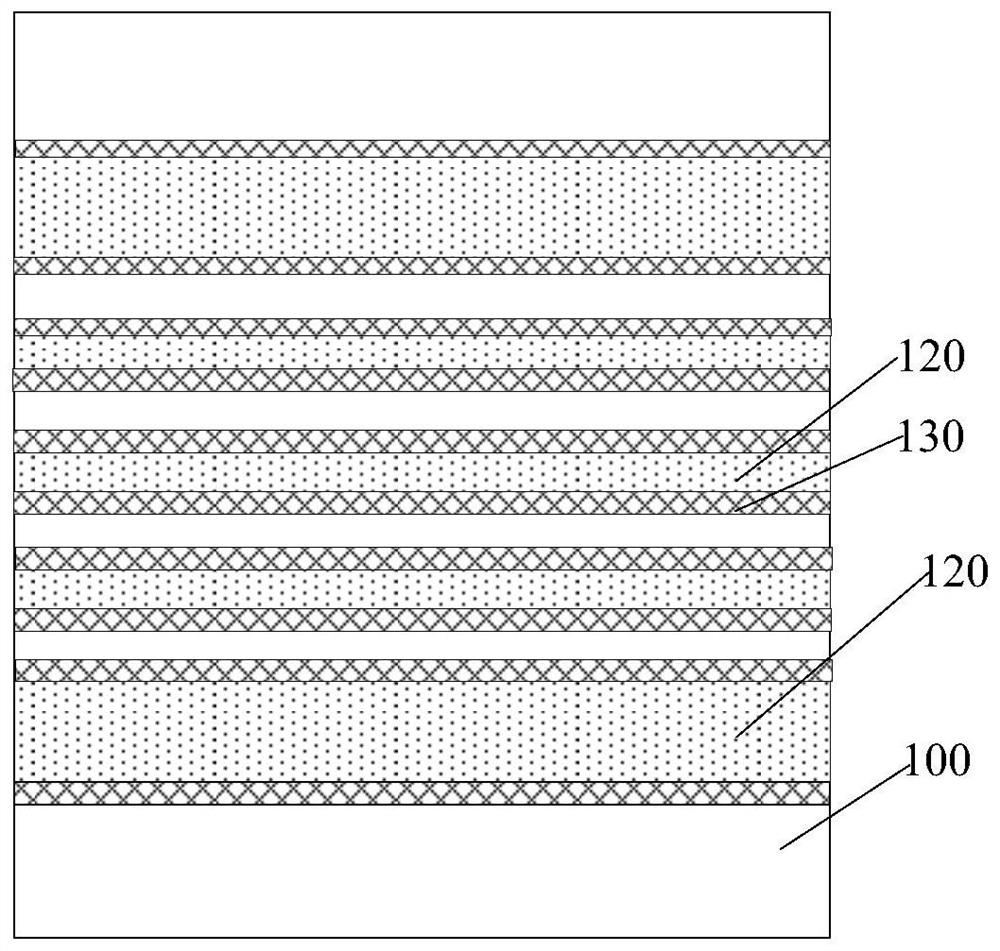

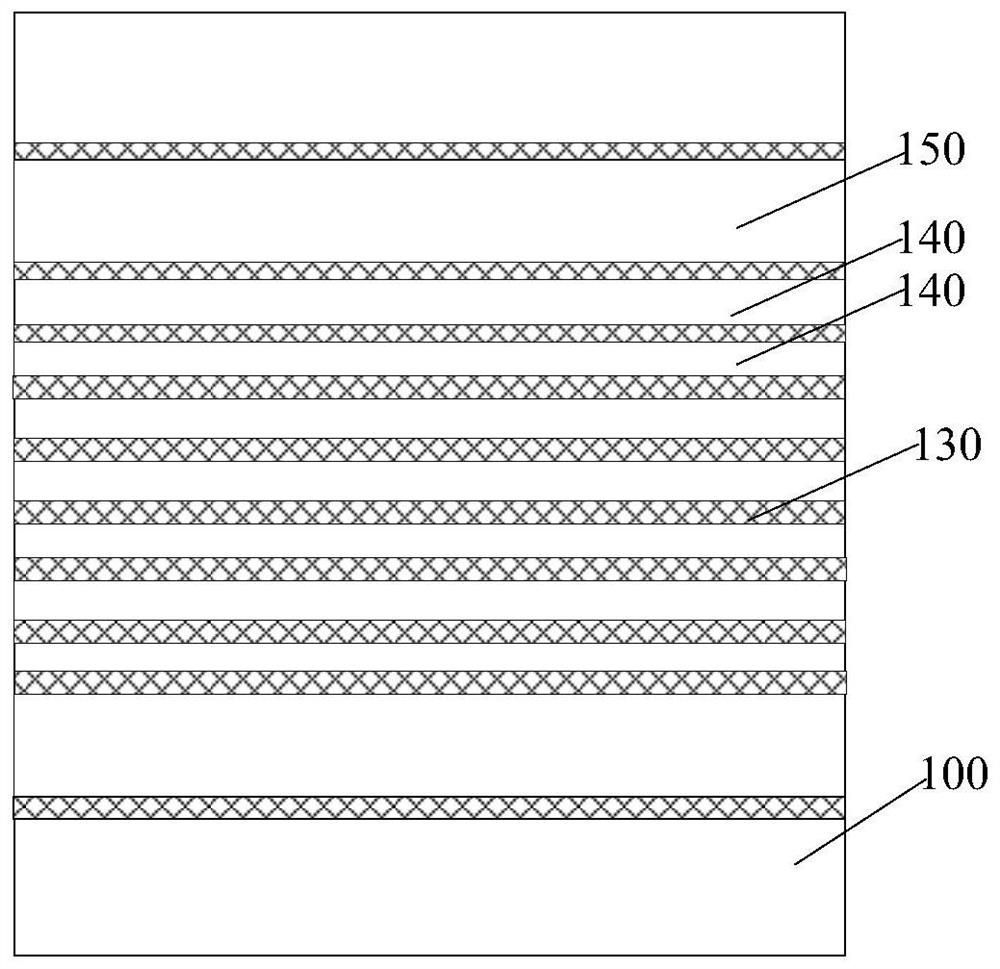

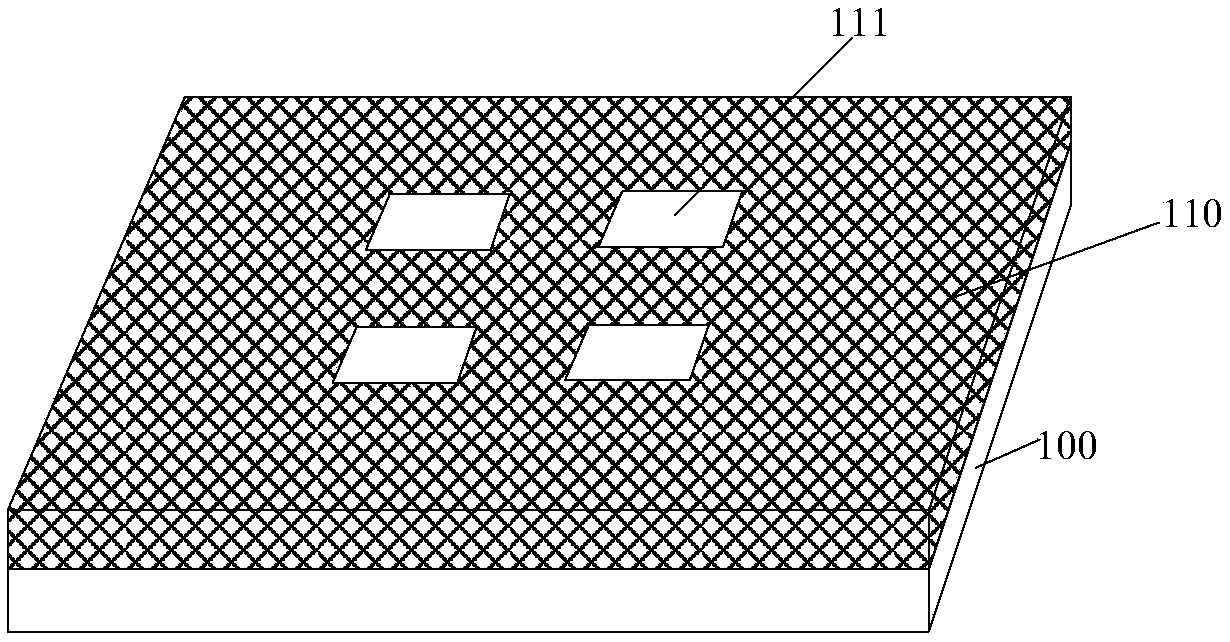

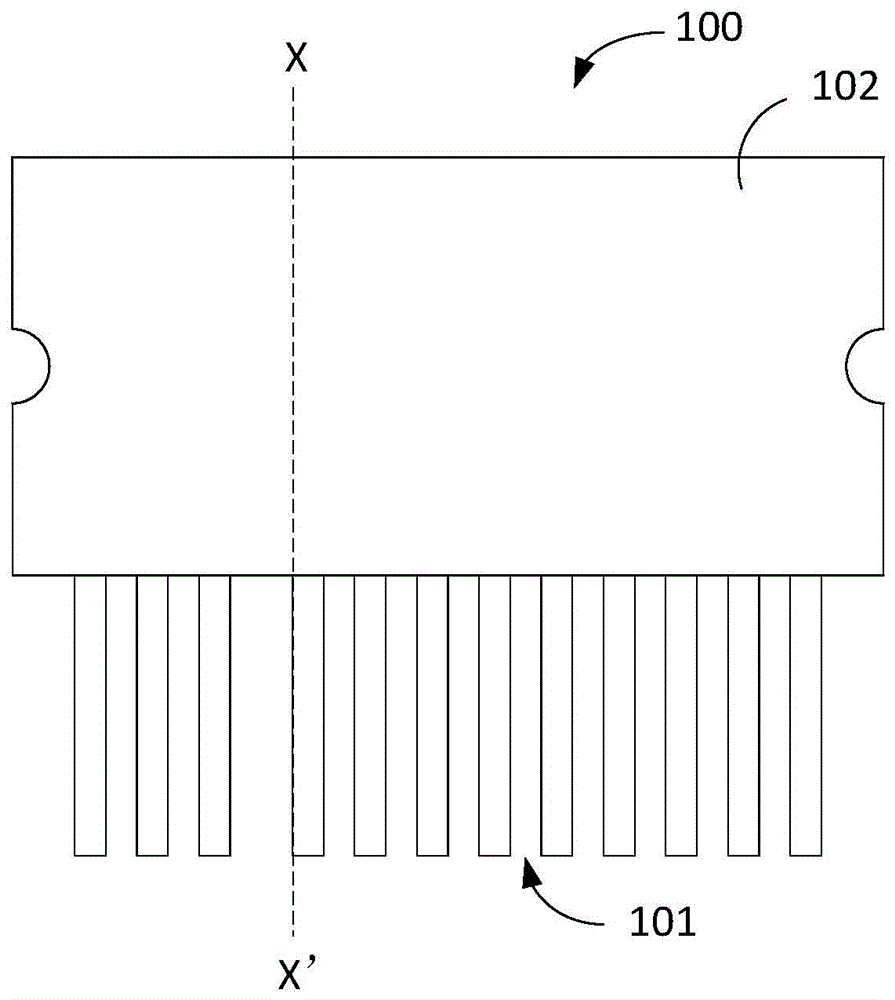

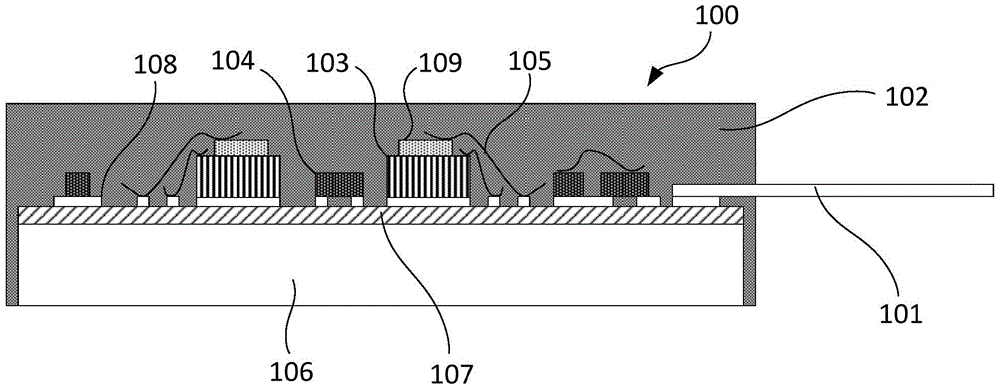

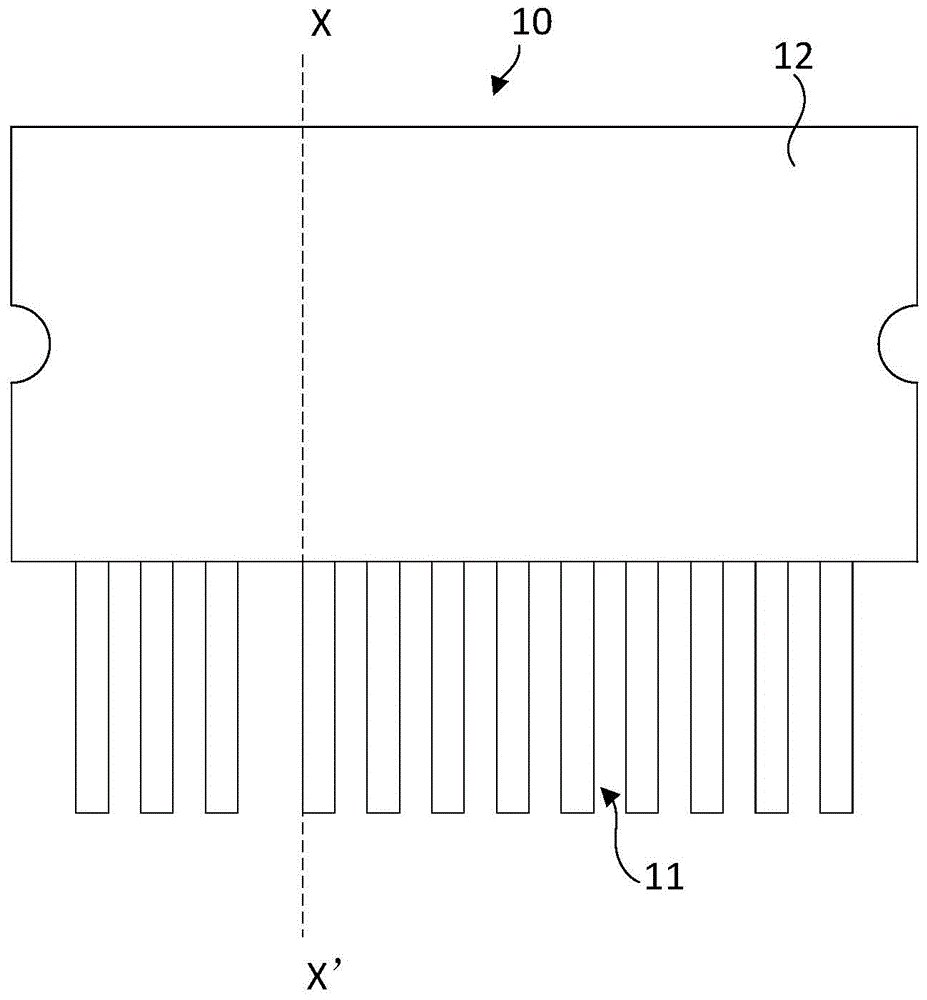

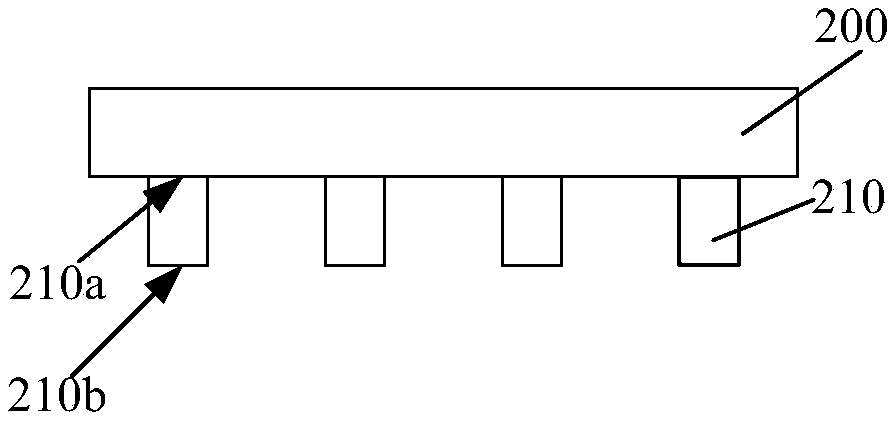

Hybrid integrated circuit module and manufacturing method thereof

ActiveCN104112719AReduce areaLow raw material costSemiconductor/solid-state device detailsSolid-state devicesGlass fiberPunching

Provided is a hybrid integrated circuit module and a manufacturing method thereof. The manufacturing method comprises the steps that a substrate, a heat radiator and a glass fiber plate with through holes arranged at preset positions are manufactured, and an insulating layer is covered on one of the surfaces of the substrate; the glass fiber plate and the heat radiator are arranged on the surface of the insulating layer; a circuit wiring layer is arranged on the surface of the glass fiber plate; power elements and non-power elements are respectively distributed on the heat radiator and the corresponding positions of the circuit wiring layer; and metal wires are connected between the circuit wiring layer, the heat radiator, the power elements and the non-power elements. Contact reliability of bonding points is enhanced, length of bonding wires is reduced and height difference of the bonding wires is reduced so that wire punching rate in molding can be effectively reduced, and thus qualified rate of manufacturing and long-term reliability of an intelligent power module are enhanced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

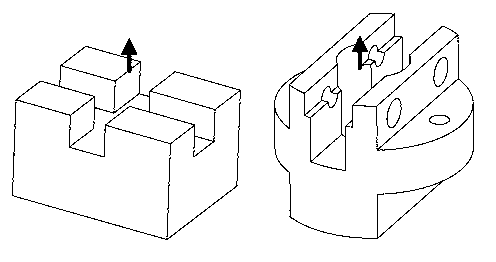

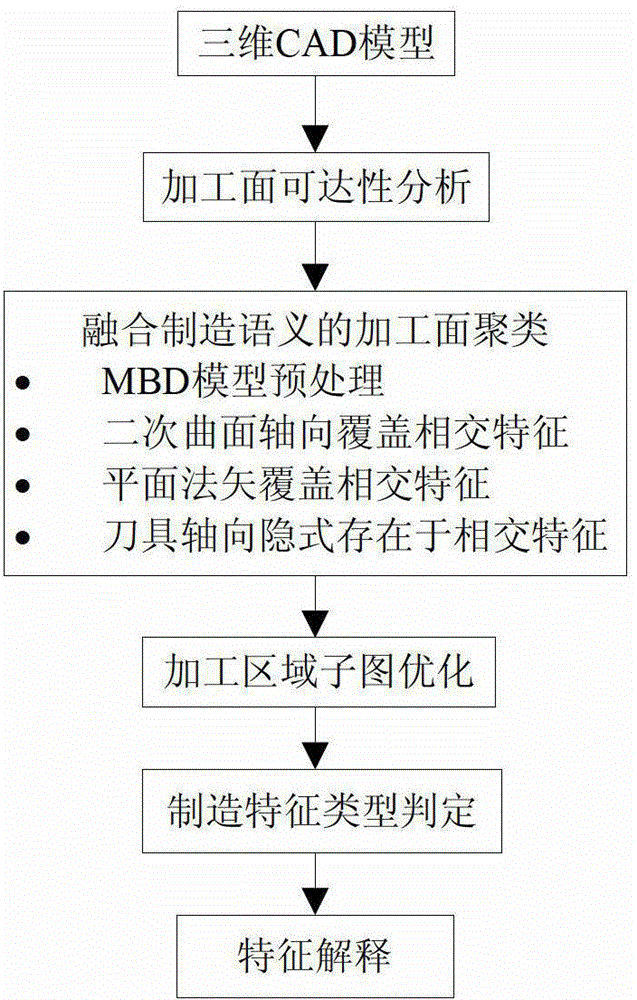

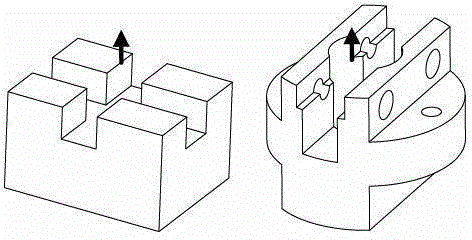

Identification method for three-dimensional computer-aided design (CAD) model intersection manufacture characteristics

InactiveCN103164582AMeet manufacturability requirementsMeet the requirements of process designSpecial data processing applicationsCluster algorithmComputer Aided Design

The invention discloses an identification method for three-dimensional computer-aided design (CAD) model intersection manufacture characteristics. The identification method for the three-dimensional CAD model intersection manufacture characteristics is used for solving the technical problem that a combinatorial explosion exists in an existing part manufacturability automatic analysis method in a process that an optional solution is generated. According to the technical scheme of the identification method for the three-dimensional CAD model intersection manufacture characteristics, a three-dimensional CAD model expressed by model based definition (MBD) is used as an information input source, firstly a reachability analysis is conducted on each machined face through an illumination-type rule, and the axial space of a feasible cutter of each machined face is ascertained; then with the axial space of the feasible cutter of each machined face as a restraint, a machined face clustering algorithm merging a manufacture semanteme is adopted to construct each of machined area subgraphs; and finally, with each machined area subgraph as a manufacture characteristic trace which is combined together with dimensioning information, the machined area subgraphs are optimized and merged, so that identification of the manufacture characteristics is achieved. According to the identification method for the three-dimensional CAD model intersection manufacture characteristics, the manufacturability analysis is merged in the identification process of the intersection manufacture characteristics, so that the machined faces are identical in the accuracy level. In the characteristic identification process, the influence, on the characteristic identification, of the design semanteme is fully considered and practicality is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

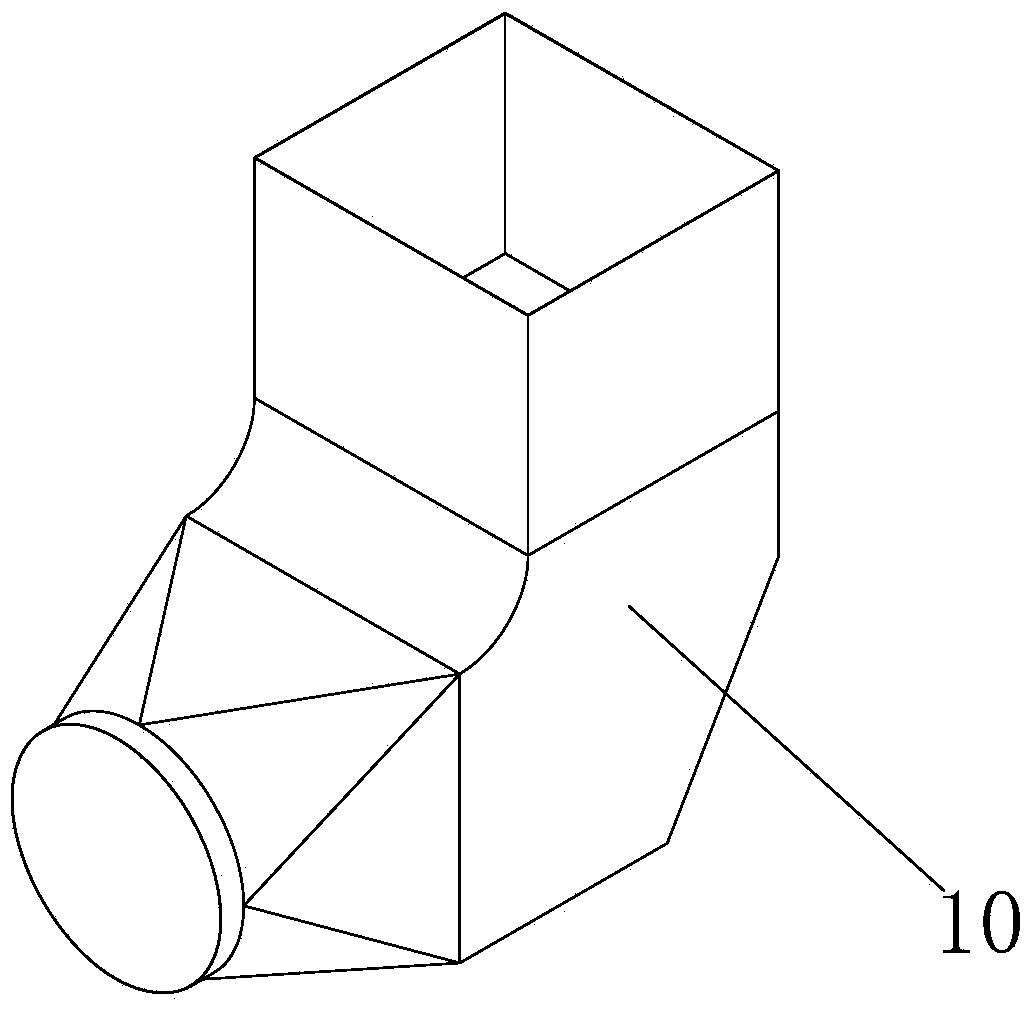

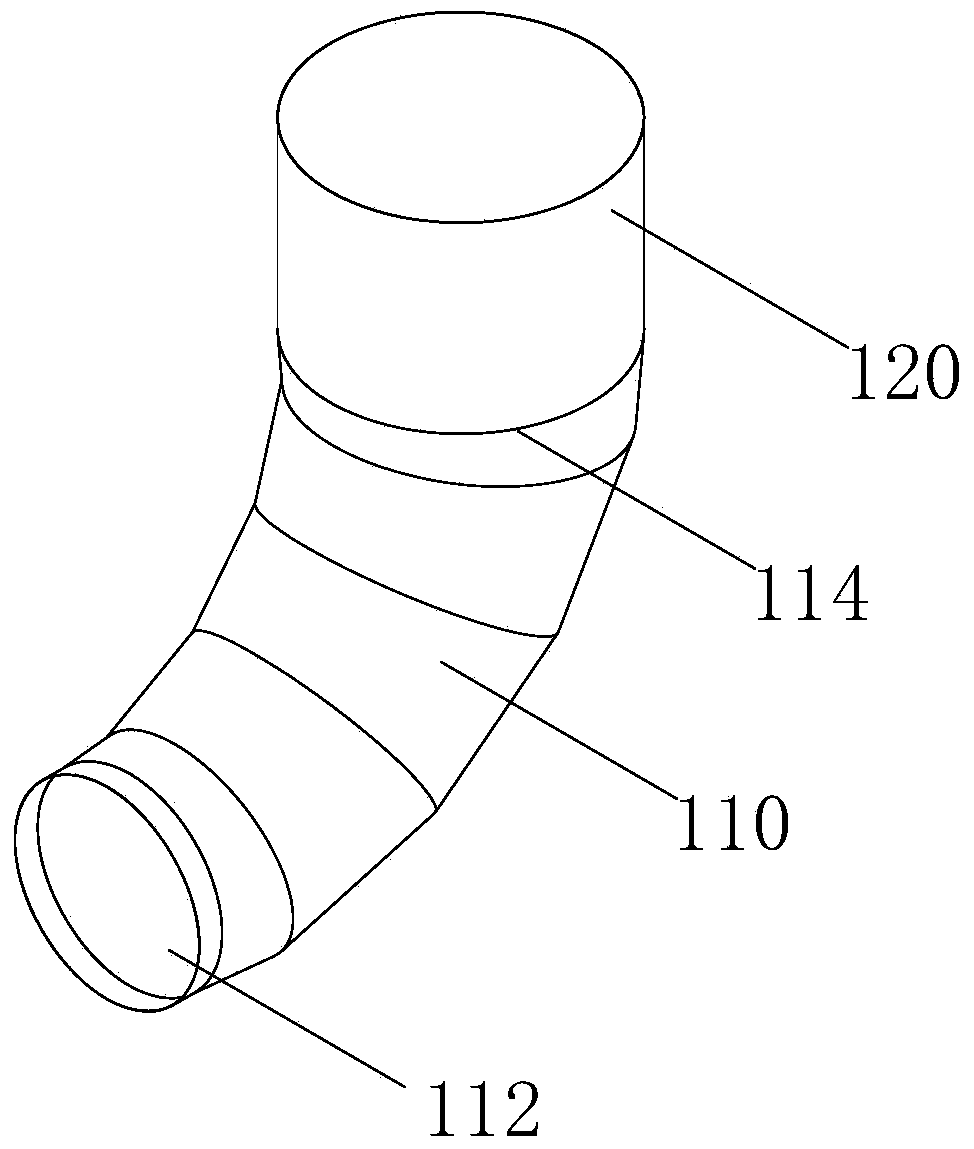

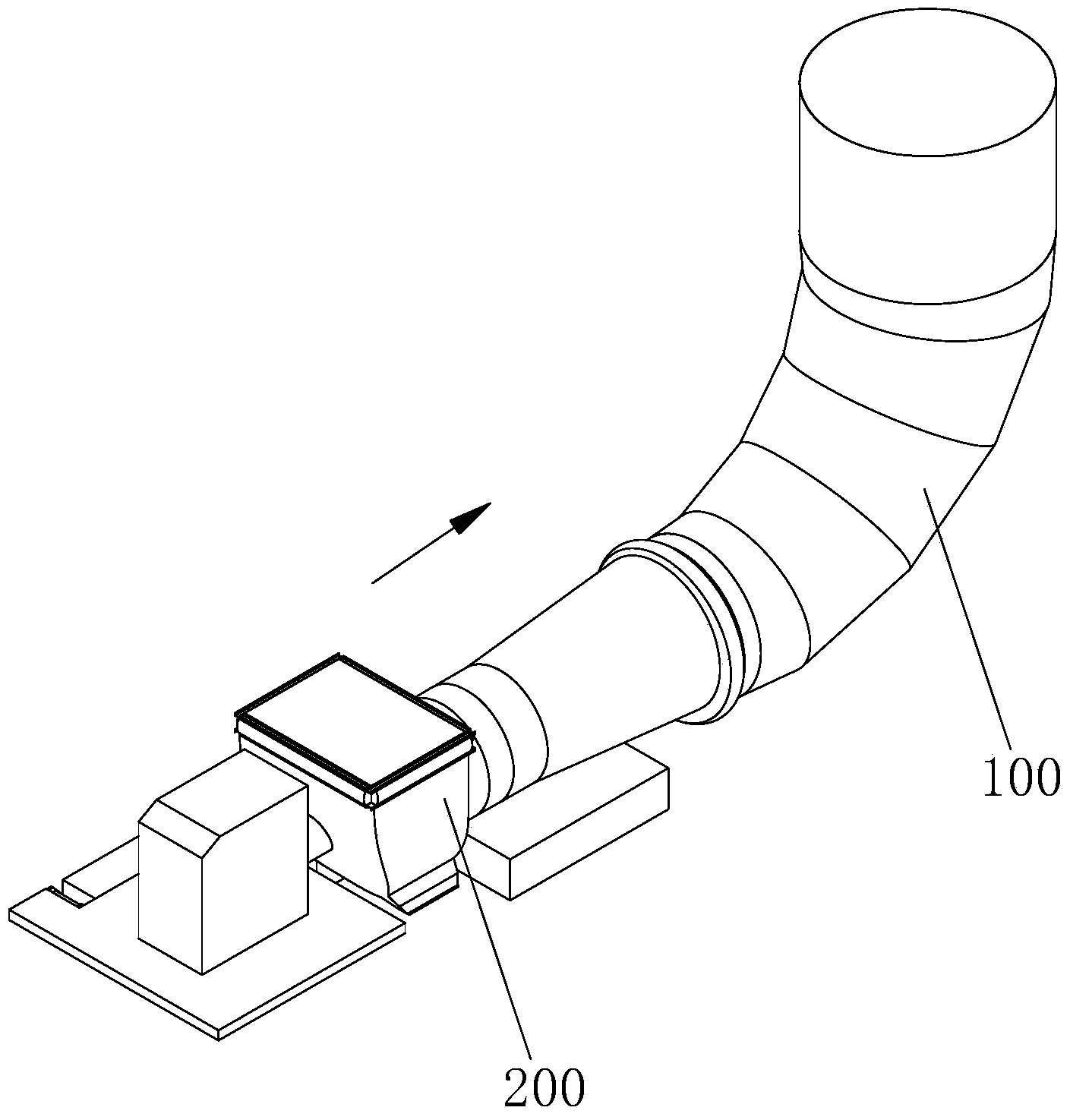

Smoke duct device and reducing elbow thereof

The invention discloses a reducing elbow which comprises a reducing section and a body section. The cross section of the reducing section and the cross section of the body section are circular, the reducing section comprises a large end and a small end, the diameter of the reducing section is gradually enlarged from the small end to the large end, the reducing section is curved, the large end of the reducing section is communicated with the body section, and the ratio of the curved radius of the reducing section to the diameter of the small end is 1.0-3.0. The cross section of the reducing section and the cross section of the body section are circular, the diameter of the reducing section is gradually enlarged from the small end to the large end, the reducing section is curved, the large end of the reducing section is communicated with the body section, and therefore reducing and turning are achieved synchronously, reducing has the enough diffusion section, turning has the enough turning radius, the reducing elbow is even in smoke flow field, and a smoke duct body is prevented from vibrating to generate noise. The conclusion that the resistance generated by the reducing elbow is far smaller than that generated by a traditional rectangular reducing elbow is obtained through FLUENT fluid simulation software analog computation. The invention further discloses a smoke duct device.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Grinding method for thin wall guide tube with tungsten carbide coating

InactiveCN109277885AEliminate the effects of processingCorrection of concentricity errorGrinding work supportsProcess systemsThin walled

The invention discloses a grinding method for a thin wall guide tube with a tungsten carbide coating and particularly relates to the grinding method for the thin wall guide tube with the tungsten carbide coating and a fixture. According to the grinding method for the fixture, the fixture is ground by operating a grinding machine, and the positioning accuracy of workpieces is improved; according tothe grinding method for the thin wall guide tube with the tungsten carbide coating, grinding machining process parameters are confirmed on base of the grinding technical requirements for the outer outline (an outer circle, a transition circle angle, an end face and an end face chamfer) of the thin wall guide tube with the tungsten carbide coating, and grinding process control is performed on theouter outline of the thin wall guide tube with the tungsten carbide coating; by means of the grinding method for the thin wall guide tube with the tungsten carbide coating and the fixture, the fact that the grinding machine, the fixture, a grinding wheel and the workpieces form a complete process system in grinding is realized, in this way, occurrence of the coating grinding quality problem of aluminum alloy sleeve type thin-wall parts of some type is completely eradicated, and the long-term practice test is performed, the qualified rate of the parts is increased, and the grinding method for the thin wall guide tube with the tungsten carbide coating and the fixture has reference significance in guiding production.

Owner:HARBIN UNIV OF SCI & TECH

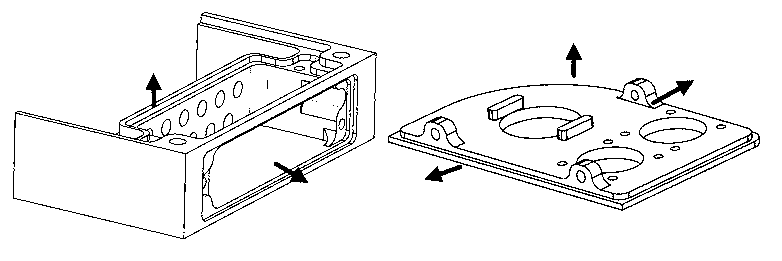

Forming method of large-diameter thin-walled stainless steel barrel

The invention discloses a forming method of a large-diameter thin-walled stainless steel barrel. The method includes the following steps that firstly, groove pre-bending and machining are conducted; secondly, stainless steel plates are hoisted to tool supports and fixed to the tool supports; thirdly, turnover is conducted; fourthly, assembling and longitudinal joint welding are conducted; fifthly, weld joint correction is conducted; and sixthly, the tool supports are detached. By means of the large-diameter thin-walled stainless steel barrel formed through the method, hoisting difficulty can be eliminated, ferrite pollution is avoided, the barrel does not need to be overturned, and it is ensured that the circular degree of the barrel meets the process design requirement.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

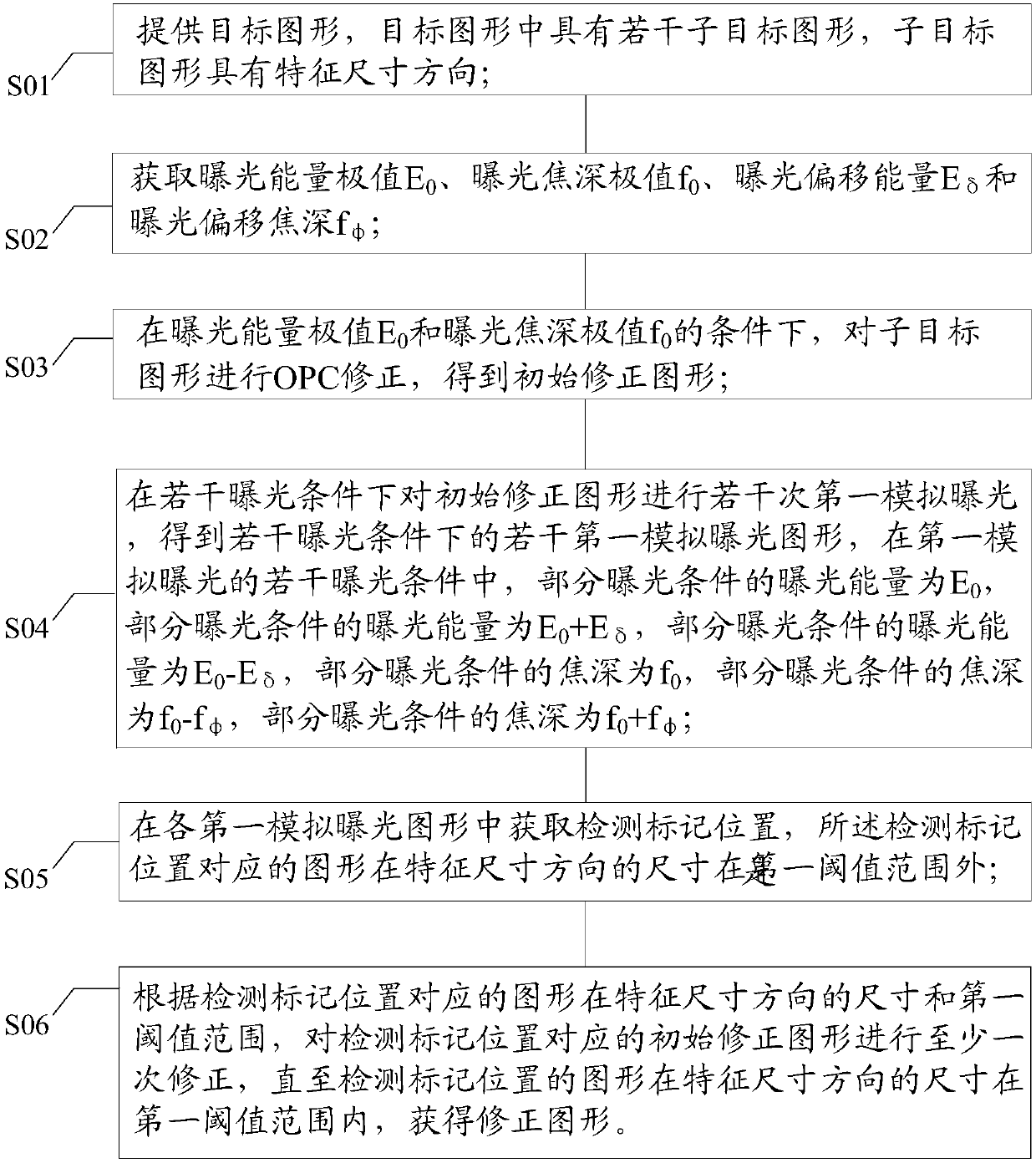

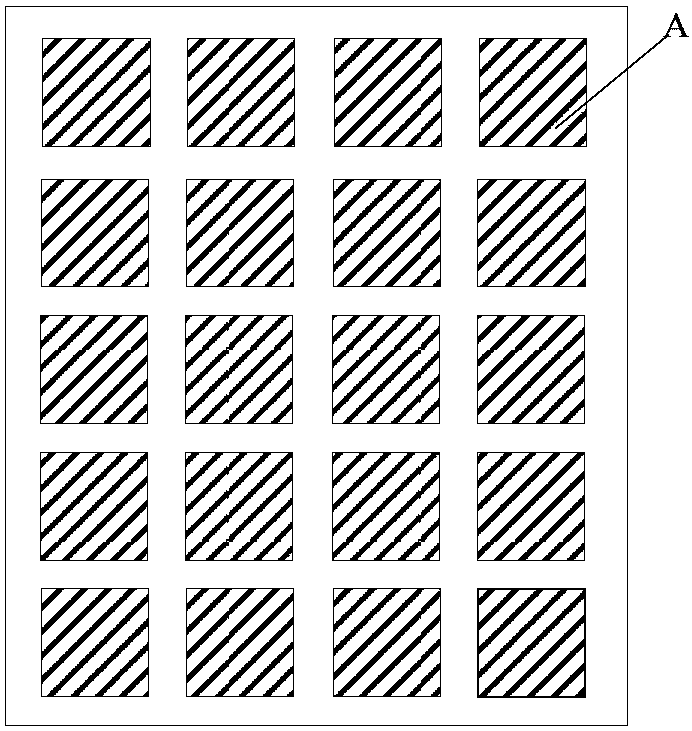

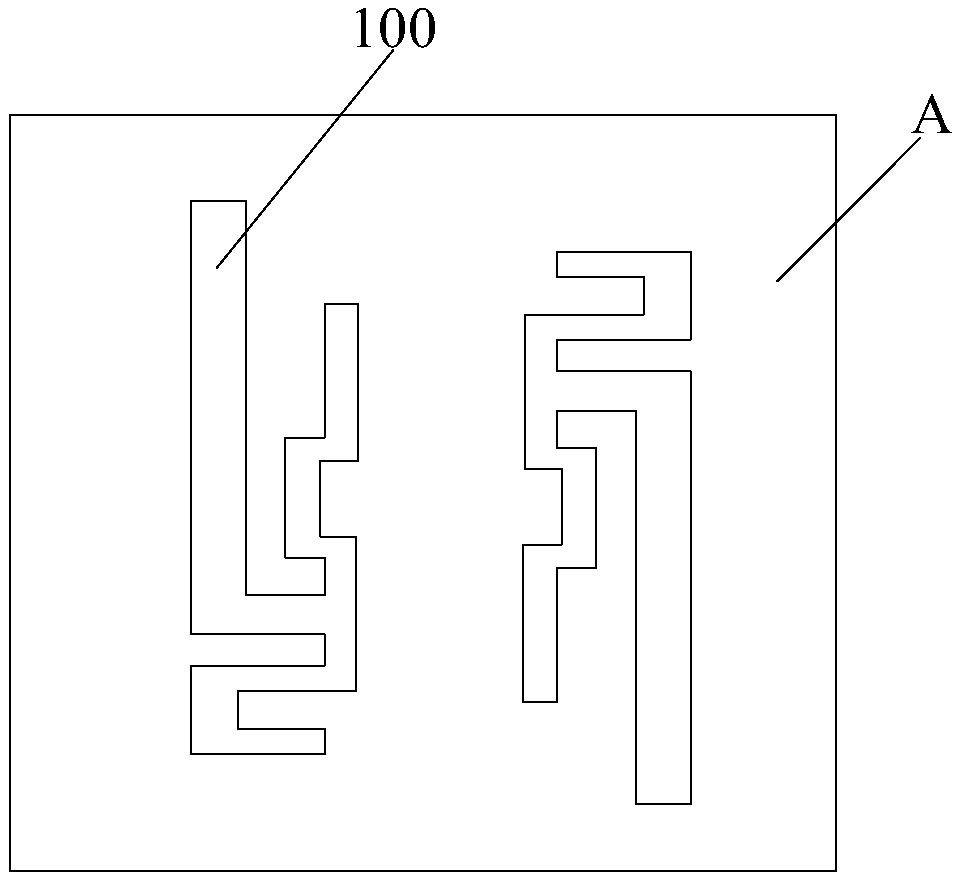

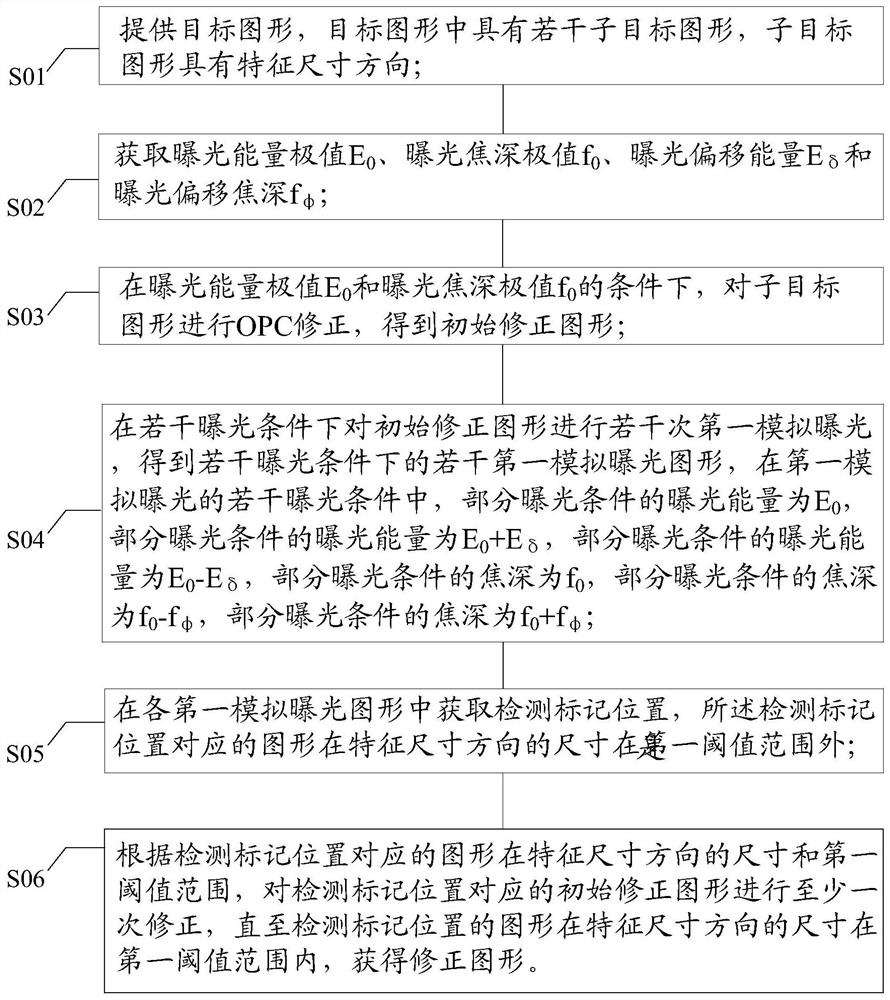

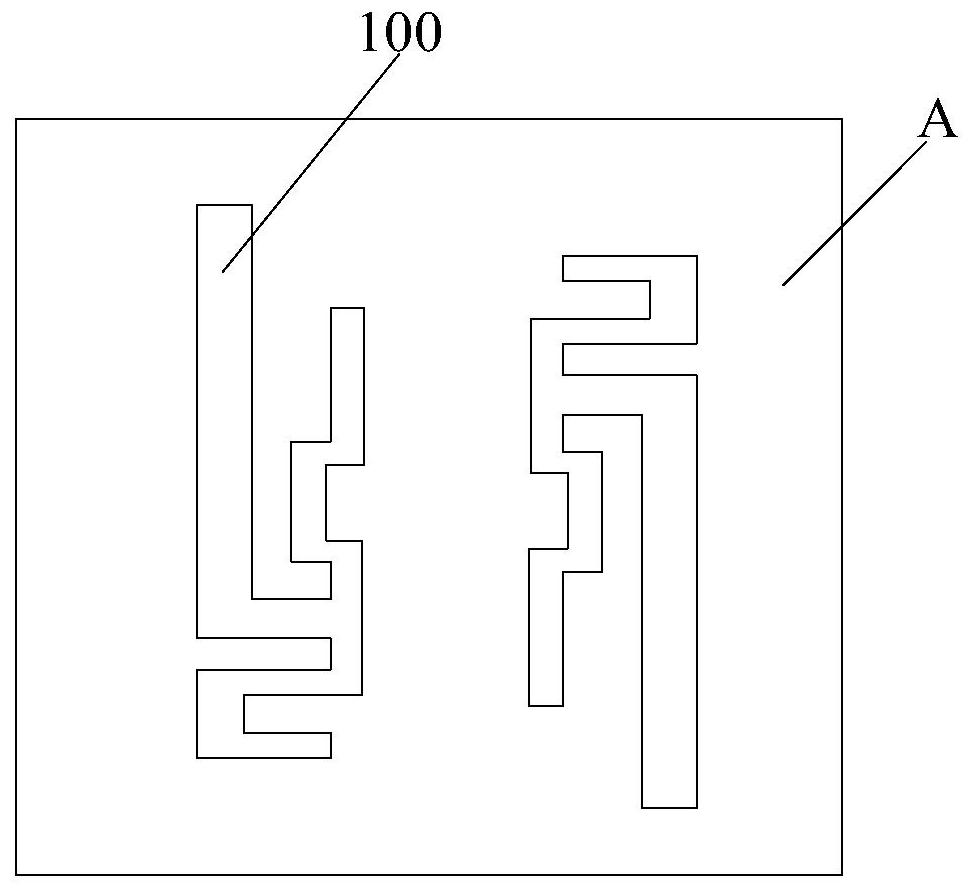

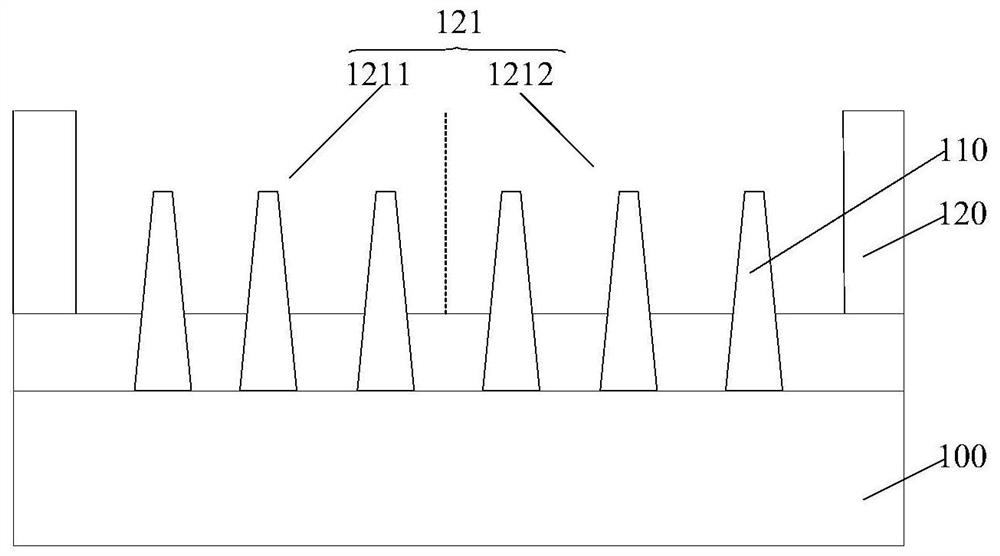

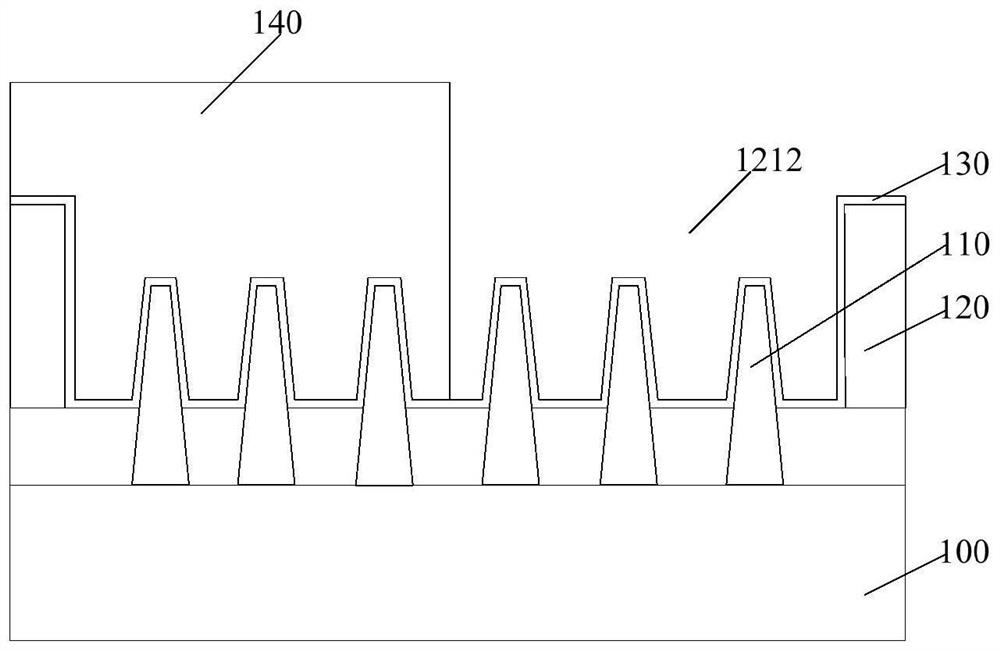

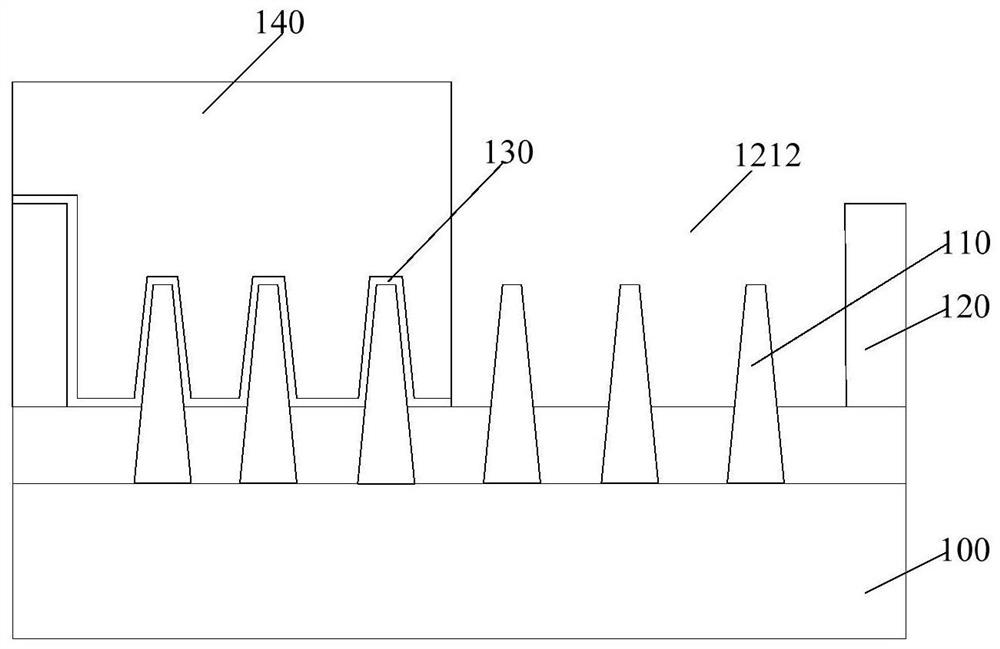

Optical proximity correction method and manufacturing method of mask plate

ActiveCN110032037AIncreased process windowMeet the requirements of process designOriginals for photomechanical treatmentGraphicsAlgorithm

The invention discloses an optical proximity correction method and a manufacturing method of a mask plate, and the method comprises the steps: carrying out the OPC correction of a sub-target graph toobtain an initial correction graph; performing first simulated exposure of the initial correction graph for a plurality of times to obtain a plurality of first simulated exposure graphs under a plurality of exposure conditions; acquiring a detection mark position in each first simulated exposure graph, wherein the size of the graph corresponding to the detection mark position in the characteristicsize direction is out of a first threshold range; and according to the size of the graph corresponding to the detection mark position in the characteristic size direction and the first threshold range, carrying out correction of the initial correction graph corresponding to the detection mark position for at least one time to obtain a correction graph. A process window for correcting the graph isenlarged.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

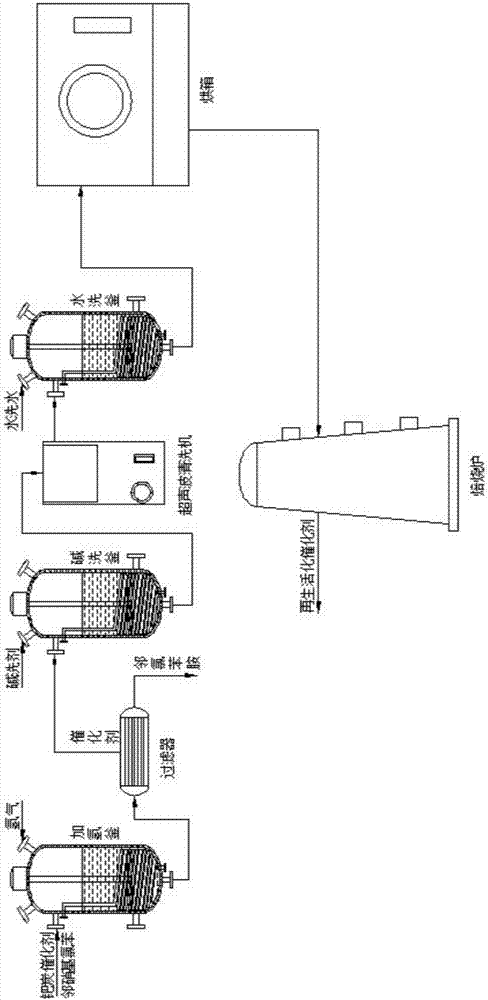

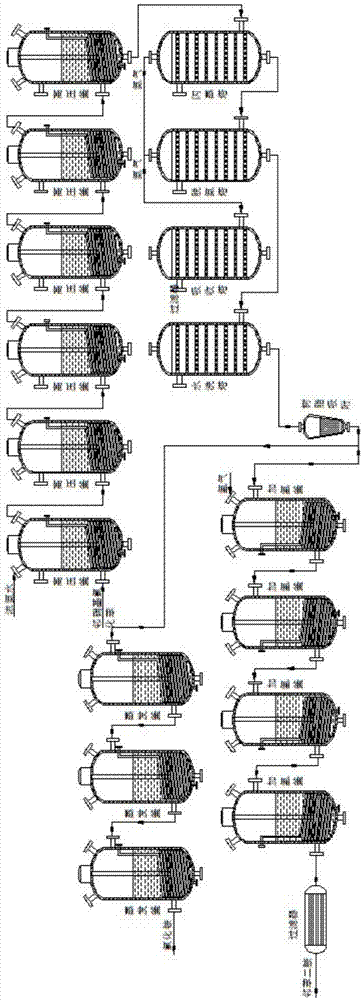

Method for regenerating catalyst for synthesizing o-chloroaniline

InactiveCN107570215AImprove regeneration efficiencyImprove recycling ratesOrganic-compounds/hydrides/coordination-complexes catalystsMetal/metal-oxides/metal-hydroxide catalystsEconomic benefitsMegasonic cleaning

The invention discloses a method for regenerating a catalyst for synthesizing o-chloroaniline. The method for regenerating the catalys specifically includes the following steps of: filtering a palladium-carbon catalyst out in a filter which is provided with a metal sintered tube and arranged in a final-stage kettle of four-stage series hydrogenation kettles, introducing the palladium-carbon catalyst into an alkaline washing kettle, conducting alkaline washing on the palladium-carbon catalyst with a hot alkaline solution, introducing the alkaline-washed palladium-carbon catalyst into an ultrasonic cleaner to perform ultrasonic cleaning, introducing the ultrasonic-cleaned palladium-carbon catalyst into a water washing kettle for water washing, putting the water-washed palladium-carbon catalyst into an oven for drying and water removal, and then raising the temperature and calcining the dried palladium-carbon catalyst to obtain the dried and regenerated palladium-carbon catalyst. According to the method for regenerating the catalyst for synthesizing the o-chloroaniline, the useful palladium-carbon catalyst can be effectively recycled, the content of o-phenylenediamine obtained throughthe catalysis of the palladium-carbon catalyst is 98% or above, the synthesis cost is saved, and the economic benefit is improved; besides, the method and the process design of the regeneration of the catalyst used for synthesizing the o-chloroaniline are optimized, and requirements of the industrial design are met.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

Method for heaping up waterproof tailing pond dam body at one time using tailing coarse sand together with geomembrane

The invention discloses a method for heaping up a waterproof tailing pond dam body at one time using tailing coarse sand together with geomembrane. The method includes the steps that (1) beneficiation tailing sand is classified through a cyclone, the settling sand is further classified through a high frequency linear vibrating screen, the coarse sand with containing water being about 15%-18% is obtained, it is guaranteed that the coarse sand with the grain size being more than 0.2 mm can be over 50%, and the material uniformity deviation factor K is equal to 40%-60%; (2) grinding damming is conducted on the obtained coarse sand on a treated dam base, it can be guaranteed that the inner and outer slope ratio is 1:2 to 1:3, the dry bulk density is 1.6-1.8 t / m<3>, and the permeability coefficient is 1.3*10-4-1.5*10-4 cm / s; (3) the inner slope of the heaped dam body is covered with a waterproof geomembrane layer; (4) the outer slope of the heaped dam body is protected by plain concrete precast blocks. The water content, mean grain size and evenness of the coarse sand after being screened can all meet requirements, the stability of the dam body is guaranteed, and one-time heaping shaping can be achieved.

Owner:TONGLING NON FERROUS METAL GROUP CORP

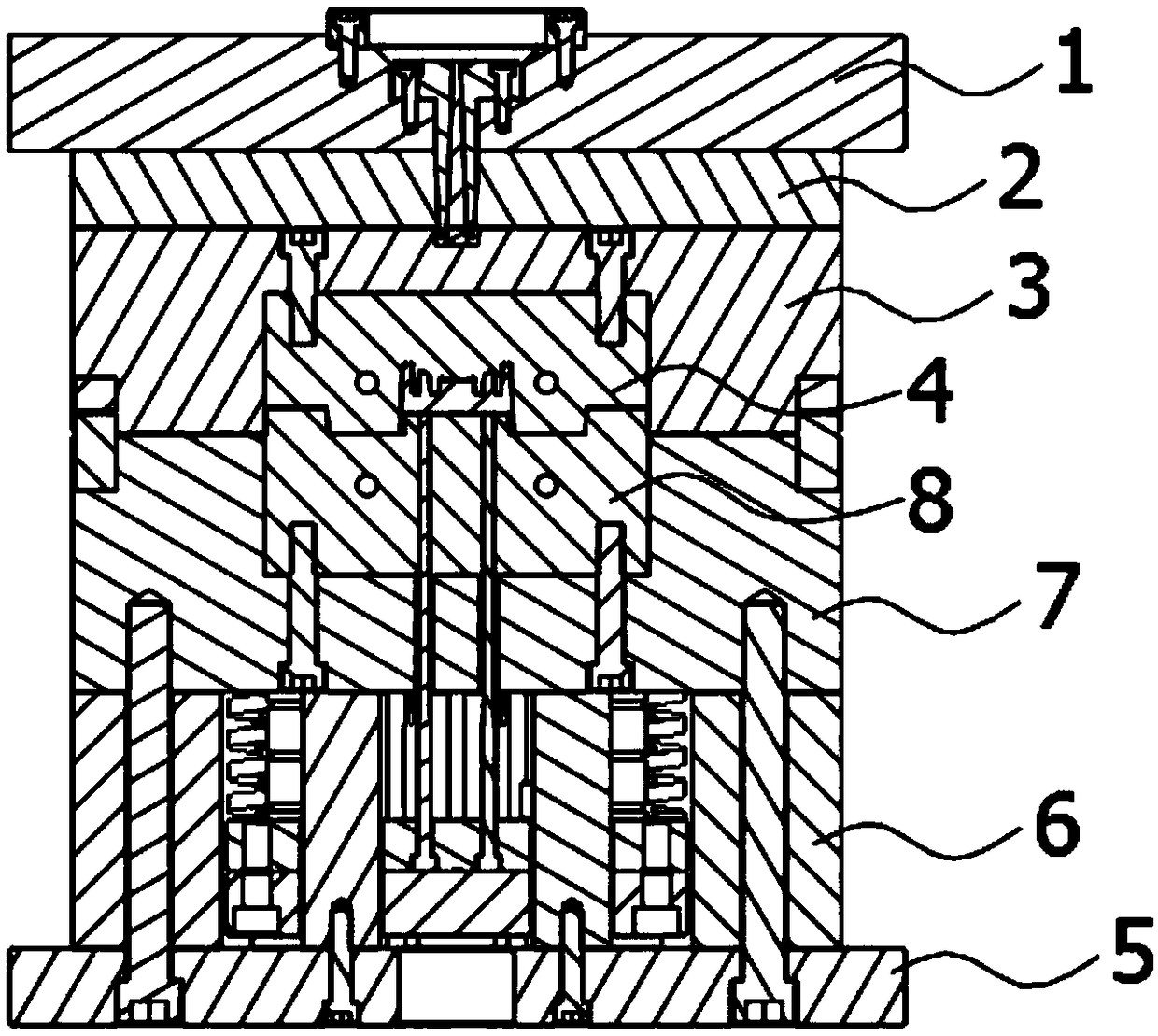

Glass light guide plate injection mold and light guide plate injection molding process

InactiveCN109093938ASimple structureImprove stabilityOptical articlesLight guideInjection molding process

The invention discloses a glass light guide plate injection mold and a light guide plate injection molding process. The glass light guide plate injection mold comprises a male mold holder and a femalemold holder which are used in cooperation. The female mold holder comprises a panel, a stripper plate, a female mold plate and a female mold core. The male mold holder comprises a bottom plate, moldlegs, a male mold plate and a male mold core. A light guide plate cavity is formed between the female mold core and the male mold core. The male mold holder is internally provided with a male mold cooling water runner. The female mold holder is internally provided with a female mold cooling water runner. A positioning structure used for relative sliding of the male mold holder and the female moldholder is included. The positioning structure further comprises positioning sleeves fixedly connected with the periphery of the male mold plate and positioning rods fixedly connected with the female mold plate, and further comprises positioning convex blocks located on the side wall of the male mold plate and positioning grooves located in the side wall of the female mold plate. According to the mold, positioning stability of the male mold holder and the female mold holder can be improved through matched sleeving connection of the positioning sleeves and the positioning rods and matched clamping connection of the positioning convex blocks and the positioning grooves.

Owner:昆山弘正电子科技有限公司

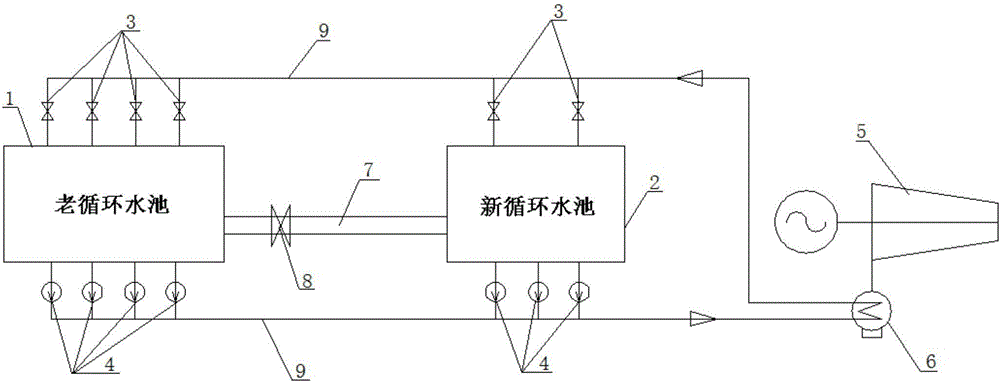

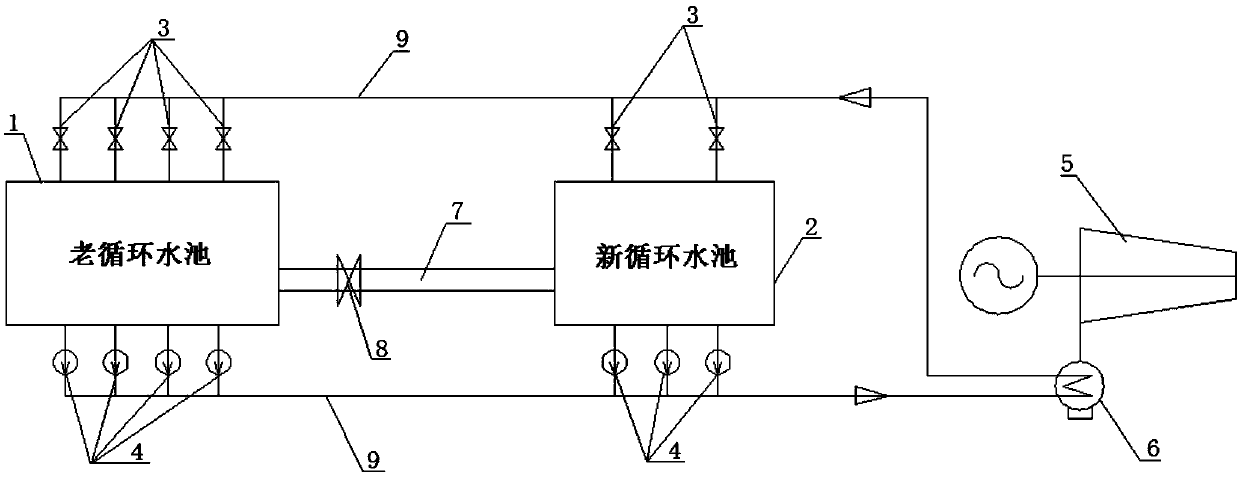

Extension method for circulating water system of power plant

ActiveCN106088214APrevent overflowOperation impactService pipe systemsWater mainsWater resourcesStop time

The invention discloses an extension method for a circulating water system of a power plant. A new circulating water pool is independently built beside an old circulating water pool, and is communicated with the old circulating water pool through a communicating pipe, the new circulating water pool and the old circulating water pool are connected in parallel with a main pipe, running of an existing circulating water system is not influenced in a process of building the new circulating water pool, safe and stable running of original equipment is ensured, and a turboset and the circulating water system are required to be stopped only in a process of communicating the new circulating water pool with the old circulating water pool. According to the method, the stopping time is greatly shortened, economic loss caused by stopping is reduced, and process design requirements are met; the communicating pipe is arranged between the new circulating water pool and the old circulating water pool, so that problems about water level balance between the new circulating water pool and the old circulating water pool are solved, and overflow of the circulating water pools and waste of water resources are avoided.

Owner:武汉钢铁有限公司

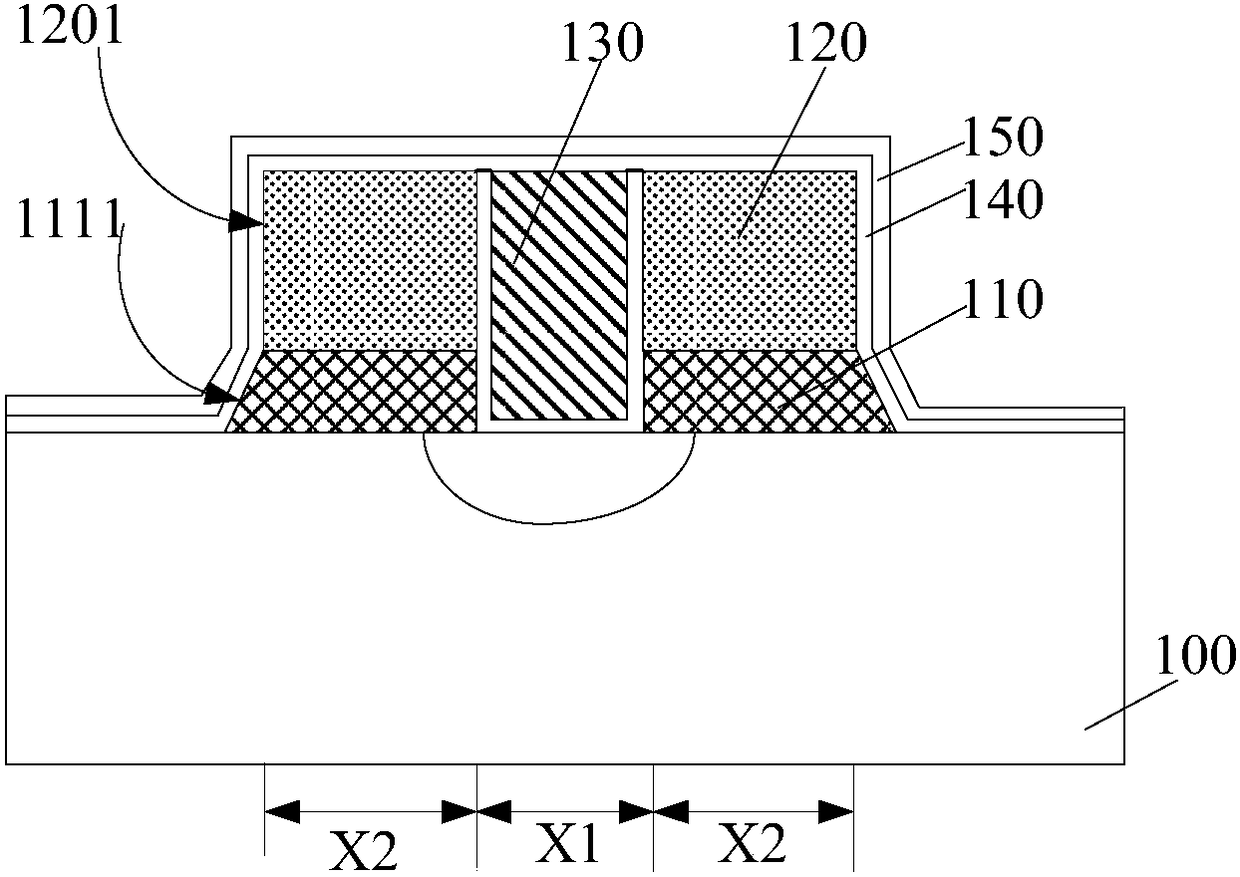

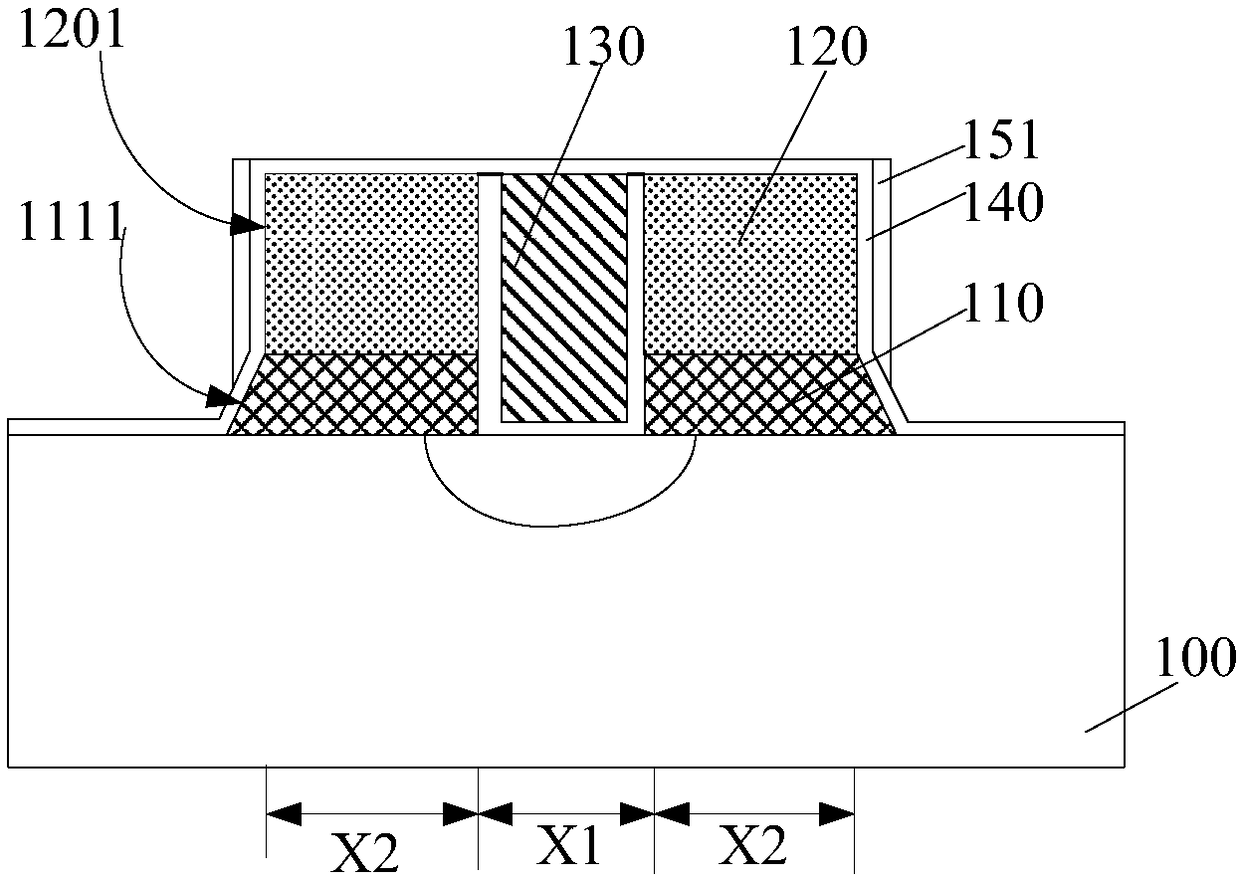

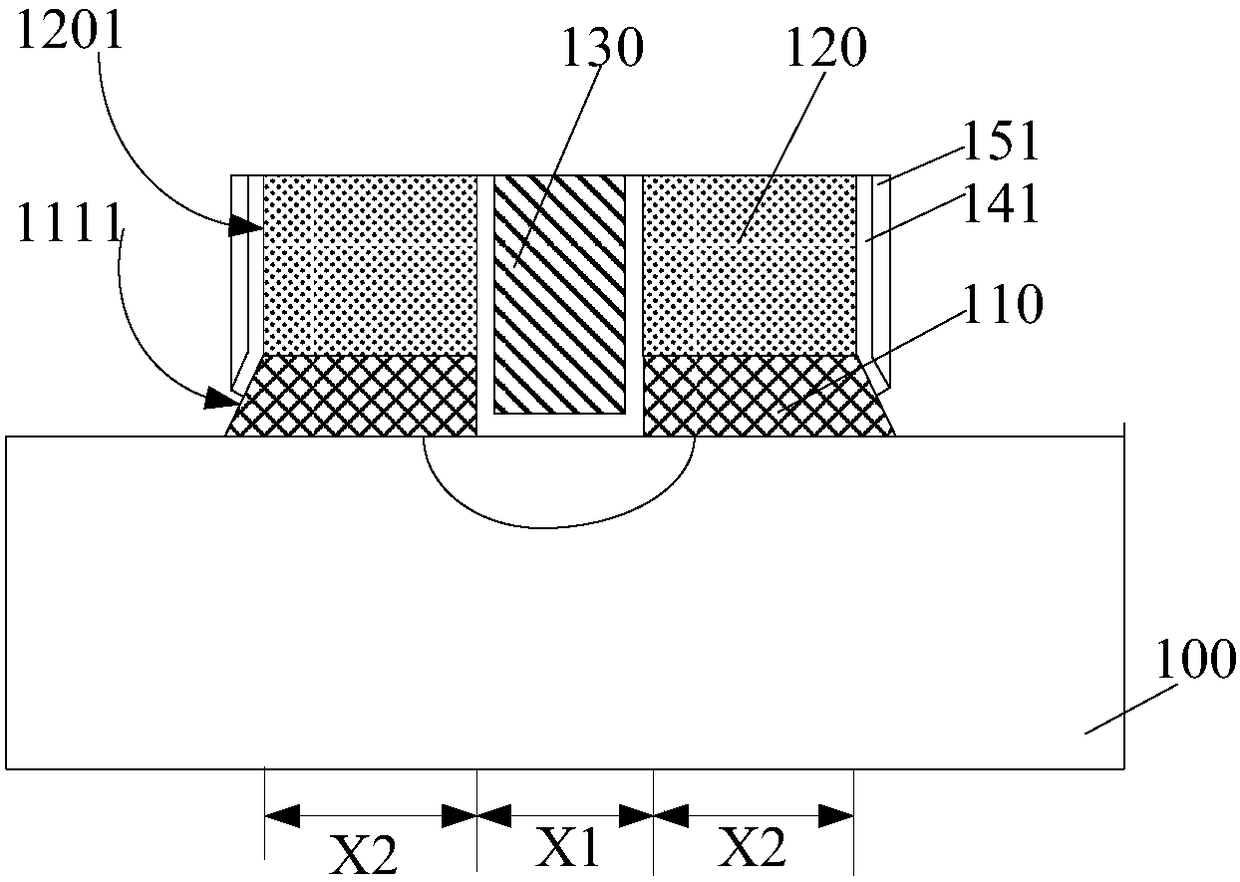

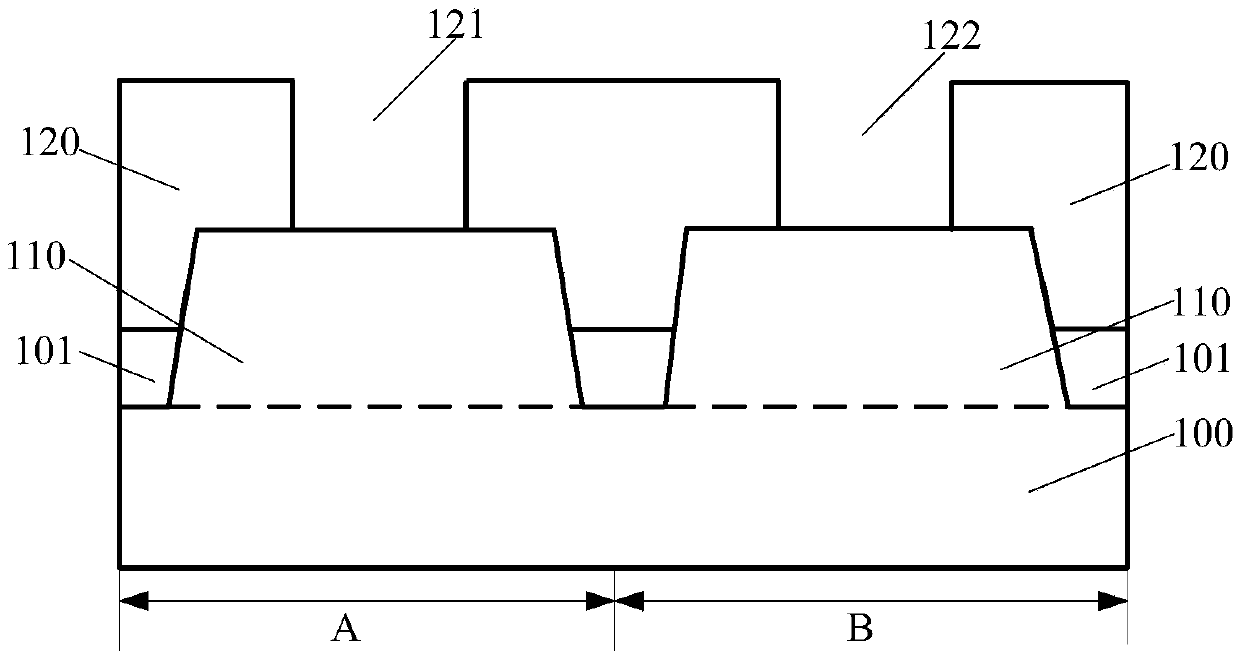

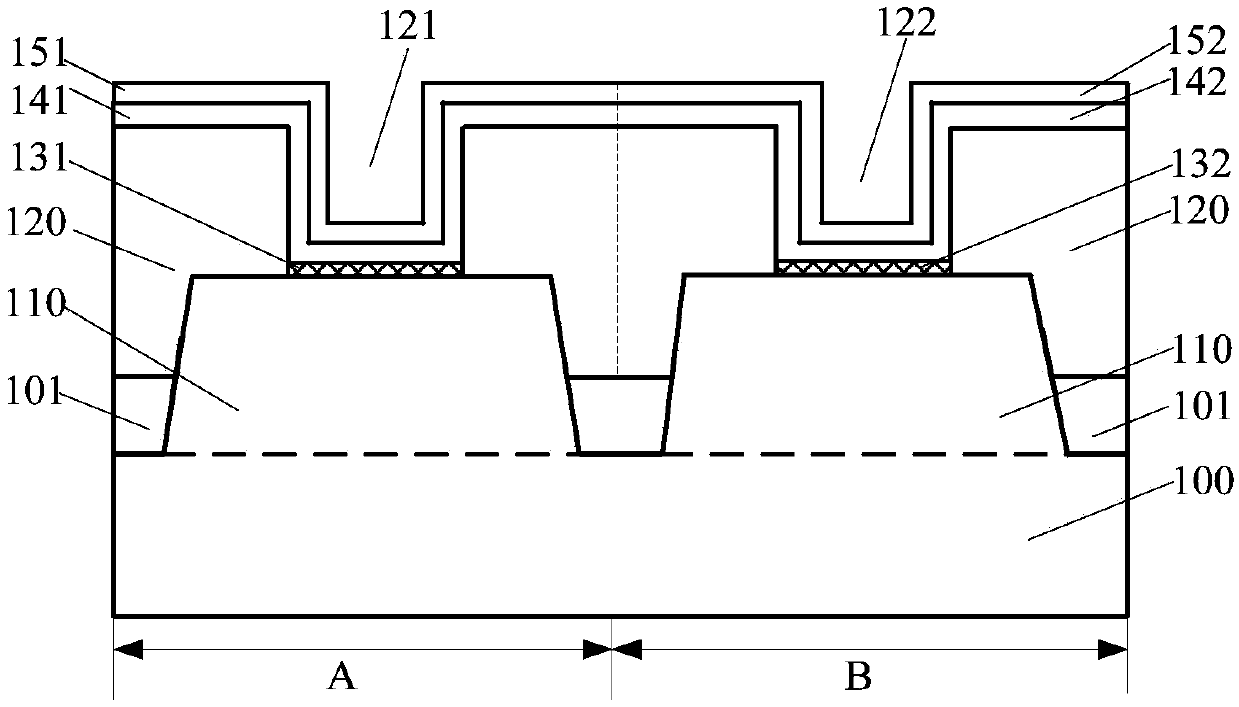

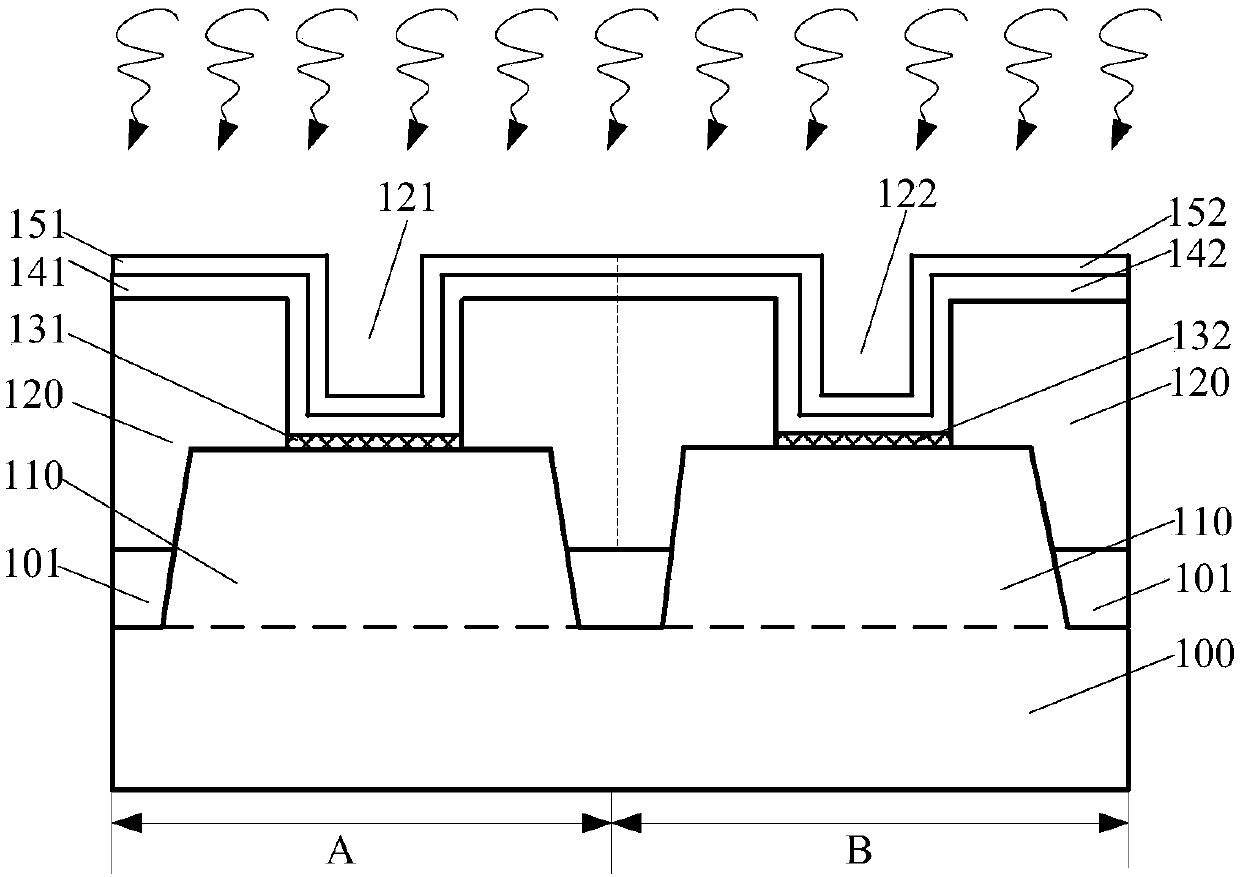

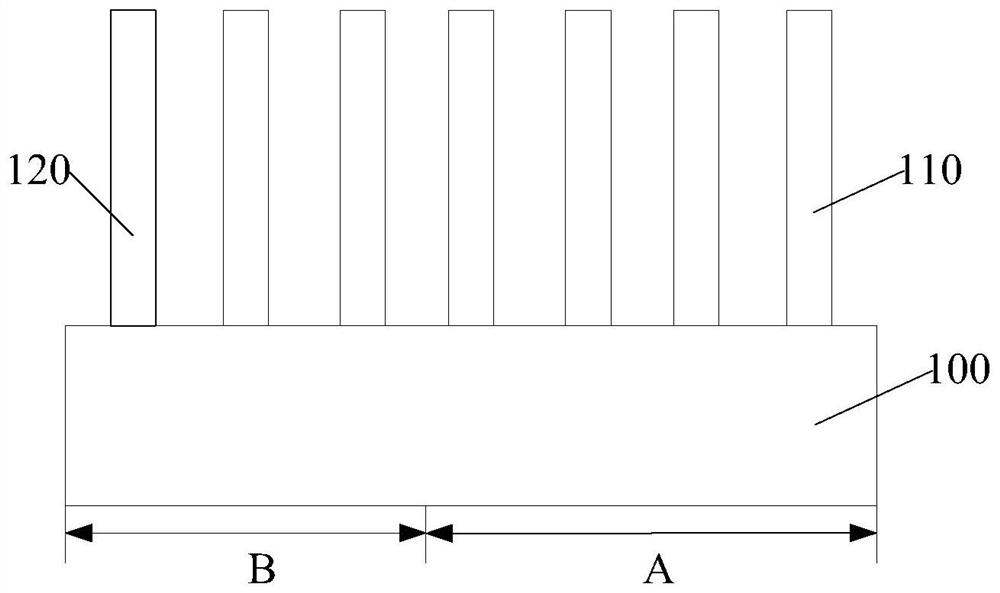

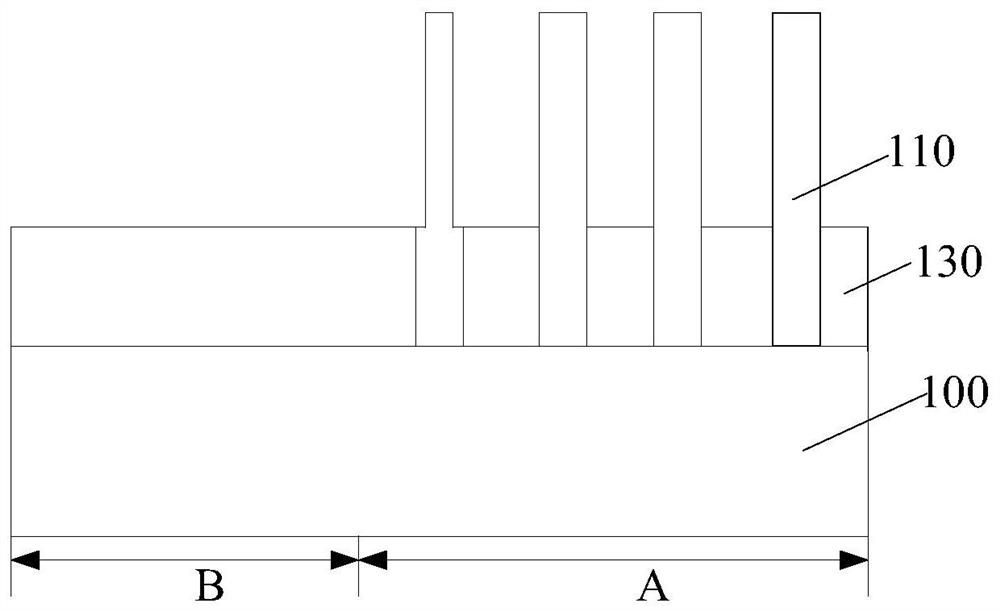

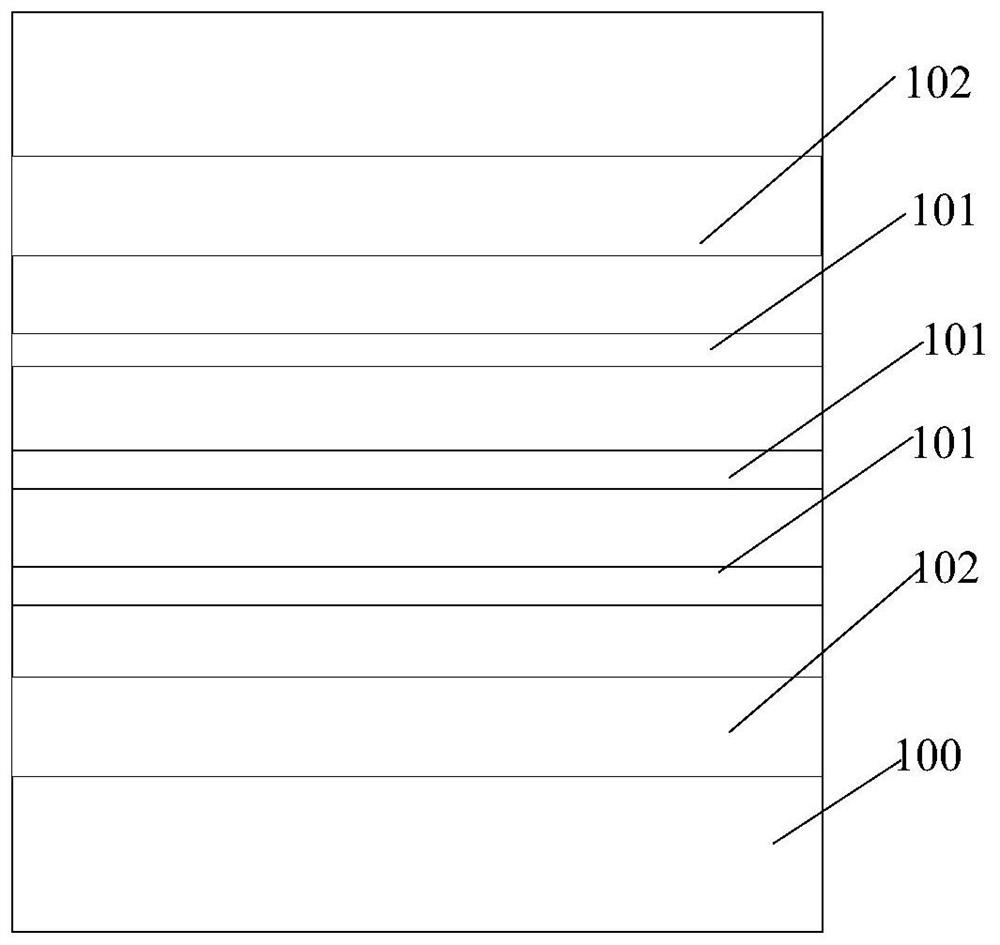

Memory and forming method thereof

ActiveCN108493190ACapable of holding electronsAvoid exposureSolid-state devicesSemiconductor devicesEngineeringSemiconductor

A memory and a forming method are disclosed. The forming method comprises: forming an erase gate structure, a floating gate structure, and a sidewall on the floating gate structure, wherein the floating gate structure and the sidewall are corresponding to a first side wall and a second side wall opposite to the erase gate structure in the channel direction respectively, the first side wall is planar, the first side wall is recessed toward the erasing gate structure with respect to the second side wall, and the first side wall and the second side wall are discontinuous; forming an isolation film on outer surfaces of the erase gate structure, the floating gate structure and the sidewall, and a surface of a semiconductor substrate, the isolation film covering the first side wall and the second side wall; forming a barrier film on a surface of the isolation film; etching the barrier film to expose the isolation film on the surface of the semiconductor substrate, and forming a barrier layercovering the first side wall and the second side wall; etching the isolation film with the barrier layer as a mask to expose the surface of the semiconductor substrate, and forming an isolation layercovering the first side wall and the second side wall; and removing the barrier layer. The method improves the performance of the memory.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

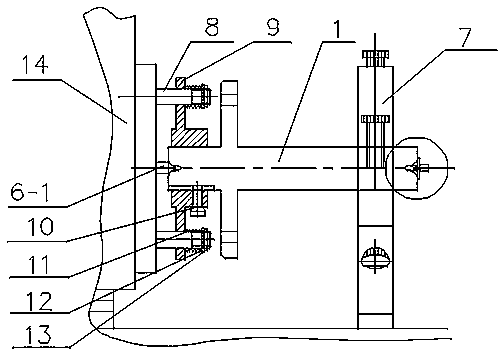

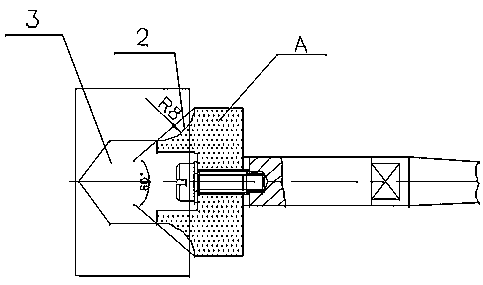

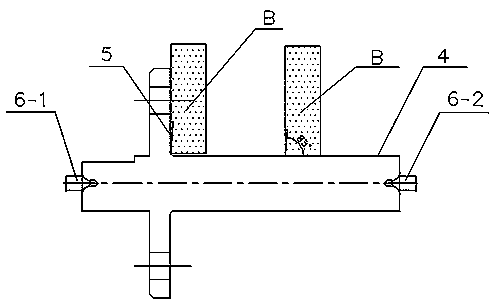

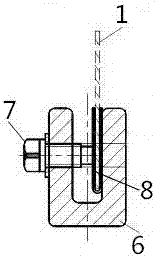

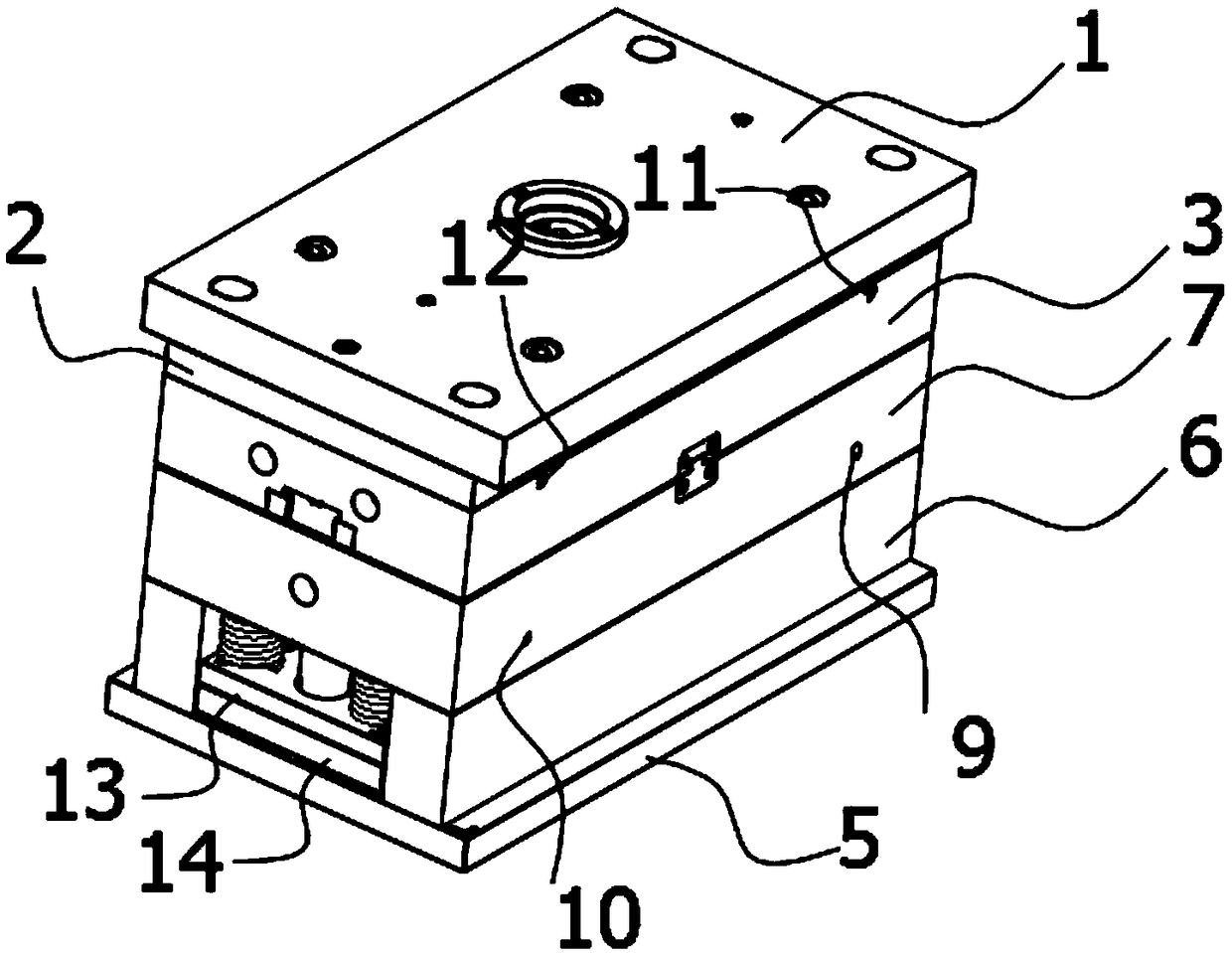

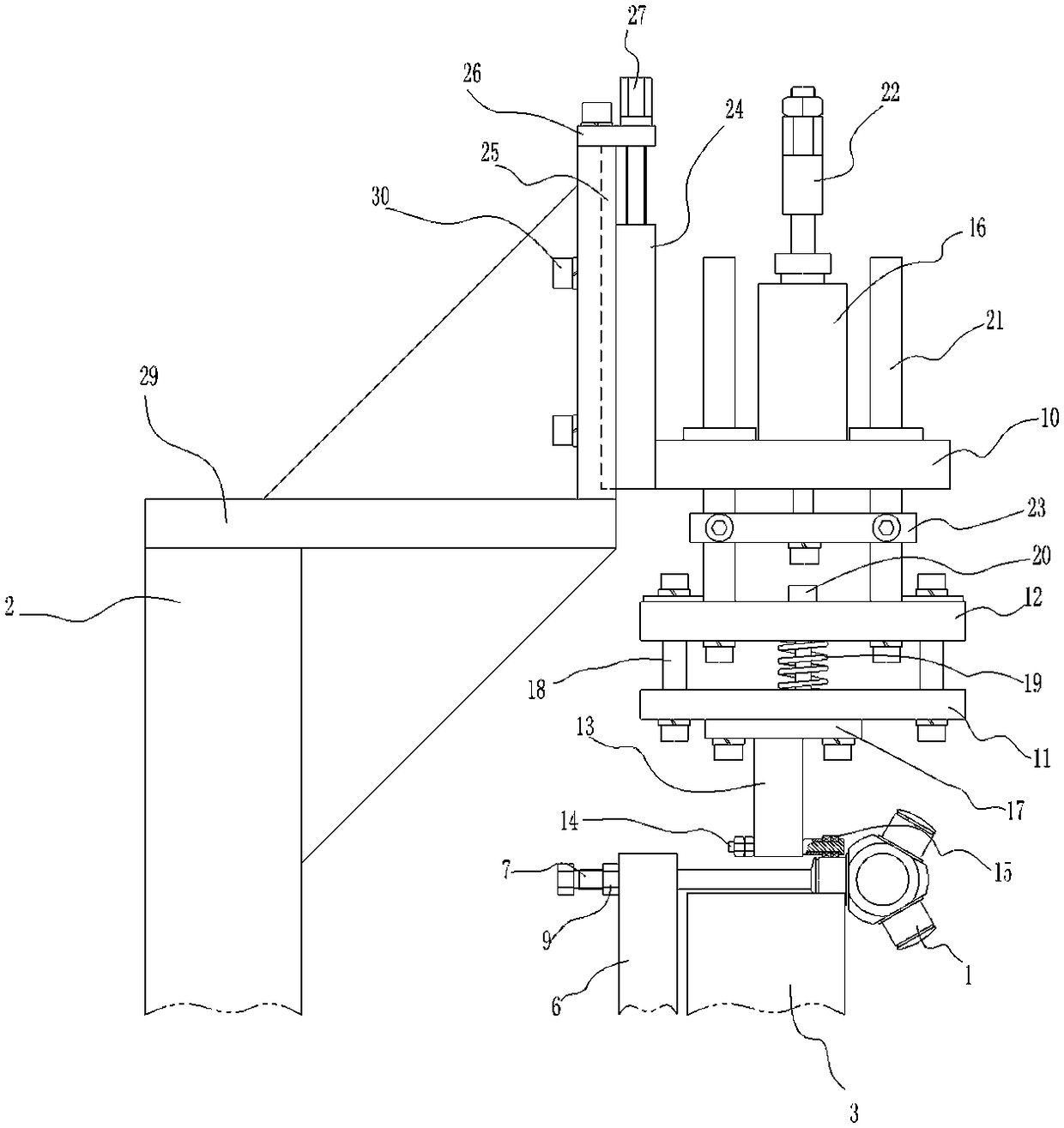

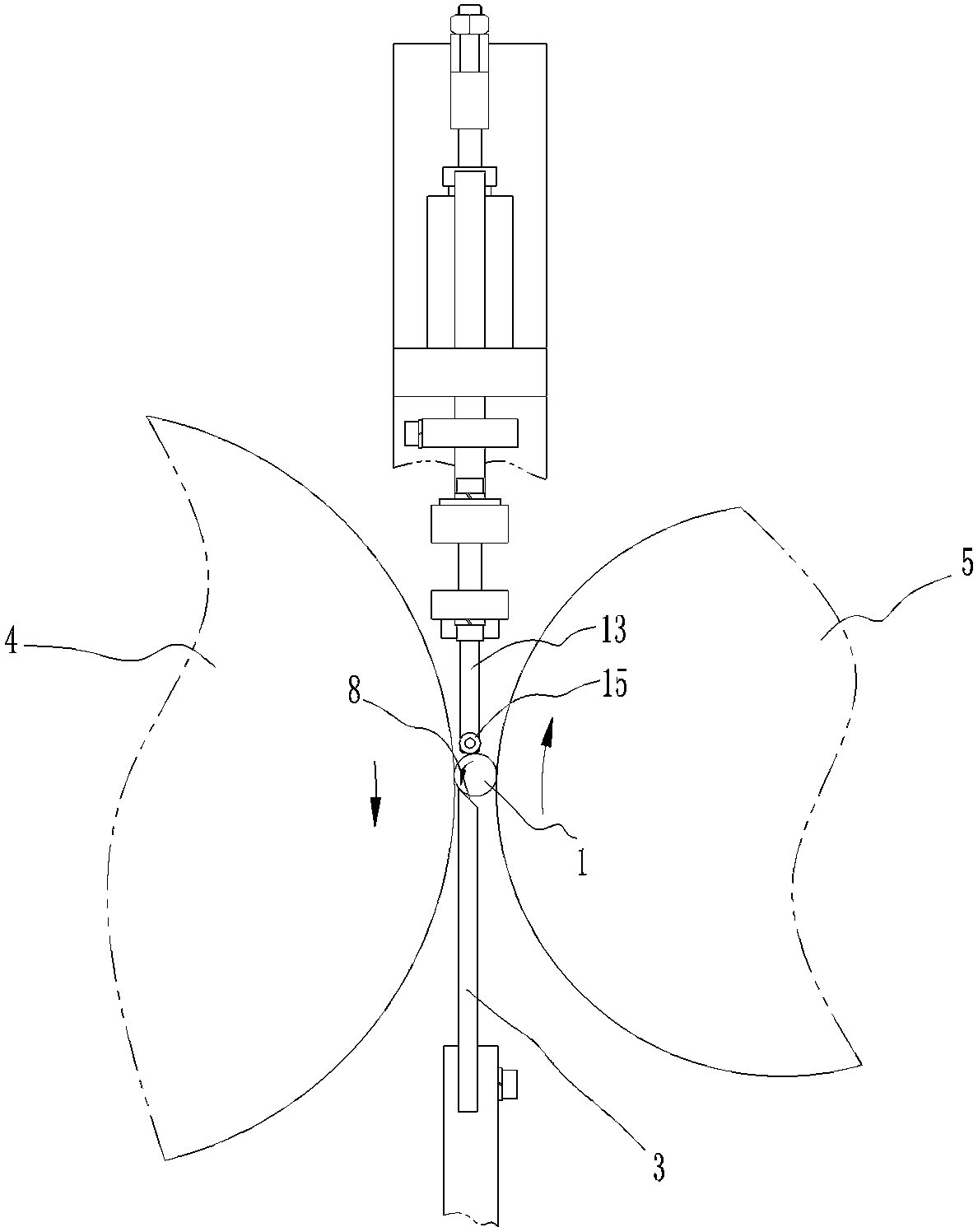

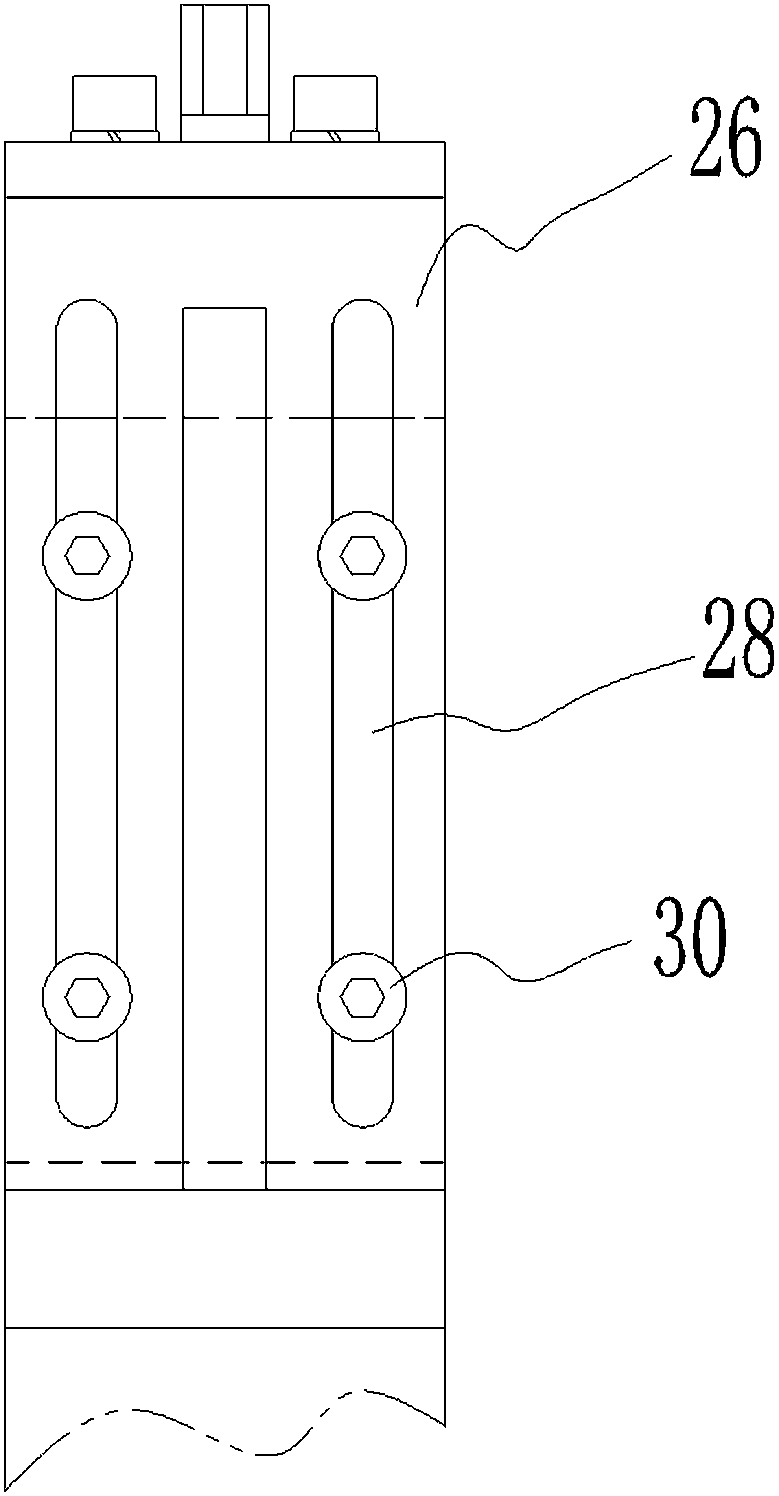

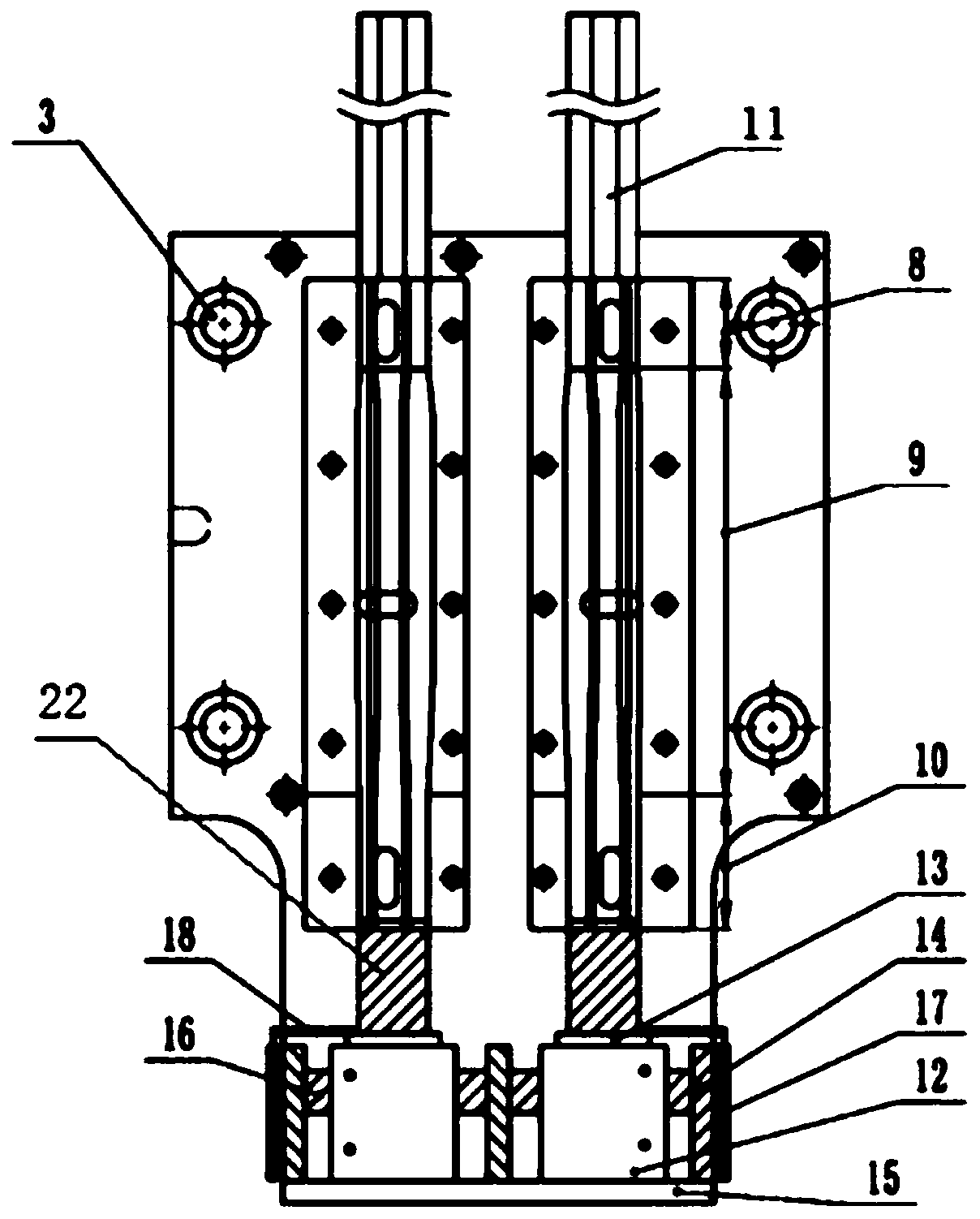

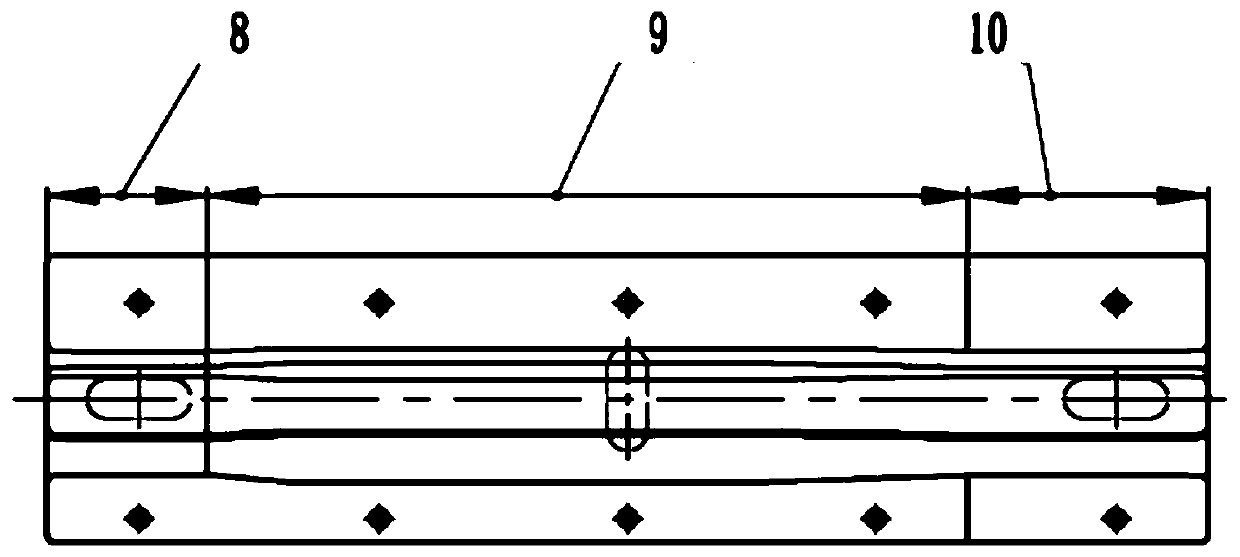

Three-pin frame centerless grinding pre-pressing mechanism and grinding method thereof

PendingCN108296893AAvoid compromising performance strengthReduced risk of fracture failureRevolution surface grinding machinesGrinding drivesEngineeringMechanical engineering

The invention relates to a pre-pressing mechanism, in particular to a three-pin frame centerless grinding pre-pressing mechanism and an operation method thereof. The three-pin frame centerless grinding pre-pressing mechanism comprises a workpiece and grinding machine equipment and further comprises a grinding assembly and a pressing assembly, the workpiece is ground through an axial guiding wheelassembly, and adjustable compression joint is conducted on the workpiece through the pressing assembly. According to the three-pin frame centerless grinding pre-pressing mechanism and the operation method thereof, the structure is compact, the grinding precision is further improved, and the product quality is improved.

Owner:HANGZHOU RADICAL ENERGY SAVING TECH

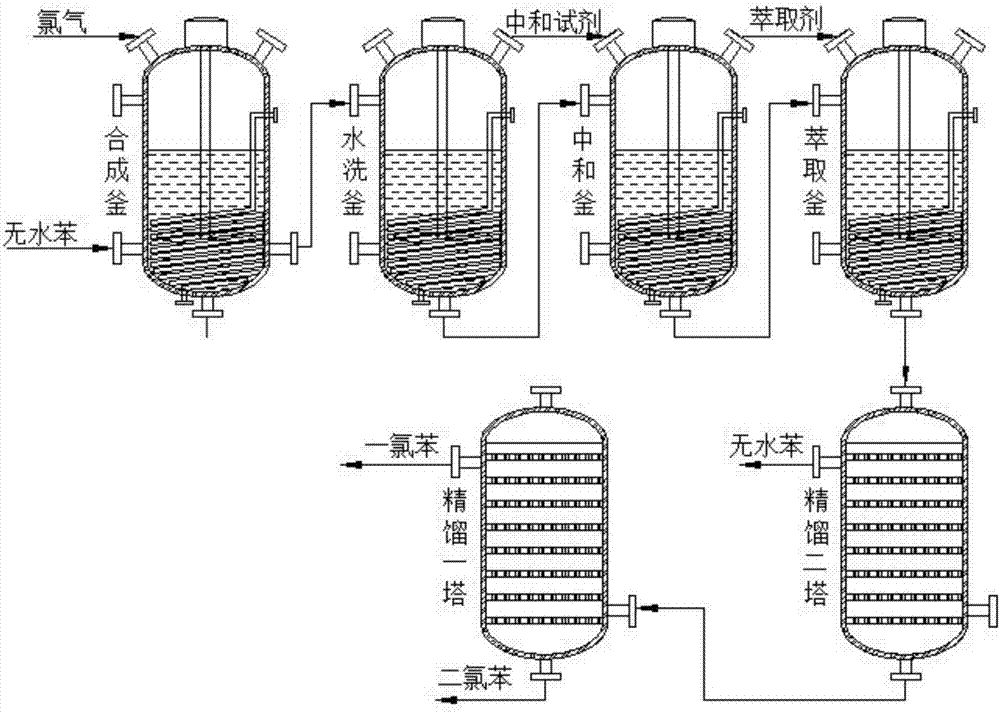

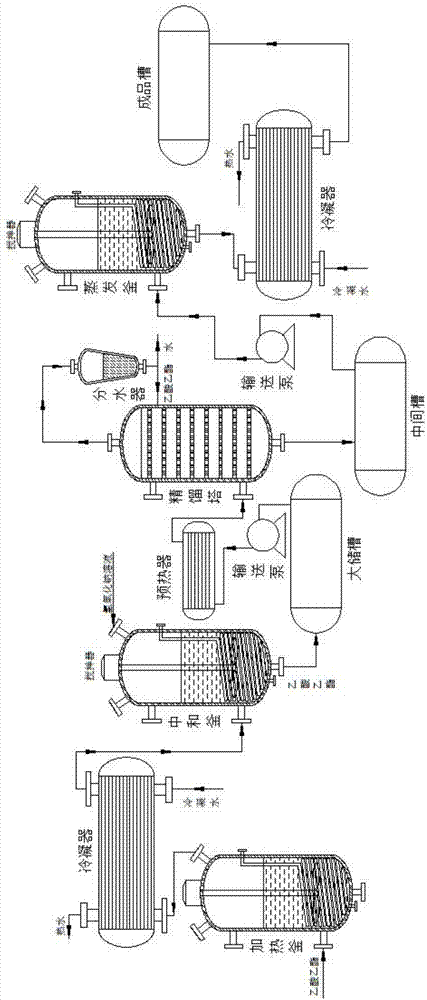

Rectifying separation method for chlorinated benzene production

InactiveCN107445793AHigh conversion selectivityNot easy to cause confusionHalogenated hydrocarbon separation/purificationEnvironmental resistanceSeparation technology

The invention discloses a rectifying separation method for chlorinated benzene production. The rectifying separation method comprises the following specific steps: feeding chlorine and excessive anhydrous benzene into a chlorinator filled with an iron ring catalyst; controlling the reaction temperature at the boiling point of benzene, namely, setting the temperature to 80-90 DEG C; starting a stirrer for constant-speed and constant-temperature stirring to generate chloride liquid; washing an obtained chlorinated benzene solution by a washing tower, neutralizing by a neutralizing kettle, extracting in an extraction kettle, and distilling by a two-stage rectifying tower to obtain a finished product. The rectifying separation method for the chlorinated benzene production disclosed by the invention is a universal method of the rectifying separation technology for the chlorinated benzene production at home, and has the following main advantages: high-temperature continuous chlorination is realized; the conversion selectivity of chlorinated benzene is high, the slender chlorination reactor does not tend to cause material mixing return, and a small amount of benzene dichloride is generated; a distillation process is adopted for separation, the technology is mature and reliable, useful matters are recycled, the synthesis cost is saved, the economic benefits are increased, and the method conforms to the scientific concept of greenness, environmental protection and zero pollution.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

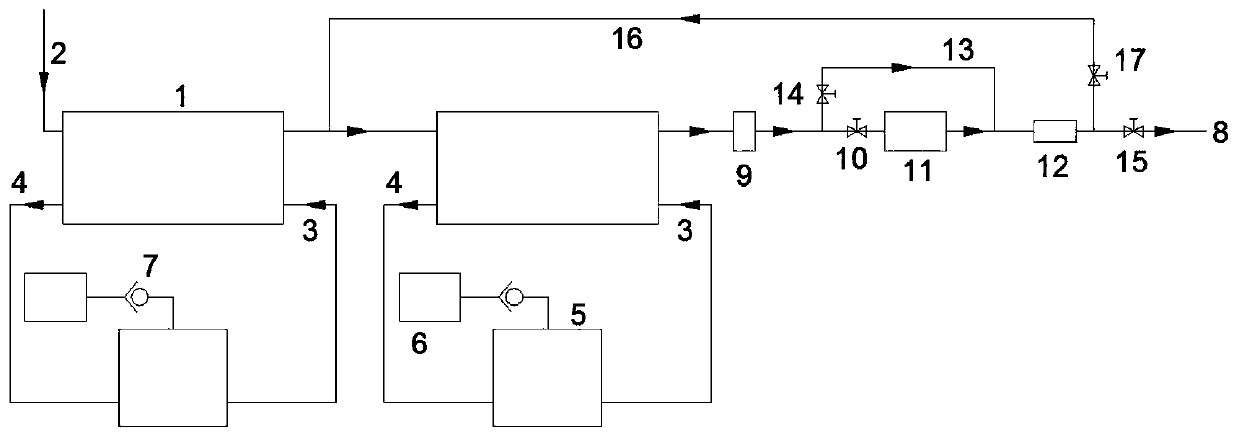

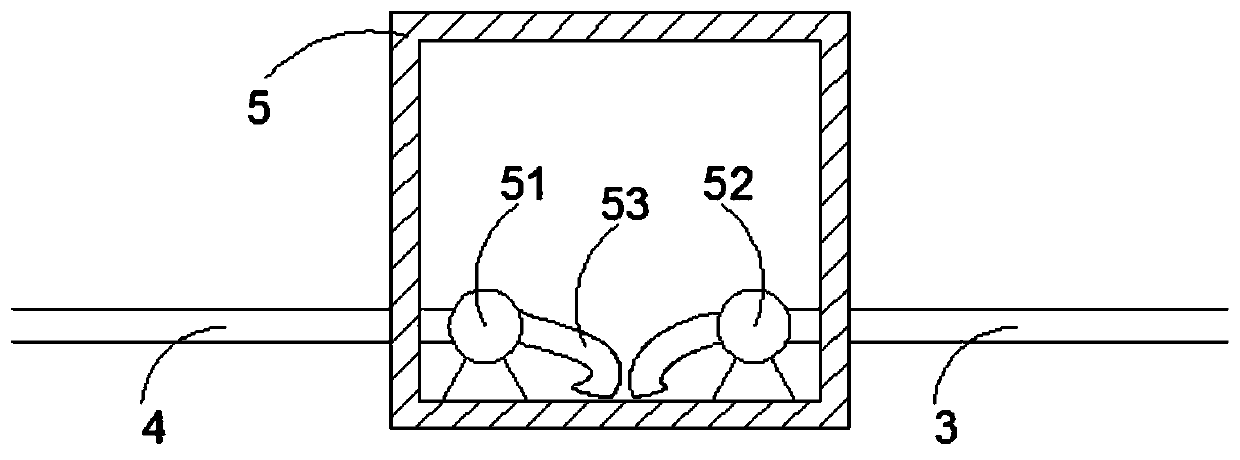

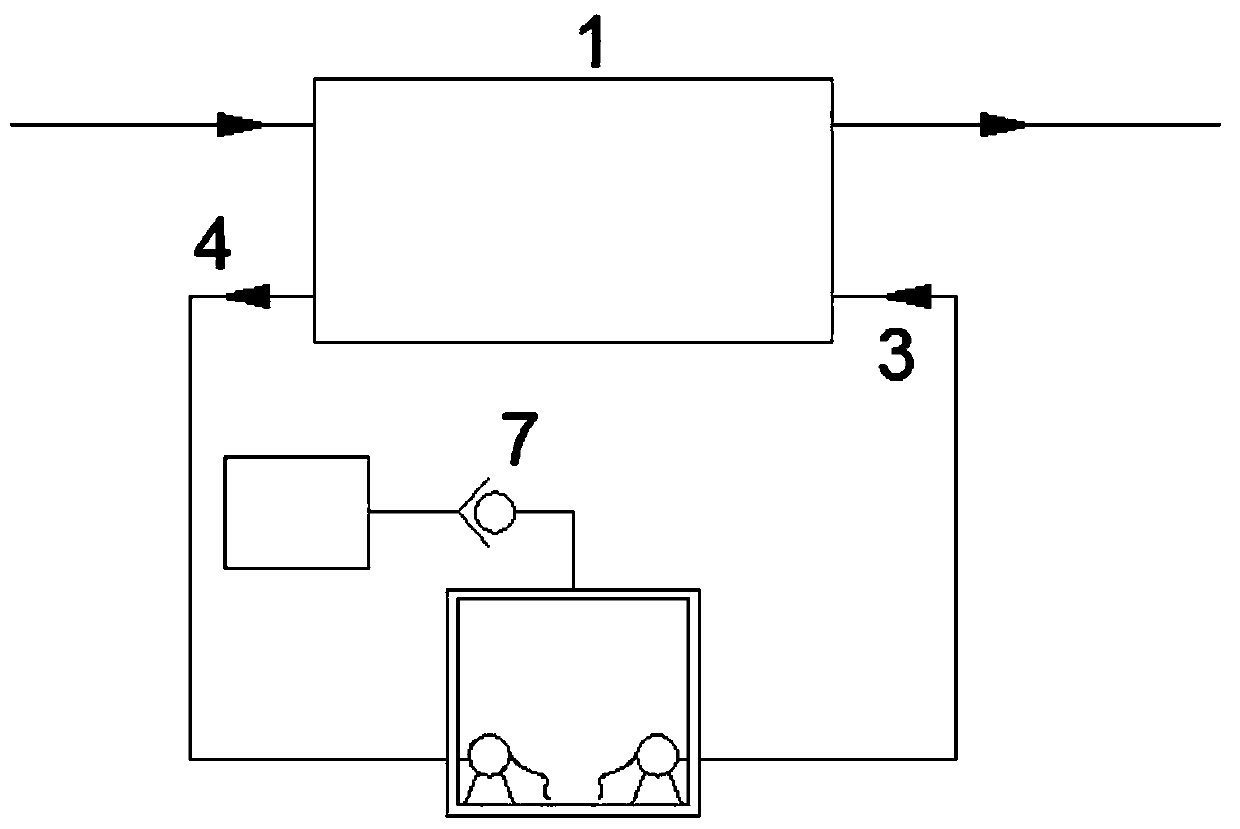

Series heat exchanger radioactive waste gas cooling system

InactiveCN110335688AAchieve recyclingImprove reliabilityNuclear energy generationNuclear monitoringEngineeringRadioactive waste

The invention discloses a series heat exchanger radioactive waste gas cooling system in the technical field of waste gas cooling equipment, THE series heat exchanger radioactive waste gas cooling system comprises two groups of gas-water heat exchangers, wherein the air inlet of the left gas-water heat exchanger is connected with a waste gas inlet pipeline, the air outlet of the left gas-water heatexchanger is communicated with the air inlet of the right gas-water heat exchanger, the water inlets of the two gas-water heat exchangers are both communicated with a cooling water inlet pipeline, and the water outlets of the two gas-water heat exchangers are both communicated with a cooling water outlet channel. The inner cavity of a water tank is respectively connected with the cooling water outlet channel and the cooling water inlet pipeline through a first water pump and a second water pump, so that the circulation utilization of cooling water is realized, heat conversion is continuouslycarried out twice, efficient cooling is realized, radioactivity detection is carried out after reaching the temperature, and if the detected radioactivity does not reach the standard, heat exchange cooling is carried out again, and discharging is performed until the radioactivity reaches the standard, so that waste gas temperature meets the technical design requirements of the system, the coolingeffect is good, and the reliability of the system is improved.

Owner:山东普瑞普勒能源科技有限公司

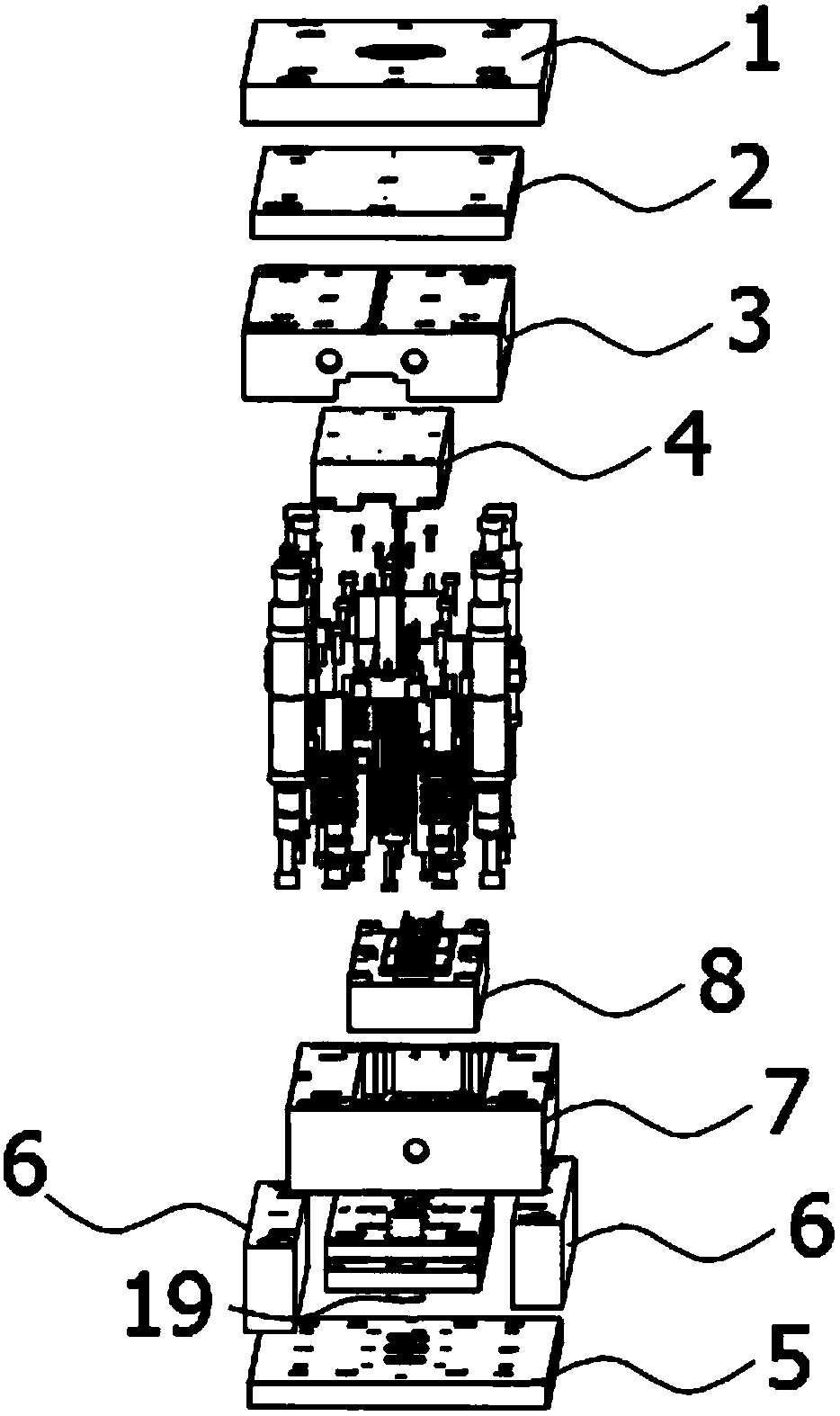

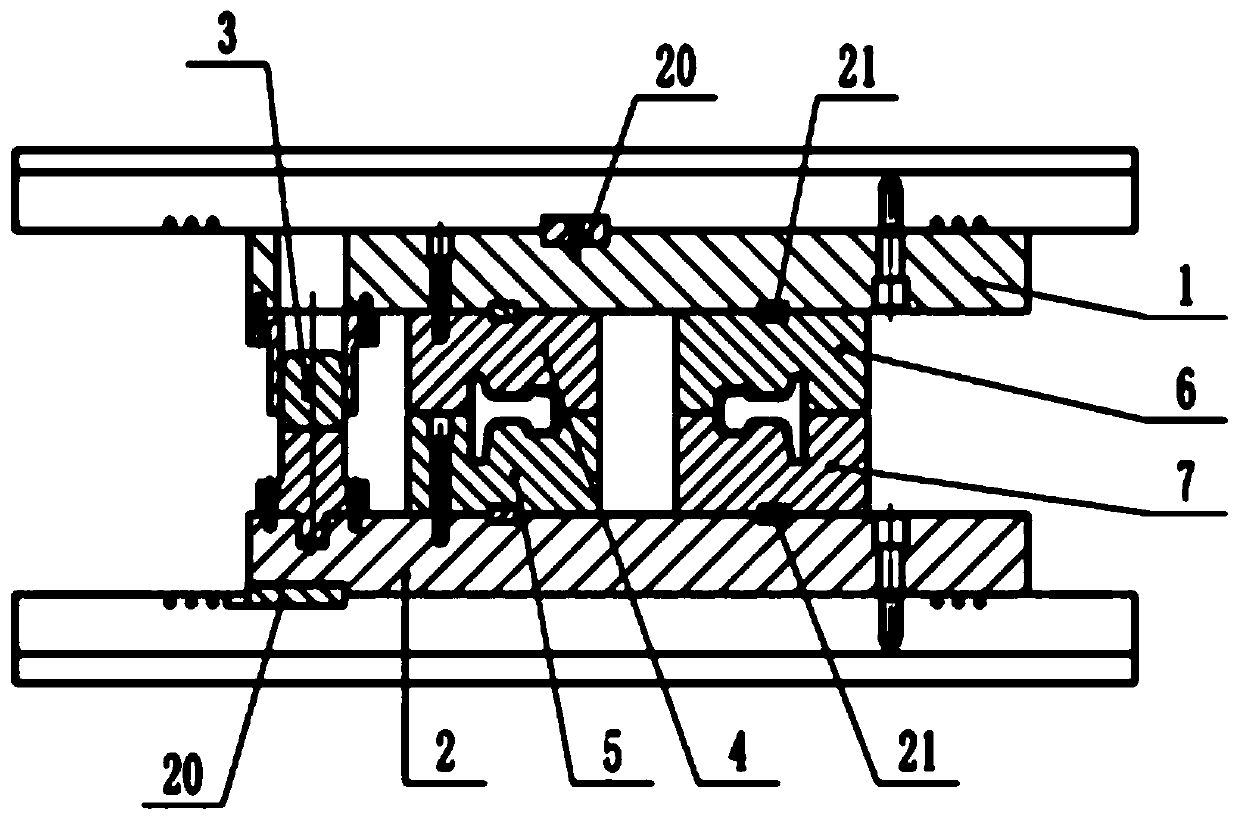

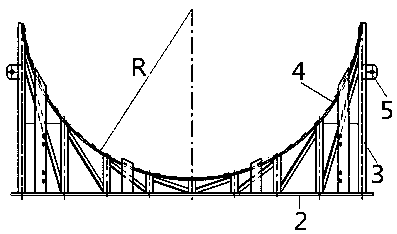

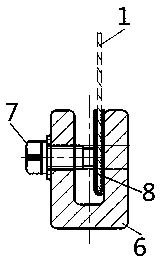

Upsetting device for steel rail with asymmetric section

PendingCN109877266APrecise control of upsetting amountMeet the requirements of process designRailway componentsForging/hammering/pressing machinesStructural engineeringProcess design

The invention discloses an upsetting device for a steel rail with a symmetric section. Upper and lower moulding boards are connected through a guide device; two upper moulds and two lower moulds are arranged between the upper and lower moulding boards; the two upper moulds are fixedly arranged on the lower end surface of the upper moulding board, the two lower moulds are fixedly arranged on the upper end surface of the lower moulding board, and the two upper moulds are separately positioned right on the two lower moulds; the two upper moulds and the two lower moulds are closed to separately form two mould cavities; each mould cavity sequentially consists of a clamping mould cavity section, an upsetting mould cavity section and a guide mould cavity section, wherein the clamping mould cavity section, the upsetting mould cavity section and the guide mould cavity section are separately in a close-fit state, an clearance fit state and a sliding fit state with a to-be-upset steel rail; twoupsetting oil cylinders are fixedly arranged on the lower moulding boards; and piston rods of the two upsetting oil cylinders are separately opposite to the two guide mould cavity sections. Integral upsetting for different product types of the steel rail with the symmetric section is accomplished through a set of tool moulds; and meanwhile, a ball grid digital display system is utilized to precisely control steel rail upsetting amount, so that process design requirements are met.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

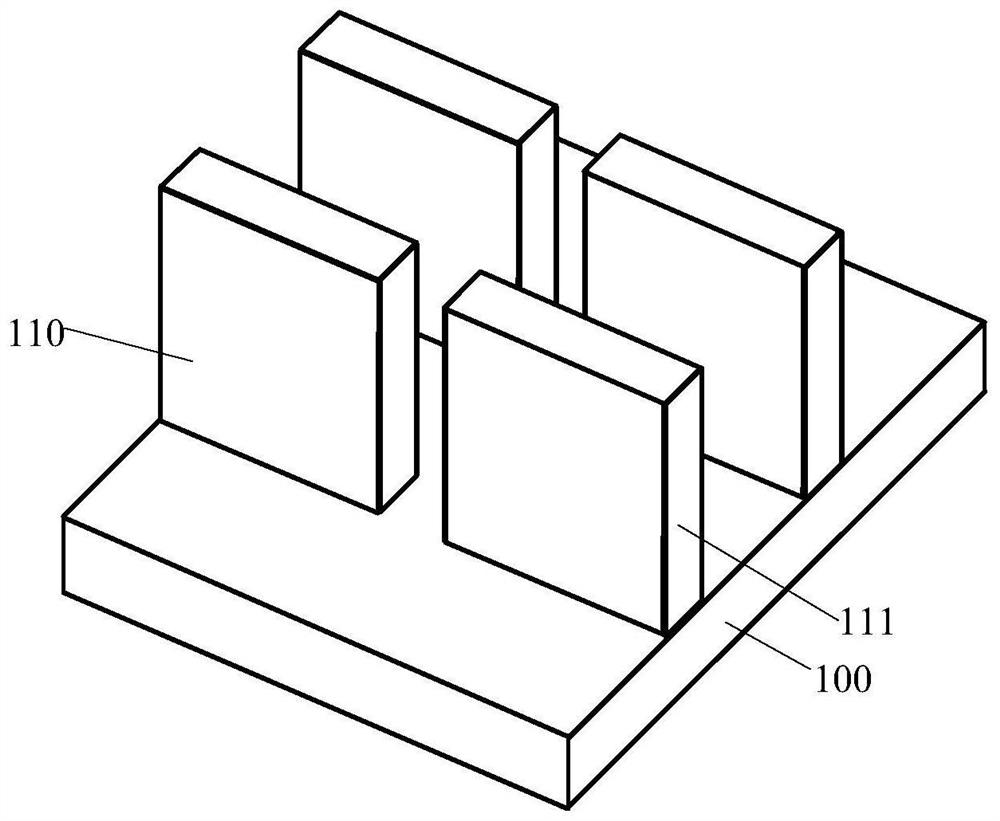

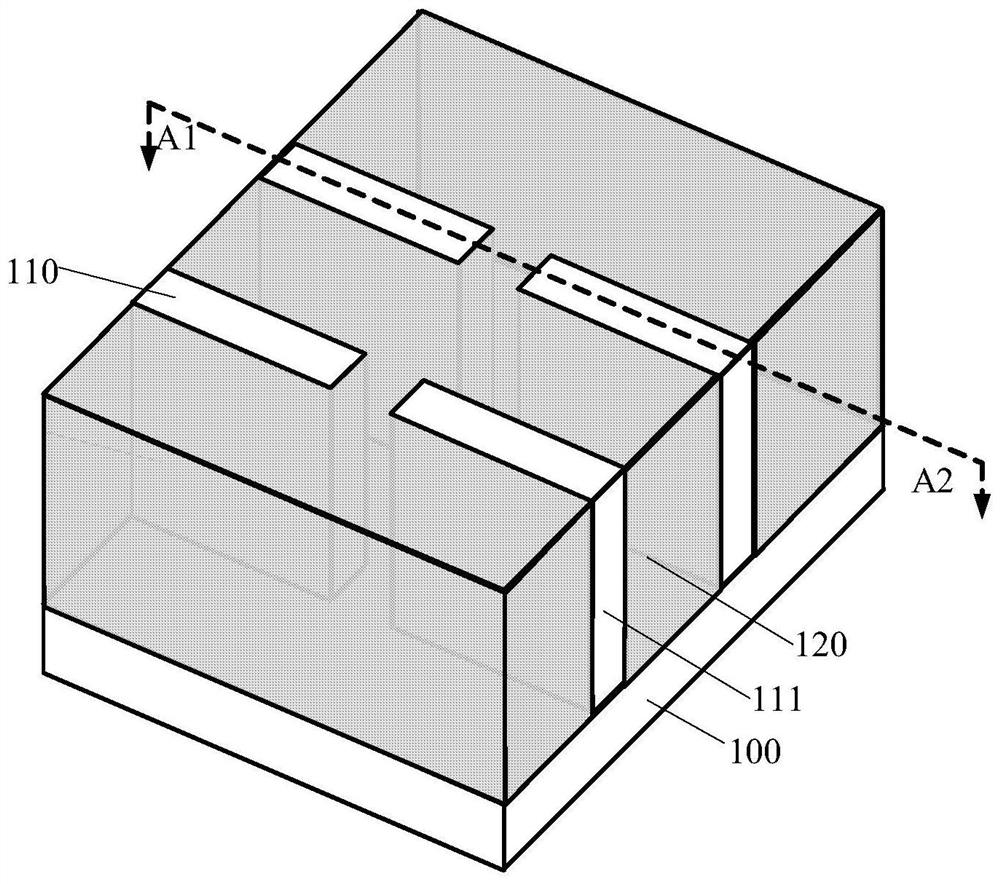

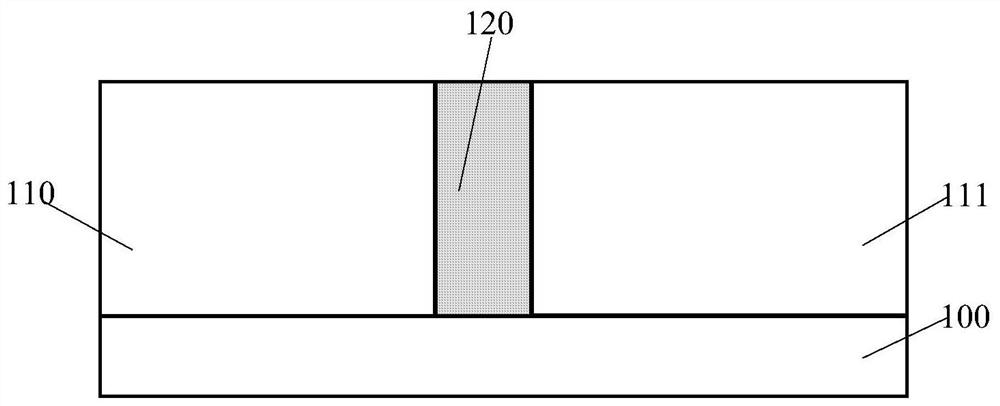

Semiconductor device and forming method thereof

InactiveCN109585546AImprove performanceReduce the chance of electric leakageSemiconductor/solid-state device manufacturingSemiconductor devicesPhysicsSemiconductor

The invention provides a semiconductor device and a forming method thereof. The method comprises the following steps that a substrate is provided; a dielectric layer is formed on the substrate, wherein a first gate opening which penetrates through the dielectric layer is formed in the dielectric layer; a first interface layer is formed at the bottom of the first gate opening; a first gate dielectric layer is formed on the side walls and the bottom of the first gate opening, wherein the first gate dielectric layer is located on the first interface layer; annealing treatment is carried out on the first interface layer; after annealing treatment is carried out, a first gate electrode layer located on the first gate dielectric layer is formed in the first gate opening; first through holes areformed in the dielectric layer on the two sides of the first gate electrode layer; and a first source drain doping layer is formed in the substrate at the bottoms of the first through holes. Accordingto the method, the performance of the semiconductor device is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Semiconductor device and method of forming the same

ActiveCN109887845BReduce widthAvoid lossSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialIsolation layer

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Semiconductor device and method of forming the same

ActiveCN110120366BImprove performanceReduce resolutionSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A semiconductor device and a method for forming the same, the method comprising: obtaining a plurality of discrete contact hole regions in a second groove region; obtaining a second groove modification region located in the second groove region according to the position of the contact hole region; The width of the correction area is smaller than the width of the second groove area; a sacrificial layer is respectively formed on the second groove correction area and the first groove area of the dielectric layer; a first side wall and a second side wall are formed on the dielectric layer; on the second side A barrier layer is formed on the second groove area exposed by the wall, and the distance from the edge of the barrier layer to the edge of the sacrificial layer on the adjacent first groove area is equal to the minimum distance between the first side wall and the second side wall; sacrificial layer; then use the barrier layer, the first sidewall and the second sidewall as masks to etch the dielectric layer, form the first groove in the dielectric layer on both sides of the first sidewall, and form the first groove in the dielectric layer in the second groove correction area of the dielectric layer A second groove is formed in the middle. The performance of the semiconductor device is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

A method of preparing an o-phenylenediamine intermediate used for carbendazim production

InactiveCN107488117ALower synthesis costIncrease incomeOrganic compound preparationChemical recyclingPalladium on carbonMolten state

A method of preparing an o-phenylenediamine intermediate used for carbendazim production is disclosed. The method includes reacting nitrochlorobenzene and concentrated aqueous ammonia in six tandem autoclaves to obtain 2-nitroaniline; washing ammoniated 2-nitroaniline with water to remove ammonium chloride; performing a hydrogenation reaction by utilizing a 2-nitroaniline dry basis in a molten state, adopting a palladium-on-charcoal catalyst and an organic salt as auxiliary agents, and adopting four tandem hydrogenation kettles; after hydrogenation is finished, conveying a liquid to a next process to obtain the o-phenylenediamine intermediate. After a preliminary reaction step is finished, useful compounds can be recovered effectively, and the o-phenylenediamine content after hydrogenation is 98% or above, thus saving a synthesis cost and increasing economic benefit. The preparing method and process design of the o-phenylenediamine intermediate used for carbendazim production are optimized, and requirements on the preparing method and the process design of the o-phenylenediamine intermediate used for carbendazim production are satisfied.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

Recognition method of intersecting manufacturing features of 3D cad model

InactiveCN103164582BMeet manufacturability requirementsMeet the requirements of process designSpecial data processing applicationsComputer Aided DesignCluster algorithm

The invention discloses an identification method for three-dimensional computer-aided design (CAD) model intersection manufacture characteristics. The identification method for the three-dimensional CAD model intersection manufacture characteristics is used for solving the technical problem that a combinatorial explosion exists in an existing part manufacturability automatic analysis method in a process that an optional solution is generated. According to the technical scheme of the identification method for the three-dimensional CAD model intersection manufacture characteristics, a three-dimensional CAD model expressed by model based definition (MBD) is used as an information input source, firstly a reachability analysis is conducted on each machined face through an illumination-type rule, and the axial space of a feasible cutter of each machined face is ascertained; then with the axial space of the feasible cutter of each machined face as a restraint, a machined face clustering algorithm merging a manufacture semanteme is adopted to construct each of machined area subgraphs; and finally, with each machined area subgraph as a manufacture characteristic trace which is combined together with dimensioning information, the machined area subgraphs are optimized and merged, so that identification of the manufacture characteristics is achieved. According to the identification method for the three-dimensional CAD model intersection manufacture characteristics, the manufacturability analysis is merged in the identification process of the intersection manufacture characteristics, so that the machined faces are identical in the accuracy level. In the characteristic identification process, the influence, on the characteristic identification, of the design semanteme is fully considered and practicality is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Optical proximity correction method and mask making method

ActiveCN110032037BIncreased process windowMeet the requirements of process designOriginals for photomechanical treatmentGraphicsFeature Dimension

An optical proximity correction method and a method for making a mask plate. The correction method includes: performing OPC correction on a sub-target figure to obtain an initial correction figure; performing several first simulation exposures on the initial correction figure to obtain a number of The first simulated exposure pattern; obtain the detection mark position in each first simulated exposure pattern, the size of the figure corresponding to the detection mark position in the direction of the feature size is outside the first threshold range; according to the figure corresponding to the detection mark position in the feature size The size of the direction and the first threshold range are corrected at least once on the initial correction figure corresponding to the position of the detection mark to obtain the correction figure. The crafting window for correction graphics has been increased.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

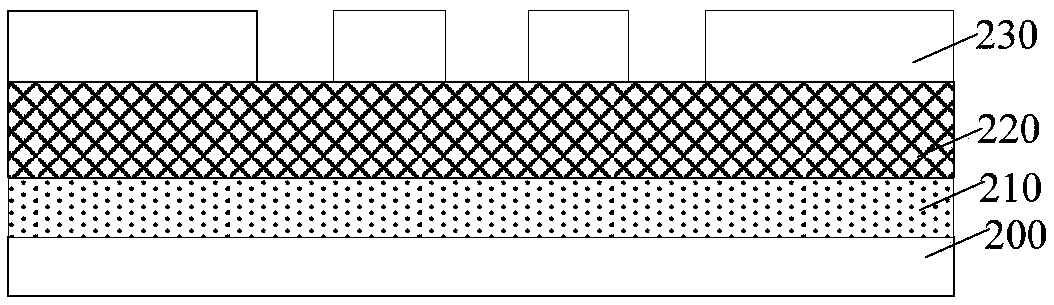

Mask plate, manufacturing method of mask plate and forming method of semiconductor device

InactiveCN109283786AHigh strengthImprove exposureOriginals for photomechanical treatmentPhase shiftedBlock layer

The invention discloses a mask plate, a manufacturing method of the mask plate and a forming method of a semiconductor device. The mask plate comprises a substrate, a light blocking layer located on the substrate, and a phase shifting layer, wherein an opening set is arranged in the light blocking layer, and the opening set comprises a plurality of openings adjacent to each other; the openings runthrough the light blocking layer and are exposed out of the surface of the substrate; a phase shifting notch running through the light blocking layer is further formed in the light blocking layer, and the phase shifting notch is separated from the openings and is surrounded by the openings in the opening set; the phase shifting layer is located on the surface, at the bottom of the phase shiftingnotch, of the substrate. The performance of the mask plate is improved.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

A method for expanding the circulating water system of a power plant

ActiveCN106088214BPrevent overflowOperation impactService pipe systemsWater mainsWater resourcesStop time

The invention discloses an extension method for a circulating water system of a power plant. A new circulating water pool is independently built beside an old circulating water pool, and is communicated with the old circulating water pool through a communicating pipe, the new circulating water pool and the old circulating water pool are connected in parallel with a main pipe, running of an existing circulating water system is not influenced in a process of building the new circulating water pool, safe and stable running of original equipment is ensured, and a turboset and the circulating water system are required to be stopped only in a process of communicating the new circulating water pool with the old circulating water pool. According to the method, the stopping time is greatly shortened, economic loss caused by stopping is reduced, and process design requirements are met; the communicating pipe is arranged between the new circulating water pool and the old circulating water pool, so that problems about water level balance between the new circulating water pool and the old circulating water pool are solved, and overflow of the circulating water pools and waste of water resources are avoided.

Owner:武汉钢铁有限公司

A method for forming a large-diameter thin-walled stainless steel cylinder

The invention discloses a forming method of a large-diameter thin-walled stainless steel barrel. The method includes the following steps that firstly, groove pre-bending and machining are conducted; secondly, stainless steel plates are hoisted to tool supports and fixed to the tool supports; thirdly, turnover is conducted; fourthly, assembling and longitudinal joint welding are conducted; fifthly, weld joint correction is conducted; and sixthly, the tool supports are detached. By means of the large-diameter thin-walled stainless steel barrel formed through the method, hoisting difficulty can be eliminated, ferrite pollution is avoided, the barrel does not need to be overturned, and it is ensured that the circular degree of the barrel meets the process design requirement.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Hybrid integrated circuit module and manufacturing method thereof

ActiveCN104112719BReduce areaLow raw material costSemiconductor/solid-state device detailsSolid-state devicesGlass fiberPunching

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

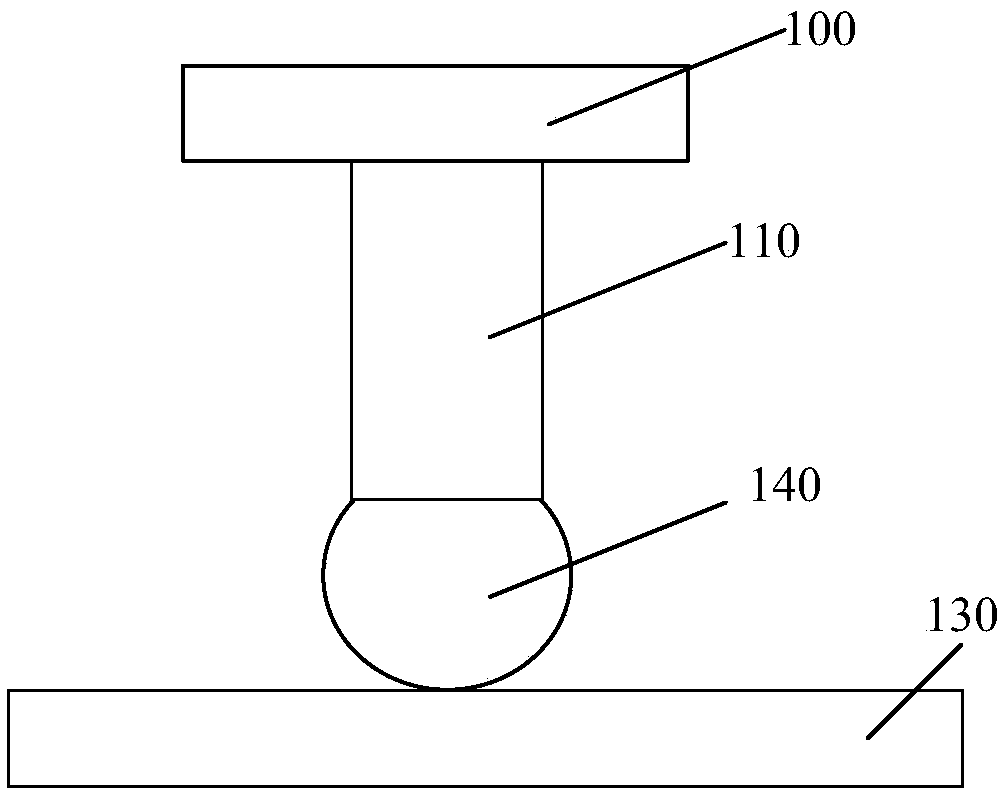

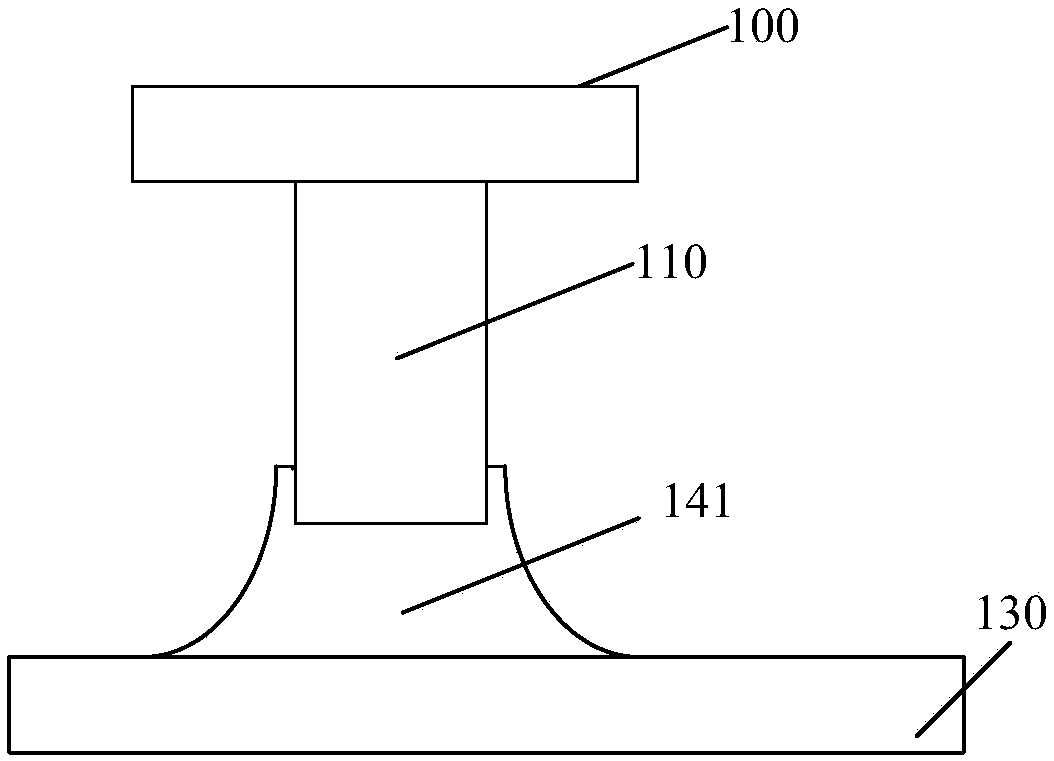

Packaging structure

ActiveCN110610916AImprove performancePrevent collapseSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chip

The invention provides a packaging structure. The packaging structure comprises a semiconductor chip, and a conductive connection post which comprises opposite first and second sides. The first side of the conductive connection post is fixed with the surface of the semiconductor chip. The packaging structure further comprises a carrier board which is opposite to the semiconductor chip. The conductive connection post is located between the semiconductor chip and the carrier board, and the second side faces the carrier board. The packaging structure further comprises a solder layer located between the surface of the carrier board and the second side. The performance of the packaging structure is improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

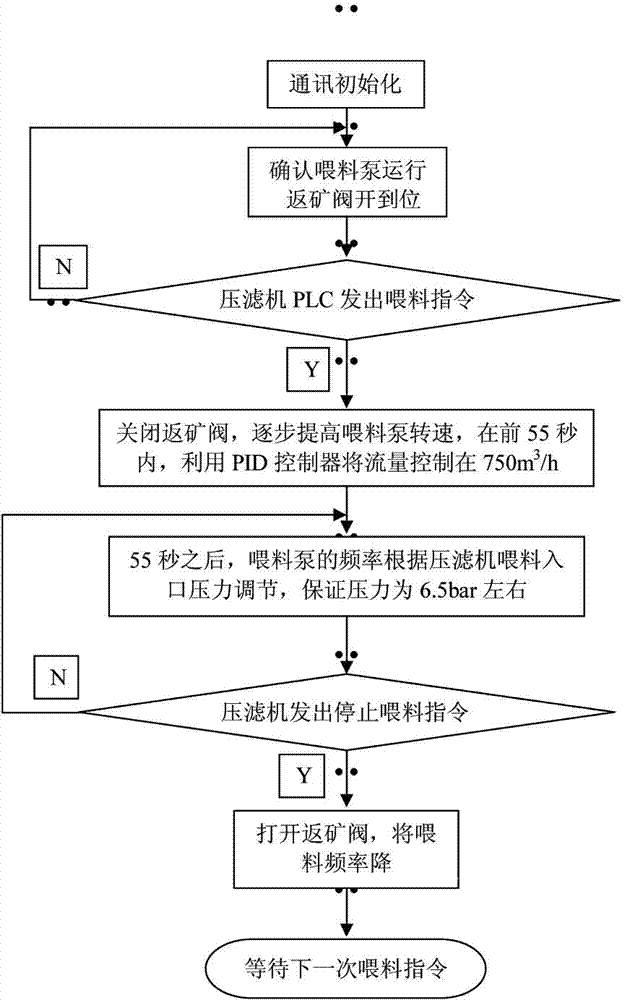

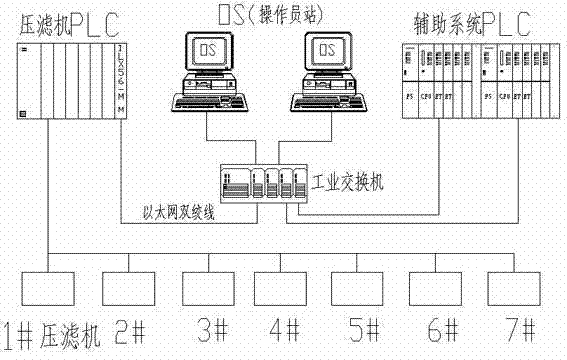

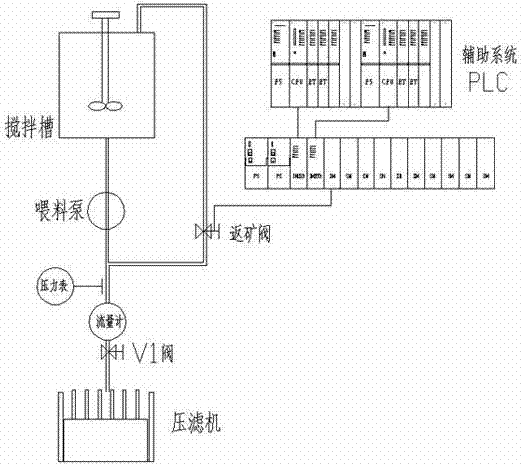

Press filter control system based on industrial field communication technology

ActiveCN103389679BEasy to controlReasonable optimization of the control processFiltration separationProgramme control in sequence/logic controllersControl systemComputer module

The invention provides a press filter control system based on the industrial field communication technology. The press filter control system is characterized in that a protocol module is inserted into a frame of a press filter PLC, and connected to an industrial exchanger through an Ethernet twisted-pair cable; an auxiliary system PLC and an OS station are respectively connected to the industrial exchanger through the Ethernet; a mine back valve is designed to be mounted on a process pipe line; a signal of an auxiliary device is sent to the press filter PLC through the auxiliary system PLC; meanwhile, another signal sent by the press filter PLC is sent to the auxiliary system PLC; according to a working process of press filters, the real-time control of the auxiliary device can be completed so as to reduce moisture content in finished ore, improve amount of ore discharge and realize the purposes of cyclic utilization of filter liquor in a feeding process of the press filters, and the efficient and safe transportation of finished ore. According to the press filter control system provided by the invention, problems that a wiring work amount is large, and the control process of an auxiliary system is simple, which is not conducive to reasonable optimization use of the press filters to the utmost extent in the prior art are solved.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Semiconductor device and method of forming the same

ActiveCN109979822BImprove performanceReduce etch damageSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialEngineering

A semiconductor device and its forming method, wherein the method includes: forming a dielectric layer on a semiconductor substrate and a fin, the dielectric layer has a groove exposing the fin, and the groove includes a first groove region exposing part of the fin and the second groove area exposing part of the fin, the direction from the center of the first groove area to the center of the second groove area is perpendicular to the extending direction of the fin; forming a first work function layer on the fin at the bottom; forming a first covering layer in the first groove area of the trench, the first covering layer being located on the first work function layer of the first groove area and exposing the second groove area The first work function layer of the second groove area is etched and removed with the first cover layer as a mask; after the first work function layer of the second groove area is etched and removed, the second groove of the trench A second covering layer is formed in the region; the second covering layer and the first covering layer are removed by etching. The method improves the performance of semiconductor devices.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Method for continuously rectifying thiophanate-methyl ethyl acetate

InactiveCN107286019AHigh purityImprove recycling efficiencyOrganic compound preparationCarboxylic acid esters preparationChemistryBoiling point

The invention discloses a method for continuously rectifying thiophanate-methyl ethyl acetate. The method comprises the following steps: firstly, reclaiming ethyl acetate in a material by steam heating into a neutralizing kettle through a condenser, starting to stir, dropwise adding 30% sodium hydroxide to neutralize until the pH is 8-9, standing for 30-60 minutes, and separating moisture; pumping into an ethyl acetate crude product large storage tank, and rectifying in a rectification tower through a pump with a preheater; leading low-boiling-point components, moisture and azeotrope of ethyl acetate and moisture to the tower top, liquefying through the condenser, and automatically separating moisture through a customized moisture separator; returning upper ethyl acetate to the tower top to stay moisture-carrying ethyl acetate at the tower top; staying ethyl acetate and heavy components at the tower bottom, and continuously discharging ethyl acetate and heavy components from the tower bottom to an intermediate tank; and pumping into an evaporation kettle with a pump, opening steam to heat and evaporate qualified ethyl acetate, and receiving into a finished product tank through a condenser. The continuous rectifying method can be used for controlling the moisture of ethyl acetate to be lower than 0.1 percent and has low energy consumption, and the reclaimed ethyl acetate has high quality and can reach over 99 percent.

Owner:ANHUI GUANGXIN AGROCHEM

Semiconductor device and method of forming the same

ActiveCN109830438BAvoid misalignmentImprove the isolation effectSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialIsolation layer

A semiconductor device and a method for forming the same, wherein the method includes: providing a semiconductor substrate with initial fins on the semiconductor substrate; forming a gate structure material layer on the semiconductor substrate and the initial fins, the gate The top surface of the pole structure material layer is higher than the top surface of the initial fin; a groove is formed in the gate structure material layer and the initial fin, and the groove is along a direction perpendicular to the extending direction of the initial fin and parallel to the semiconductor substrate. The direction of the bottom surface runs through the initial fin so that the initial fin forms a fin; an isolation layer is formed in the groove, the top surface of the isolation layer is higher than the top surface of the fin; and the gate structure material is etched layer, so that the gate structure material layer forms a gate structure on both sides of the isolation layer, the gate structure straddles the fin and covers part of the top surface and part of the sidewall surface of the fin. The method improves the isolation performance of the semiconductor device.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com