Crusher

A crusher and casing technology, applied in the field of mechanical equipment, can solve problems such as poor filter performance, variability of rubber powder, uncontrollable working temperature of grinding discs, etc., and achieve the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A crusher, comprising: a casing, a screw feeding mechanism, a moving knife, a fixed knife, a moving knife disc, a fixed knife disc, an airflow cavity conductor, and a first positive pressure airflow inlet.

[0044] The screw feeding mechanism, the moving knife, the fixed knife, the moving knife disc and the fixed knife disc are arranged in the casing; the fixed knife or / and the moving knife are provided with a fixed knife through hole or / and a moving knife through hole; The chamber conducting body shoots out from the through hole of the fixed knife or / and the through hole of the moving knife, forms a jet air curtain layer between the working surface of the moving knife and the working surface of the fixed knife, and shoots to the working surface of the moving knife or the fixed knife, or shoots at the same time. Working face of moving knife and fixed knife.

[0045] The air flow contains ions, and the material to be ground is fully oxidized by the air flow, while elimin...

Embodiment 2

[0047] In this embodiment, the wind flow is emitted through the air flow cavity conductor, forming a jet air curtain layer between the working surface of the movable knife and the working surface of the fixed knife, and shoots towards the working surface of the fixed knife.

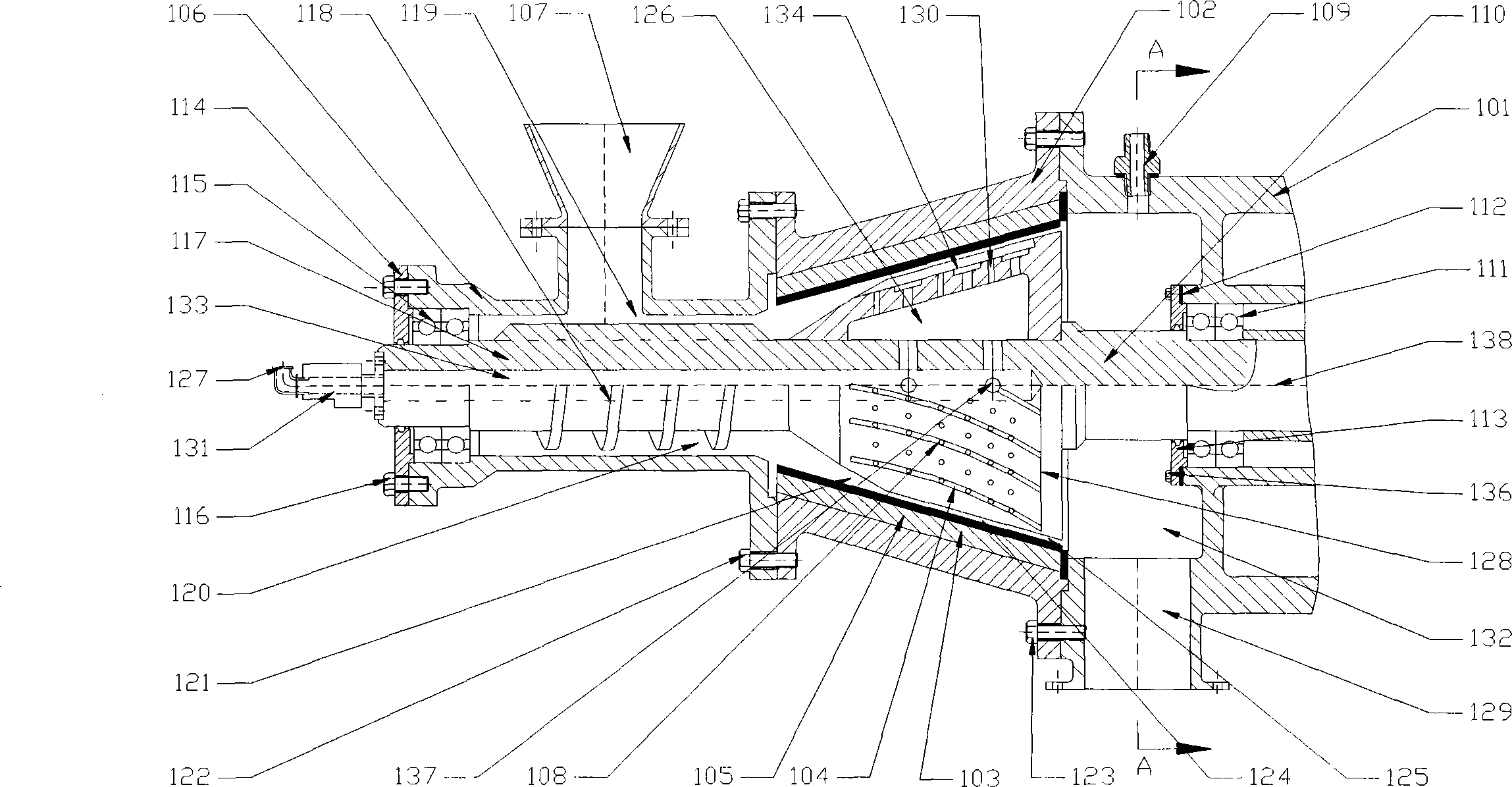

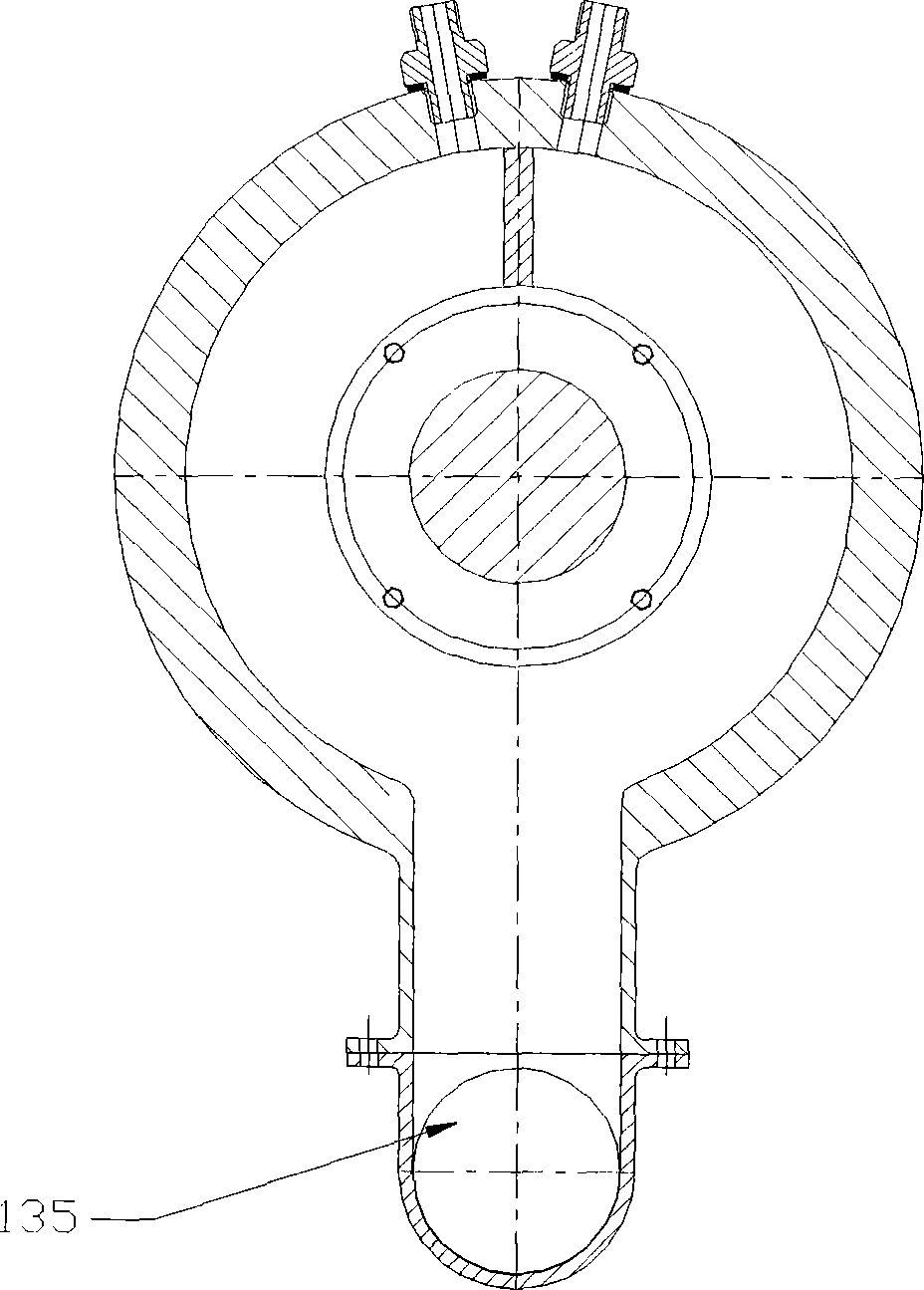

[0048] see Picture 1-1 , Figure 1-2, the present invention discloses a jet air curtain layer glue breaking machine, the glue breaking machine includes: rear frame 101, conical casing 102, front frame 106, feeding hopper 107, screw feeding mechanism, moving knife 104 , fixed cutter 105, movable cutterhead 128, fixed cutterhead 103, wind flow cavity conductor. The rear frame 101, the conical casing 102, and the front frame 106 may be collectively referred to as a casing. The conical casing 102 and the front frame 106 are fixed by fastening screws 122 , and the rear frame 101 and the conical casing 102 are fixed by fastening screws 123 . Described screw feeding mechanism, moving knife 104, fixed knife 10...

Embodiment 3

[0060] In this embodiment, the wind flow is emitted through the air flow cavity conducting body, forming a jet air curtain layer between the working surface of the moving knife and the working surface of the fixed knife, and shooting towards the working surface of the moving knife.

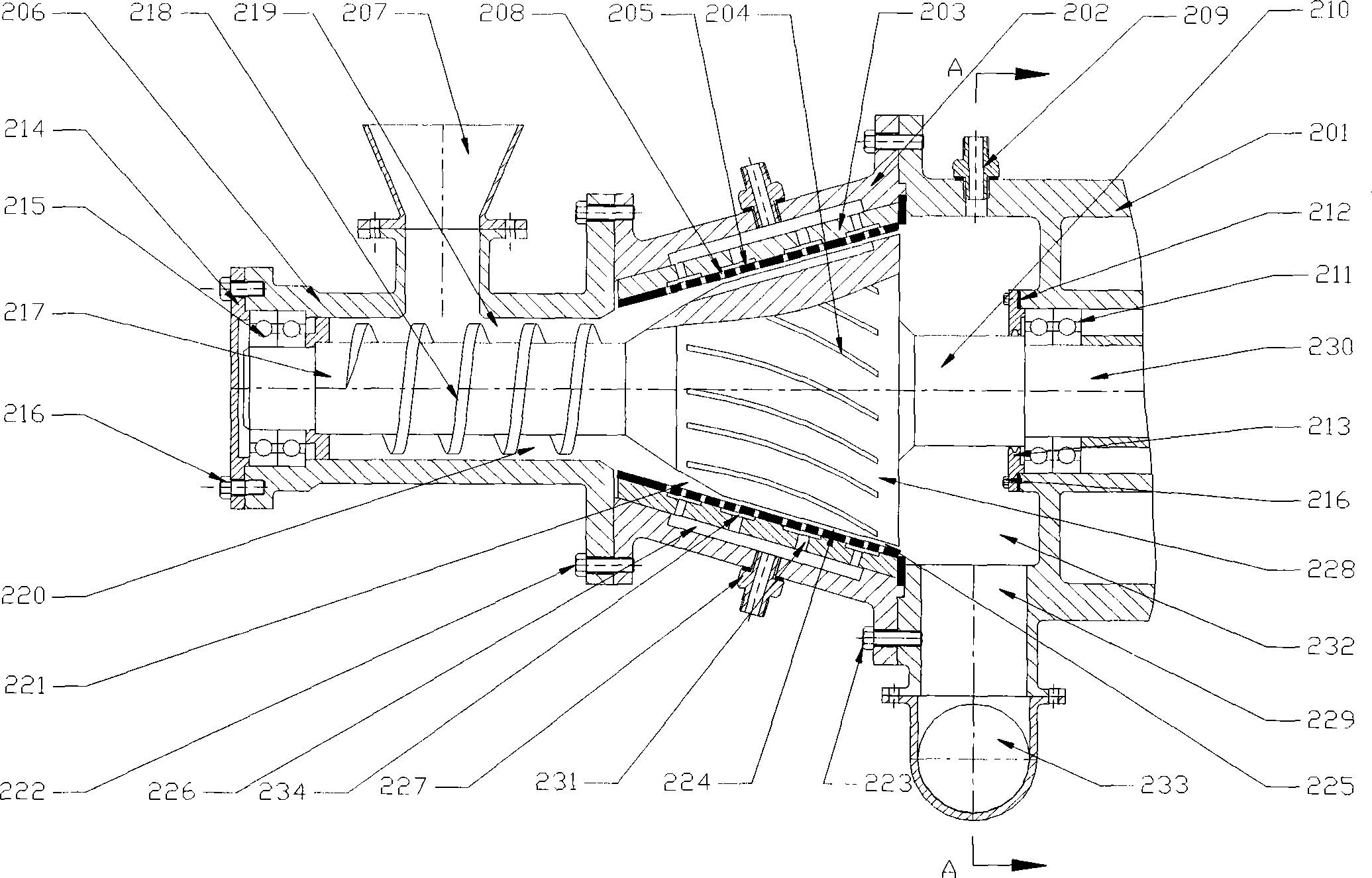

[0061] see diagram 2-1 , Figure 2-2 , the present invention discloses a jet air curtain layer glue breaking machine, the glue breaking machine includes: rear frame 201, conical casing 202, front frame 206, feeding hopper 207, screw feeding mechanism, moving knife 204 , fixed cutter 205, movable cutterhead 228, fixed cutterhead 203, wind flow cavity conductor. The rear frame 201, the conical casing 202, and the front frame 206 may be collectively referred to as a casing. The conical casing 202 and the front frame 206 are fixed by fastening screws 222 , and the rear frame 201 and the conical casing 202 are fixed by fastening screws 223 . The screw feeding mechanism, moving knife 204, fixed knif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com