A method of preparing an o-phenylenediamine intermediate used for carbendazim production

A technology of phenylenediamine and carbendazim, which is applied in the field of preparation of intermediate o-phenylenediamine, can solve the problems of reduced safety and cleanliness, increased equipment investment and energy consumption, and increased product post-processing procedures, so as to save synthesis cost, meet the requirements of process design, and optimize the effect of process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

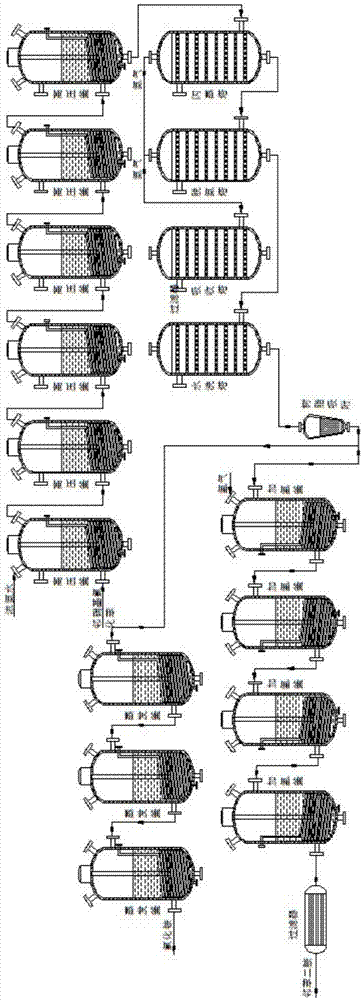

[0025] see figure 1 Shown, the technical scheme that the present invention adopts is: a kind of preparation method of the intermediate o-phenylenediamine that is used for the production of carbendazim, the concrete of described preparation method comprises the following steps:

[0026] (1). Initial reaction: transfer a certain amount of o-nitrochlorobenzene and a certain concentration of concentrated ammonia into an autoclave connected in six stages, set the temperature and pressure inside the autoclave, and react for a period of time to obtain o-nitrochloride Base aniline solution, obtain by-product;

[0027] (2). Ammonia recovery: The discharge liquid containing o-nitroaniline is flashed through the flash tower to recover the excess ammonia gas generated, and then the liquid phase is heated up through the deammonization tower to further recover ammonia gas. The recovered ammonia gas Absorbed under pressure through the ammonia absorption tower;

[0028] (3).Water washing: A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com