Press filter control system based on industrial field communication technology

An industrial field and control system technology, applied in the direction of electrical program control, program control in sequence/logic controller, filtration and separation, etc., can solve problems such as unfavorable filter press, increase of failure points, simple control process, etc., and achieve high efficiency The effect of safe conveying concentrate, optimizing production process and optimizing feeding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

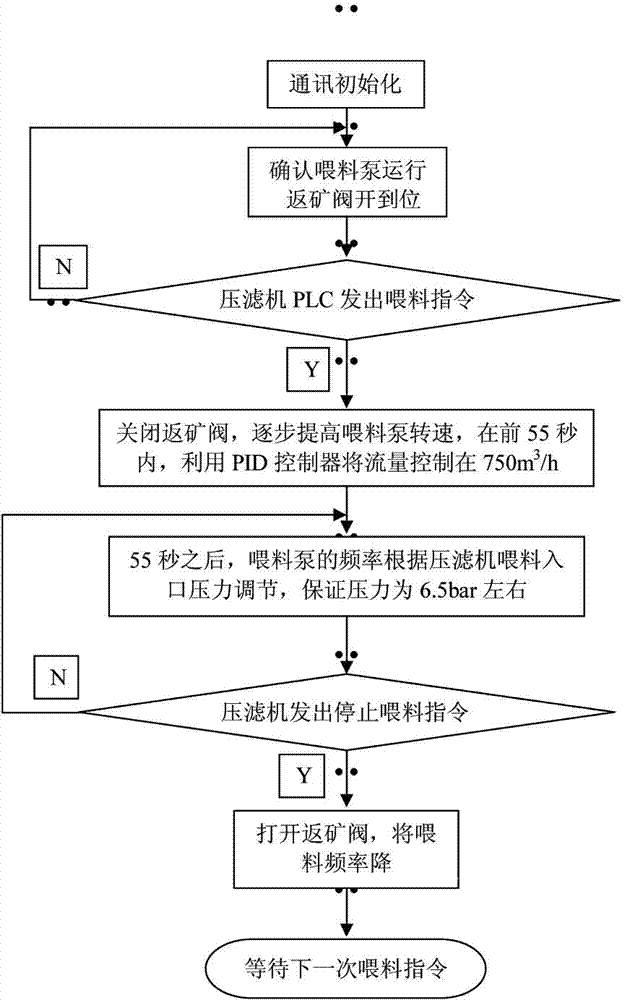

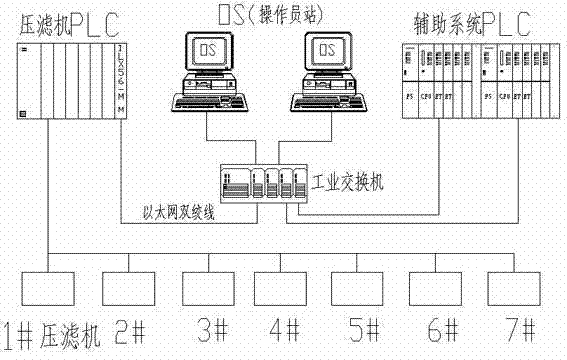

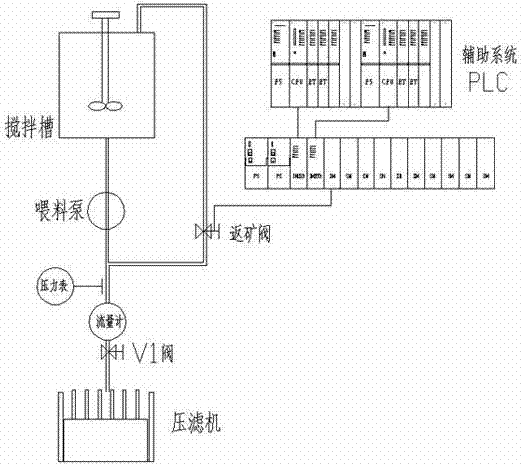

[0012] The present invention adopts the signals of all auxiliary equipments (including flushing water pump ready signal, feeding pump system ready signal, compressed air system ready signal, flushing water pump operation signal, return mine valve open in place signal, return mine valve close in place signal) signal, feeding pump running signal, feeding belt running signal), using the protocol conversion module as an intermediary, using Ethernet to send the signal to the filter press PLC, and at the same time, the signal sent by the filter press PLC (including the feeding pump start command, The switch return valve command, material receiving belt start signal, filter press operation signal, filter press fault signal, filter press position signal, filter press cycle completion signal) are sent to the auxiliary system PLC in the same way, and then two Two-way d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com