A method for forming a large-diameter thin-walled stainless steel cylinder

A technology of stainless steel cylinder and forming method, which is applied in the field of pressure vessel manufacturing, can solve problems such as difficulty in lifting, and achieve the effects of avoiding deformation, ensuring quality, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

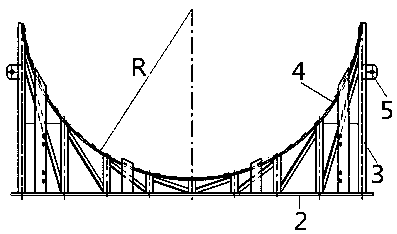

[0030] The present invention will be further described below in conjunction with drawings and embodiments.

[0031] The forming method of the large-diameter thin-walled stainless steel cylinder of the present invention comprises the following steps:

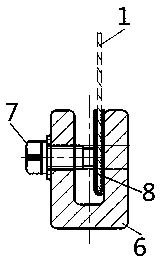

[0032] 1) Pre-bending and processing groove: first calculate the expansion length of the cylinder of the design size, and then cut two rectangular stainless steel plates 1 whose length is half the expansion length of the cylinder from the raw material stainless steel plate, and then make the two stainless steel plates The two ends of 1 are processed to splicing grooves, and then the two ends of the two stainless steel plates 1 are pre-bent;

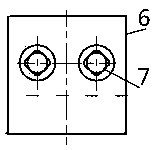

[0033] 2) Hoist to the tooling support and fix it with the tooling support: hoist the two stainless steel plates 1 in step 1) to their respective tooling supports with vacuum suction cups, and then fix the two stainless steel plates 1 on their respective tooling On the support, two stainles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com