Three-pin frame centerless grinding pre-pressing mechanism and grinding method thereof

A technology of centerless grinding and three-pin rack, which is applied to the parts of grinding machine tools, machine tools designed for grinding the rotating surface of workpieces, grinding drive devices, etc. Problems such as preloading, to achieve product structure optimization, compact structure, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

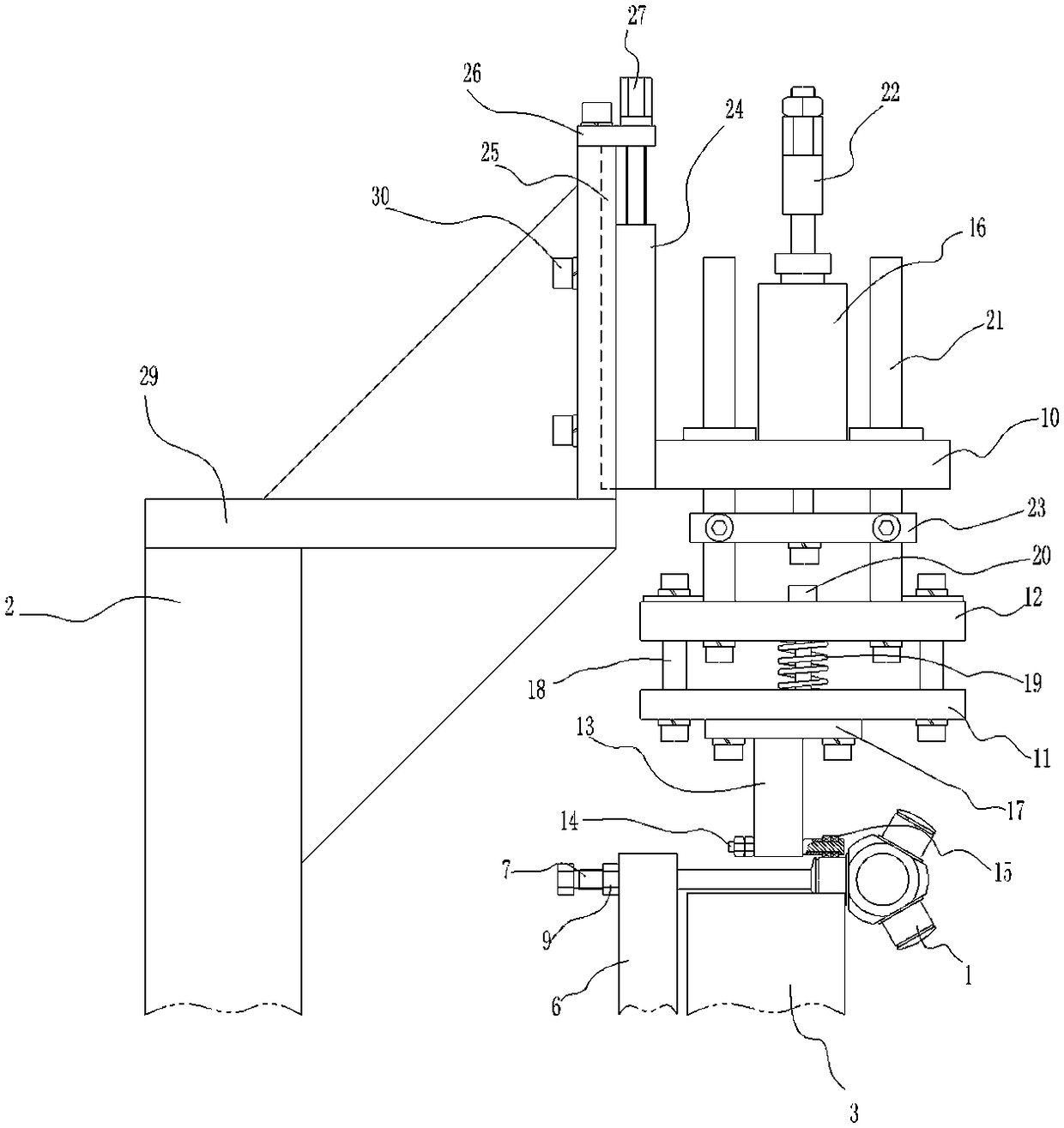

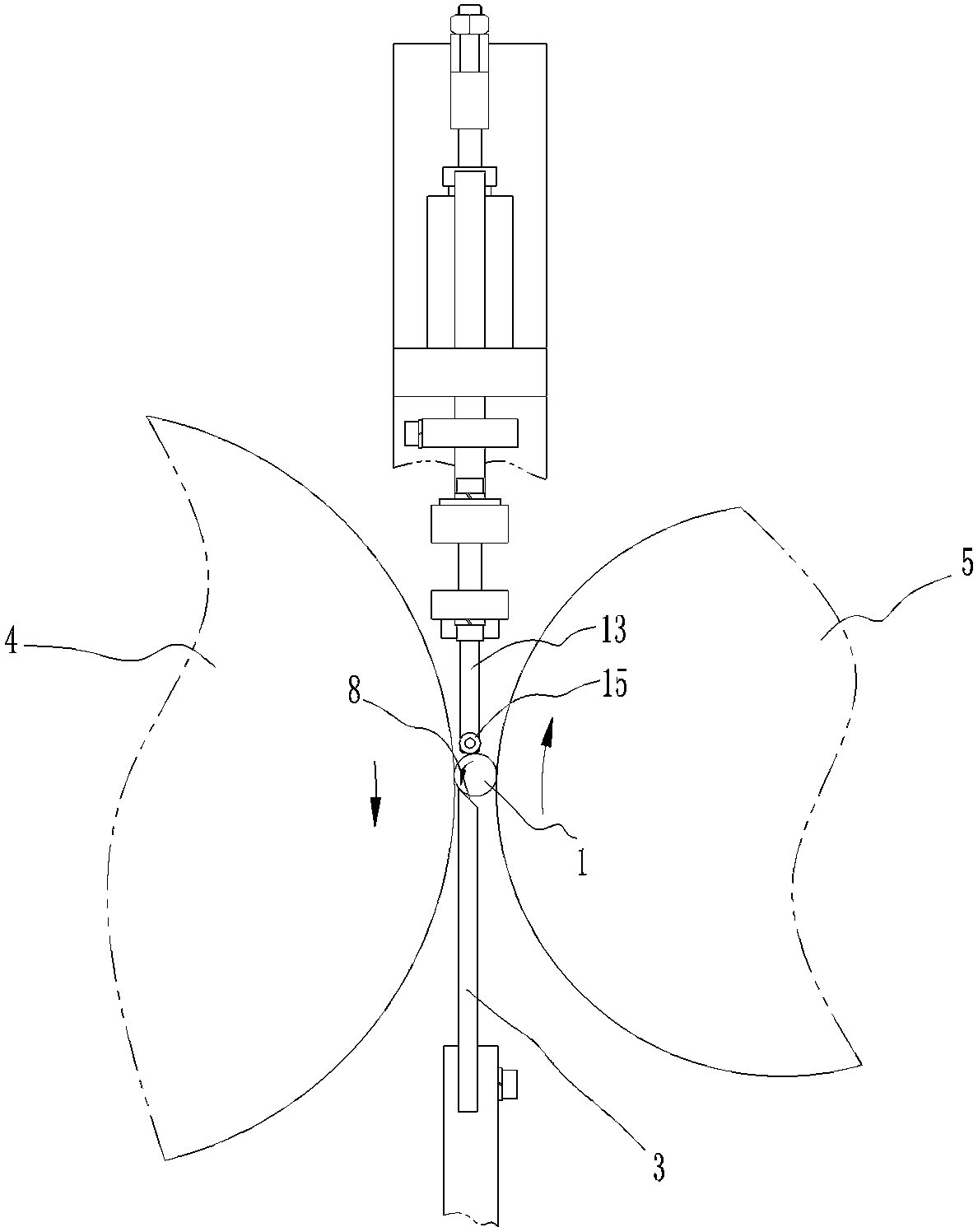

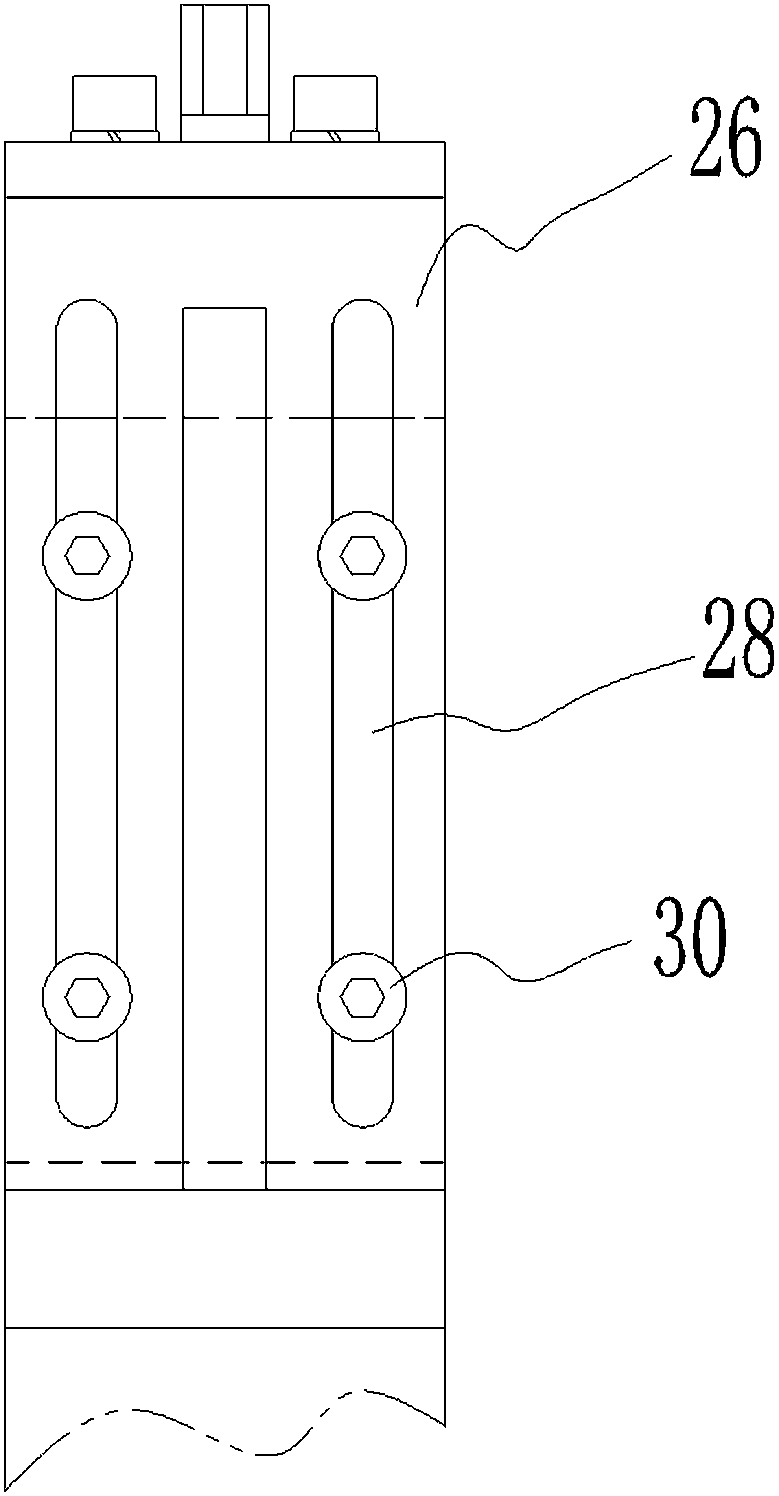

[0037] Embodiment 1: as figure 1 , figure 2 and image 3 As shown, a centerless grinding and pre-pressing mechanism of a three-pin frame includes a workpiece 1 and a grinding machine equipment 2, and also includes a grinding assembly and a pressing assembly. The workpiece 1 is axially positioned and ground by an axial guide wheel assembly. , the workpiece 1 is adjustable for crimping through the pressing assembly.

[0038] The grinding assembly includes a guide plate 3, a grinding wheel 4 and a guide wheel 5, the bottom of the guide plate 3 is fixed to the grinding machine equipment 2, the workpiece 1 is arranged between the grinding wheel 4 and the guide wheel 5, and the guide wheel The rotation of 5 drives the workpiece 1 to rotate in reverse, and the grinding wheel 4 is reversely ground with the forwardly rotating workpiece 1, and the guide wheel 5, grinding wheel 4 and workpiece 1 are distributed in a mating manner;

[0039] The grinding machine equipment 2 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com