Dual flue gas purification technology and purification system thereof

A flue gas purification process, flue gas purification technology, applied in the direction of chemical instruments and methods, dispersed particle filtration, combined devices, etc., can solve the problems of air secondary pollution, pollution, and affecting people's health, and achieve the prevention of secondary pollution , The system structure is simple, and the effect of enhancing the environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

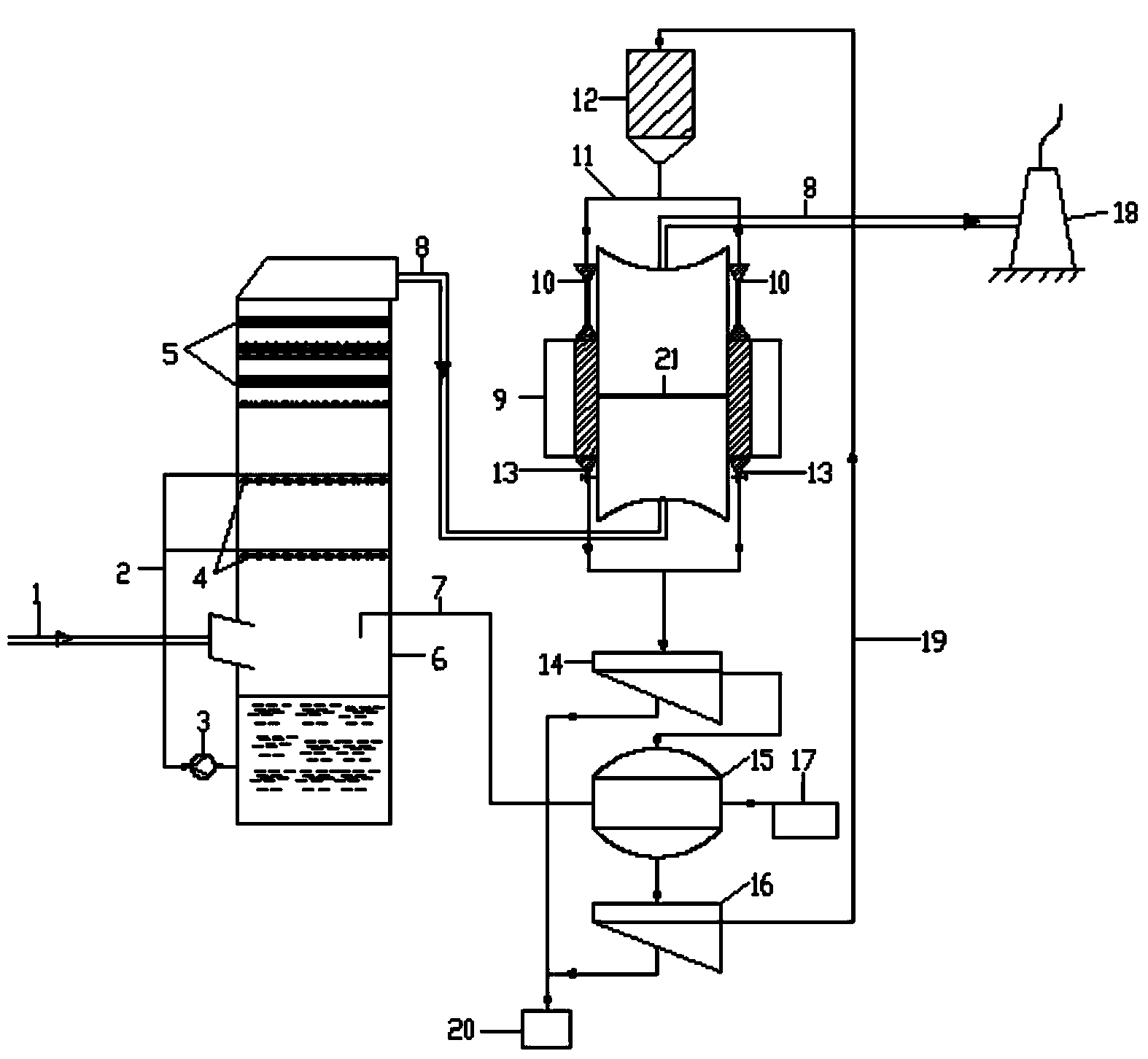

[0024] Such as figure 1 As shown, a double flue gas purification process of the present invention includes one-stage wet purification. In the one-stage wet purification, the original flue gas enters the absorption tower 6 through the original flue 1 for wet purification treatment. The final clean flue gas enters the clean flue 8; it also includes secondary adsorption purification, in which the clean flue gas obtained in the primary wet purification is purified.

[0025] The above double flue gas purification process can be carried out by the following double flue gas purification system, such as figure 1 As shown, in the double flue gas purification system, it includes a primary wet purification device, which includes the original flue 1, the absorption tower 6 and the clean flue 8 connected to each other in sequence; it also includes the A secondary adsorption purification device connected to the primary wet purification device, the secondary adsorption purification device i...

Embodiment 2

[0029] Such as figure 1 As shown, a double flue gas purification process of the present invention, its basic implementation steps are the same as in Example 1, specifically, in the secondary adsorption purification, the clean flue gas is carried out by the purifier 9 set in the clean flue Adsorption and purification: The purifier 9 is filled with an adsorbent, and the adsorbent is in contact with the clean flue gas to adsorb and purify the clean flue gas; the saturated adsorbent after absorbing the clean flue gas is regenerated and recovered by the adsorbent regeneration device. As a result, while the flue gas is purified through double purification, higher environmental protection requirements are met, and resources are recycled to avoid waste; among them, other clean flue gas can also be set for the purifier 9 on the way before discharge into the atmosphere.

[0030] In the above embodiments, the adsorbent is preferably activated coke; preferably, the pores of the activated...

Embodiment 3

[0033] Such as figure 1 As shown, a double flue gas purification process of the present invention, its basic implementation steps are the same as in Example 2. Specifically, in order to better realize the recycling of adsorbents and to avoid other pollution and waste caused by adsorbents, In the regeneration and recovery of the adsorbent, the saturated adsorbent is sequentially subjected to primary screening, thermal desorption and secondary screening for regeneration and recovery treatment, and the regenerated adsorbent is transported to the purifier for reuse, pyrolysis The desorption liquid generated by the absorption is transported to the absorption tower to react with the absorption slurry in the tower for reprocessing, and the sieved solid waste is collected by the waste collector 20 or other treatment.

[0034] The above double flue gas purification process can be carried out by the following double flue gas purification system, such as figure 1 As shown, the basic str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com