Grinding method for thin wall guide tube with tungsten carbide coating

A tungsten carbide coating and thin-walled technology, which is applied in the direction of grinding workpiece supports, can solve problems such as cracks, restrictions on normal product delivery, and micro-cracks, and achieve the effect of improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

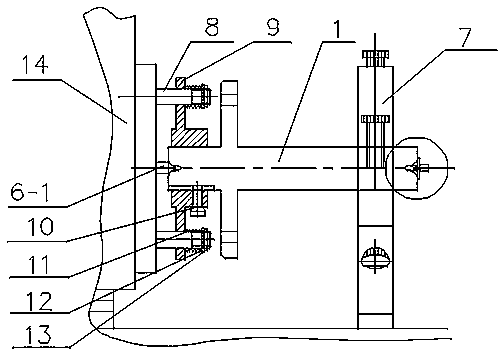

[0168] Combine below Figure 1 to Figure 18 The technical solution provided by the present invention is described in more detail.

[0169] Such as Figures 1 to 3 and Figure 18 As shown, a grinding method of a tungsten carbide coated thin-wall guide cylinder fixture is based on grinding the fixture through the following steps, controlling the grinding action and the dressing action of the grinding wheel, and grinding the fixture by operating the grinding machine , improving the positioning accuracy of the workpiece;

[0170] The specific steps are as follows:

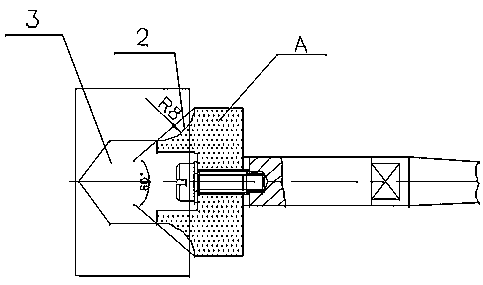

[0171] 1) Finely grind the tapered surface 2 of the center hole on both sides of the main body of the fixture 1;

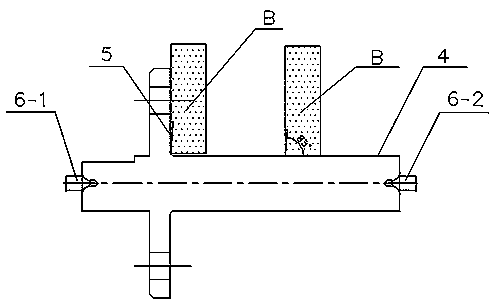

[0172] 2) Use the central hole 3 to locate the outer diameter 4 of the main body of the fine grinding jig and the end face 5 of the shoulder;

[0173] 3) Finely grind the two planes of the end cover 33 with a surface grinder;

[0174] The specific implementation of the step 1) is to clamp the two cen...

specific Embodiment approach 2

[0181] Such as Figures 4 to 10 and Figure 18 Shown, described a kind of grinding method of tungsten carbide coating thin-walled guide cylinder, described grinding machine comprises:

[0182] The alleged head frame 14: the speed of the head frame spindle 53 is 20-220r / min (stepless), the head frame top 6-1 is Mohs 5#;

[0183] Alleged tailstock 16: tailstock top 6-2 is Mohs 4#;

[0184] The alleged grinding wheel frame 54: the linear velocity of the outer circular grinding wheels B, C, and D is 35m / s or 17.5m / s, the movement of the grinding wheel frame 54 is 1mm per revolution of the hand wheel 55; the feeding of the grinding wheel frame with one grid of the hand wheel 55 is the large hand wheel The moving amount of 55-1 is 0.005mm (coarse), the hand wheel 55 is fed by a small grinding wheel frame, the moving amount of 55-2 is 0.001mm (fine), the rapid advance and retreat of the grinding wheel frame 54 is 20mm, and the rotation angle of the grinding wheel frame 54 is ±30°;...

specific Embodiment approach 3

[0285] Such as Figure 11 to Figure 17 Shown, the grinding method of described a kind of tungsten carbide coating thin-walled guide cylinder, carry out grinding process control based on the outer contour of the tungsten carbide coated thin-walled guide cylinder is the control measures in the grinding process, the complaint grinding The steps of cutting process control measures are as follows:

[0286] 1) Before processing, check whether the coating in the area to be ground has defects such as pits and peeling;

[0287] 2) Grinding the base surface of the tungsten carbide coated thin-wall guide cylinder;

[0288] 3) After the center hole is ground, use the coloring method to check the contact between the center hole of the fixture body and the tip. The colored area of the tip is more than 95% (uninterrupted along the circumference), and the center hole is cleaned;

[0289] 4) The maximum runout tolerance of the two top aligning tungsten carbide coated thin-wall guide cylind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Cylindricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com