Machining method for ring slots in titanium alloy elastic sealing support

A technology for sealing brackets and titanium alloys, which is applied in metal processing equipment, manufacturing tools, turning equipment, etc., can solve the problems of lack of standardized guidance methods, inability to realize standardized process design, etc., and achieve the effect of convenient process design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

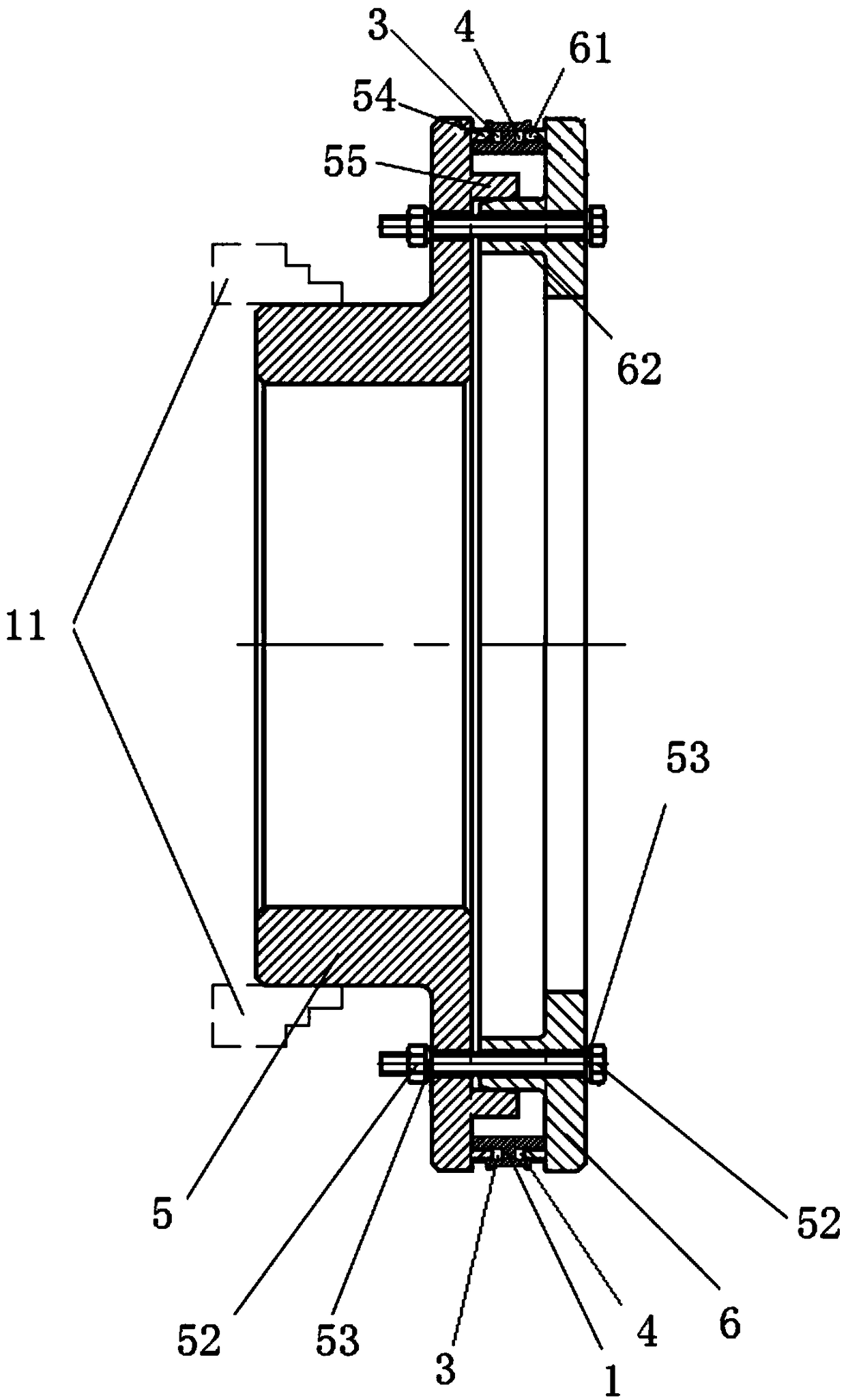

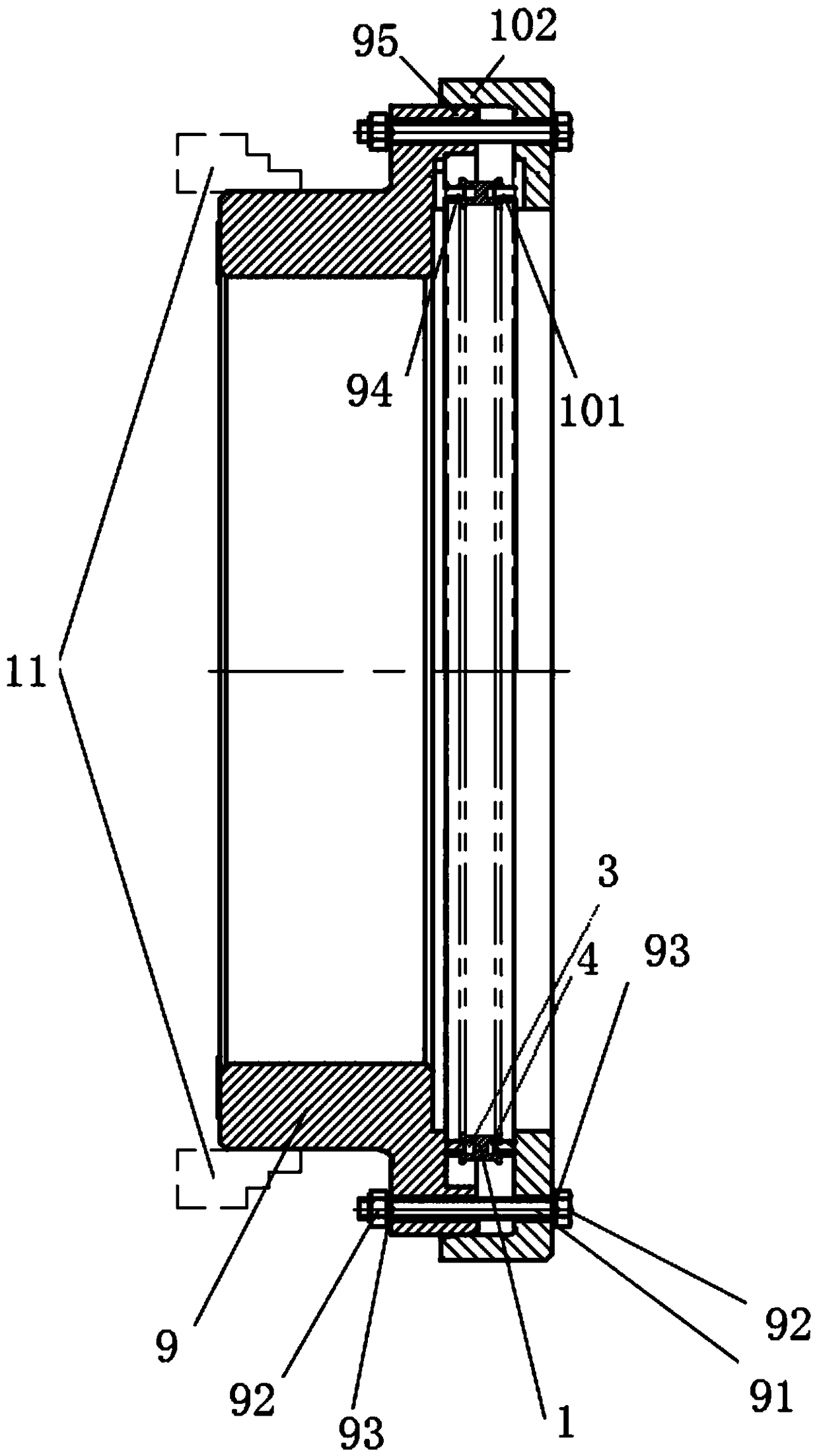

[0057] A kind of processing method of the ring groove on the titanium alloy elastic sealing bracket of the present invention, concrete steps are as follows:

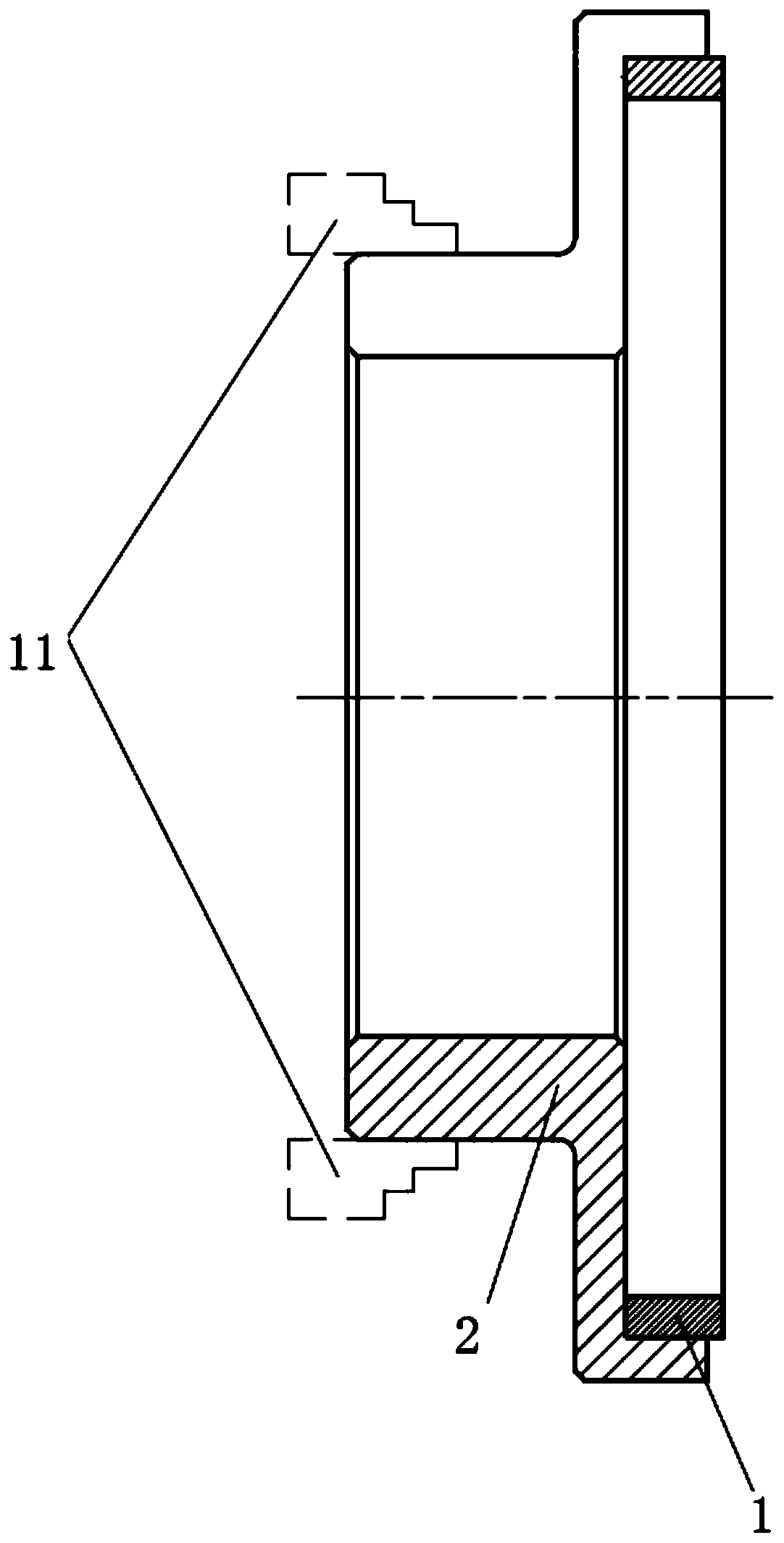

[0058] Step 1. Put the workpiece 1 into the C-shaped snap ring 2, use the lathe jaws 11 to tighten the workpiece 1, and use the end face groove cutter for processing titanium alloy to process the ring grooves on the two ends of the workpiece 1 to obtain the end face ring groove a3 and the ring groove b4 on the end surface, the workpiece 1 is a thin-walled annular structure, and the ratio of the inner circle diameter to the wall thickness is 30:1; the schematic diagram of the clamping state of the C-shaped snap ring 2 and the blank workpiece 1 is as follows figure 1 shown.

[0059] Step 1.1. Put the ring-shaped workpiece 1 into the C-shaped snap ring 2, lightly clamp the C-shaped snap ring 2 with the claws 11 of the lathe, and lightly tap the end face of the workpiece 1, so that the end face of the workpiece 1 is aligned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com