Self-driven precision guide rail type fixture accurate positioning pushing device

A precision guide rail and precise positioning technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of limited use range, high labor intensity, low work efficiency, etc., and achieve high work efficiency, high degree of automation, and great economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

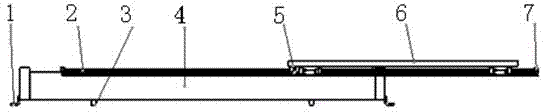

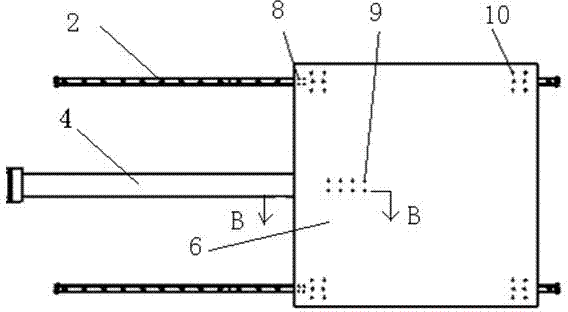

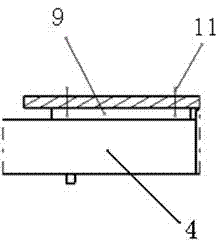

[0013] refer to Figure 1-5 , this specific embodiment adopts the following technical solutions: a self-driven precision guide rail type frame precise positioning and pushing device, including a tripod mounting part 1, a rolling linear guide rail pair 2, a supporting element 3, a rodless cylinder 4, a pneumatic clamping Component 5, connecting plate 6, block 7 and slider 11, the two sides of connecting plate 6 are installed with rolling linear guide pair 2 and pneumatic clamping element 5 through the first screw 8 and the third screw 10, and the middle part of connecting plate 6 is passed through the second Two screws 9 are equipped with a rodless cylinder 4, a slide block 11 is arranged between the rodless cylinder 4 and the connecting plate 6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com