Aluminum alloy engine cylinder block casting process design optimization method based on BP neural network and fish swarm algorithm

A BP neural network and engine block technology, applied in the field of low-pressure casting, can solve the problems of shortening the trial production time of new products, difficulty in guaranteeing the molding quality, and low design efficiency, so as to improve the molding quality, reduce the cost of trial production, and reduce the design time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the features and advantages of this patent more obvious and understandable, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0050] Such as Figure 1-10 shown.

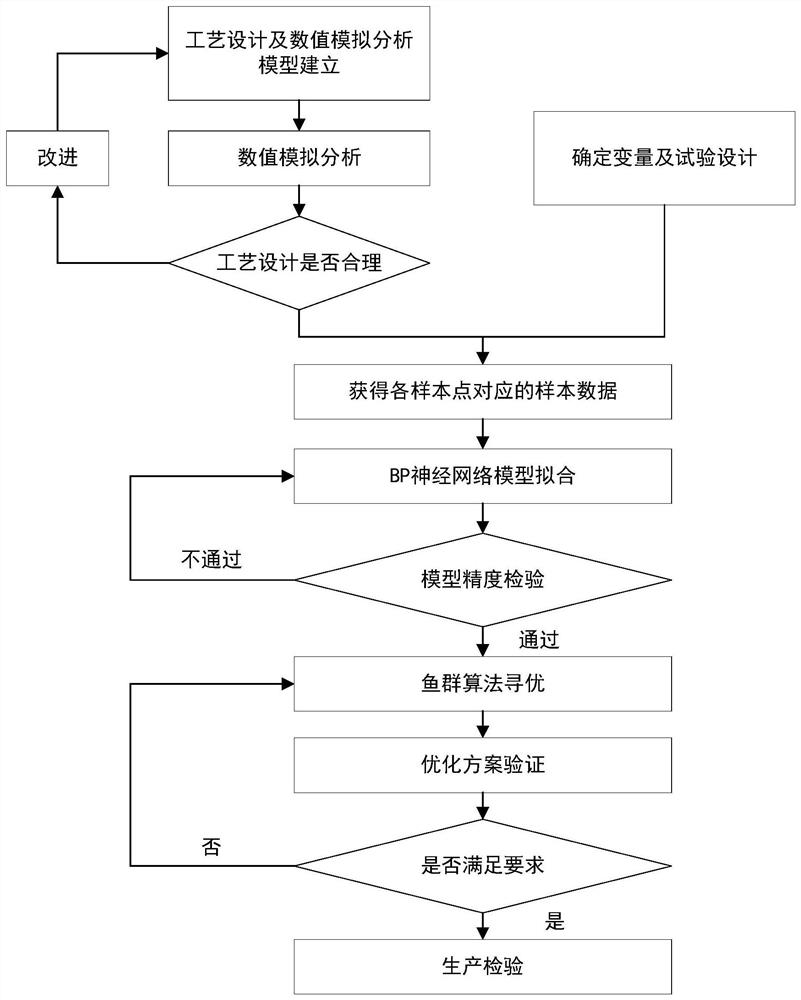

[0051] An optimization method for aluminum alloy engine block casting process design based on BP neural network and fish swarm algorithm, the process flow is as follows figure 1 As shown, it specifically includes the following steps:

[0052] Step 1: process design and establishment of numerical simulation analysis model;

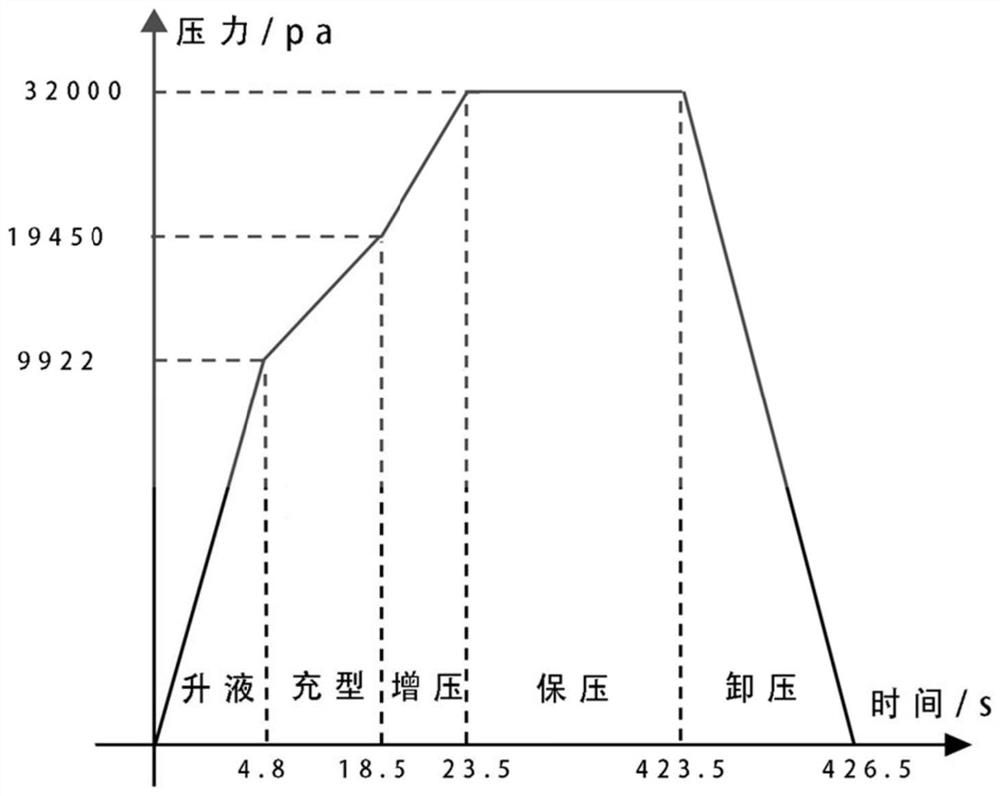

[0053] Design the mold according to the structure of the engine block, including the design of the mold structure, pouring system, cooling system, exhaust system and sand core system. Above the groove, the upper mold is designed as a split type, with a vertical parting surface, located at the middle surface of the casting; the gating system adopts a bottom pouring runner with a straight gate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com