Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Optimize process design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

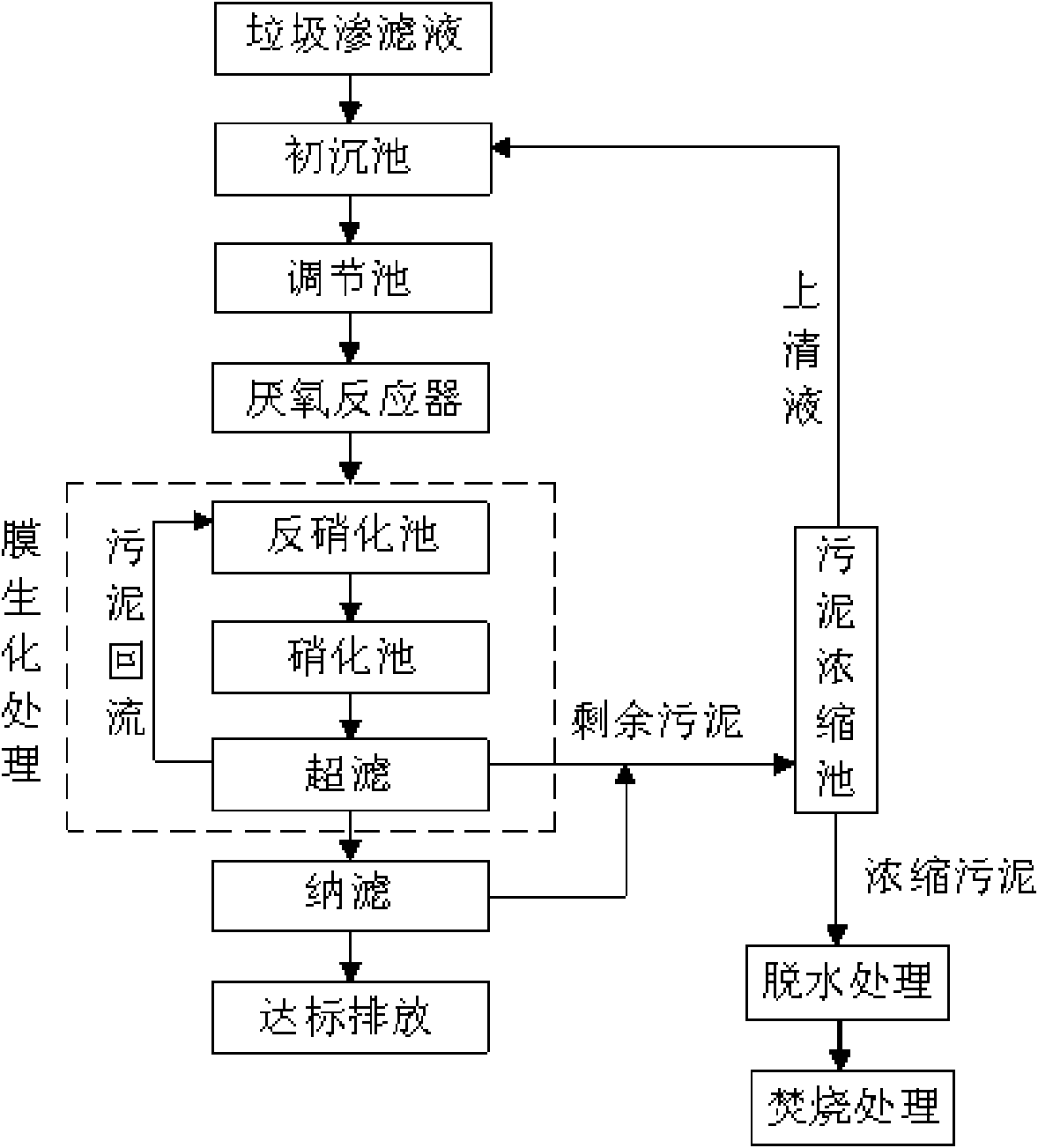

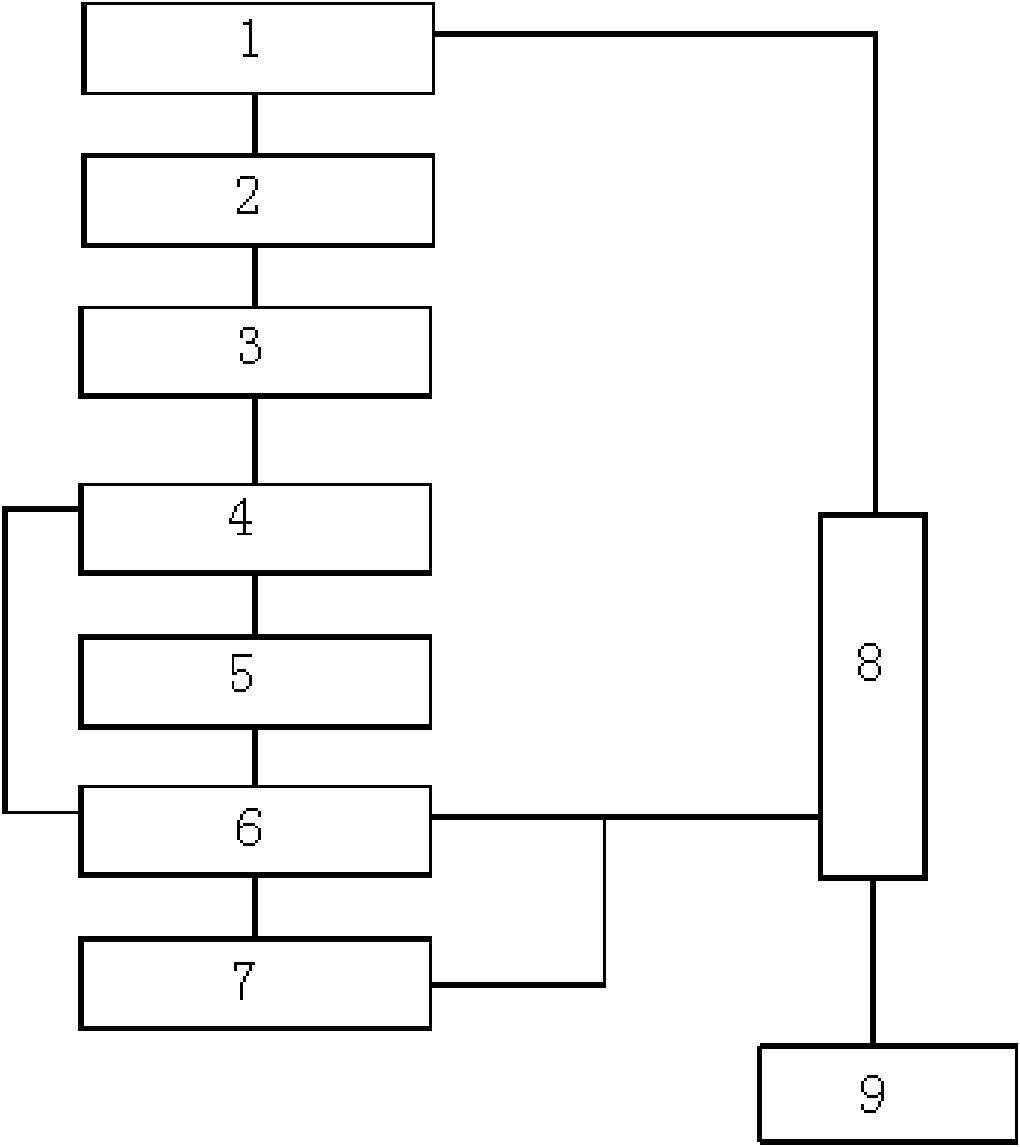

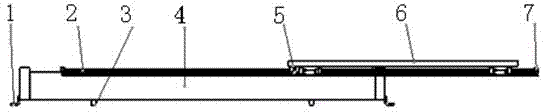

Method and device for treating garbage percolate

ActiveCN101597131AAchieving zero emissionsRelieve stressSludge treatment by de-watering/drying/thickeningTreatment with aerobic and anaerobic processesHigh concentrationAfter treatment

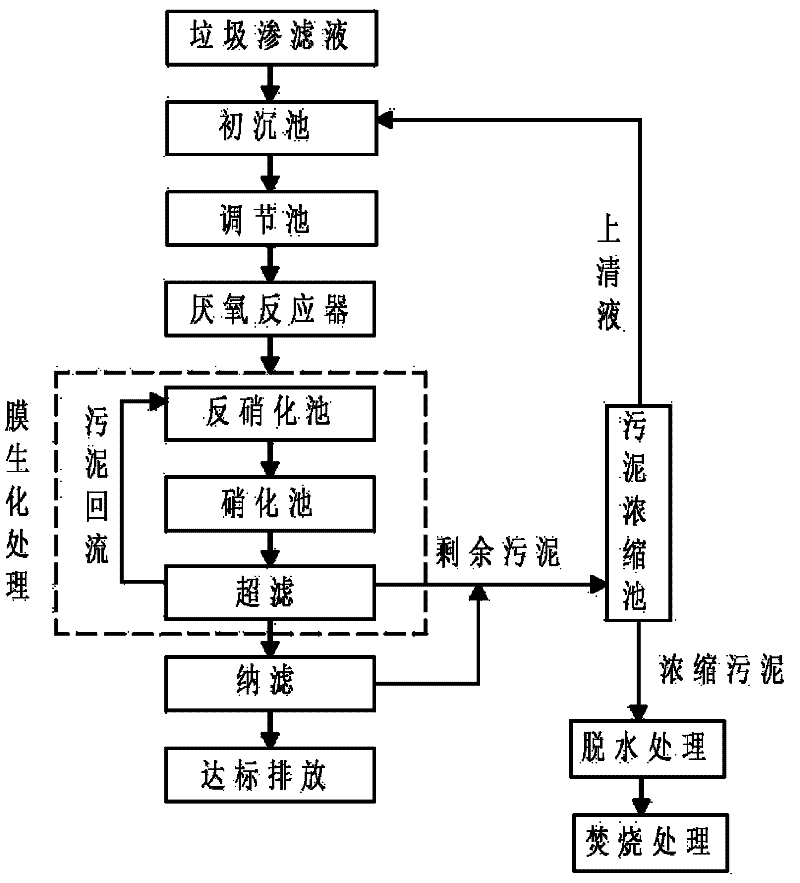

The invention discloses a method and a device for treating garbage percolate, wherein the method comprises the steps of pretreatment, anaerobic treatment, membrane biochemical treatment, nanofiltration treatment, sludge treatment and the like; the device comprises a primary sedimentation tank (1) and an adjusting tank (2), the adjusting tank (2) is connected with an anaerobic reactor (3), the anaerobic reactor (3) is connected with a denitrification tank (4), and the denitrification tank (4) is communicated with a nitrification tank (5); and the nitrification tank (5) is connected with an ultrafiltration apparatus (6), and the ultrafiltration apparatus (6) is connected with a nanofiltration device (7). The method and the device achieve COD degradation of high-concentration wastewater so that the COD of high-concentration COD of 50,000 reaches about 50 after treatment and reaches the standard of industrial reuse water, thus the method and the device achieve zero discharge of the percolate, initiate a new attempt to treat high-concentration percolate, and fill up the domestic blank.

Owner:汕头市澄海洁源垃圾发电厂有限公司

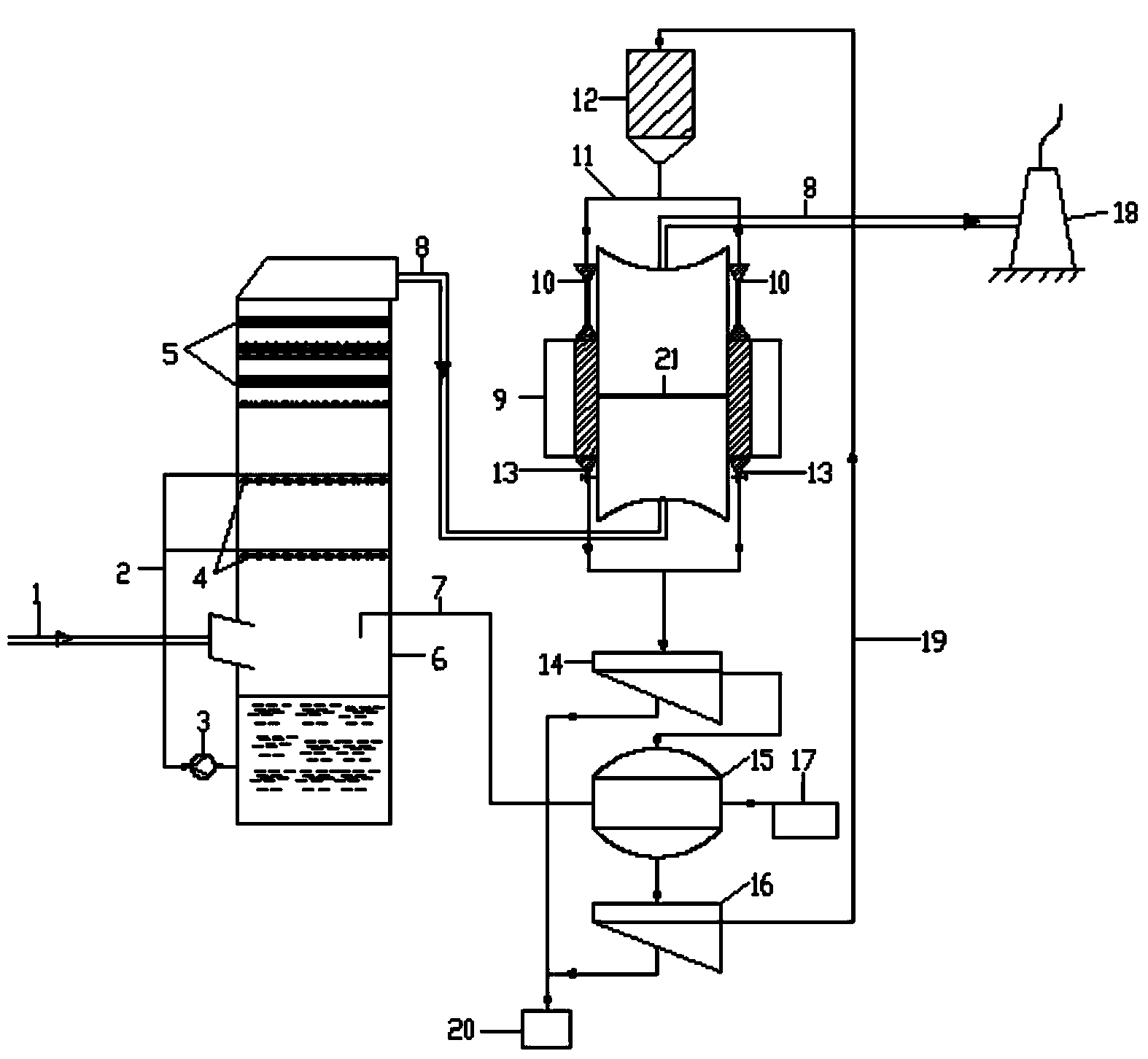

Dual flue gas purification technology and purification system thereof

ActiveCN103657275APurify thoroughlyEfficient governanceCombination devicesDispersed particle filtrationParticulatesAtmospheric air

The invention relates to a dual flue gas purification technology and a purification system thereof in the field of wet flue gas purification. The technology comprises primary wet purification and secondary adsorbing purification, wherein a clean flue gas obtained after raw flue gas is primarily purified enters a clean flue gas channel, and the clean flue gas obtained after the primary wet purification is processed by secondary adsorbing purification. The system comprises a primary wet purification device and a secondary adsorbing purification device, wherein the primary wet purification device comprises a raw flue gas channel, an adsorption tower and a clean flue gas channel which are sequentially connected with one another; the secondary adsorbing purification device is respectively connected with the clean flue gas channel and the adsorption tower. The technology disclosed by the invention is based on an optimized design, and stable in system operation, pollutants such as gas liquid slurry materials, dust, aerosol and the like mixed in the clean flue gas can be effectively controlled, especially, the substances such as sulphurous acid nitrite and the like forming particulate matters (PM)2.5 can be effectively prevented from entering the atmosphere, the environmental effect is significantly enhanced, secondary pollution of the clean flue gas to the atmosphere caused is effectively prevented, and the dual flue gas purification technology and purification system thereof are applicable to popularization and application in the field of flue gas purification.

Owner:BEIJING ZHONGNENG NUOTAI ENERGY SAVING & ENVIRONMENTAL PROTECTION CO LTD

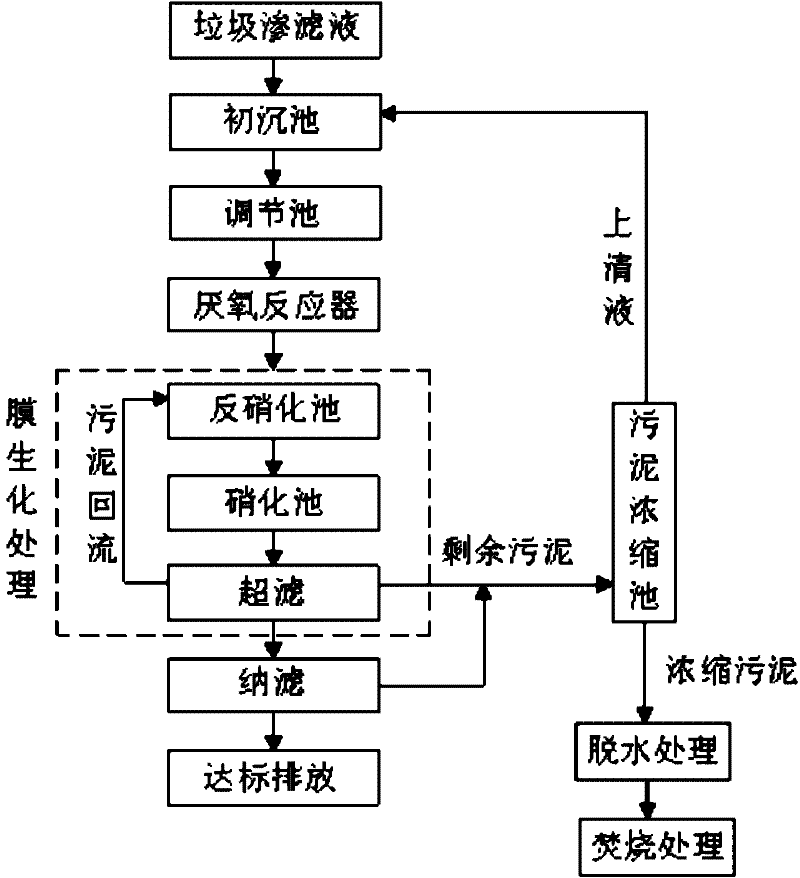

Method for applying integrated technology of combination of membrane biochemistry and nanofiltration membrane to high-density leachate advanced treatment and recycling

InactiveCN102190400ARelieve stressSolve pollutionSludge treatment by pyrolysisTreatment with aerobic and anaerobic processesHigh densityUltrafiltration

The invention discloses a processing method and a processing apparatus of landfill leachate. The processing method comprises steps of pretreatment, anaerobic treatment, membrane biochemical treatment, nanofiltration treatment, and sludge treatment and the like. And the processing apparatus includes a primary settling tank (1) and a regulating tank (2). The regulating tank (2) is connected with an anaerobic reactor (3) which is connected with a denitrifying tank (4); the denitrifying tank (4) is communicated with a nitration tank (5), which is connected with ultrafiltration equipment (6); and the ultrafiltration equipment (6) is connected with nanofiltration equipment (7). According to the invention, COD of the high-density wastewater is degraded. After processing, high-density COD of 50,000 to 60,000mg / L is degraded to COD of about 50 mg / L, which reaches the standard of industrial reused water. Moreover, zero discharge of leachate is realized. Therefore, a new attempt to treat the high-density leachate is initiated and the domestic blank is filled.

Owner:HUZHOU NANTAIHU ENVIRONMENTAL PROTECTION ENERGY

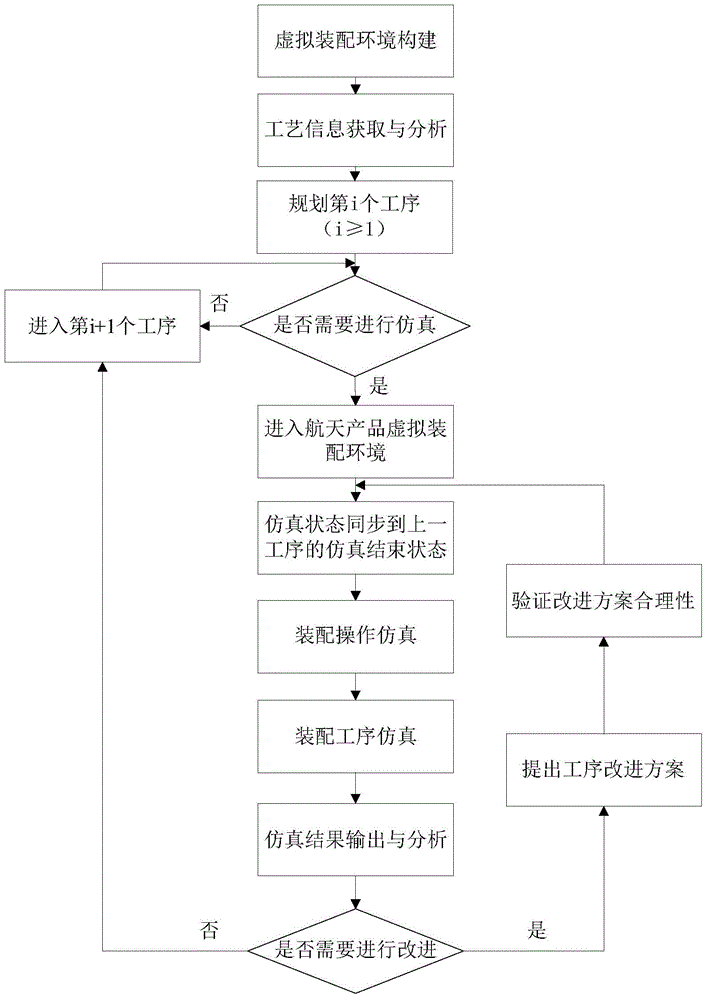

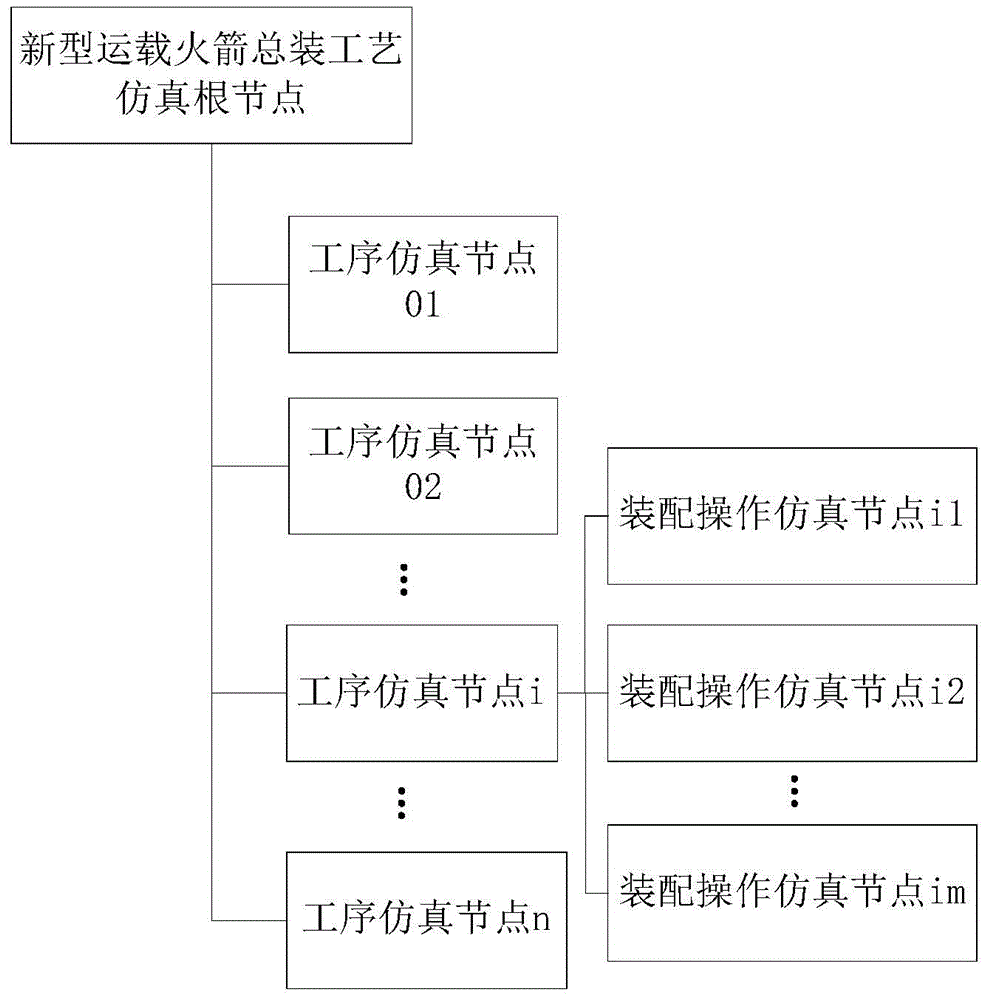

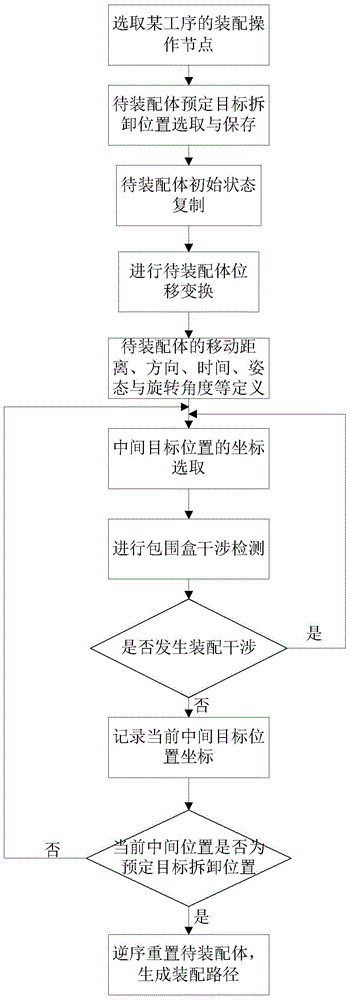

Aerospace product general assembly technology simulation analysis method

InactiveCN104951350AProcess Design Process Image and ImprovementReduce difficultySoftware simulation/interpretation/emulationSpecial data processing applicationsProcess simulationAerospace

The invention provides an aerospace product general assembly technology simulation analysis method. A three-dimensional virtual reality environment serves as a platform, after the aerospace general assembly technology is planned and each procedure is designed, the aerospace product general assembly environment is established according to the actual general assembly situation, and overall process simulation of each procedure, trial assembly of relevant parts and inspection and verification of feasibility, safety, operating comfort and the like of the assembly scheme are conducted. By the adoption of the method, technologists get rid of dependence on experience to a certain degree, the general assembly process is simulated in the three-dimensional virtual reality environment through a digital model of an aerospace product, the overall process simulation verification is conducted on the general assembly technology scheme, the problems of assembly sequence errors, part interference, wrong installation, neglected installation and the like existing in the assembly process are found in time, the general assembly technology design scheme is corrected and optimized in time, the technology planning difficulty is lowered, and the technology scheme is more optimized.

Owner:SHANGHAI JIAO TONG UNIV

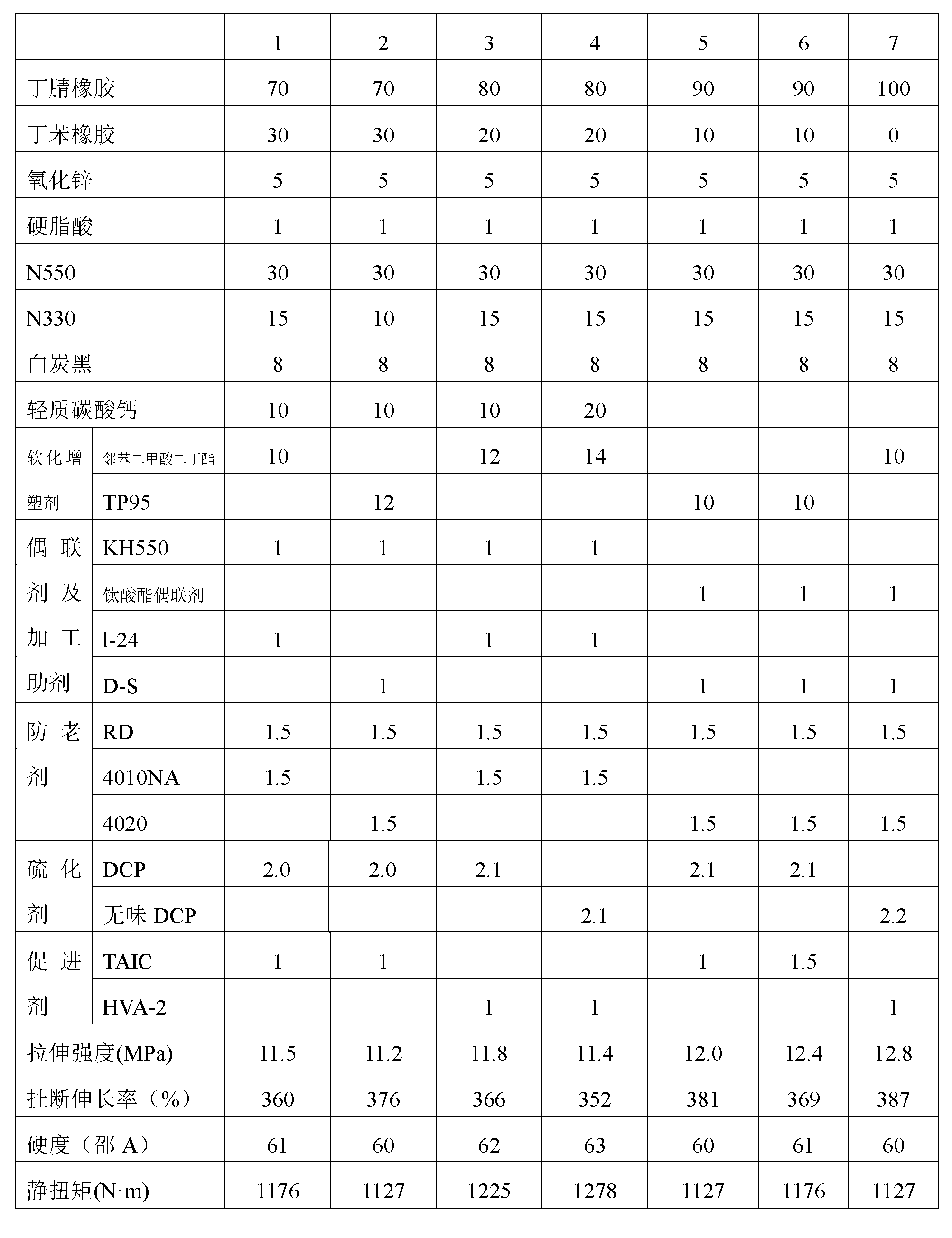

Damping rubber material with low hardness, high-temperature static torque and good durability and preparation method thereof

The invention relates to a damping rubber material with low hardness, high-temperature static torque and good durability and a preparation method thereof. The damping rubber material comprises the following components in mass parts: 100 parts of nitrile rubber and butadiene styrene rubber composite, 40-70 parts of reinforcement bulking agent, 5-10 parts of nano white carbon black, 1-3 parts of coupling agent and processing agent, 10-15 parts of softened plasticizer, 2-3 parts of anti-aging agent, and 8-10 parts of curing agent and auxiliary agent; and moreover, the technological parameters of rubber material vulcanization are as follows: a press vulcanizer is adopted for vulcanization, the vulcanization time is 10-20 minutes, the vulcanization temperature is 150-160 degree C, and the vulcanization pressure is 10-14 MPa. The damping rubber material disclosed by the invention has the advantages of low hardness, high static torque at 80 degree C, good durability at high temperature of 130 degree C, as well as good processability. The material can be used as damping rubber materials used in rubber torque vibration dampers of engines, and solves the problems of high hardness, difficulty in press fitting, low static torque at high temperature, poor durability and the like in the existing rubber composite material.

Owner:XIAN HANHUA RUBBER TECH

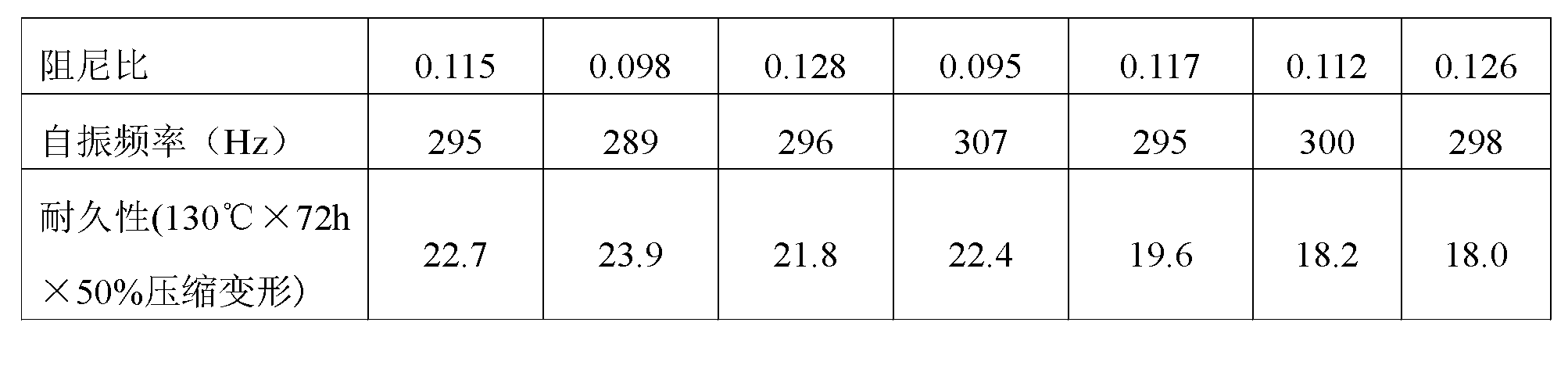

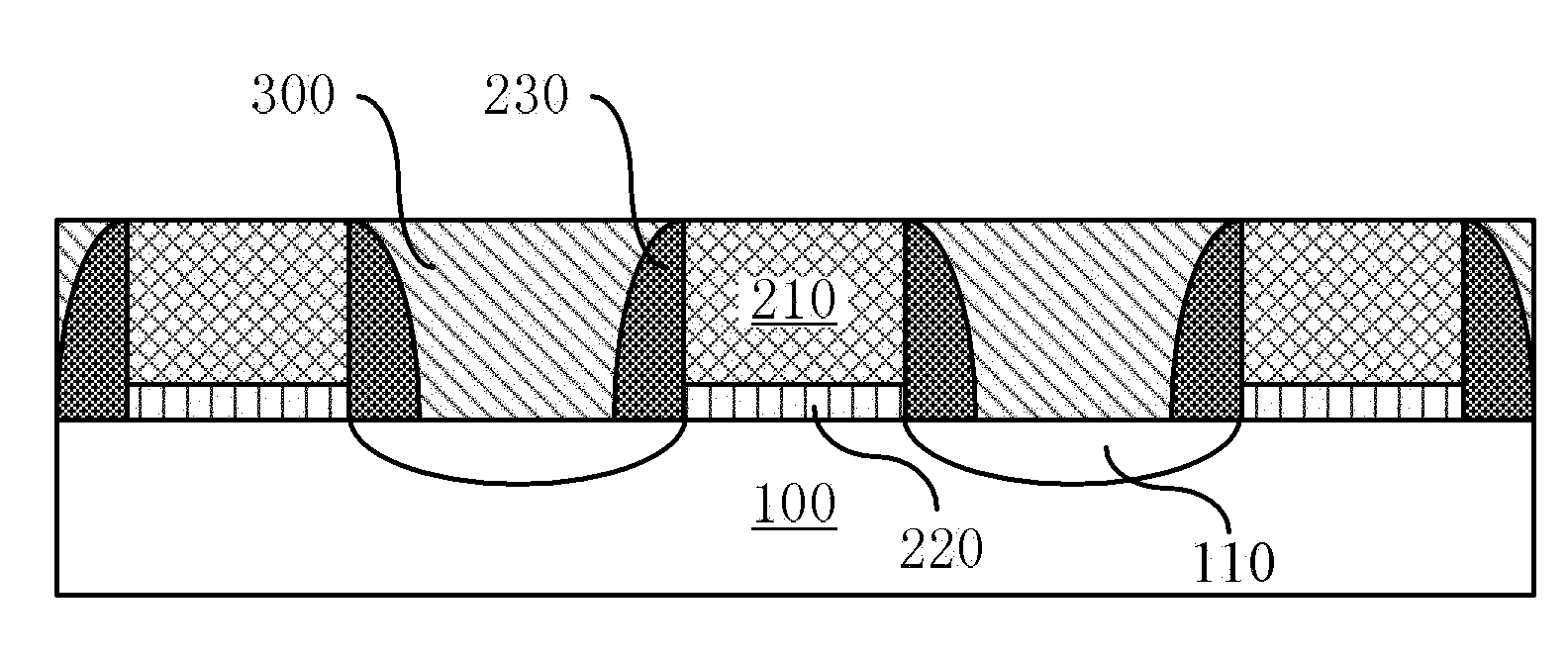

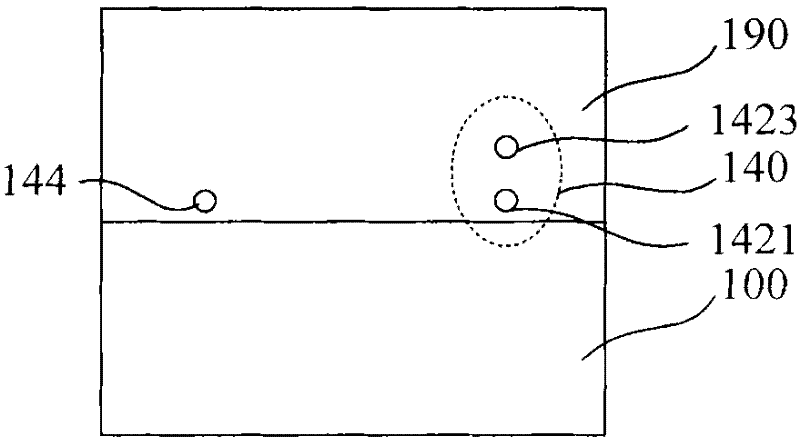

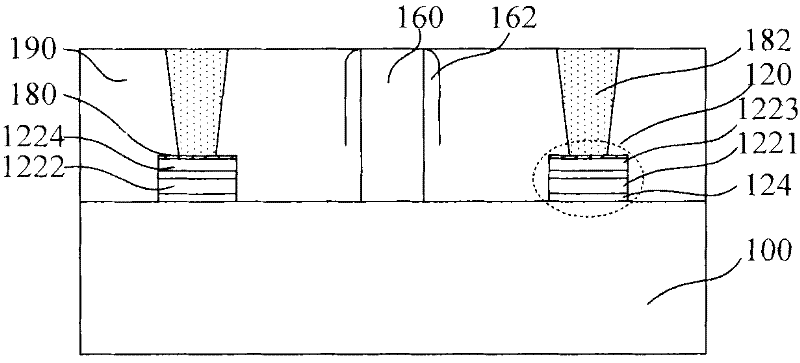

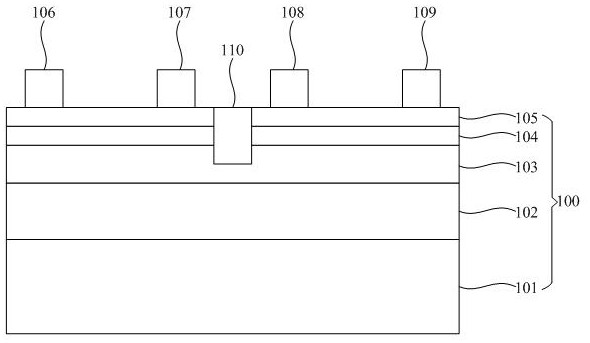

Semiconductor structure and making method thereof

ActiveCN102468226AEasily damagedHighly integratedTransistorSemiconductor/solid-state device detailsSemiconductor structureDielectric layer

The invention discloses a semiconductor structure which comprises a first interlayer structure, a second interlayer structure and a third interlayer structure. The first interlayer structure comprises a first dielectric layer and a first contact plug, the first dielectric layer is flush with a grid stack or covers the grid stack, and the first contact plug passes through the first dielectric layer and is electrically connected with at least part of a source / drain region; the second interlayer structure comprises a cover layer and a second contact plug, the cover layer covers the first interlayer structure, and the second contact plug passes through the cover layer and is electrically connected with the first contact plug and the grid stack through a first lining; and the third interlayer structure comprises a second dielectric layer and a third contact plug, the second dielectric layer covers the second interlayer structure, and the third contact plug passes through the second dielectric layer and is electrically connected with the second contact plug through a second lining. The invention also provides a making method for the semiconductor structure. With the adoption of the semiconductor structure and the making method thereof, area saving is facilitated to improve the integration degree of the semiconductor structure.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Full penetration printing production process of 34-inch thick double-sided polar fleece

ActiveCN104553419ACreativeAdvancedWeft knittingHeating/cooling textile fabricsScreen printingTextile printer

The invention relates to a full penetration printing production process of 34-inch thick double-sided polar fleece. The process is characterized in that an entire set of optimal technical scheme of system engineering design is established through technical means such as weaving, dyeing and finishing and microscopic computer image analysis. The process comprises the following steps: weaving a blank; performing dyeing and finishing pretreatment on fabric; tentering and shaping the fabric before printing; performing microscopic computer image analysis; performing rotary screen printing, evaporation, washing and emulsification on the fabric; tentering and shaping the fabric after printing; galling, combing, shearing and fleecing; shaping billet. The process has the beneficial effects that 1, the difference value of printing and dyeing color yield percentage of front and back faces of the fabric is reduced, and the front and back faces of the finished product are attractive in color, and 2, the finished fabric is full, fluffy and soft in raising, the problem of hard handfeel of the thick double-sided fleece fabric is solved, and a high added value of the product is further improved. The fleece is most suitable for making middle and top grade thermal vests, jacks, underwear, (woolen) shirts, overcoats, bedding articles, carpets, gloves, scarves, hats, back cushions and the like.

Owner:QINGDAO JIFA GROUP

Temperature detecting circuit for IGBT module

PendingCN109855758ASafe by designEasy to useThermometers using electric/magnetic elementsUsing electrical meansElectrical resistance and conductanceJunction temperature

The invention relates to a temperature detecting circuit for an IGBT module. The temperature detecting circuit for the IGBT module comprise a thermistor Rt, a chip U1 for converting an analog quantityinto an pulse quantity, and an FPGA, wherein the thermistor Rt is installed inside the IGBT module; the chip U1 for converting the analog quantity into the pulse quantity is connected with the thermistor Rt and used for converting an analog quantity of resistance change of the thermistor Rt into a digital quantity of a pulse width change; and the FPGA is connected with the chip U1 for convertingthe analog quantity into the pulse quantity, and the FPGA is used for detecting a pulse width or a duty ratio, calculating an NTC resistance value, and reading an corresponding IGBT module junction temperature through a look-up table method. Compared with the prior art, the temperature detecting circuit for the IGBT module has the advantages of having good linearity, high precision, and safety isolation.

Owner:ACREL +1

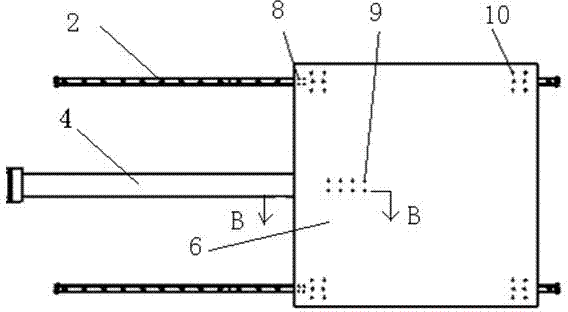

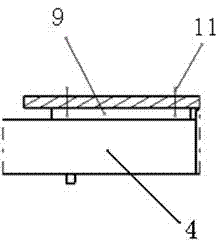

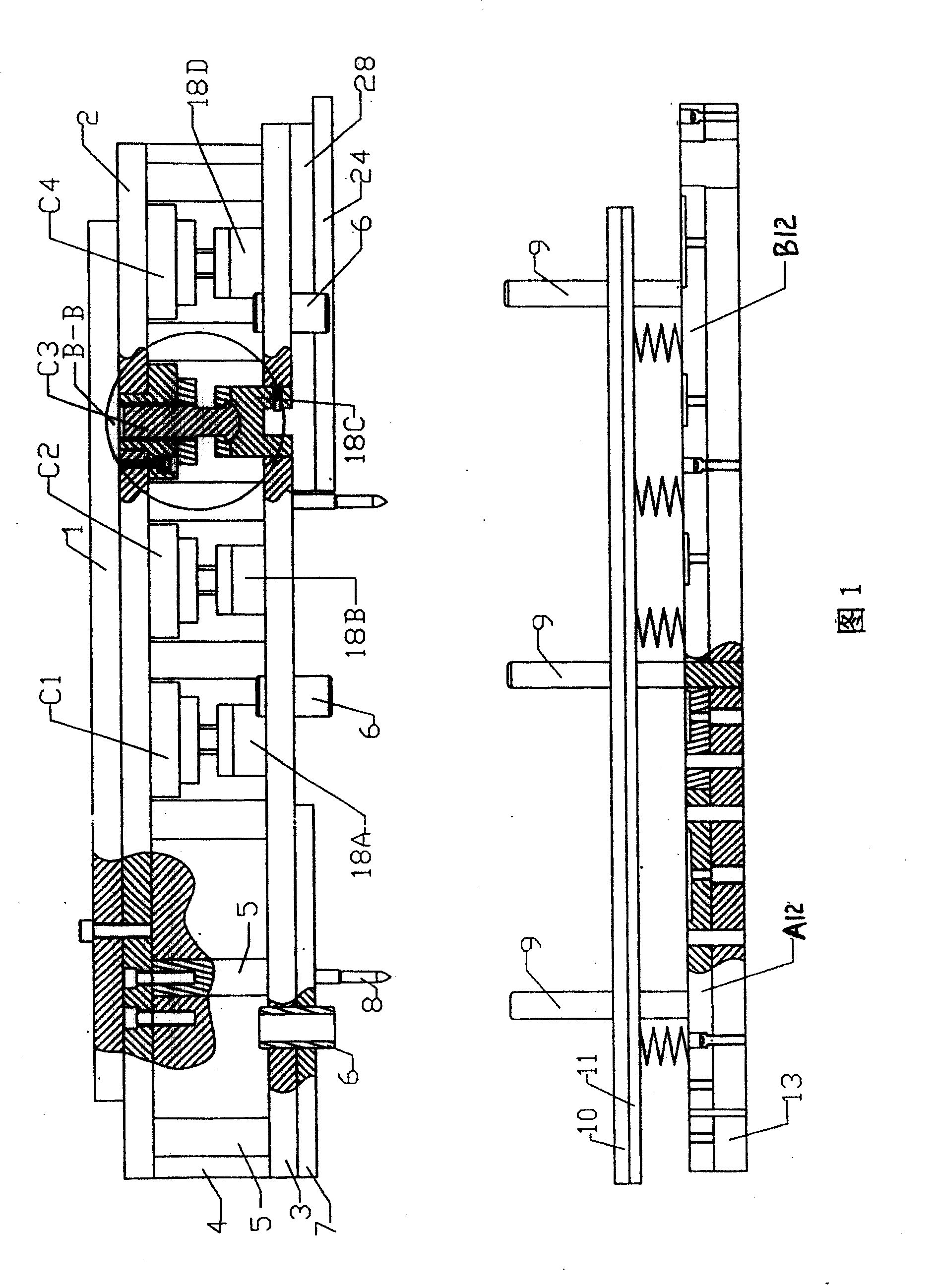

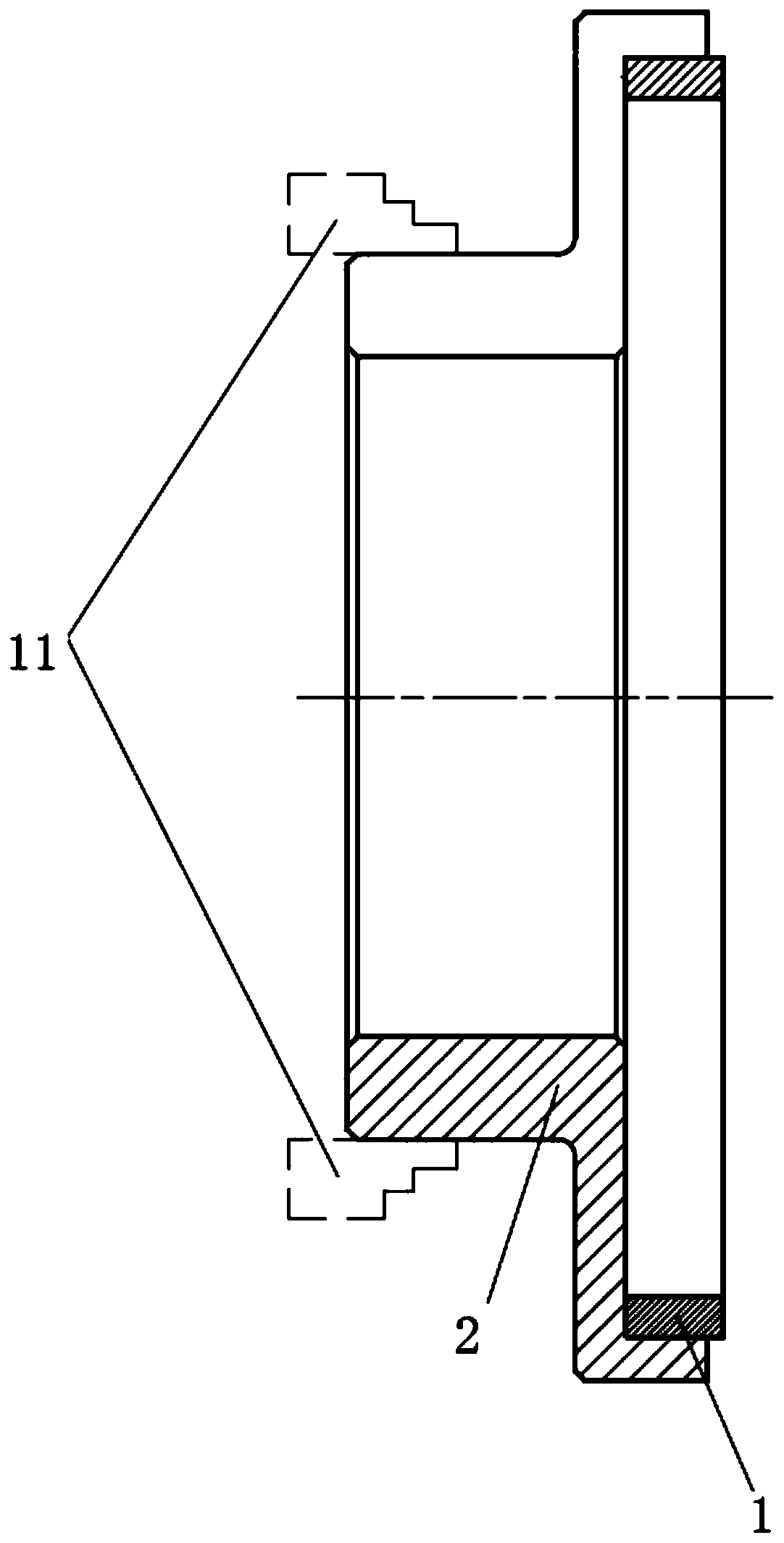

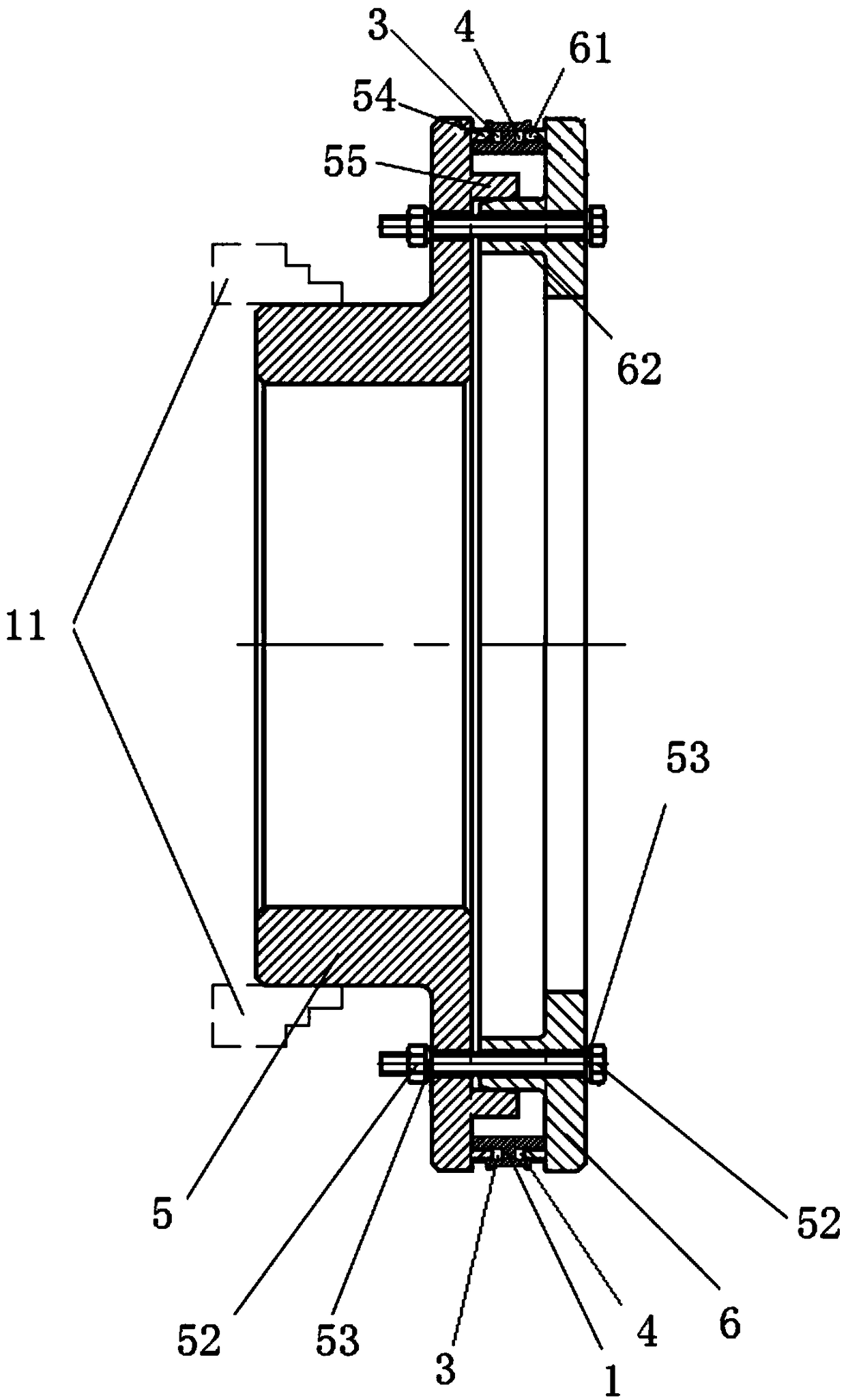

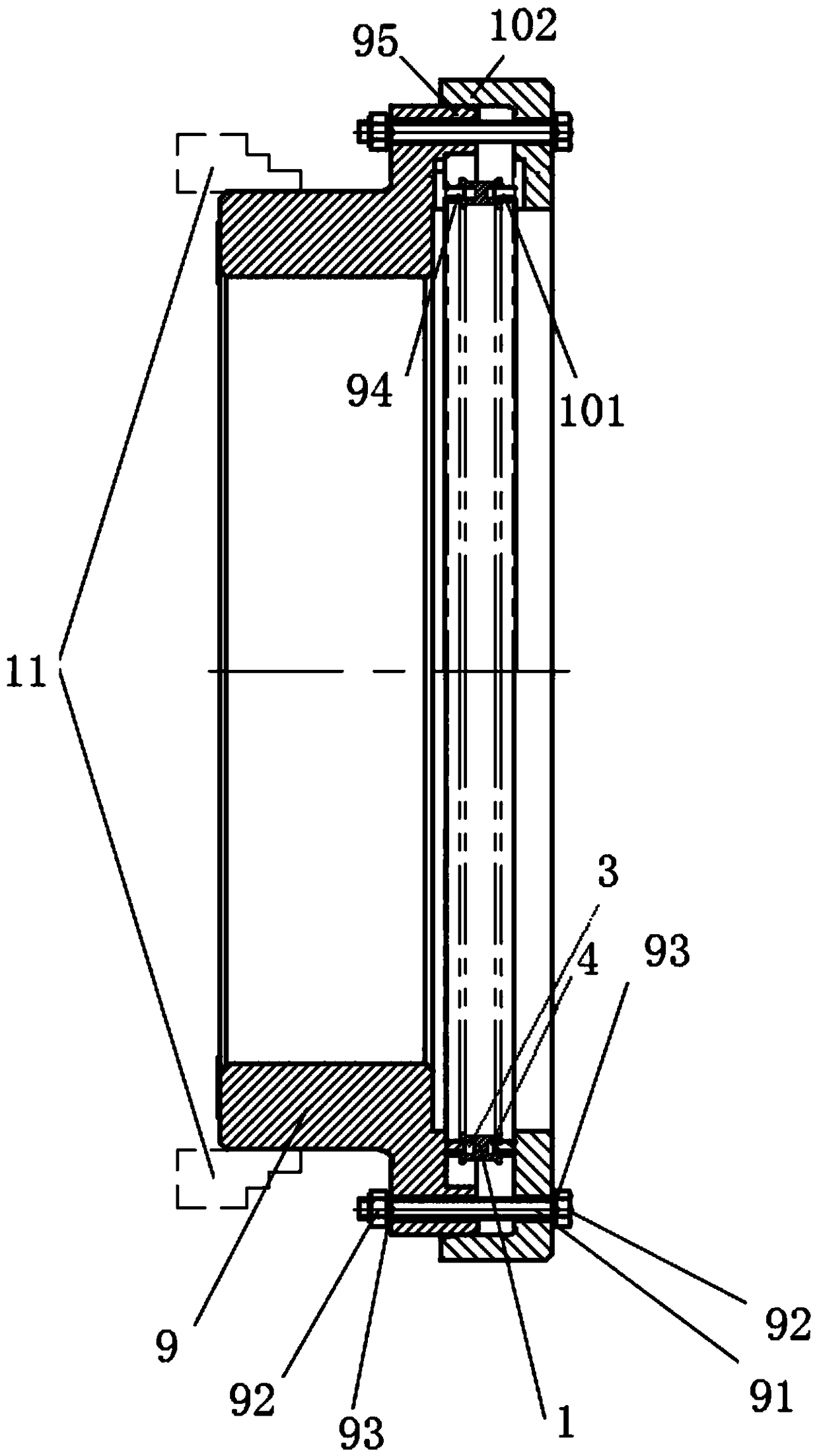

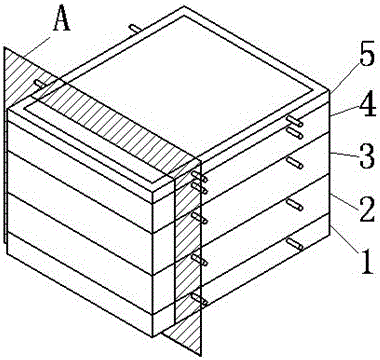

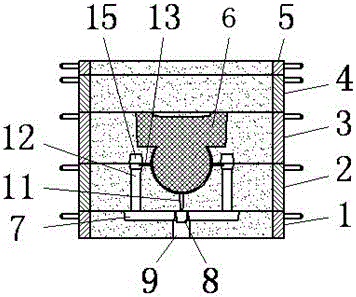

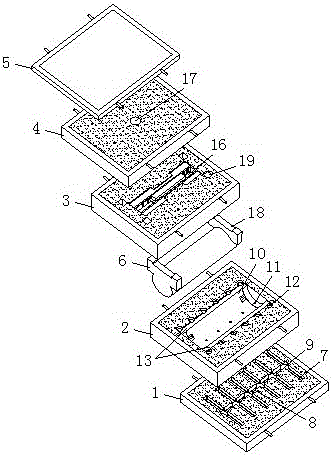

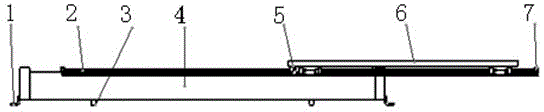

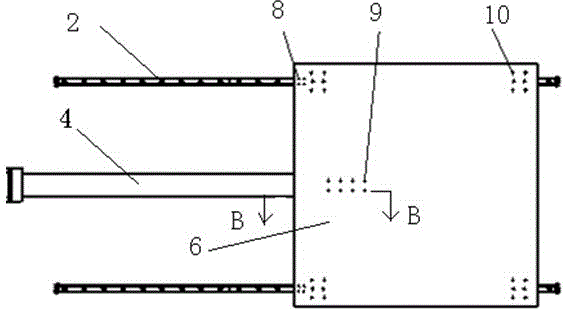

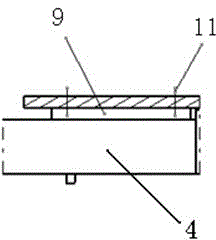

Self-driven precision guide rail type fixture accurate positioning pushing device

ActiveCN103043428AReasonable process designOptimize process designConveyor partsEconomic benefitsSelf driven

The invention discloses a self-driven precision guide rail type fixture accurate positioning pushing device and relates to the technical field of aircraft manufacturing. According to the device, two sides of a connection plate (6) are provided with a rolling linear guide rail pair (2) and a pneumatic clamping element (5) through a first bolt (8) and a third bolt (10), a rodless cylinder (4) is installed in the middle of the connection plate (6) through a second bolt (9), a sliding block (11) is arranged between the rodless cylinder (4) and the connection plate (6), a foot stand installing part (1) and a supporting element (3) are connected to the rodless cylinder (4) through a fourth bolt (13), and a retaining block (7) is installed at two ends of the rolling linear guide rail pair (2) through bolts. According to the self-driven precision guide rail type fixture accurate positioning pushing device, manufacturing processes of traditional fixtures and assembling processes of aircraft products are changed, process designs are reasonable and optimal, during fixture manufacturing and product assembling, operation space is large, automation degrees are high, work efficiency is high, and great economic benefits are produced in the field of aircraft manufacturing.

Owner:JIANGXI HONGDU AVIATION IND GRP

Method for gaining high conversion rate by catalytic hydrogenation of vacuum residue over-critical extraction slag with zeolite molecular sieve

InactiveCN101161790AOptimize process designEasy to operateWorking-up tarHydrocarbon oils refiningWater bathsSlag

The invention discloses a method for catalytic hydrogenation of vacuum residue supercritical extraction residue through adopting zeolite molecular sieve to obtain high conversion rate, belonging to the petrochemical residual oil catalytic conversion technical field. The method includes the following steps: quantitative vacuum residue supercritical extraction residue, acidifying zeolite molecular sieve and solvent cyclonexane are fed into a high pressure autoclave; moreover, the air inside the high pressure autoclave is replaced by nitrogen under room temperature and then hydrogen is fed into the autoclave which is heated to a preset temperature; meanwhile, reaction is completed under the preset temperature; after the reaction, the high pressure autoclave is quickly cooled down to room temperature by means of cold water bath; reaction mixture which is taken out by cyclonexane after the gas inside the high pressure autoclave is released slowly is transferred to a Saxhlet extractor; finally, Saxhlet fractional extraction is carried out in turn by means of cyclonexane to obtain converted product. The invention has the advantages of simple process, easy operation and high conversion rate.

Owner:XUZHOU COLLEGE OF INDAL TECH

Molybdenum wire production continuous rolling and continuous forging cogging equipment and production method thereof

InactiveCN102615510AAvoid adding ancillary projectsLess investmentOther manufacturing equipments/toolsAutomatic controlWorking environment

The invention relates to molybdenum wire production continuous rolling and continuous forging cogging equipment, which comprises a heating furnace, a rolling machine, a first rotary forcing unit, a butt-welding machine and a second rotary forging unit arranged in sequence. The invention further relates to a method for producing a molybdenum wire with the equipment. By adopting a continuous rolling and continuous forcing process in which the advantages of cogging of the rolling machine and a plurality of rotary fogging machines are combined, the investment cost is greatly reduced, production efficiency is increased, consumption is lowered, and yield is increased. Meanwhile, the automatic control degree is high, noise is small, a good dust collecting effect is achieved, working environment conditions can meet relevant industrial sanitation and environment requirement standards, and the product quality can reach the world advanced level.

Owner:ZIGONG CEMENTED CARBIDE CORP

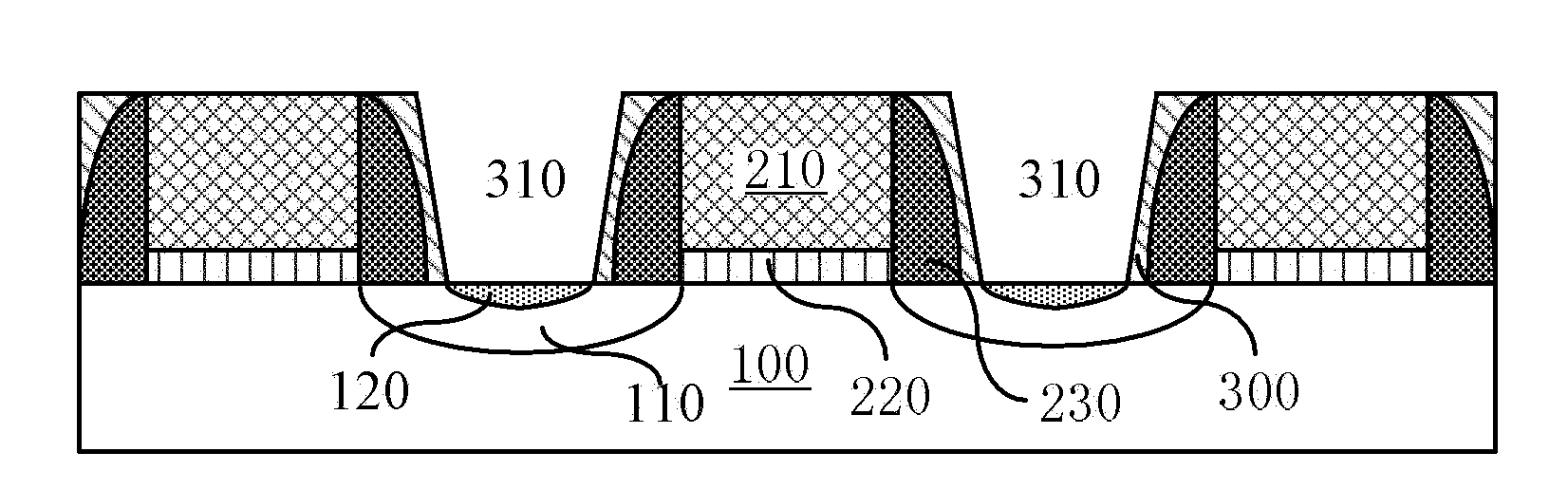

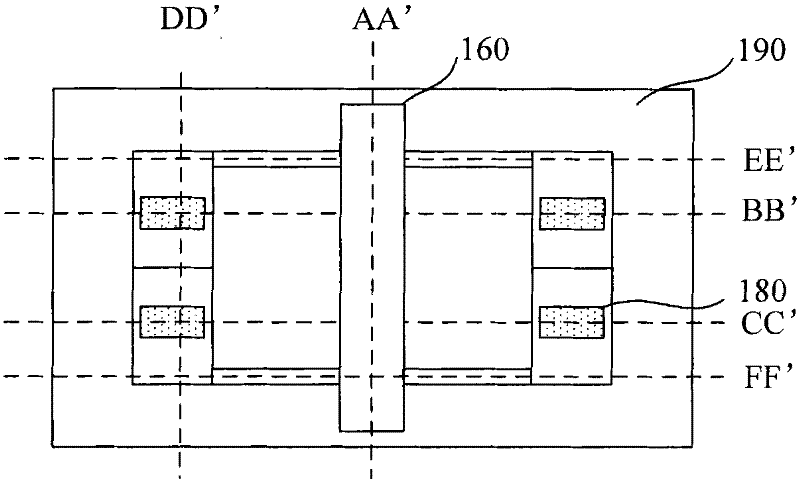

Semiconductor structure and formation method thereof

ActiveCN102446952AReduce areaHighly integratedSolid-state devicesSemiconductor/solid-state device manufacturingNanowireElectrical conductor

The invention relates to a semiconductor structure, and the semiconductor structure is formed on a first semiconductor layer; the semiconductor structure comprises a main nanometer line, a nanometer line group and two semiconductor substrates; each semiconductor substrate comprises at least two second semiconductor layers, each second semiconductor layer is formed on an insulating layer, and each second semiconductor layer is in one-to-one correspondence with each insulating layer in each semiconductor substrate; the nanometer line group comprises at least two nanometer lines, the main nanometer line and each nanometer line are independent and comprise third semiconductor layers, and the second semiconductor layers as well as the first semiconductor layer and / or the third semiconductor layers are made of different materials; the main nanometer line is connected with the corresponding second semiconductor layer adjacent to the first semiconductor layer; and each nanometer line is connected with each second semiconductor layer in one-to-one correspondence, and the projections, positioned on the first semiconductor layer, of nanometer lines are coincided. In addition, the invention also provides a formation method of the semiconductor structure. The formation method is favorable for increasing integrated level.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

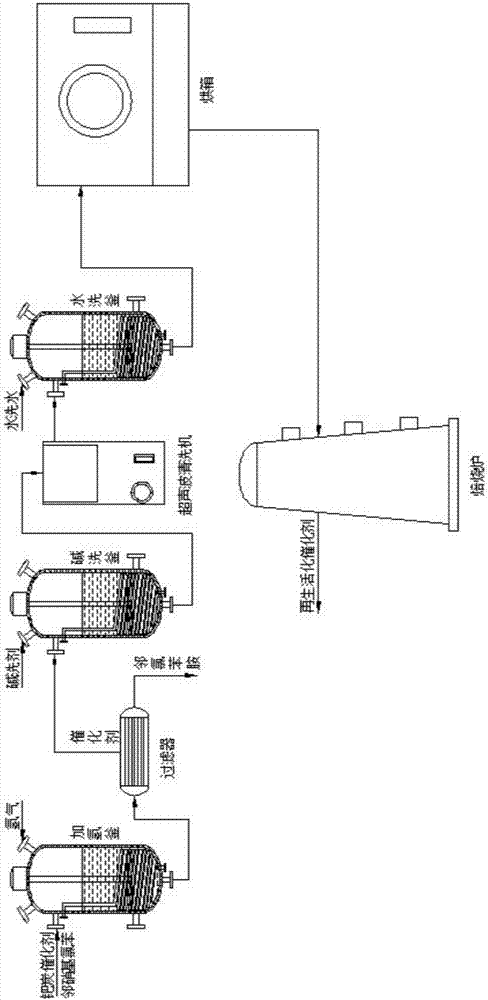

Method for regenerating catalyst for synthesizing o-chloroaniline

InactiveCN107570215AImprove regeneration efficiencyImprove recycling ratesOrganic-compounds/hydrides/coordination-complexes catalystsMetal/metal-oxides/metal-hydroxide catalystsEconomic benefitsMegasonic cleaning

The invention discloses a method for regenerating a catalyst for synthesizing o-chloroaniline. The method for regenerating the catalys specifically includes the following steps of: filtering a palladium-carbon catalyst out in a filter which is provided with a metal sintered tube and arranged in a final-stage kettle of four-stage series hydrogenation kettles, introducing the palladium-carbon catalyst into an alkaline washing kettle, conducting alkaline washing on the palladium-carbon catalyst with a hot alkaline solution, introducing the alkaline-washed palladium-carbon catalyst into an ultrasonic cleaner to perform ultrasonic cleaning, introducing the ultrasonic-cleaned palladium-carbon catalyst into a water washing kettle for water washing, putting the water-washed palladium-carbon catalyst into an oven for drying and water removal, and then raising the temperature and calcining the dried palladium-carbon catalyst to obtain the dried and regenerated palladium-carbon catalyst. According to the method for regenerating the catalyst for synthesizing the o-chloroaniline, the useful palladium-carbon catalyst can be effectively recycled, the content of o-phenylenediamine obtained throughthe catalysis of the palladium-carbon catalyst is 98% or above, the synthesis cost is saved, and the economic benefit is improved; besides, the method and the process design of the regeneration of the catalyst used for synthesizing the o-chloroaniline are optimized, and requirements of the industrial design are met.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

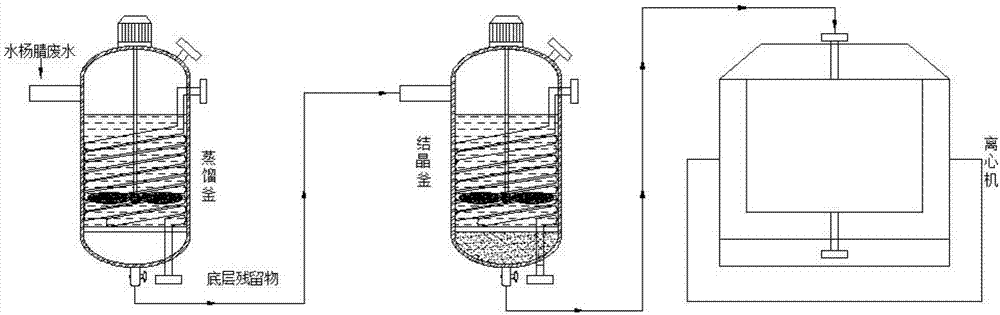

Technological method for treating 2-hydroxy-benzonitril wastewater

InactiveCN106976923AAvoid destructionLow costWater contaminantsWater/sewage treatment by heatingHigh concentrationSaline water

The invention discloses a technological method for treating 2-hydroxy-benzonitril wastewater. The technological method specifically comprises the following steps: firstly, transferring wastewater produced by refining 2-hydroxy-benzonitril into a distillation kettle; evaporating to remove acidic low-boiling residues and then evaporating to remove a large part of water, wherein the water can be used for refining the 2-hydroxy-benzonitril; secondly, transferring high-concentration saline water into a crystallization kettle and evaporating and crystalizing; centrifuging to obtain a byproduct sodium chloride, wherein the purity of the byproduct reaches 98 percent, wherein the water obtained by centrifuging can be used for refining the 2-hydroxy-benzonitril. The byproduct can be offered for sale so that the wastewater treatment cost is saved; the design of the technological method for treating the 2-hydroxy-benzonitril wastewater is optimized and requirements on the design of the technological method for treating the 2-hydroxy-benzonitril wastewater are met.

Owner:ANHUI GUANGXIN AGROCHEM

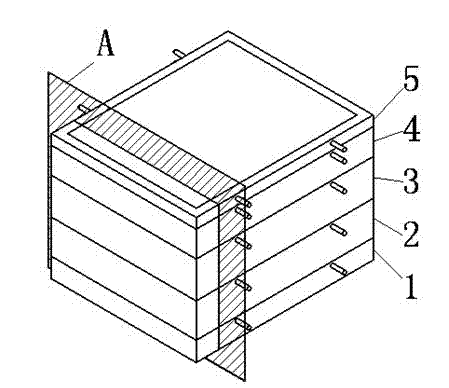

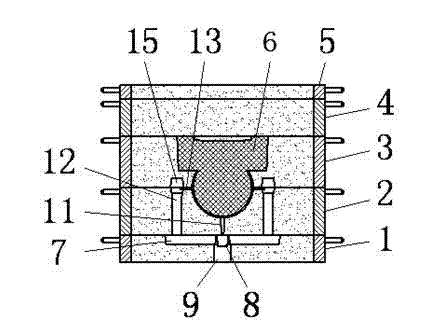

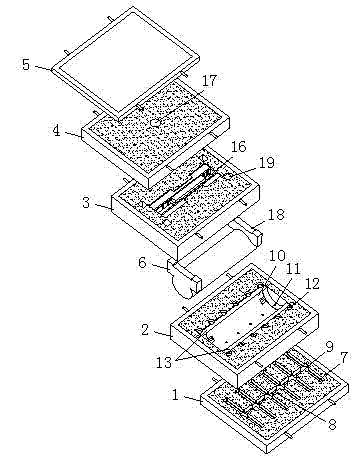

Casting method of girder having thin-walled cylinder and casting mold

ActiveCN104741542AGuarantee internal qualityEasy to follow upFoundry mouldsFoundry coresCasting moldPressure - action

The invention discloses a casting method of a girder having a thin-walled cylinder and a casting mold. A casting box consisting of fix boxes of a bottom box, a lower box, a middle box, an upper box and a cover box is adopted to cast; a core mold is transversely placed in the casting box; an inner runner, a vertical runner and a gap runner are arranged in the lower box; a pouring port is formed in the bottom box; meanwhile, transverse runners and longitudinal runners are arranged on the bottom box; pouring ports are respectively arranged in the intersections of all the transverse runners and the longitudinal runners; and molten metal is injected from the pouring port of the bottom box through a pressurization mode in casting, so that the molten metal flows into the casting cavity of the lower box through the inner runner under the pressure effect, flows to two sides through the transverse runner to enter the gap runner along with the vertical runner, and finally overflows from a riser of the upper box, so that the molten metal in the riser feeds a complex casting cavity in the top of the girder. The casting method can guarantee the internal quality of castings, is simple in molding method, is easy in subsequent treatment of the castings, can form the batch production, and is higher in pass percent.

Owner:贵州航天风华精密设备有限公司

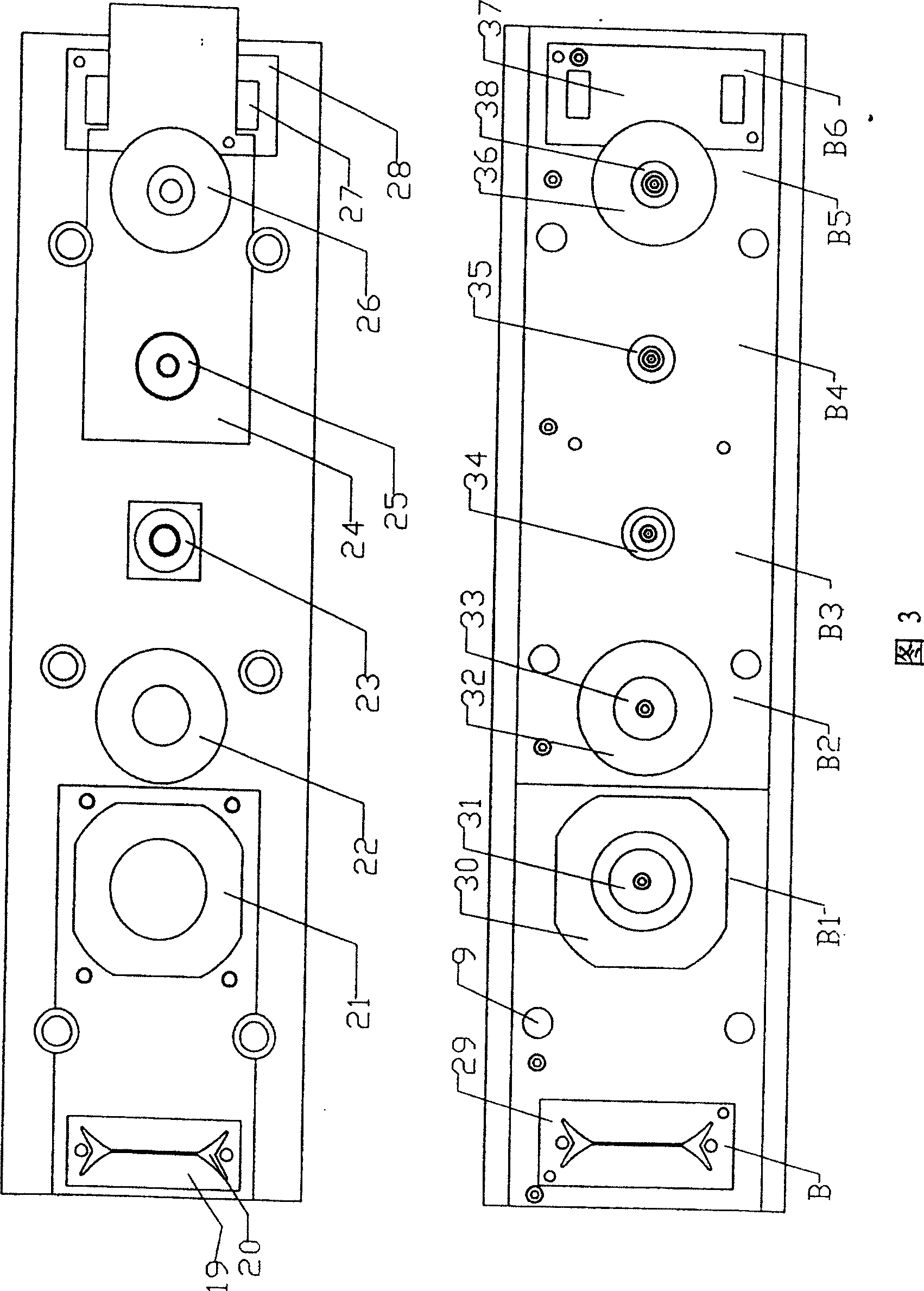

Full automatic compounding process and mould for household motor shell

InactiveCN100462157CReasonable designGuaranteed lifeShaping toolsManufacturing dynamo-electric machinesPunch pressEngineering

This invention discloses an automatic complex technology and dies for motor shell of family appliances, in which, the complex technology includes a punch technology characterizing in setting 7 steps: a first step of cut station, a second step of stretch station etc. along the transmission direction of a feed-in device on a punch, and an automatic compound die, up and down die base composed of up and down templates, a guiding device in the die and up and down dies characterizing in the up and down die base composed of up and down templates, in which, the upper base includes an upper template fixed on the punch of a punch machine tool.

Owner:佛山市南海里水中兴五金电器厂

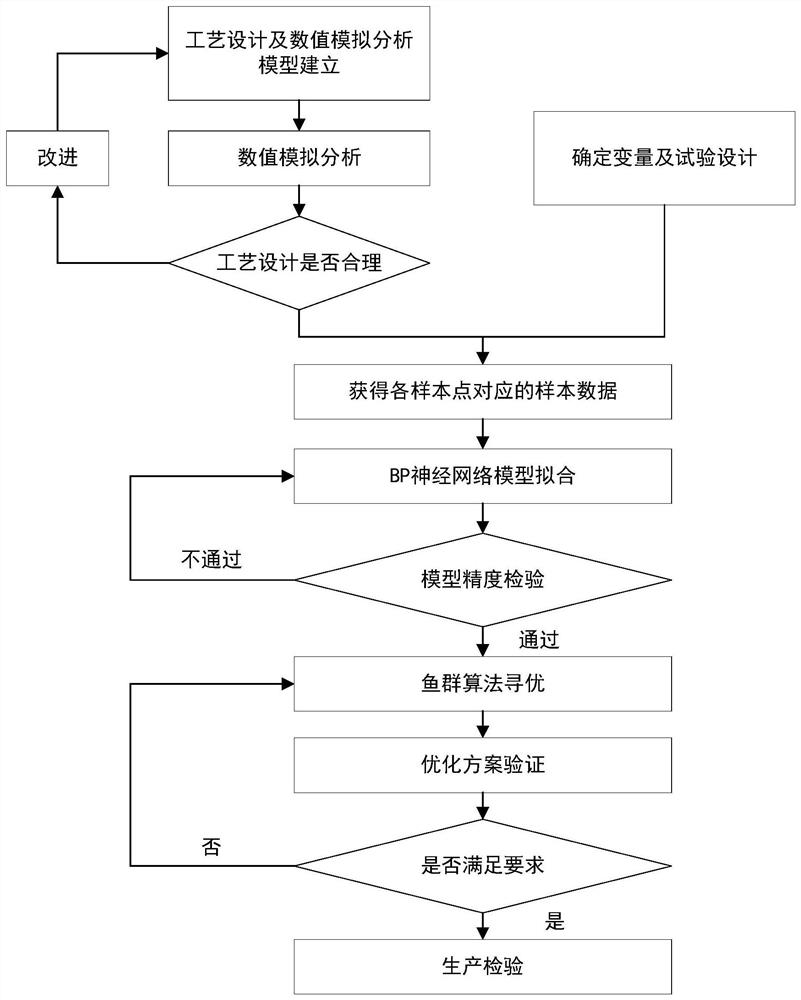

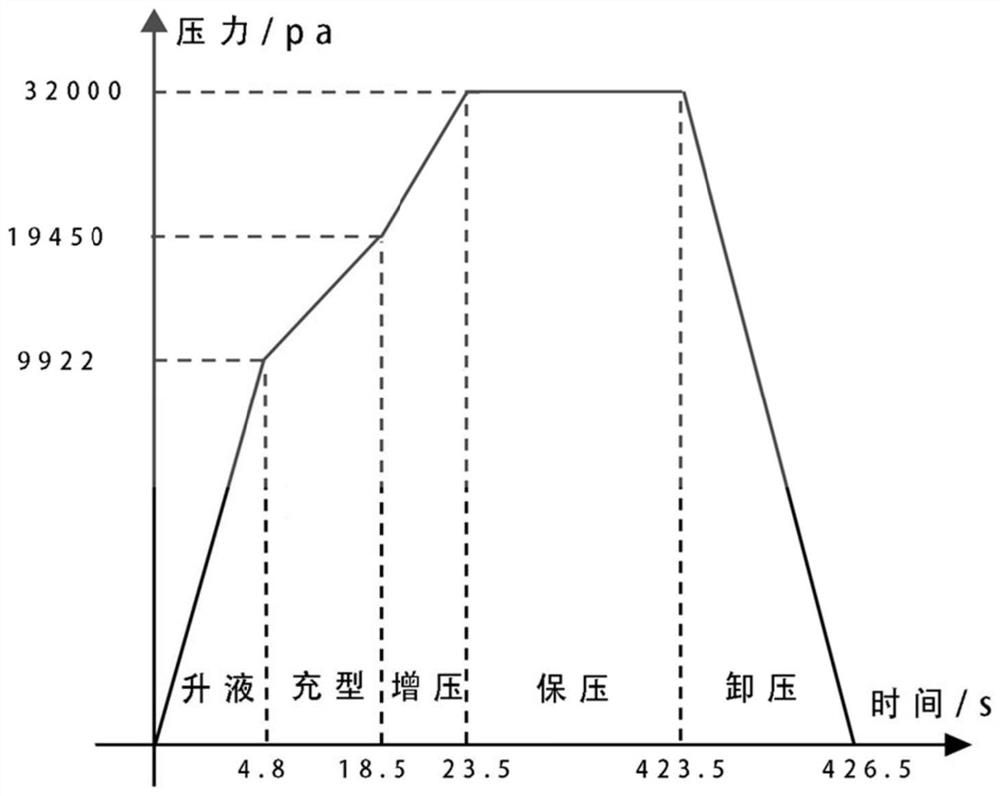

Aluminum alloy engine cylinder block casting process design optimization method based on BP neural network and fish swarm algorithm

PendingCN113642160AOptimize process designImprove molding qualityGeometric CADArtificial lifeCylinder blockSwarm algorithms

The invention discloses an aluminum alloy engine cylinder block casting process design optimization method based on a BP neural network and a fish swarm algorithm. The method is characterized by comprising the following steps: designing a process and establishing a numerical simulation analysis model; improving the process design; determining optimization variables and test design; establishing a BP neural network model; and performing fish swarm algorithm process parameter optimization and production inspection. The invention is high in reliability and applicability, the excellent casting process design and the optimal process parameter scheme of the aluminum alloy engine cylinder block can be effectively obtained, the casting forming quality can be improved, the development cost is saved, the development period is shortened, and reference is provided for development of the casting process of the automobile aluminum alloy engine cylinder block.

Owner:NANJING UNIV OF TECH

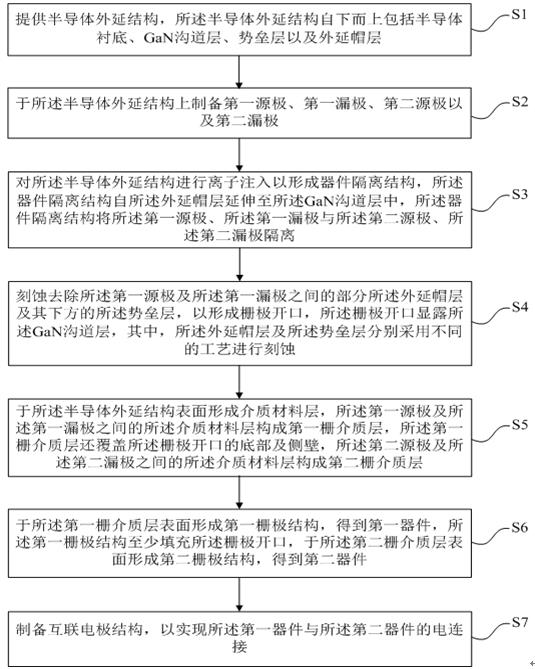

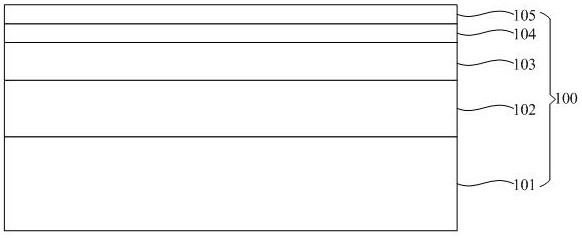

Integrated GaN device and preparation method thereof

ActiveCN111710651AConvenient circuit design and interconnectionReduce parasitic and costTransistorSolid-state devicesEtchingEngineering

The invention provides an integrated GaN device and a preparation method thereof. The preparation method comprises the following steps: preparing source and drain electrodes of different devices on asemiconductor epitaxial structure, preparing a device isolation structure, etching an epitaxial cap layer and a barrier layer, preparing a gate opening for exposing a GaN channel layer, removing the epitaxial cap layer and the barrier layer by adopting different processes, preparing a gate dielectric layer and a gate structure to obtain different devices, and preparing an interconnection electrodestructure to realize device interconnection. According to the invention, a first device and a second device are effectively integrated on the same semiconductor epitaxial substrate, so that various feasible designs are provided for circuit design, and parasitism and cost are reduced; through the process design, except for etching of the gate opening, other steps are carried out at the same time,so that the process difficulty is not increased, and the subsequent packaging cost is saved while the overall performance of the device is improved; and for etching of the epitaxial cap layer and thebarrier layer in the gate opening forming process, the etching precision can be better controlled, and damage to materials caused by traditional etching is avoided.

Owner:浙江集迈科微电子有限公司

Preparation method and application of solution type rear earth catalyst

The invention relates to a preparation method of a solution type rear earth catalyst and application of the solution type rear earth catalyst to diolefin polymerization. The preparation method comprises the following steps of adding alcohol chemical compounds into rear earth compounds; after reaction is completed, adding the reactants into organophosphorus ester; after the reaction happens for a period of time, adding rear earth compounds and performing dilution through organic solvent; after the reaction is completed, sealing the solution type rear earth catalyst for standby. The solution type rear earth catalyst can achieve dual / ternary aging modes to obtain a homogeneous phase rear earth catalysis system, avoid the problem of control difficulty of molecular weight and molecular weight distribution of polymers prepared through heterogeneous rear earth catalysts and bring convenience to technological design of industrial production. Meanwhile, the solution type rear earth catalyst can avoid generating water solution and omit multiple washing and drying of products, is simple in process and low in cost, avoids layered alkali washing and achieves simple post-processing and environmental protection. Correspondingly, the invention also provides the application of preparation of homogeneous phase catalysis systems through the solution type rear earth catalyst to catalysis of diolefin polymerization.

Owner:LIAONING HEYUN SYNTHETIC RUBBER RES INST

Machining method for ring slots in titanium alloy elastic sealing support

ActiveCN108788183ASimple process designSolve processing problemsTurning machinesTitanium alloyMaterials science

The invention discloses a machining method for ring slots in a titanium alloy elastic sealing support. The machining method comprises the following steps that firstly, end surface ring slot machiningof the elastic sealing support is realized by adopting a C-shaped clamping ring; then by utilizing machined end surface ring slots, a workpiece is arranged at an outer circle ring slot machining position for machining outer circle ring slots; and finally, by utilizing the machined end surface ring slots, the workpiece is arranged at an inner circle ring slot machining position for machining innercircle ring slots. Therefore, machining of the end surface ring slots, the outer circle ring slots and the inner circle ring slots in the titanium alloy elastic sealing support are finally realized; the problem that workpieces of the kind cannot be machined because the clamping strength is not large enough on a lathe is overcome, so that convenient machining of the workpieces of the kind on the lathe is realized; and production efficiency is improved.

Owner:BAOJI PETROLEUM MASCH CO LTD

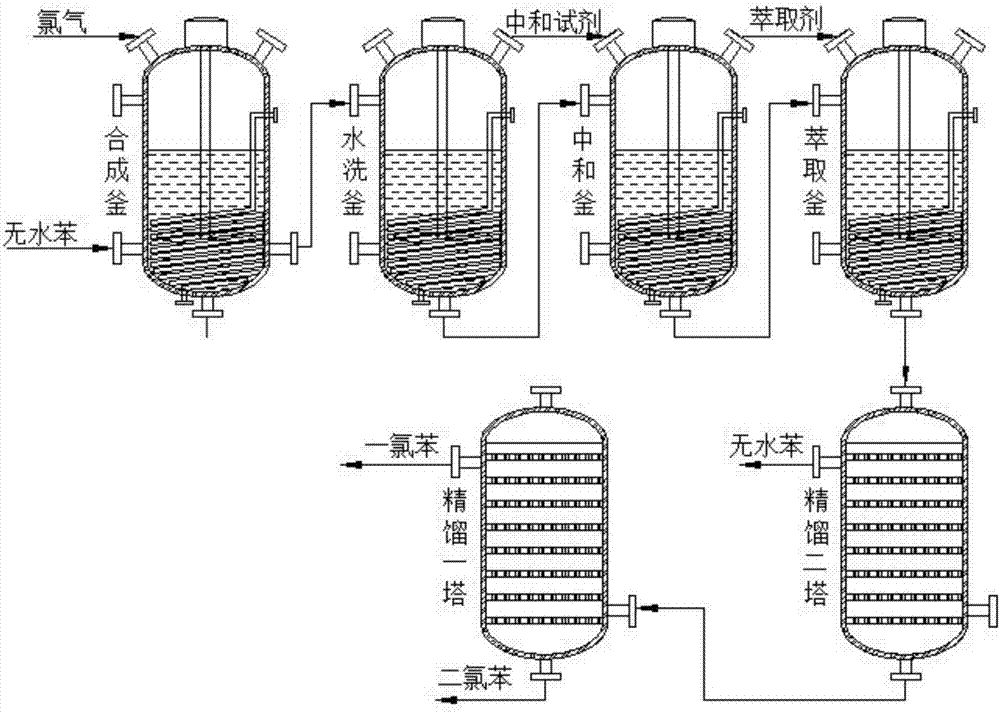

Rectifying separation method for chlorinated benzene production

InactiveCN107445793AHigh conversion selectivityNot easy to cause confusionHalogenated hydrocarbon separation/purificationEnvironmental resistanceSeparation technology

The invention discloses a rectifying separation method for chlorinated benzene production. The rectifying separation method comprises the following specific steps: feeding chlorine and excessive anhydrous benzene into a chlorinator filled with an iron ring catalyst; controlling the reaction temperature at the boiling point of benzene, namely, setting the temperature to 80-90 DEG C; starting a stirrer for constant-speed and constant-temperature stirring to generate chloride liquid; washing an obtained chlorinated benzene solution by a washing tower, neutralizing by a neutralizing kettle, extracting in an extraction kettle, and distilling by a two-stage rectifying tower to obtain a finished product. The rectifying separation method for the chlorinated benzene production disclosed by the invention is a universal method of the rectifying separation technology for the chlorinated benzene production at home, and has the following main advantages: high-temperature continuous chlorination is realized; the conversion selectivity of chlorinated benzene is high, the slender chlorination reactor does not tend to cause material mixing return, and a small amount of benzene dichloride is generated; a distillation process is adopted for separation, the technology is mature and reliable, useful matters are recycled, the synthesis cost is saved, the economic benefits are increased, and the method conforms to the scientific concept of greenness, environmental protection and zero pollution.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

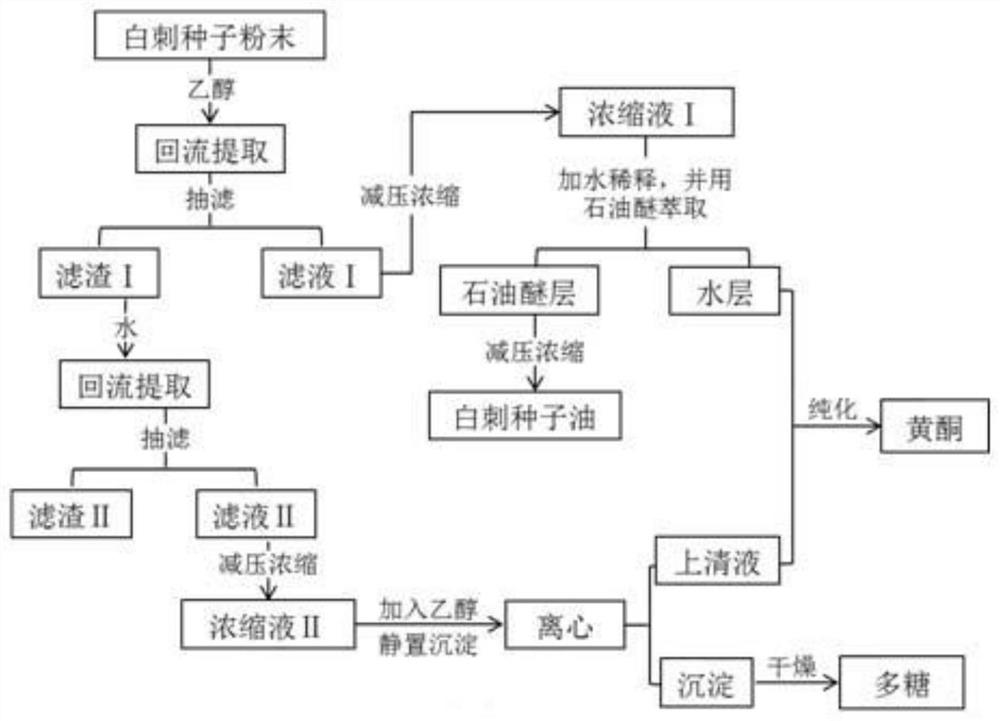

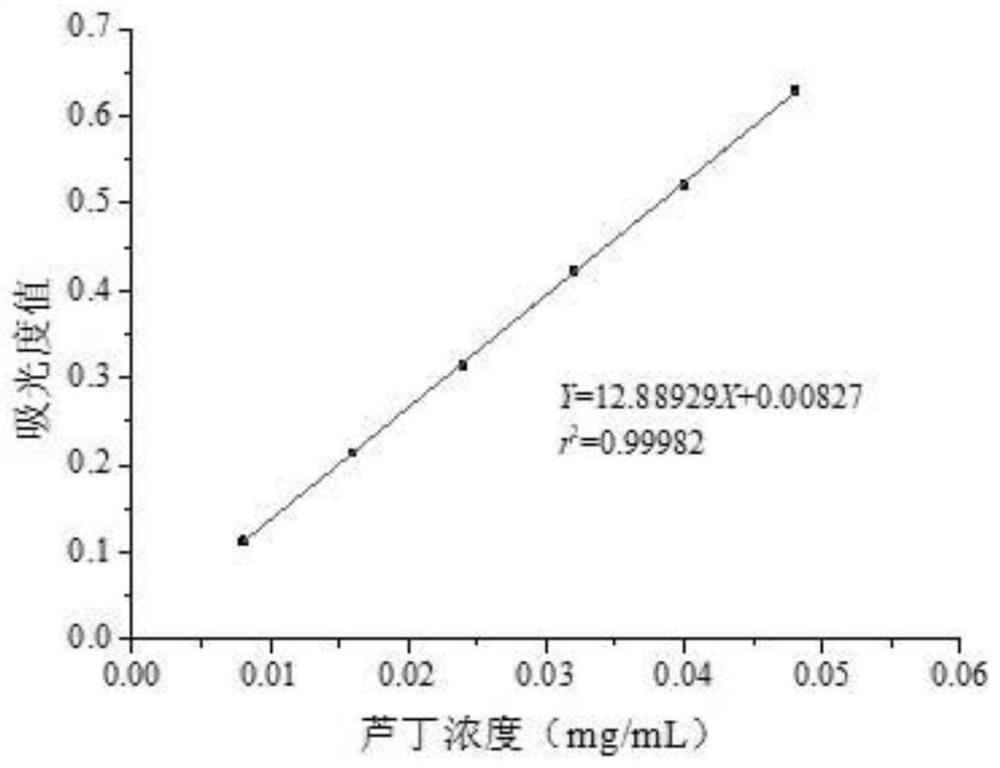

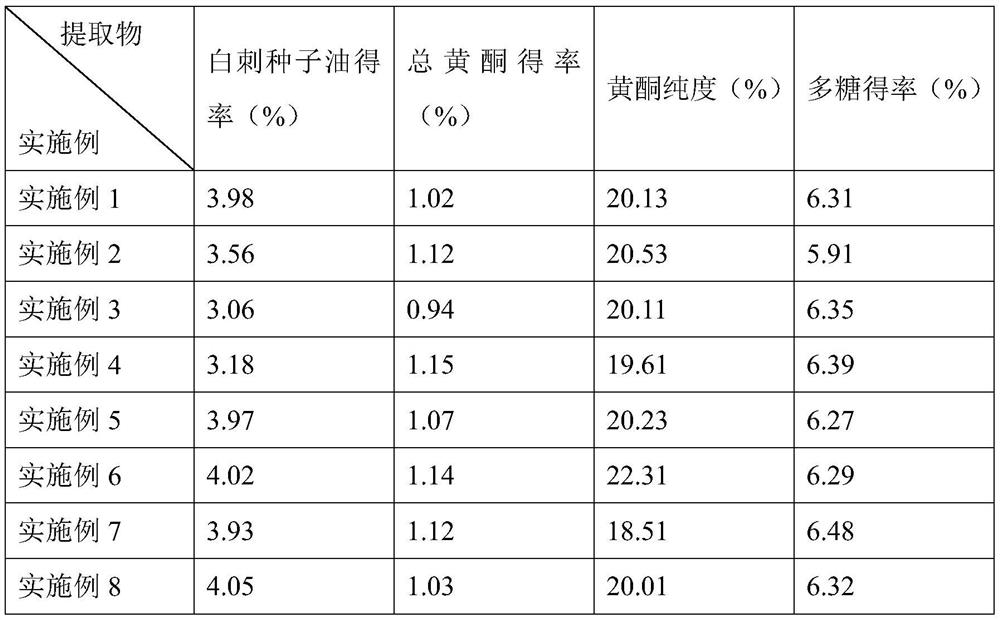

Method for continuously extracting grease, flavone and polysaccharide from nitraria tangutorum seeds

InactiveCN111759871AIngenious process designEfficient process designPlant ingredientsBiotechnologyEngineering

The invention discloses a method for continuously extracting grease, flavone and polysaccharide from nitraria tangutorum seeds. The method comprises the following steps: S1, separating filter residuesand filtrate; S2, extracting the grease; S3, extracting the flavone; and S4, extracting the polysaccharide. The method can be used for continuously extracting the grease, the flavone and polysaccharide compounds from the nitraria tangutorum seeds, the extraction process is simple and feasible, the equipment investment is low, and only one set of extraction equipment is needed. Moreover, materialsdo not need to be taken out of an extraction tank when different components are extracted, time and manpower are saved, and loss of the materials in a transfer process is avoided. According to the preferred scheme, the yield of three active components, namely the grease, the flavone and the polysaccharide, reaches a high value, and the utilization rate of the nitraria tangutorum seeds is improved.

Owner:南京益唯森生物科技有限公司

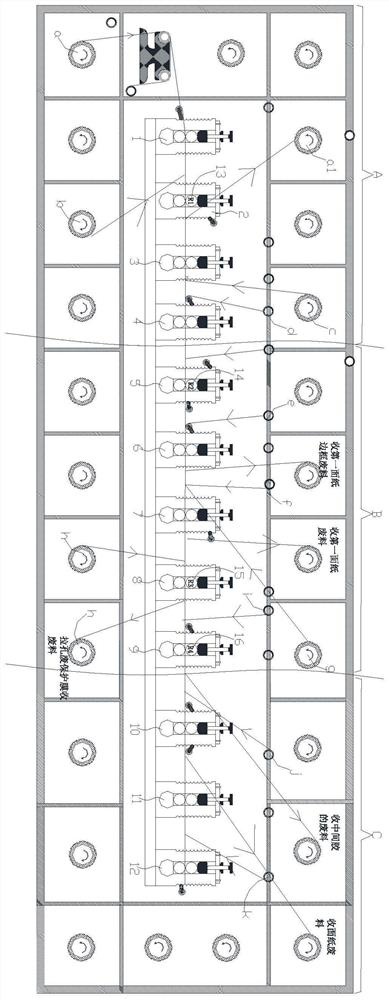

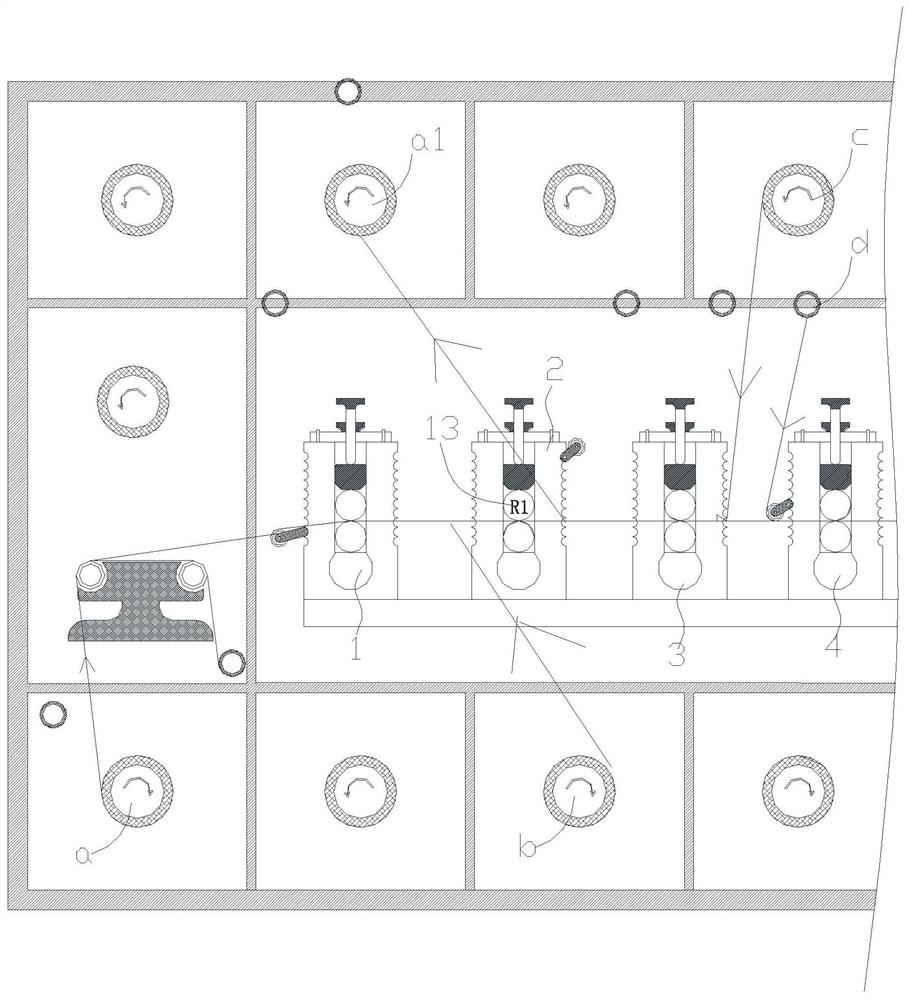

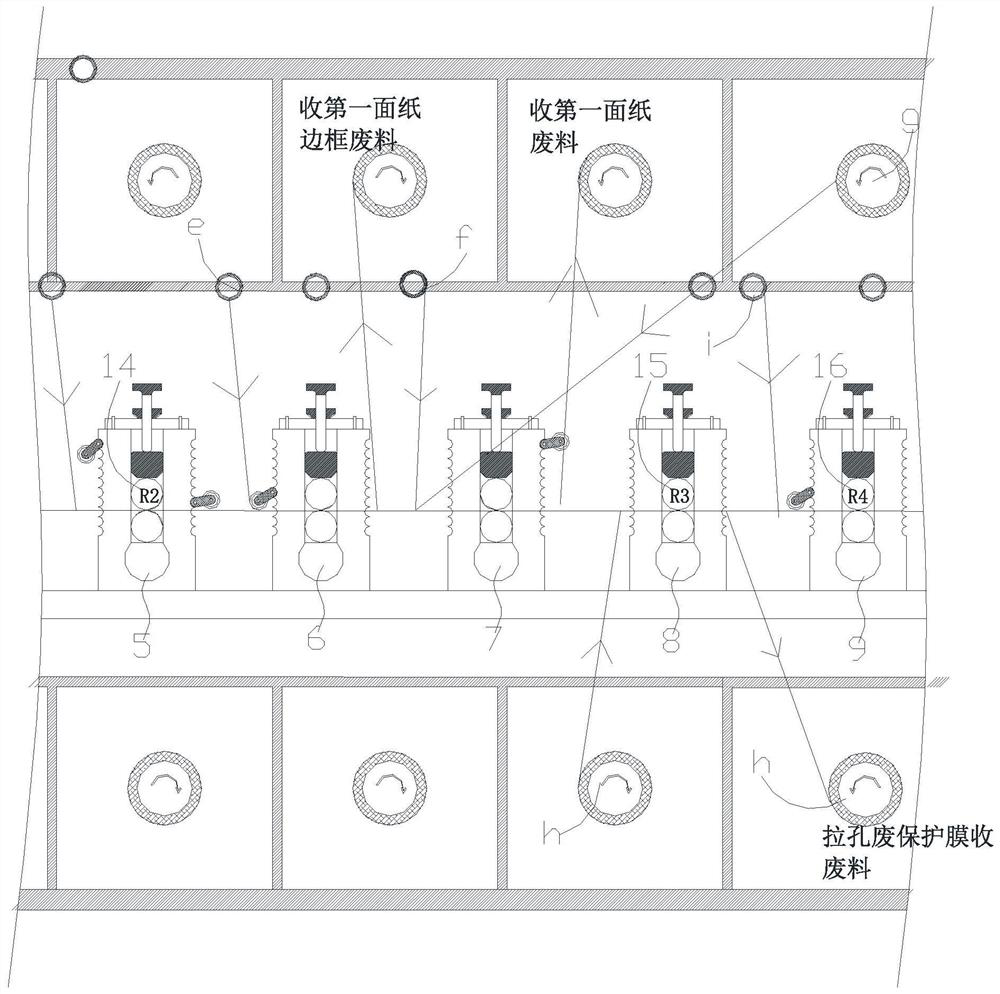

Keyboard rubber die cutting production method and production system

ActiveCN112388730AReduce usageOptimize process designMetal working apparatusProcess engineeringIndustrial engineering

The invention discloses a keyboard rubber die cutting production method and a production system. The keyboard rubber die cutting production method comprises the steps of feeding, S1-S10, and discharging. The production system applies the keyboard rubber die cutting production method and comprises a first die cutting device, a second material passing device, a third die cutting device, a fourth diecutting device, a fifth die cutting device, a sixth die cutting device, a seventh die cutting device, an eighth die cutting device, a ninth die cutting device, a tenth die cutting device, an eleventhdie cutting device and a twelfth die cutting device which are arranged in sequence. The production system is matched with the keyboard rubber die cutting production method, the process design can beoptimized, workstations used by a circular knife are reduced, and the production efficiency is improved.

Owner:LINGSHENGCHENG TECH JIANGSU CO LTD

A 34-inch thick double-sided polar fleece full-penetration printing production process

ActiveCN104553419BExcellent warmthSoft touchWeft knittingHeating/cooling textile fabricsScreen printingEvaporation

The invention relates to a full penetration printing production process of 34-inch thick double-sided polar fleece. The process is characterized in that an entire set of optimal technical scheme of system engineering design is established through technical means such as weaving, dyeing and finishing and microscopic computer image analysis. The process comprises the following steps: weaving a blank; performing dyeing and finishing pretreatment on fabric; tentering and shaping the fabric before printing; performing microscopic computer image analysis; performing rotary screen printing, evaporation, washing and emulsification on the fabric; tentering and shaping the fabric after printing; galling, combing, shearing and fleecing; shaping billet. The process has the beneficial effects that 1, the difference value of printing and dyeing color yield percentage of front and back faces of the fabric is reduced, and the front and back faces of the finished product are attractive in color, and 2, the finished fabric is full, fluffy and soft in raising, the problem of hard handfeel of the thick double-sided fleece fabric is solved, and a high added value of the product is further improved. The fleece is most suitable for making middle and top grade thermal vests, jacks, underwear, (woolen) shirts, overcoats, bedding articles, carpets, gloves, scarves, hats, back cushions and the like.

Owner:QINGDAO JIFA GROUP

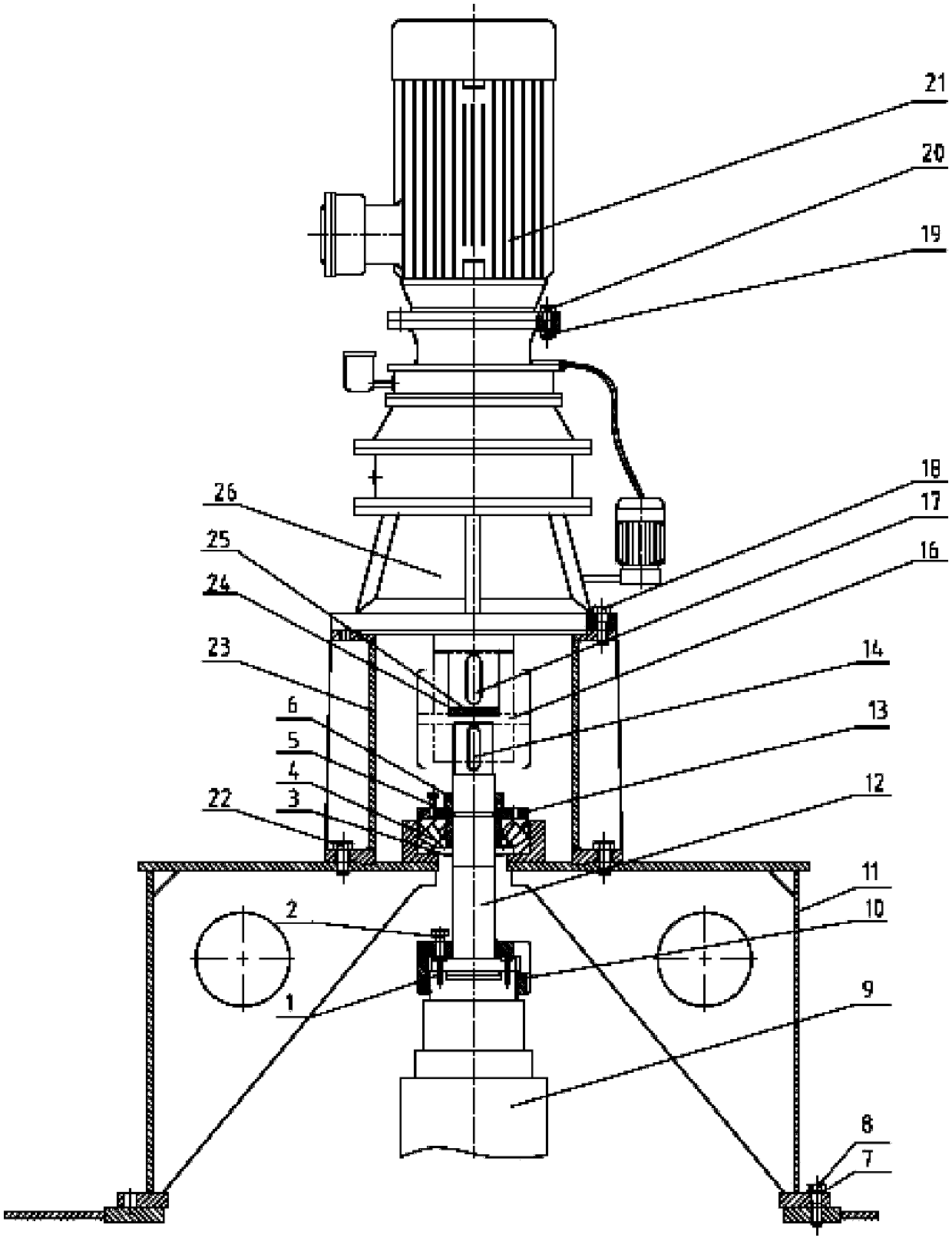

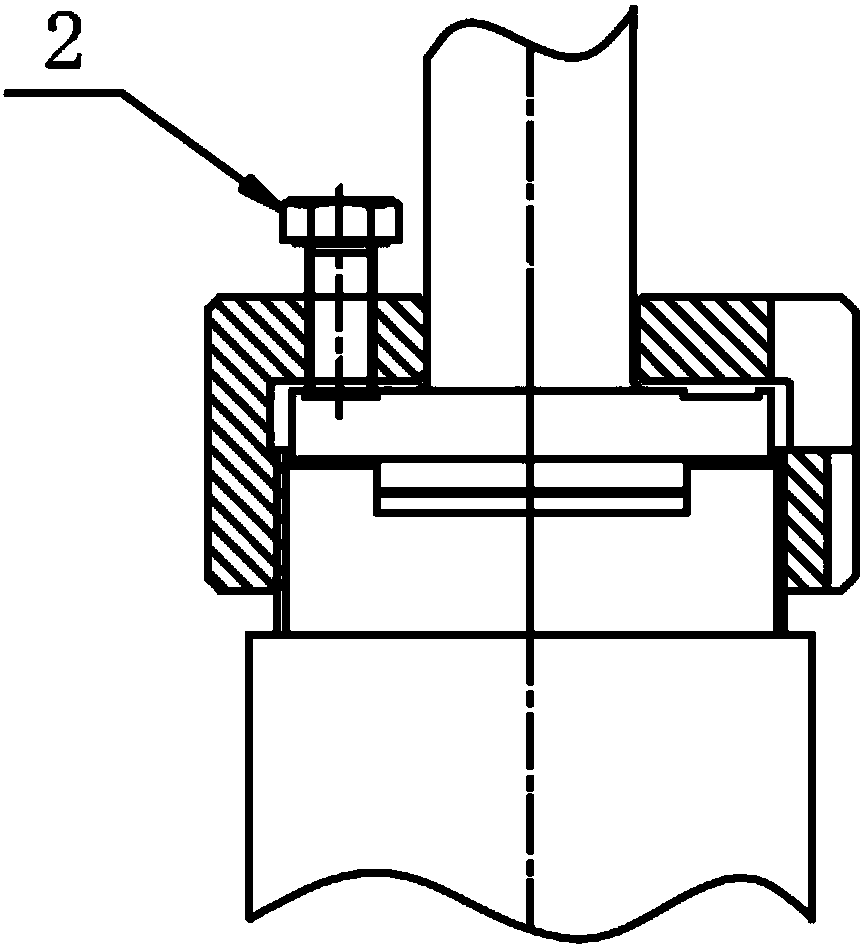

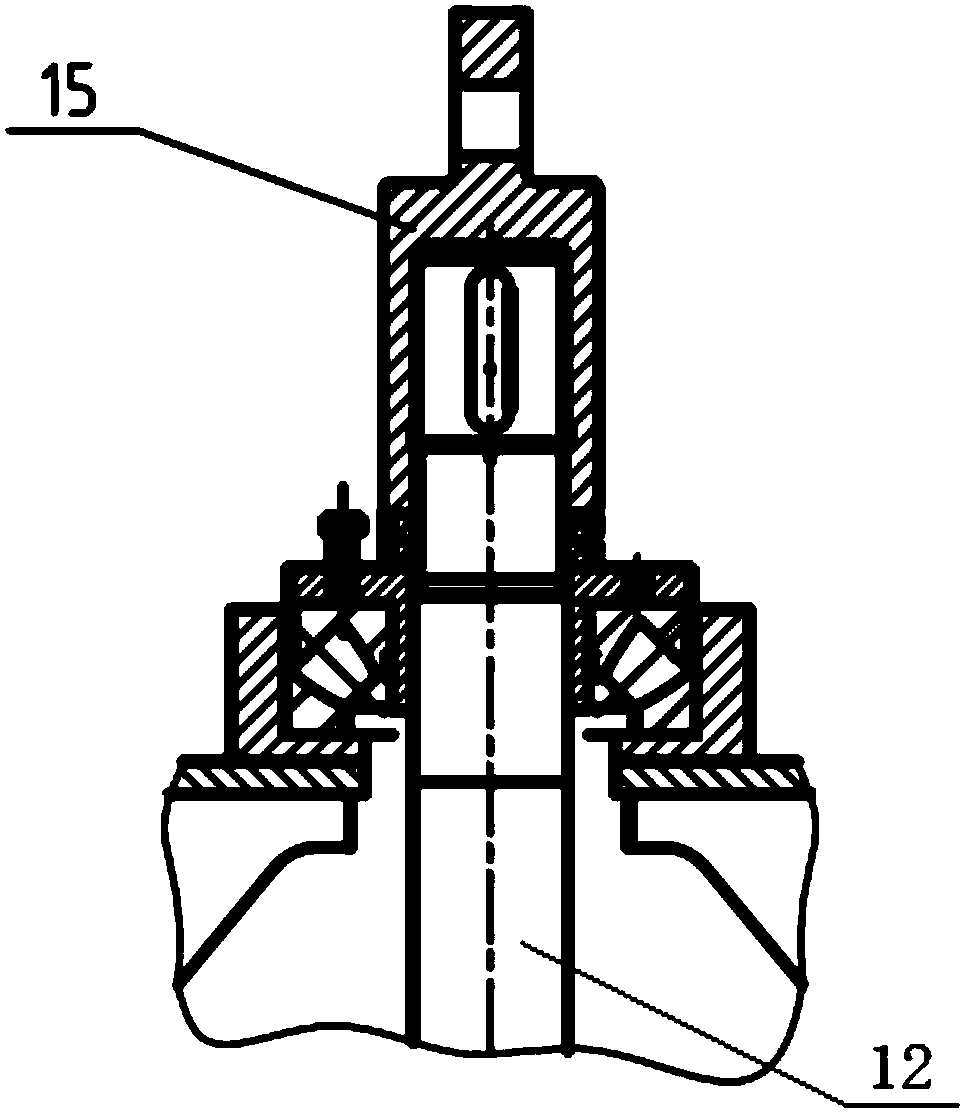

Reactor-circuit main pump motor electric engine driving apparatus

ActiveCN107707085AEasy to useOptimize process designNuclear energy generationManufacturing dynamo-electric machinesReduction driveElectric machinery

The invention belongs to the technical field of mounting and overhauling of a main pump unit of a nuclear power plant, specifically relates to a reactor-circuit main pump motor electric engine drivingapparatus, and aims to research and develop a set of electric engine driving tool suitable for a three-bearing main pump unit, wherein the tool is required to be capable of eliminating the potentialsafety hazard and shortcomings of the original manual engine driving tool; and meanwhile, the new engine driving tool is capable of satisfying extremely high requirement on throw and centering of thethree-bearing main pump unit quickly, and is safe and reliable, simple and practical, and capable of improving the overhaul quality of the main pump and shortening the overhauling time. The reactor-circuit main pump motor electric engine driving apparatus is characterized by comprising an ejection bolt, an oil baffle ring, a bearing, a thrust nut, a connecting nut, a bracket, a tool shaft, a bearing housing, a motor, a speed reducer bracket, a baffle and a speed reducer. By virtue of improvement of the process design of the whole set of the tool, a process with multiple times of repeated assembling and disassembling and repeated adjustment caused by the original manual tool can be avoided.

Owner:CNNC NUCLEAR POWER OPERATION MANAGEMENT +1

A beam casting method and casting mold with a thin-walled cylinder

ActiveCN104741542BGuarantee internal qualityEasy to follow upFoundry mouldsFoundry coresCasting moldThin walled cylinder

The invention discloses a casting method of a girder having a thin-walled cylinder and a casting mold. A casting box consisting of fix boxes of a bottom box, a lower box, a middle box, an upper box and a cover box is adopted to cast; a core mold is transversely placed in the casting box; an inner runner, a vertical runner and a gap runner are arranged in the lower box; a pouring port is formed in the bottom box; meanwhile, transverse runners and longitudinal runners are arranged on the bottom box; pouring ports are respectively arranged in the intersections of all the transverse runners and the longitudinal runners; and molten metal is injected from the pouring port of the bottom box through a pressurization mode in casting, so that the molten metal flows into the casting cavity of the lower box through the inner runner under the pressure effect, flows to two sides through the transverse runner to enter the gap runner along with the vertical runner, and finally overflows from a riser of the upper box, so that the molten metal in the riser feeds a complex casting cavity in the top of the girder. The casting method can guarantee the internal quality of castings, is simple in molding method, is easy in subsequent treatment of the castings, can form the batch production, and is higher in pass percent.

Owner:贵州航天风华精密设备有限公司

A Self-Driven Precision Guide Rail Type Frame Accurate Positioning and Pushing Device

ActiveCN103043428BReasonable process designOptimize process designConveyor partsEconomic benefitsSelf driven

The invention discloses a self-driven precision guide rail type fixture accurate positioning pushing device and relates to the technical field of aircraft manufacturing. According to the device, two sides of a connection plate (6) are provided with a rolling linear guide rail pair (2) and a pneumatic clamping element (5) through a first bolt (8) and a third bolt (10), a rodless cylinder (4) is installed in the middle of the connection plate (6) through a second bolt (9), a sliding block (11) is arranged between the rodless cylinder (4) and the connection plate (6), a foot stand installing part (1) and a supporting element (3) are connected to the rodless cylinder (4) through a fourth bolt (13), and a retaining block (7) is installed at two ends of the rolling linear guide rail pair (2) through bolts. According to the self-driven precision guide rail type fixture accurate positioning pushing device, manufacturing processes of traditional fixtures and assembling processes of aircraft products are changed, process designs are reasonable and optimal, during fixture manufacturing and product assembling, operation space is large, automation degrees are high, work efficiency is high, and great economic benefits are produced in the field of aircraft manufacturing.

Owner:JIANGXI HONGDU AVIATION IND GRP

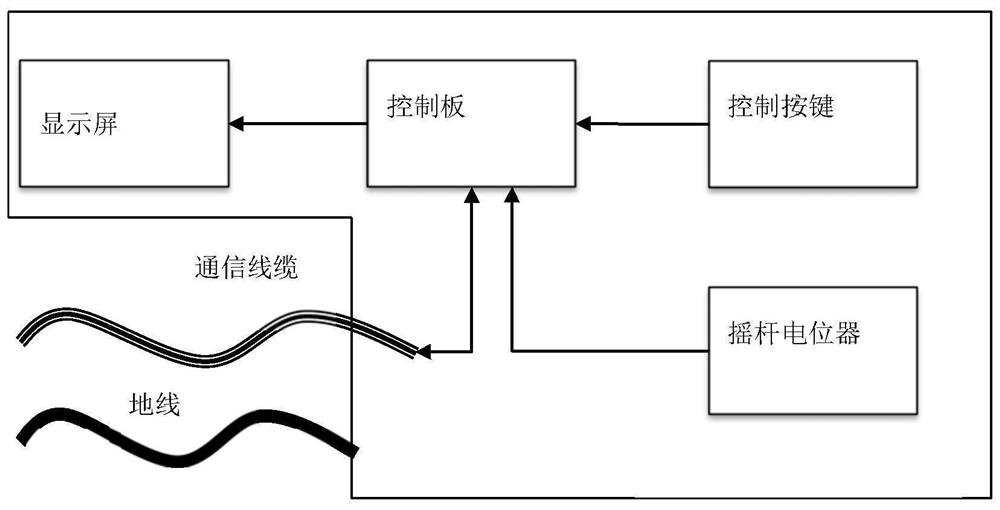

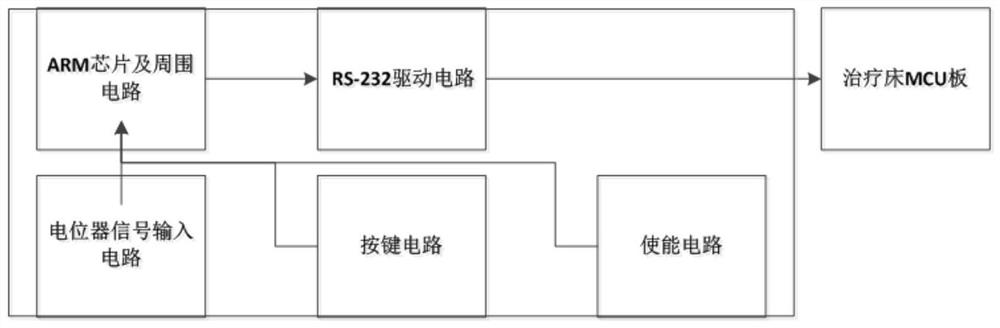

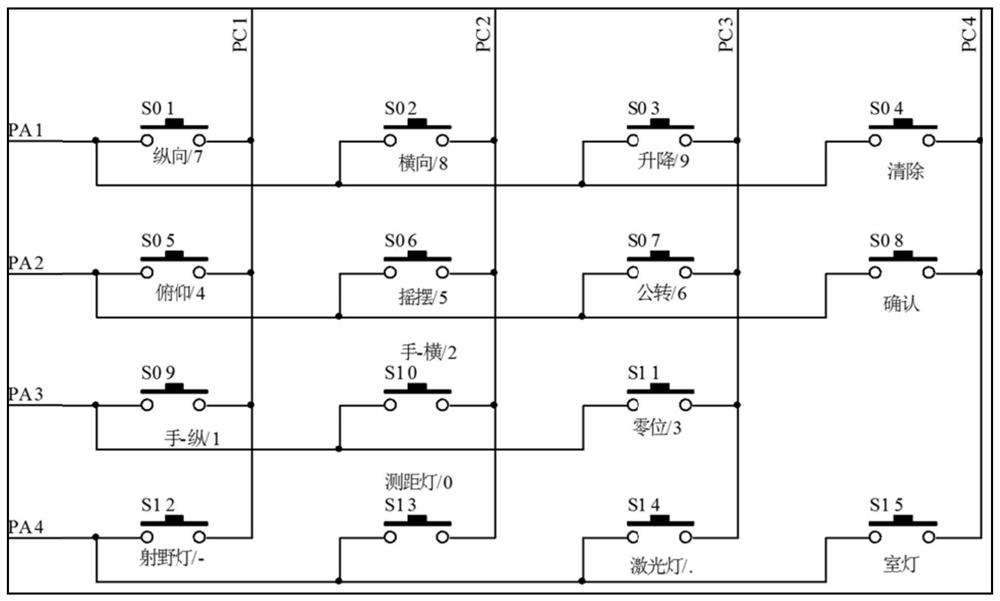

Medical accelerator bed controller

PendingCN112295119AOptimize process designImprove securityProgramme controlComputer controlTherapeutic bedEngineering

The invention relates to a radiotherapy equipment controller, and specifically relates to a medical accelerator bed controller. The controller includes an operating panel, a control panel, control buttons, a rocker potentiometer, a display screen and a ground wire; the display screen, the control buttons and the rocker potentiometer are embedded into the operating panel; the rocker potentiometer,the control buttons and the display screen are connected to the control panel; and the control panel is in communication with a treatment table through a communication module. In the invention, a medical accelerator host computer can judge and completely control all instructions sent by the controller, so that the safety of the whole medical accelerator can be enhanced.

Owner:SHINVA MEDICAL INSTR CO LTD

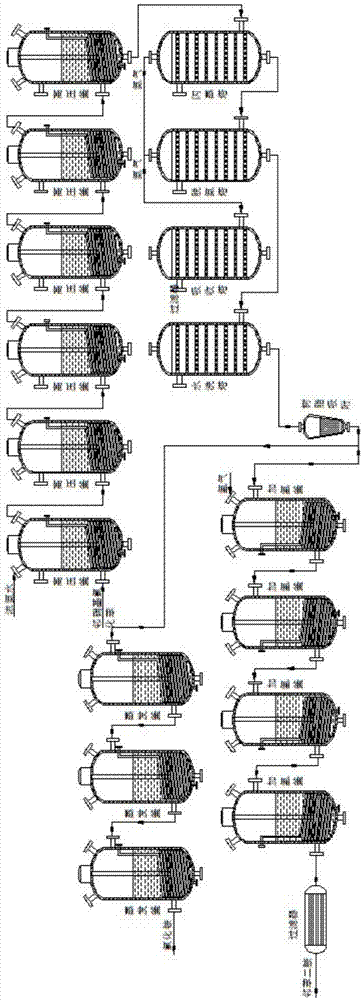

A method of preparing an o-phenylenediamine intermediate used for carbendazim production

InactiveCN107488117ALower synthesis costIncrease incomeOrganic compound preparationChemical recyclingPalladium on carbonMolten state

A method of preparing an o-phenylenediamine intermediate used for carbendazim production is disclosed. The method includes reacting nitrochlorobenzene and concentrated aqueous ammonia in six tandem autoclaves to obtain 2-nitroaniline; washing ammoniated 2-nitroaniline with water to remove ammonium chloride; performing a hydrogenation reaction by utilizing a 2-nitroaniline dry basis in a molten state, adopting a palladium-on-charcoal catalyst and an organic salt as auxiliary agents, and adopting four tandem hydrogenation kettles; after hydrogenation is finished, conveying a liquid to a next process to obtain the o-phenylenediamine intermediate. After a preliminary reaction step is finished, useful compounds can be recovered effectively, and the o-phenylenediamine content after hydrogenation is 98% or above, thus saving a synthesis cost and increasing economic benefit. The preparing method and process design of the o-phenylenediamine intermediate used for carbendazim production are optimized, and requirements on the preparing method and the process design of the o-phenylenediamine intermediate used for carbendazim production are satisfied.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

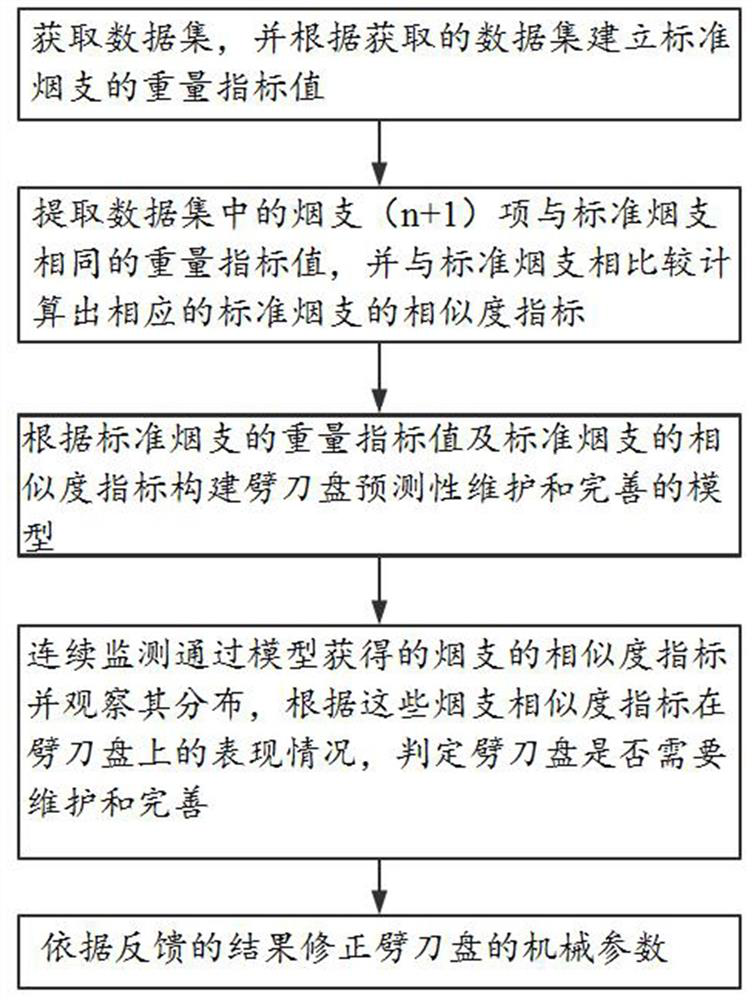

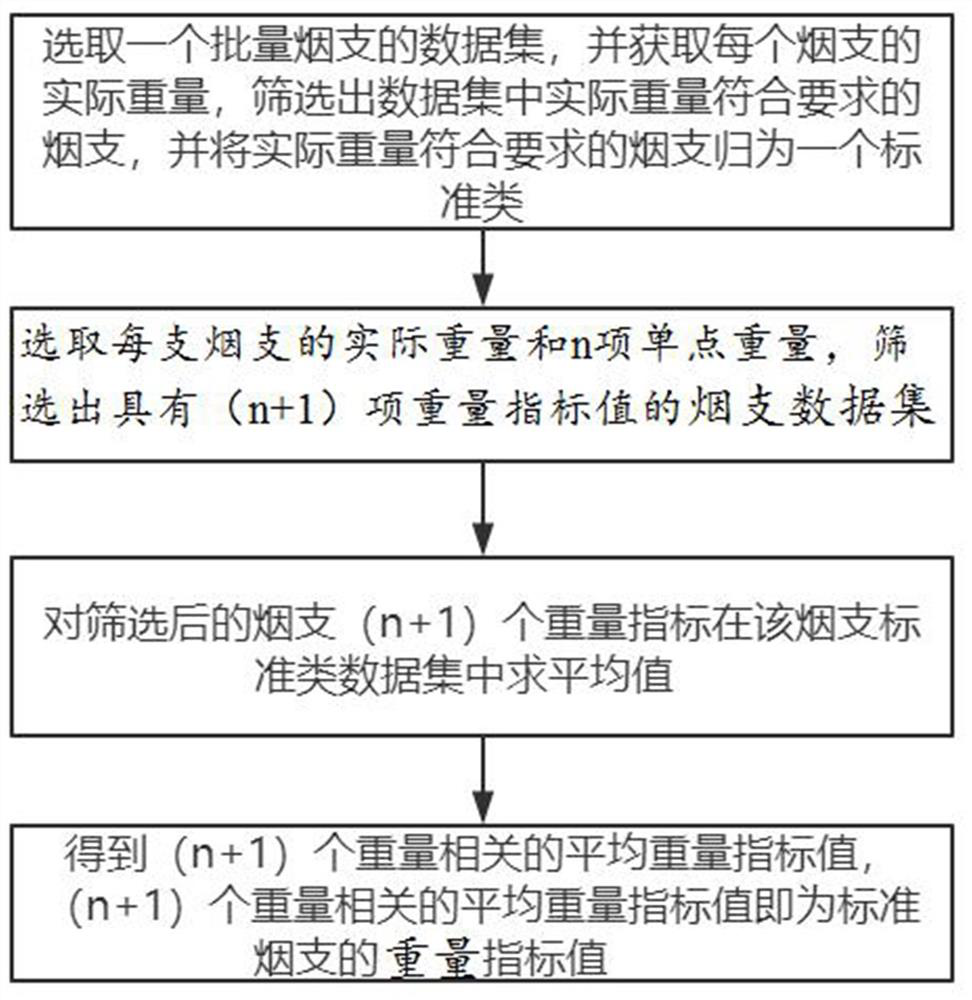

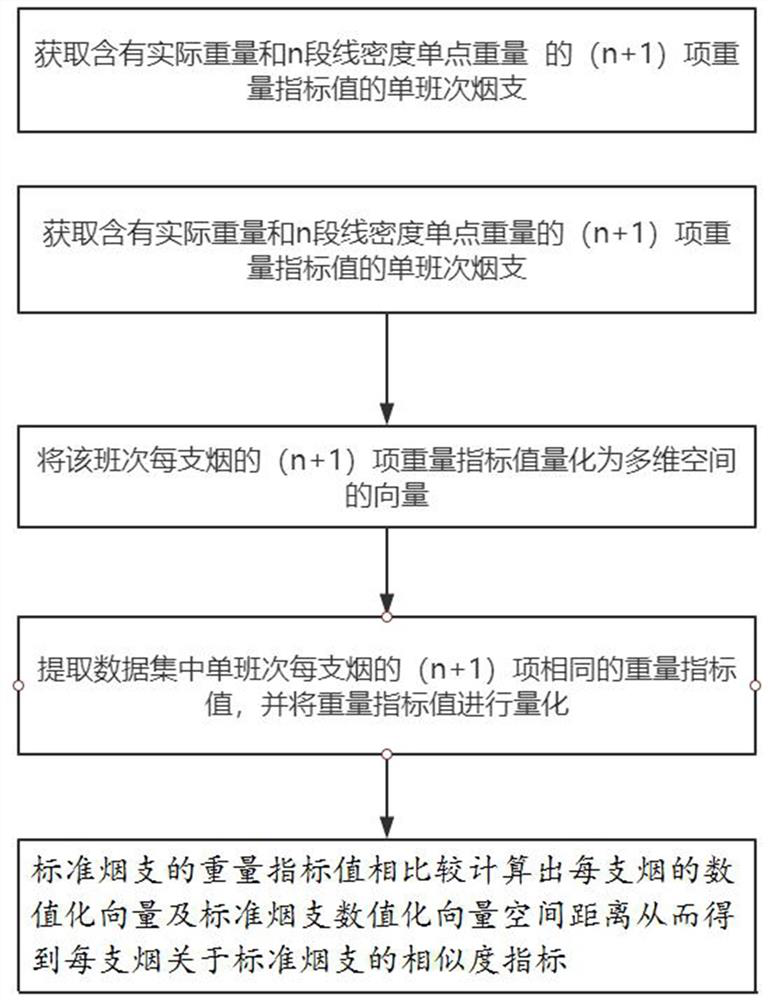

An Algorithm for Predictive Maintenance and Perfection of Riving Cutter Wheels

The invention belongs to the technical field of cigarette production, and relates to an algorithm for implementing predictive maintenance and improvement of a chopper disc, comprising the following steps: S1: acquiring a data set, and establishing a weight index value of a standard cigarette according to the acquired data set; S2: Comparing with standard cigarettes, calculate the similarity index of corresponding standard cigarettes; S3: Construct a predictive maintenance and improvement model of chopper disc according to the weight index value of standard cigarettes and the similarity index of standard cigarettes; S4: Continuously monitor the similarity indicators of cigarettes obtained through the model and observe their distribution, and determine whether the chopper needs to be maintained and improved according to the performance of the similarity indicators of these cigarettes on the chopper disc; S5: Based on the feedback As a result, the mechanical parameters of the riving cutter disc are corrected. Its advantage is that it can give an early warning of abnormal values on the cigarette data and the state of the rivet disc, and analyze the quality of cigarettes produced at different positions of the rivet disc, thereby completing the predictive maintenance of the rivet disc.

Owner:深圳市鸿捷源自动化系统有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com