Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

113results about How to "Improve post-processing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Digital intermediate (DI) processing and distribution with scalable compression in the post-production of motion pictures

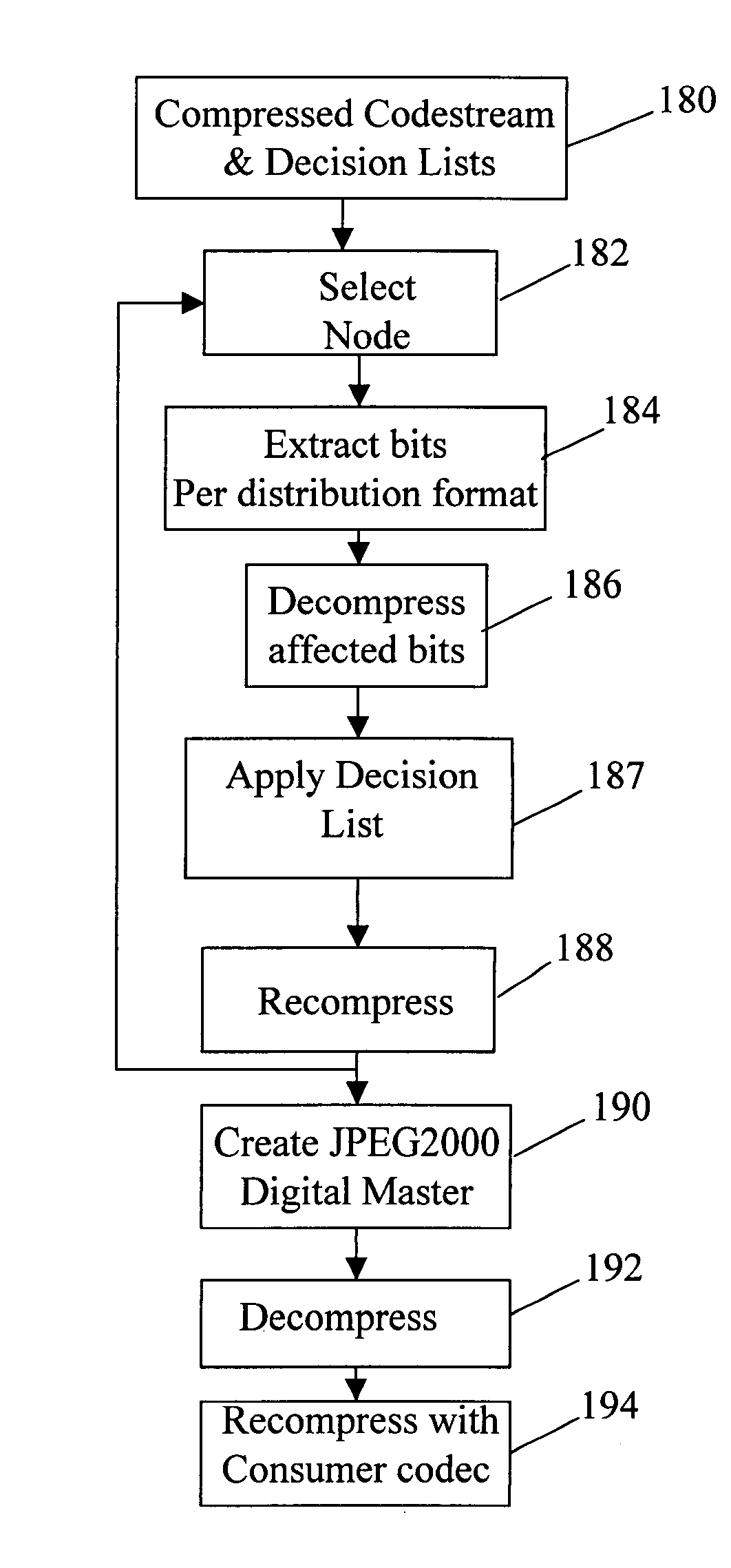

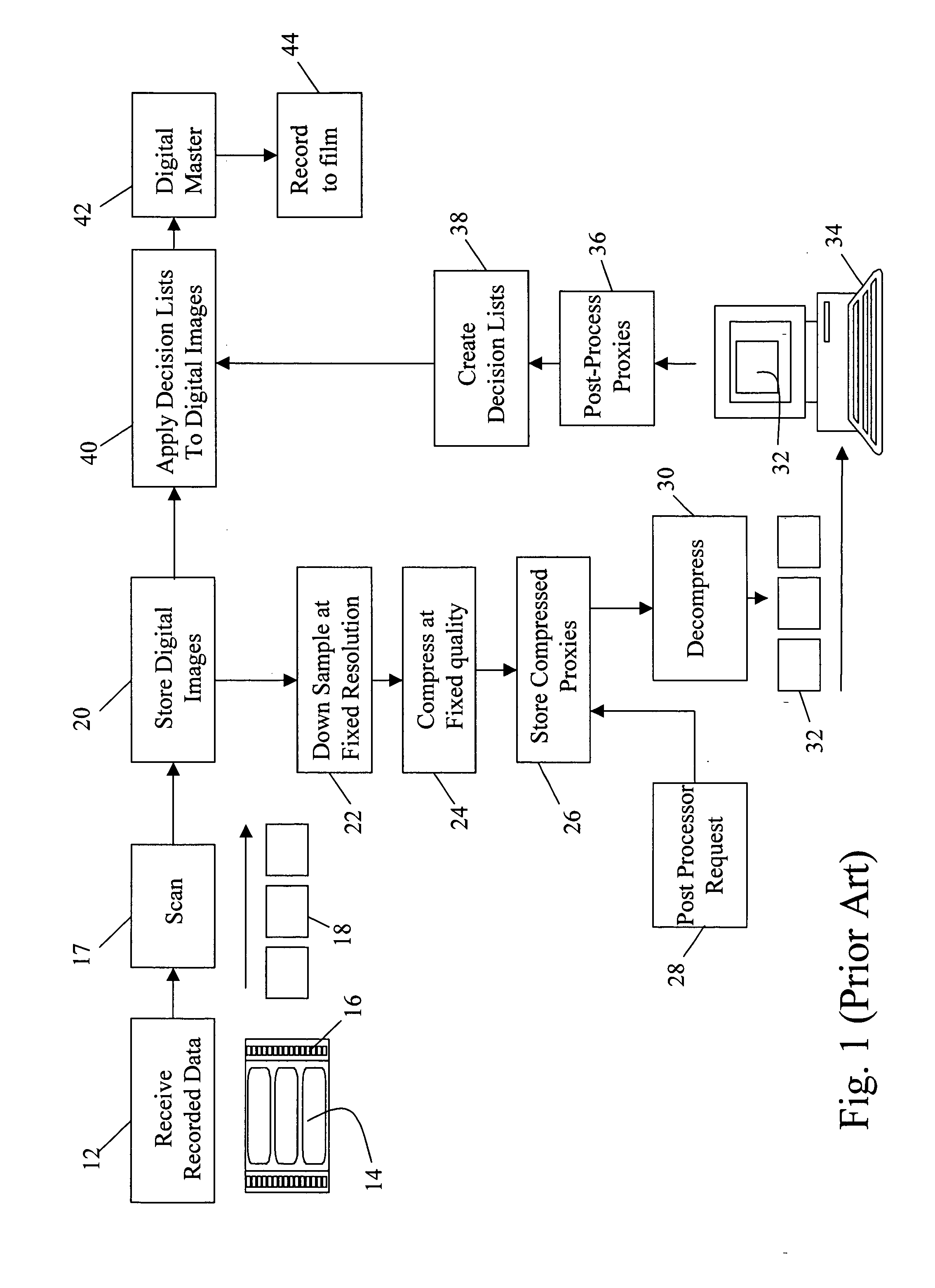

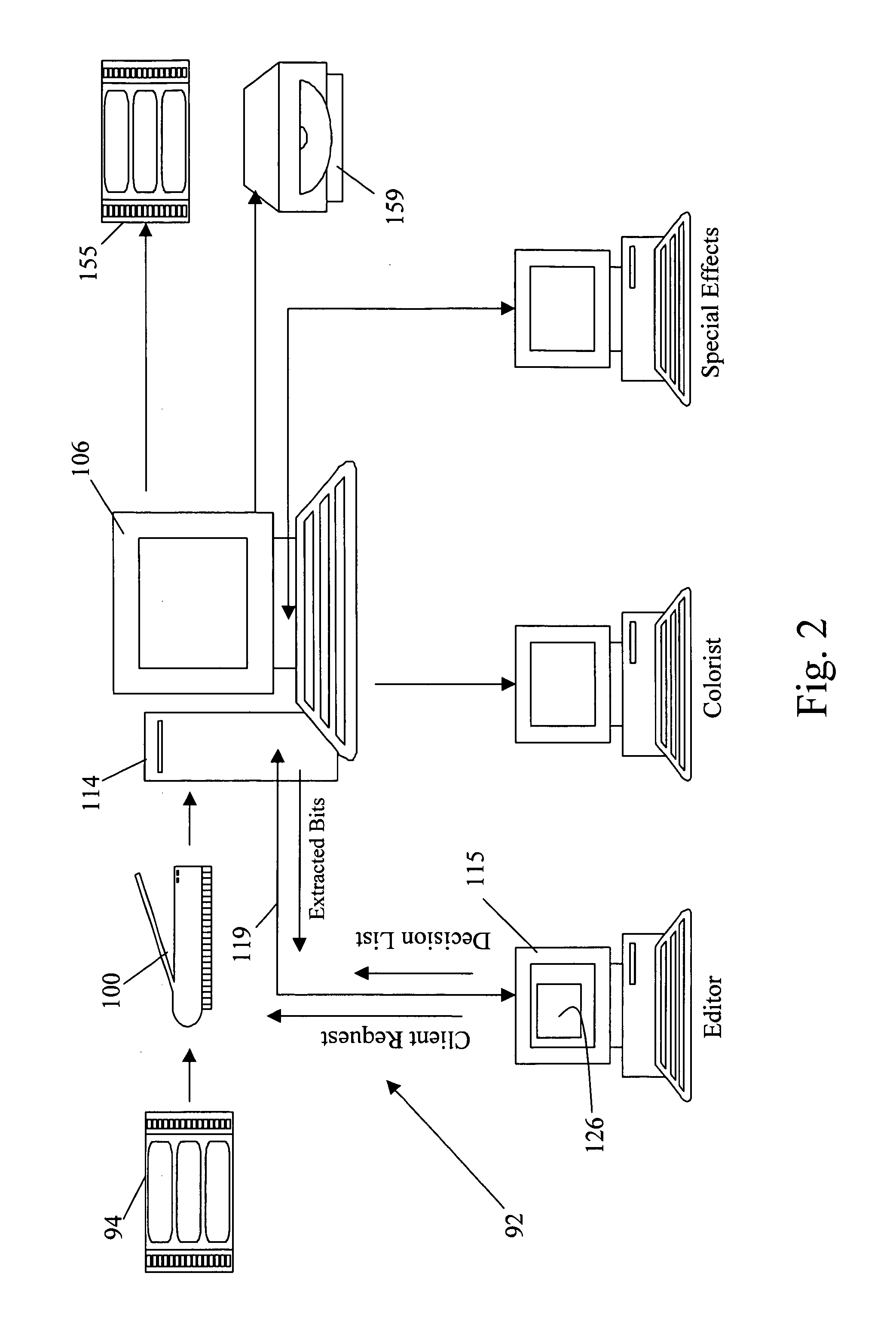

InactiveUS20060177139A1Easy to createImprove post-processing efficiencyPicture reproducers using cathode ray tubesPicture reproducers with optical-mechanical scanningScalable compressionWork product

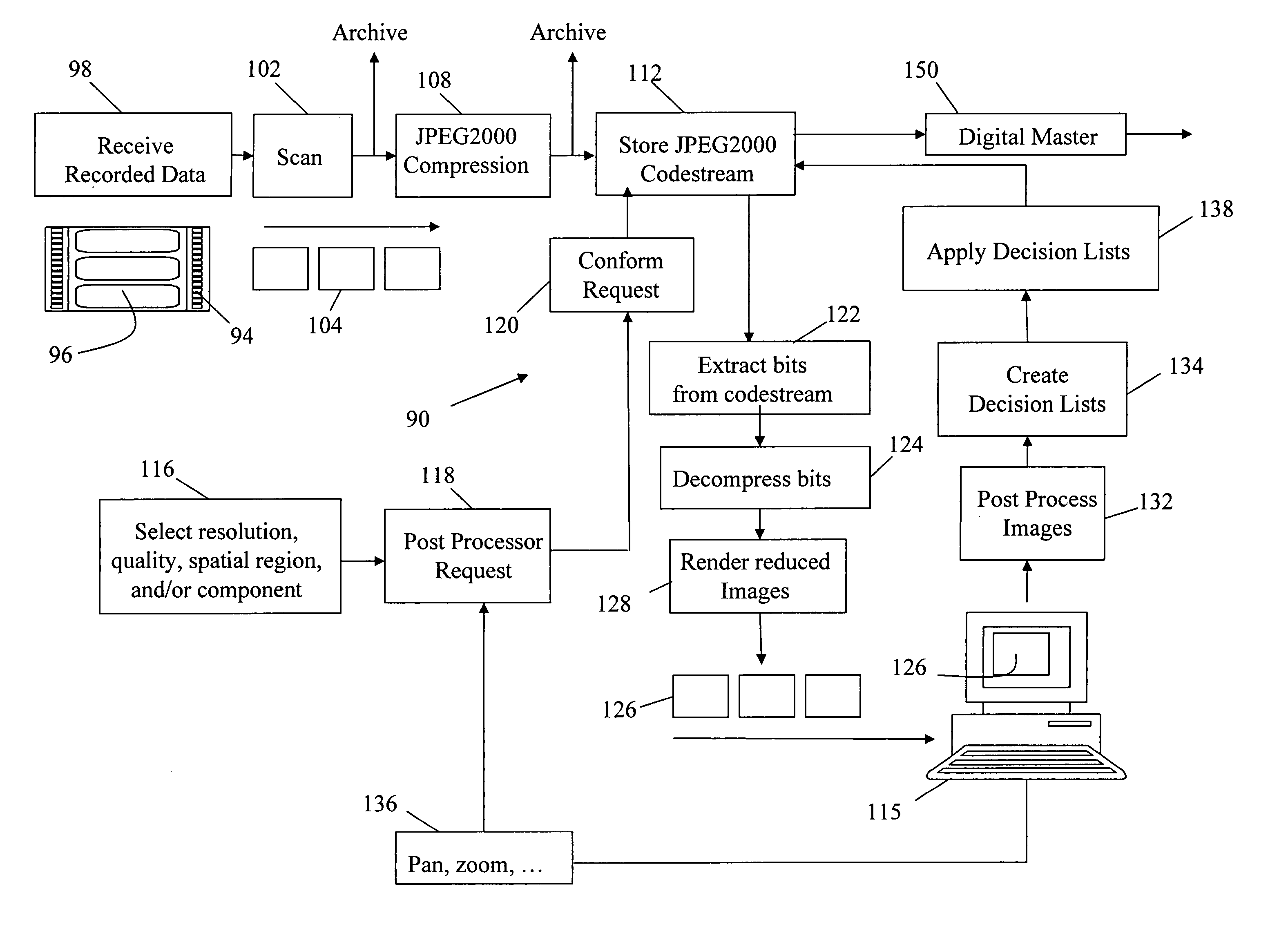

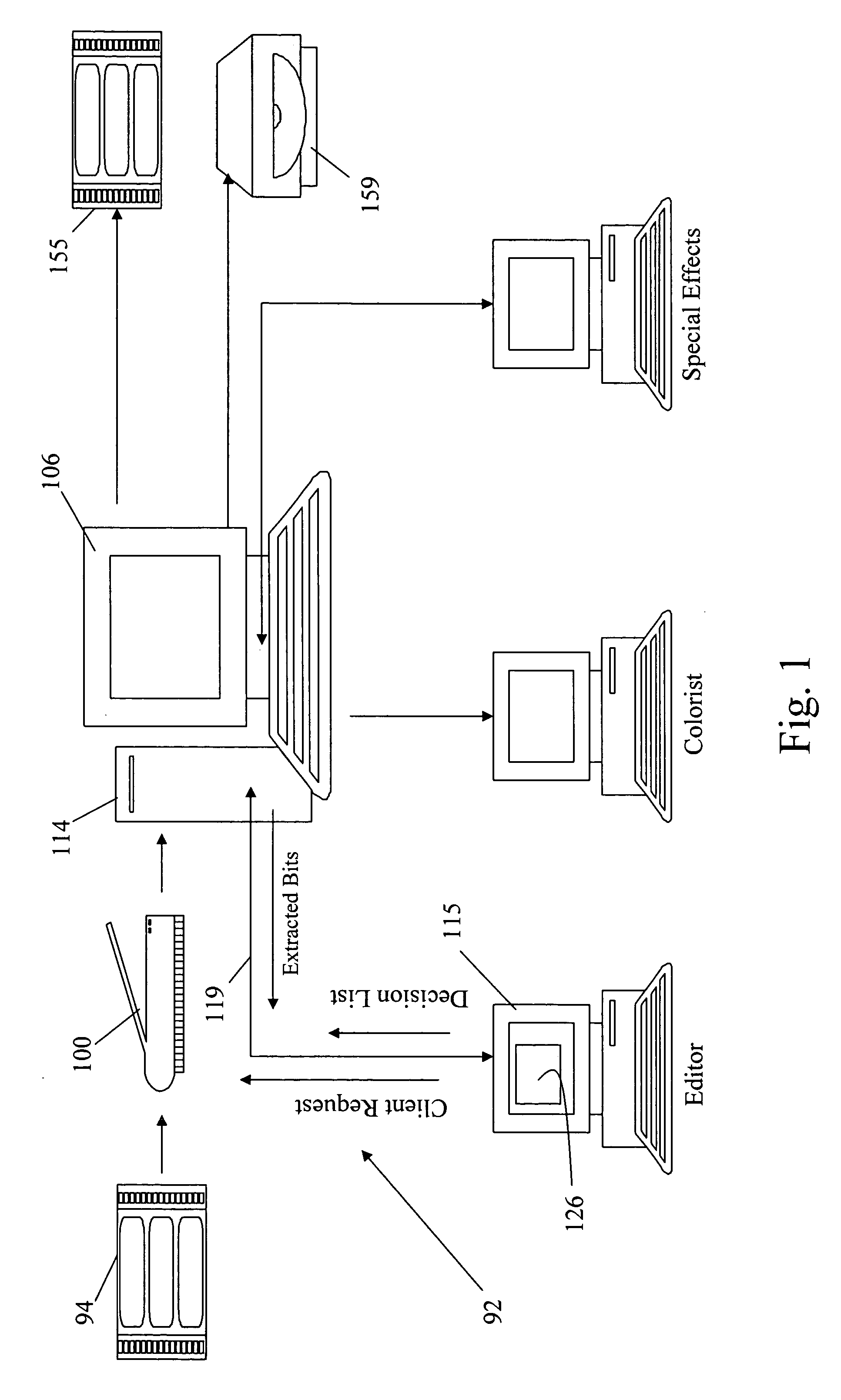

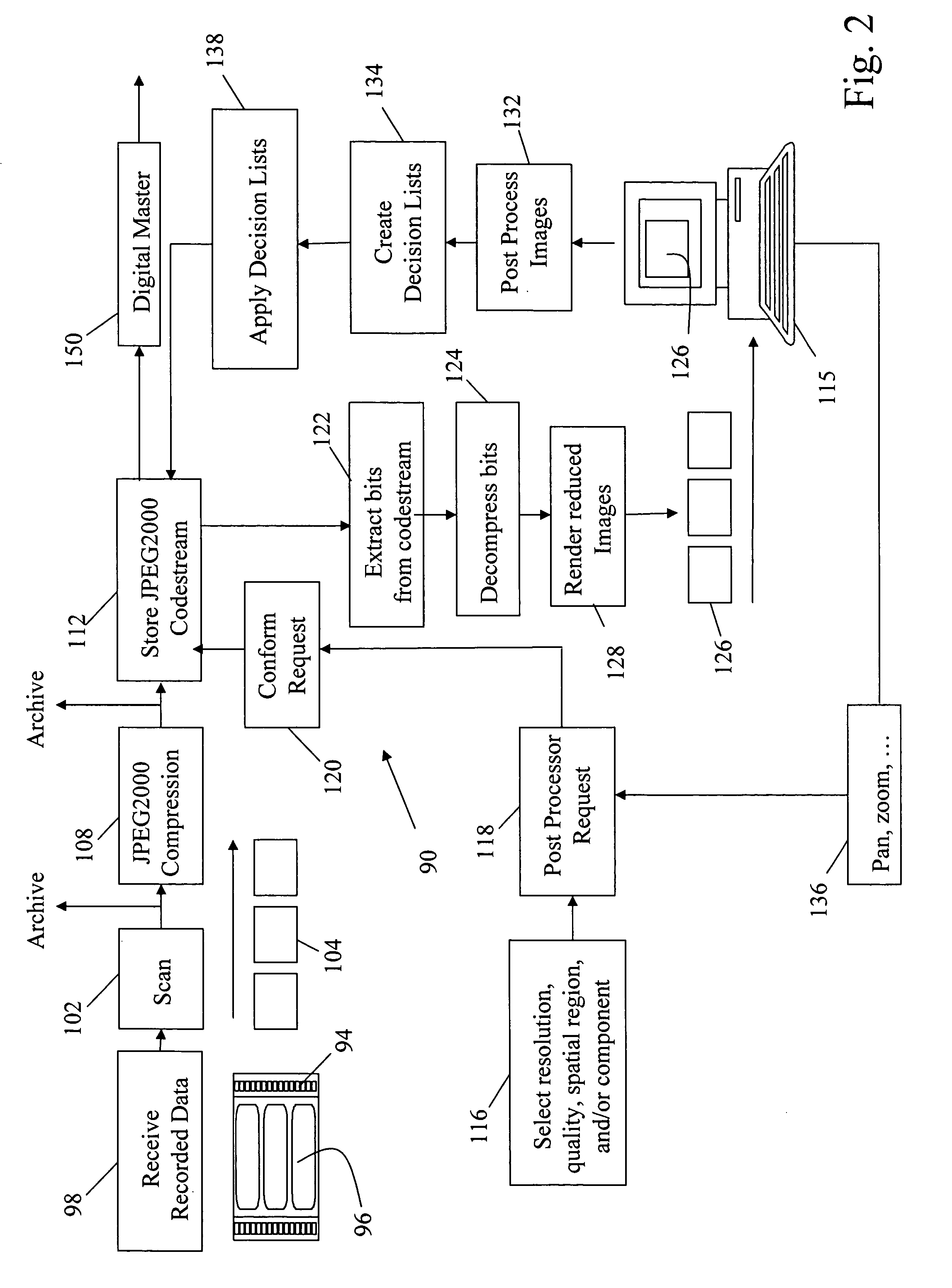

Scalable image compression is exploited to facilitate the creative process in the post-production of motion pictures. Specifically, digital intermediate (DI) processing of motion pictures is enabled by dynamically rendering proxies in response to client requests. A DI application is designed to enhance the efficiency of post-processing and the quality of the work product of the editors, colorists and other creative people. The DI application also provides a method for efficiently formatting the product for film, digital cinema, DVD and other video applications.

Owner:DTS

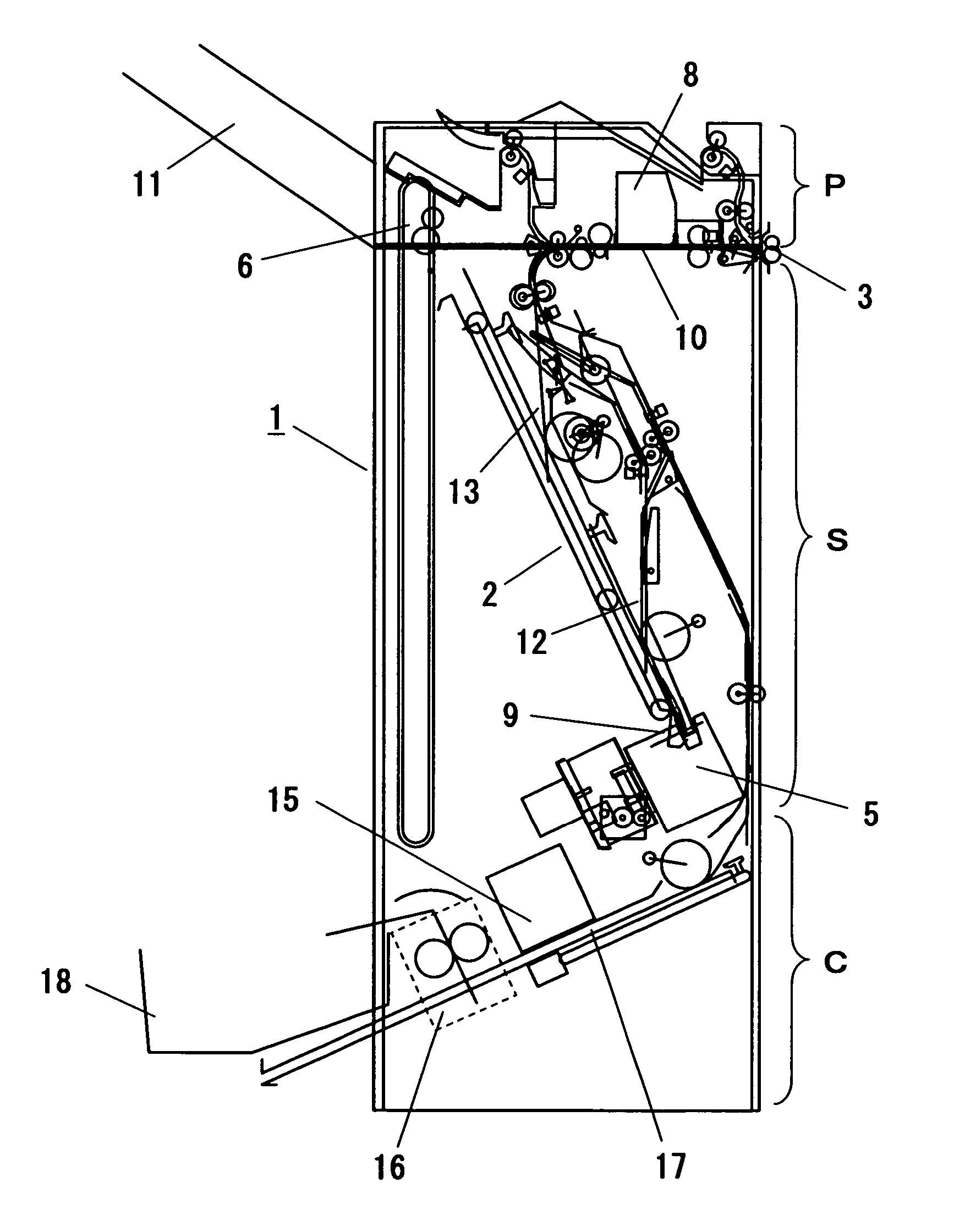

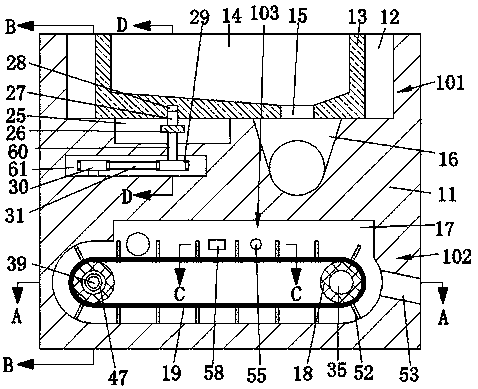

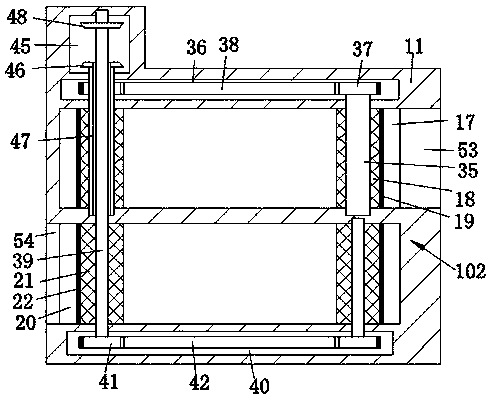

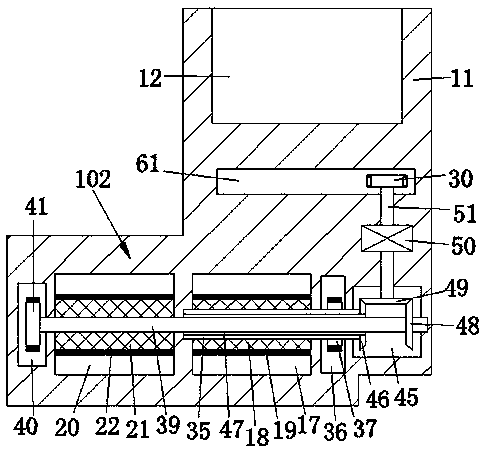

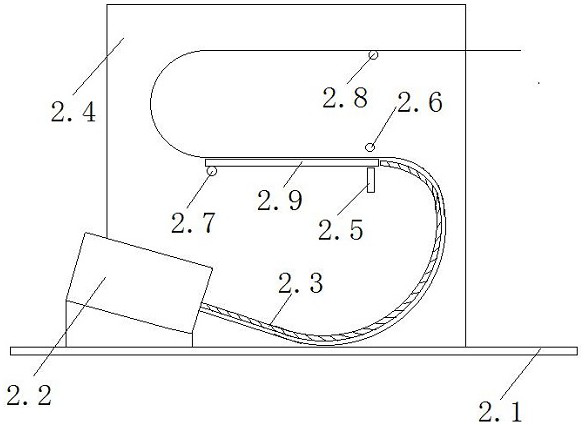

Sheet post-processing apparatus

InactiveUS7497425B2Simple structureImprove processing effectivenessFunction indicatorsFolding thin materialsPunchingEngineering

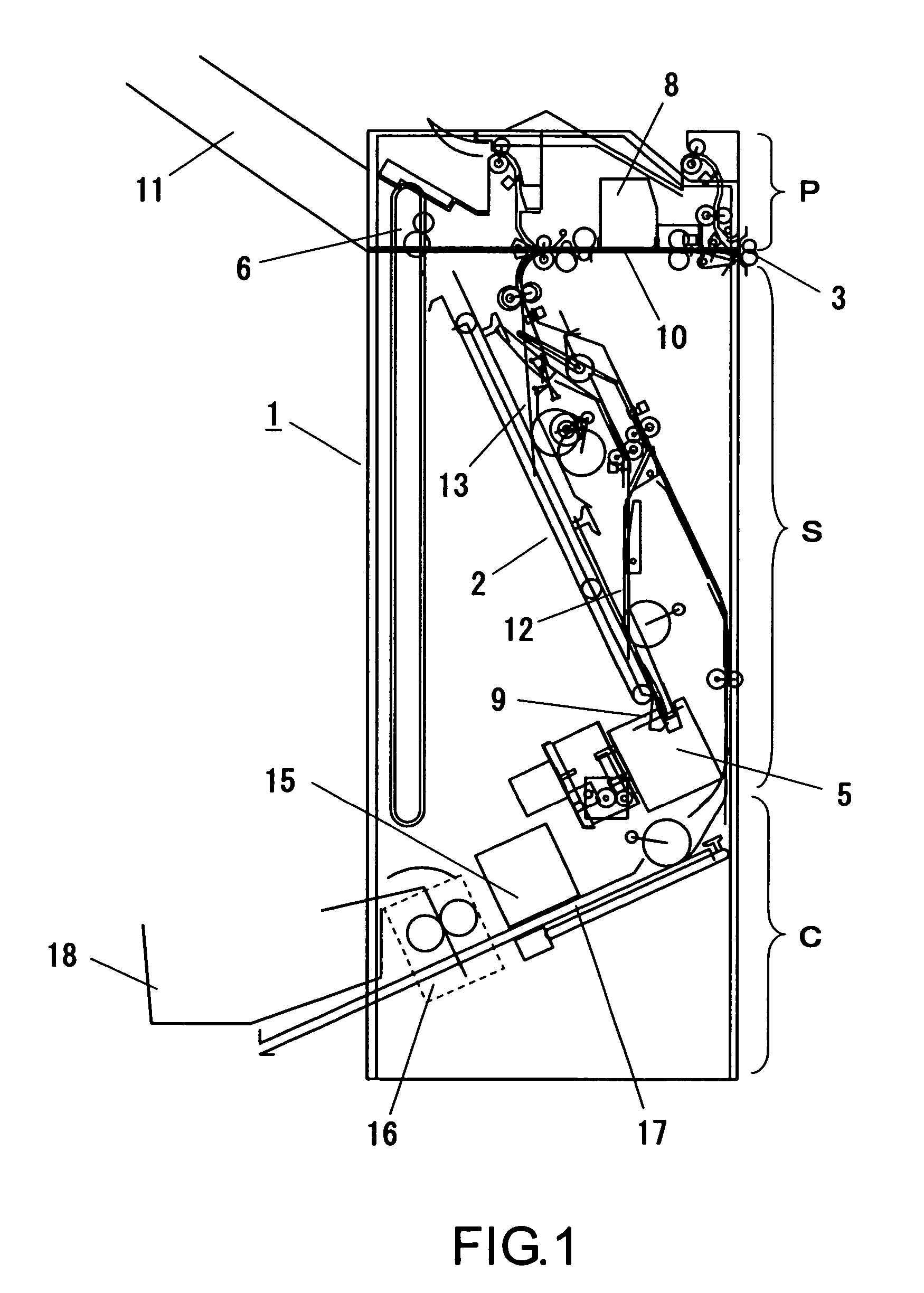

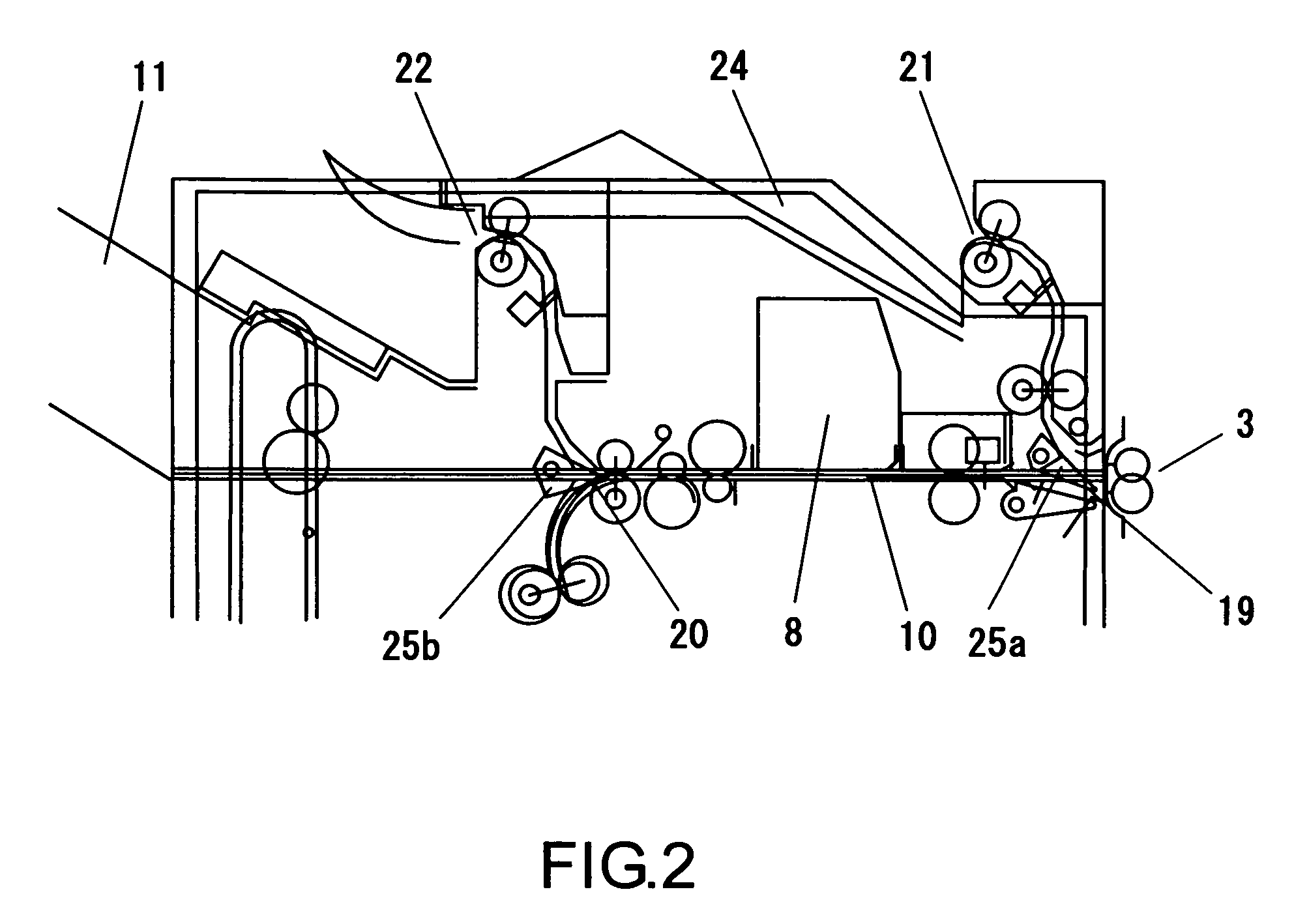

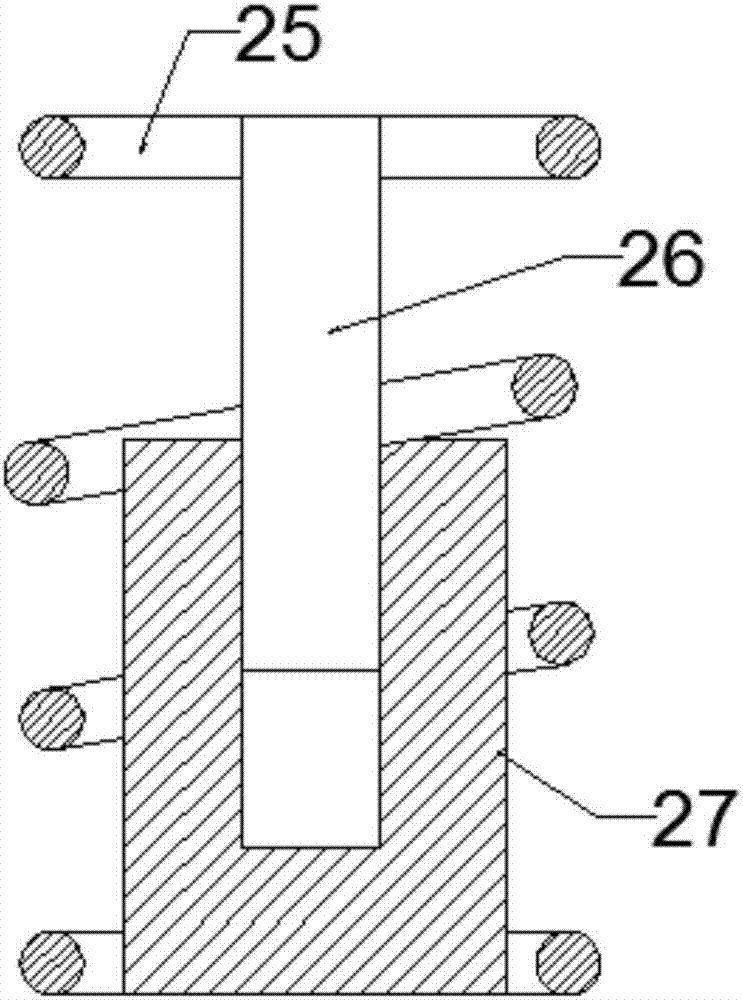

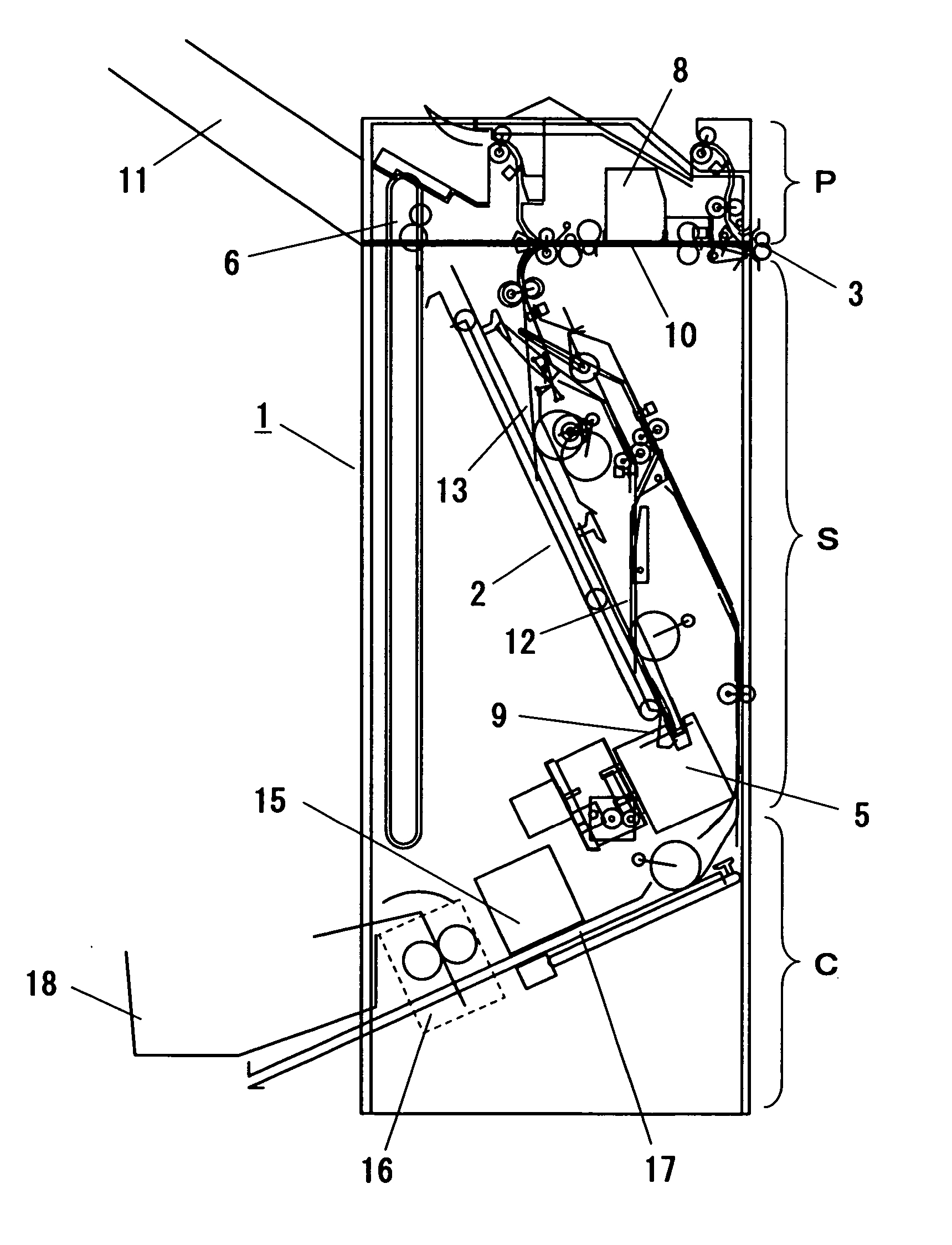

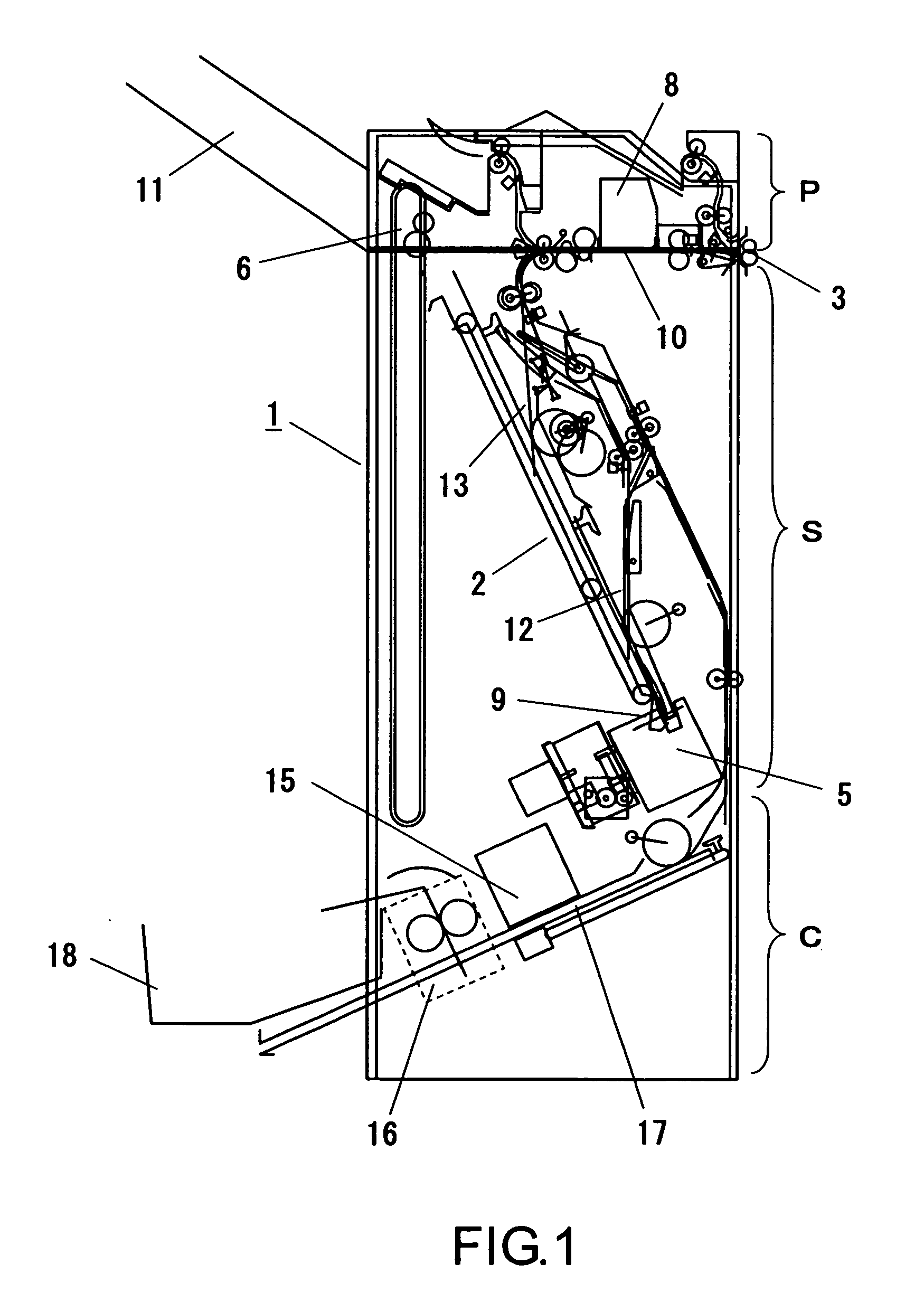

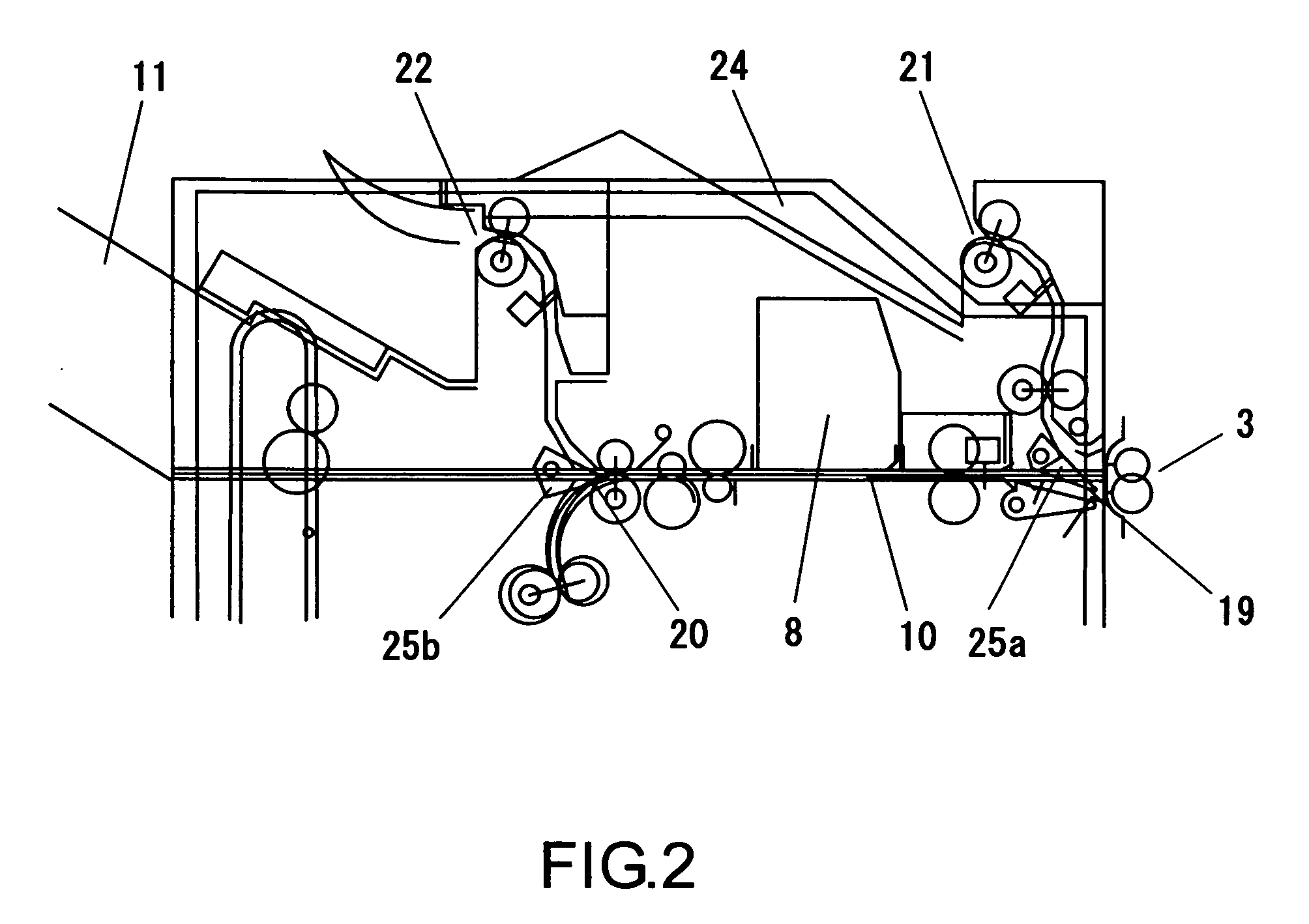

A sheet post-processing apparatus (1) includes a punching unit (P), an end-binding unit (S) which aligns end portions of a sheet bundle piled on a processing tray (2) and performs a stapling process, and a middle-binding and middle-folding unit (C) which performs a stapling process on the center of the sheet bundle and then folds centering around the stapling portion to be in a brochure form. The middle-binding and middle-folding unit (C) is independently provided on the lower side of the end-binding unit (S) and a middle-binding and middle-folding feeding path (27) feeds sheets to the middle-binding and middle-folding unit (C) without via the processing tray (2) of the end-binding unit (S).

Owner:KYOCERA DOCUMENT SOLUTIONS INC

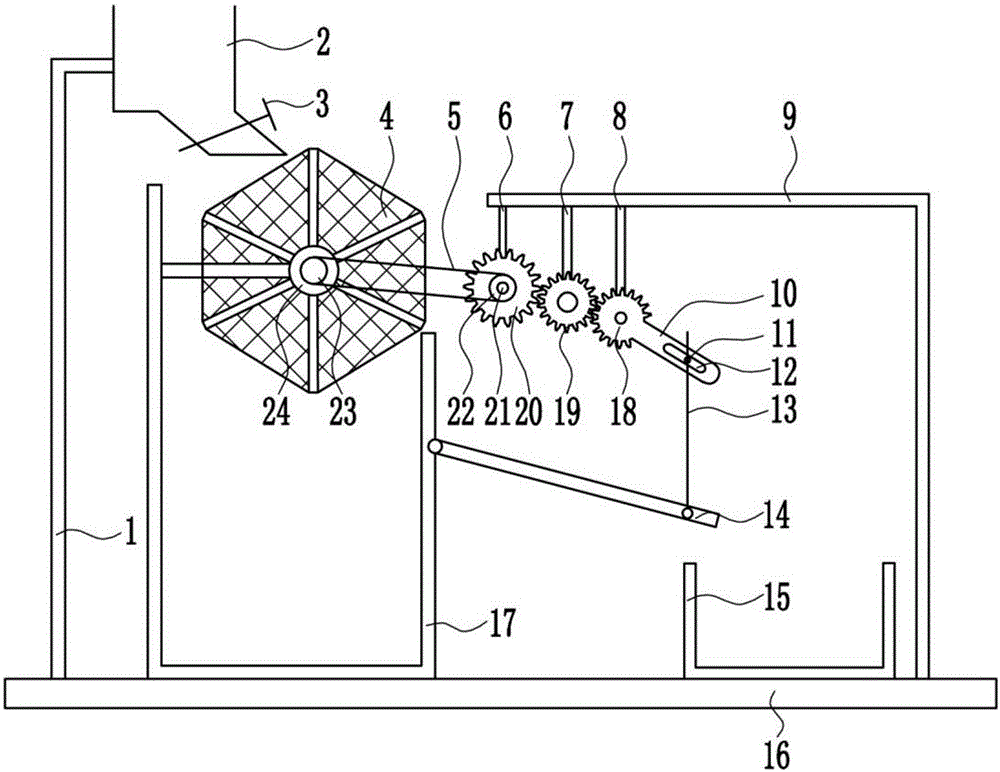

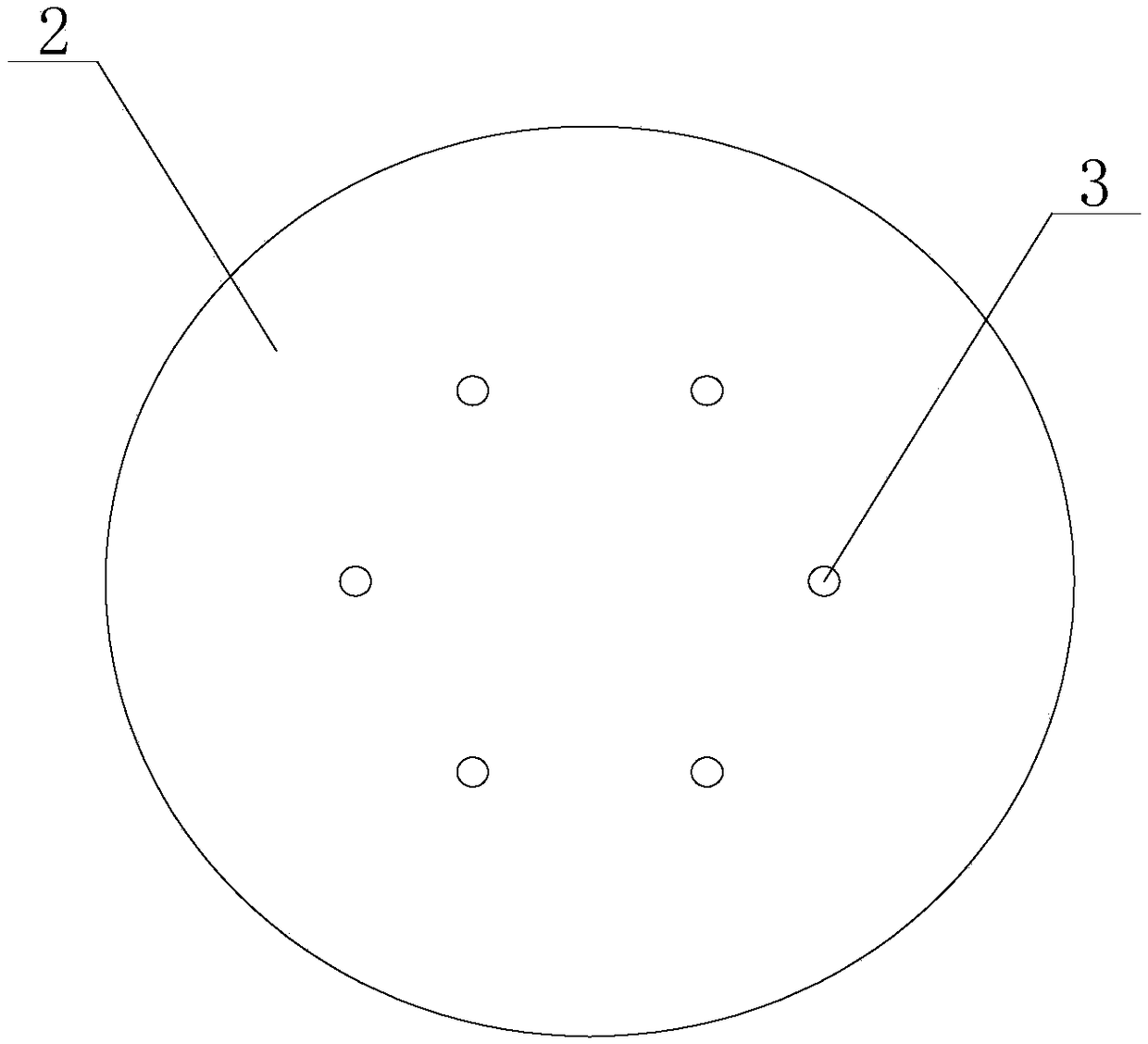

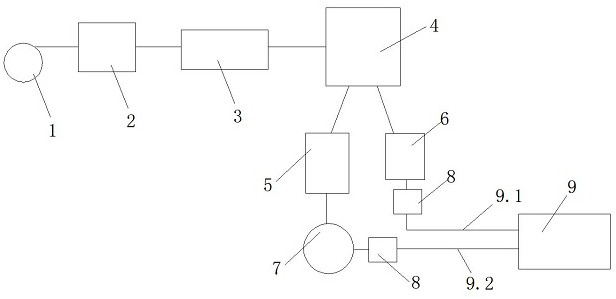

Corn kernel grading sieving device with dust removal function

InactiveCN107961976AImprove the effectImprove efficiencySievingGas current separationMaterial SeparationDrive motor

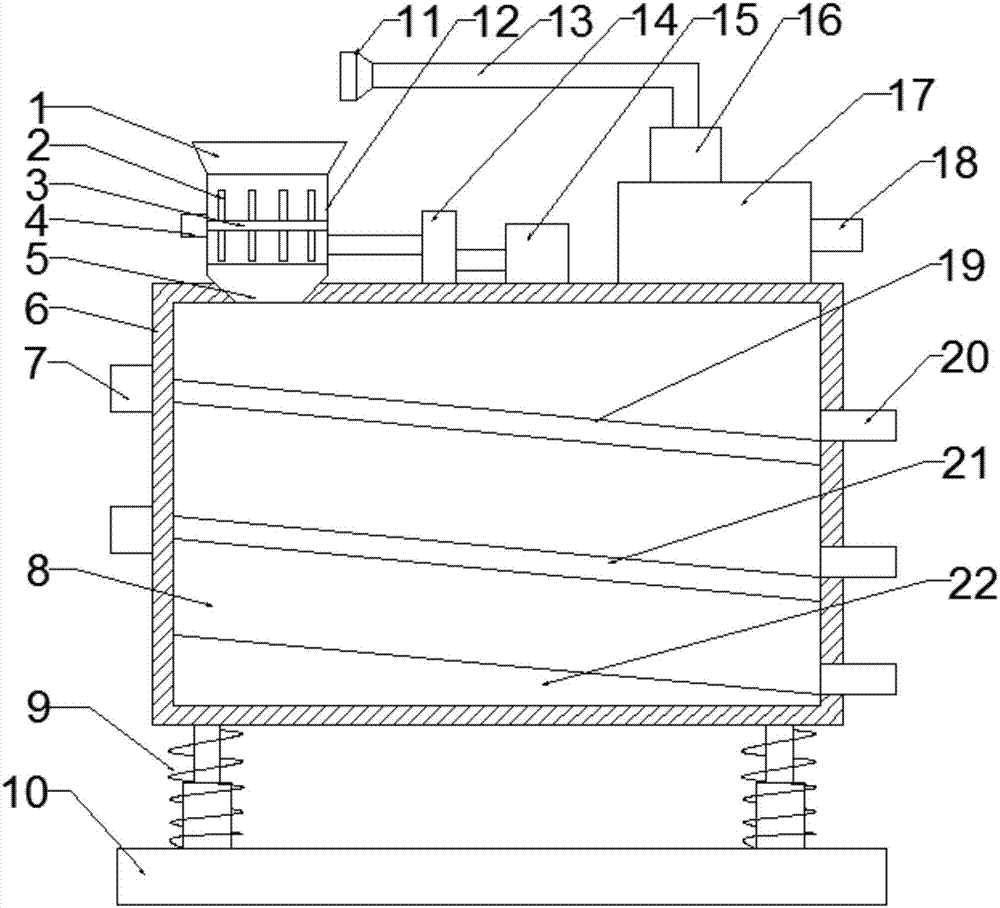

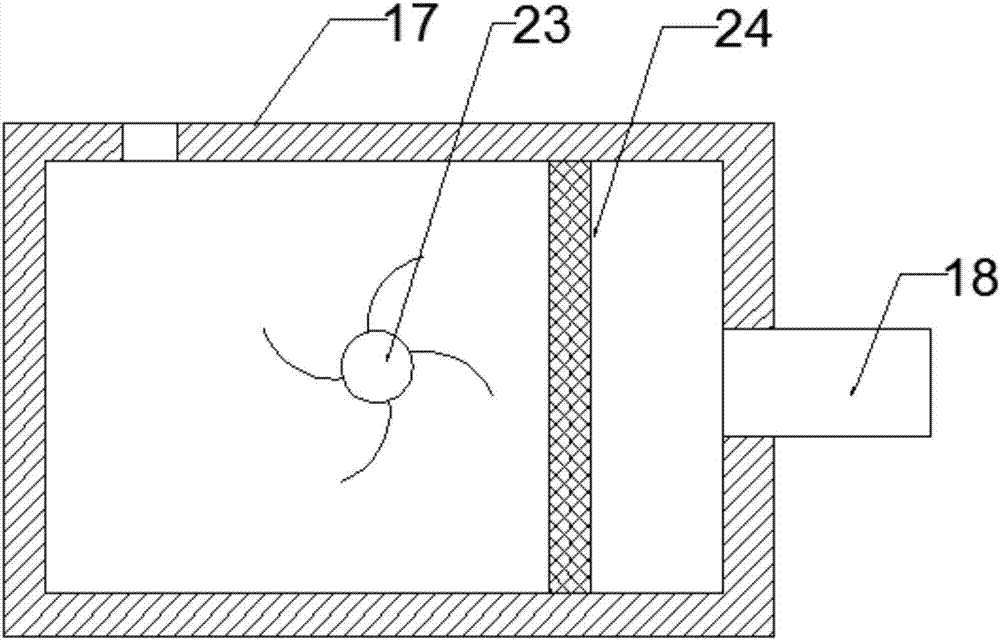

The invention discloses a corn kernel grading sieving device with a dust removal function, and belongs to the field of material separation equipment. The corn kernel grading sieving device comprises adust collecting device and a sieving device, the lower end of a feeding box is connected with a box body through a feeding pipe, and the upper end of the feeding box is provided with a charging hopper; a driving motor is arranged on the left side of the feeding box, and the output end of the driving motor is connected with a rotating shaft; an air blower is arranged on the right side of the feeding box and is connected with a heater through a pipeline; the heater is connected with the feeding box through a pipeline; a dust collecting hood is arranged on the right side of the upper portion ofthe charging hopper; and a box body is internally provided with a sieving cavity, a large hole filter net, a small hole filter net and an inclined discharging plate are sequentially arranged in the sieving cavity from top to bottom, the right side of the box body is provided with three corresponding discharging openings, and two vibration motors are arranged on the left side of the box body. According to the corn kernel grading sieving device with the dust removal function, the structure is reasonable, using is convenient, corn kernels can be sieved by grading, the sieving effect is good, drying and dust removal can be achieved, and the damping effect is good.

Owner:季梅

Digital intermediate (DI) processing and distribution with scalable compression in the post-production of motion pictures

InactiveUS20070014476A1Easy to createImprove post-processing efficiencyElectronic editing digitised analogue information signalsCharacter and pattern recognitionScalable compressionWork product

Scalable image compression is exploited to facilitate the creative process in the post-production of motion pictures. Specifically, digital intermediate (DI) processing of motion pictures is enabled by dynamically rendering proxies 126 (steps 122, 124, 128) in response to client requests (steps 116, 118). A DI application is designed to enhance the efficiency of post-processing and the quality of the work product of the editors, colorists and other creative people. The DI application also provides a method for efficiently formatting the product for film, digital cinema, DVD and other video applications.

Owner:DTS

Sheet post-processing apparatus

InactiveUS20060290044A1Simple structureImprove processing effectivenessFunction indicatorsFolding thin materialsPunchingEngineering

A sheet post-processing apparatus (1) includes a punching unit (P), an end-binding unit (S) which aligns end portions of a sheet bundle piled on a processing tray (2) and performs a stapling process, and a middle-binding and middle-folding unit (C) which performs a stapling process on the center of the sheet bundle and then folds centering around the stapling portion to be in a brochure form. The middle-binding and middle-folding unit (C) is independently provided on the lower side of the end-binding unit (S) and a middle-binding and middle-folding feeding path (27) feeds sheets to the middle-binding and middle-folding unit (C) without via the processing tray (2) of the end-binding unit (S).

Owner:KYOCERA DOCUMENT SOLUTIONS INC

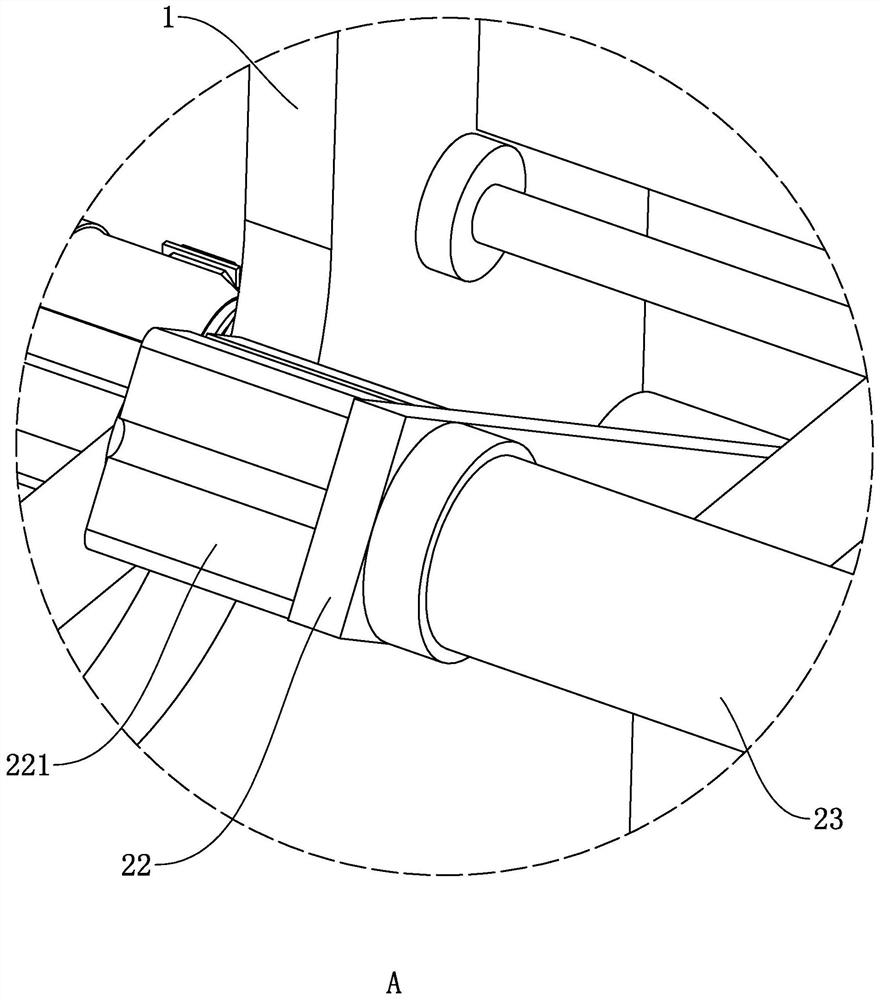

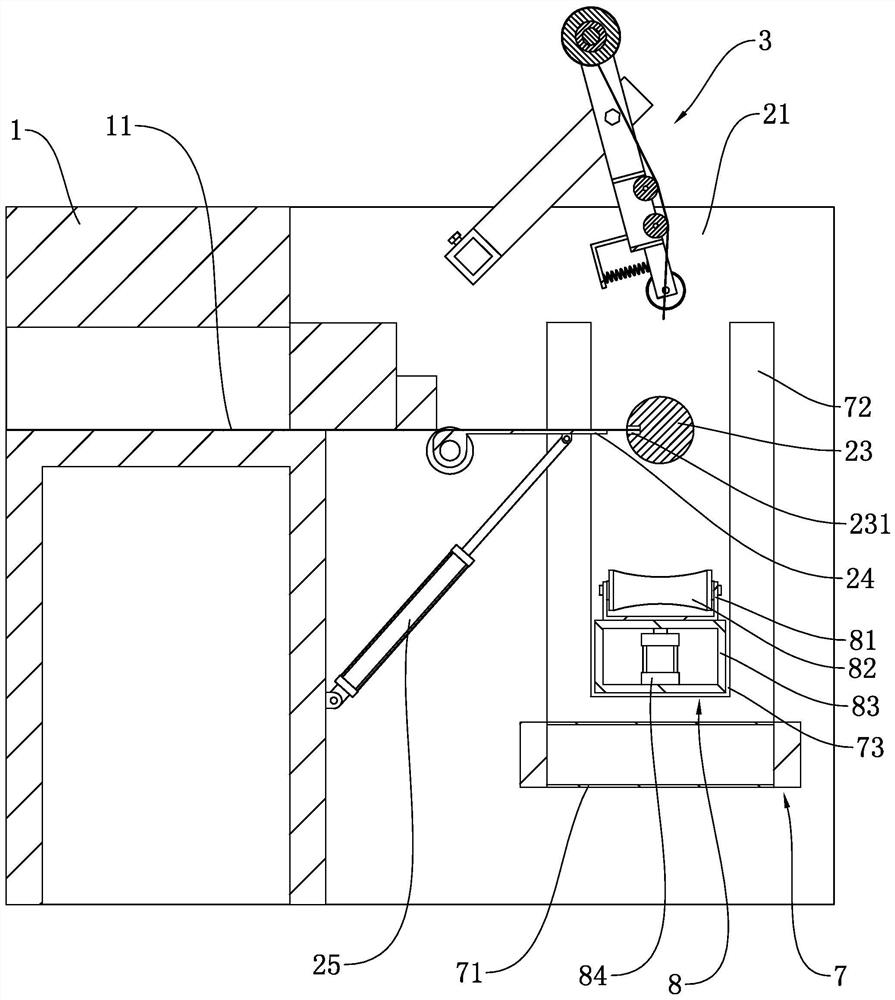

Automatic winding device integrating winding, packing and unloading

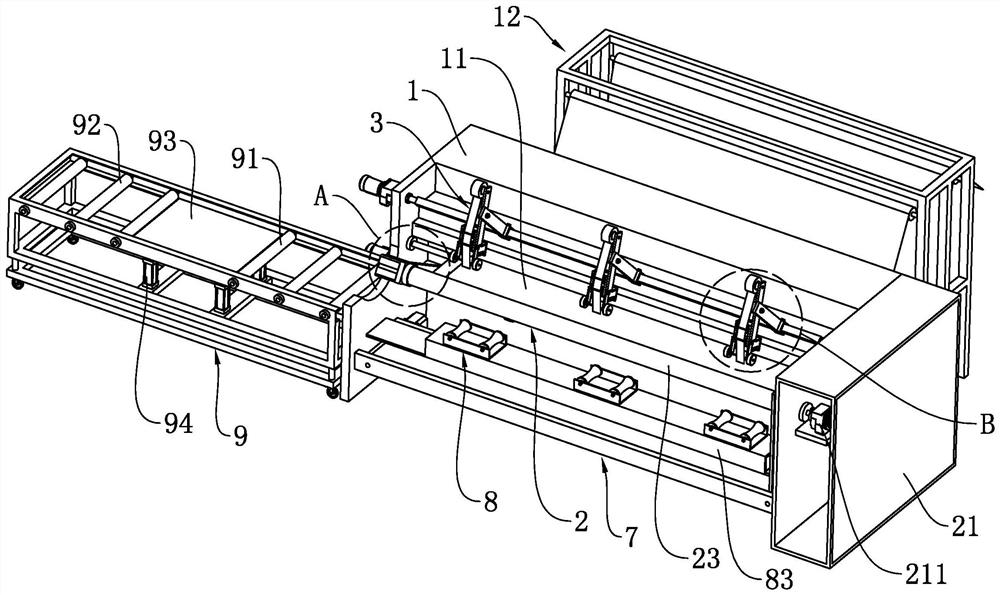

PendingCN111807115AImprove post-processing efficiencyImprove processing efficiencyBinding material applicationWebs handlingAdhesive beltDrive by wire

The invention relates to the technical field of sheet finished product post-processing equipment and discloses an automatic winding device integrating winding, packing and unloading. The device comprises a frame. The frame is provided with a winding module, a packaging module and a blanking module. The winding module comprises a supporting plate, a rocker arm and a clamping shaft. The supporting plate is fixedly connected with the frame. The rocker arm is rotatably connected with the frame. One end of the clamping shaft is rotatably connected with the supporting plate, and the other end is against the rocker arm. A sheet enters the frame and is conveyed toward the clamping shaft side until the clamping shaft clamps the end of the sheet and winds the sheet. The packaging module comprises arotating frame and a tape roll. The rotating frame is rotatably connected to the frame and is located diagonally above the clamping shaft. The tape roll is rotatably connected to the rotating frame. The blanking module is located below the clamping shaft, and the blanking module comprises a linear driving member and a pushing member. The linear driving member drives the pushing member to move fromthe side of the supporting plate toward the side of the rocker arm. The device solves the problems of low post-processing efficiency and high labor cost of the sheet finished product.

Owner:常州新达力塑料机械有限公司

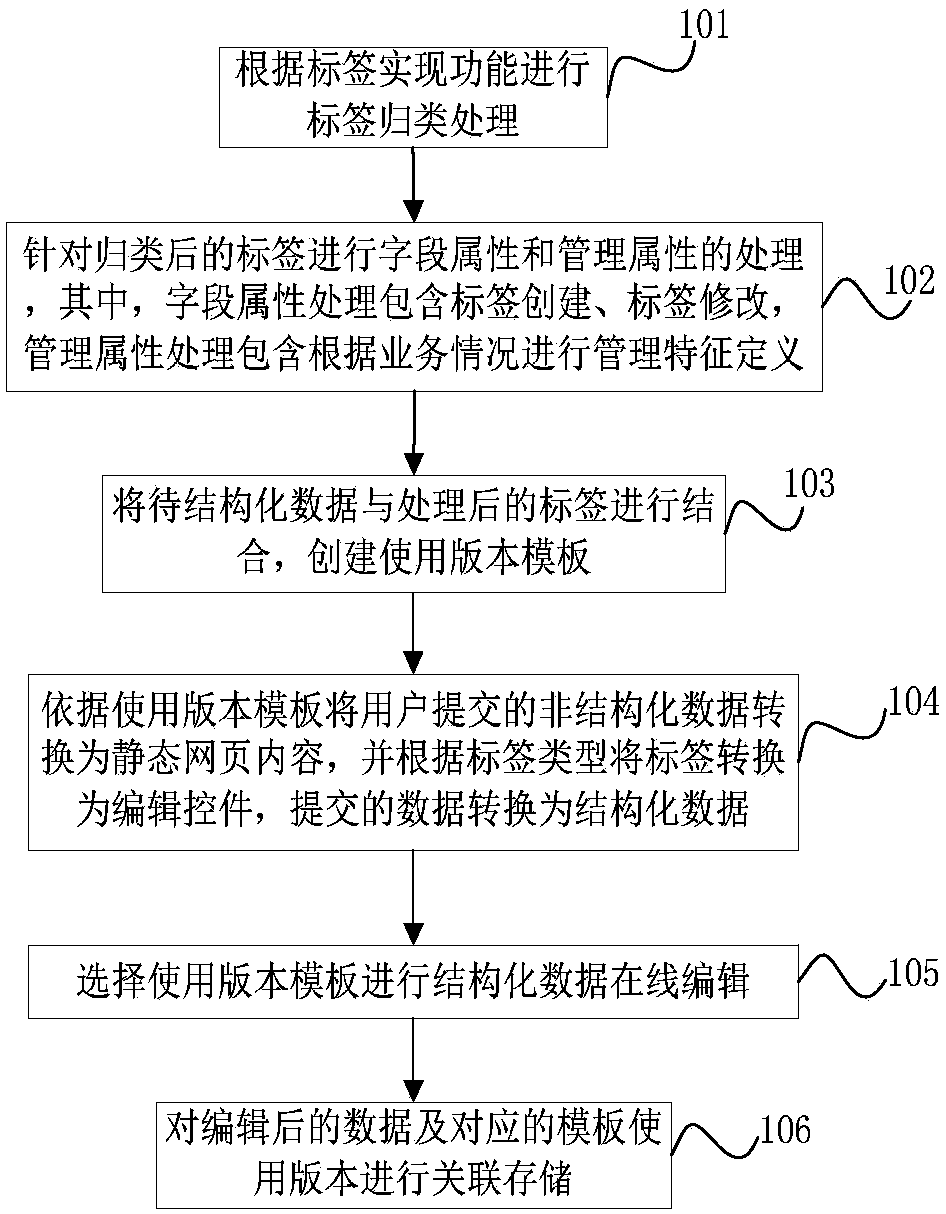

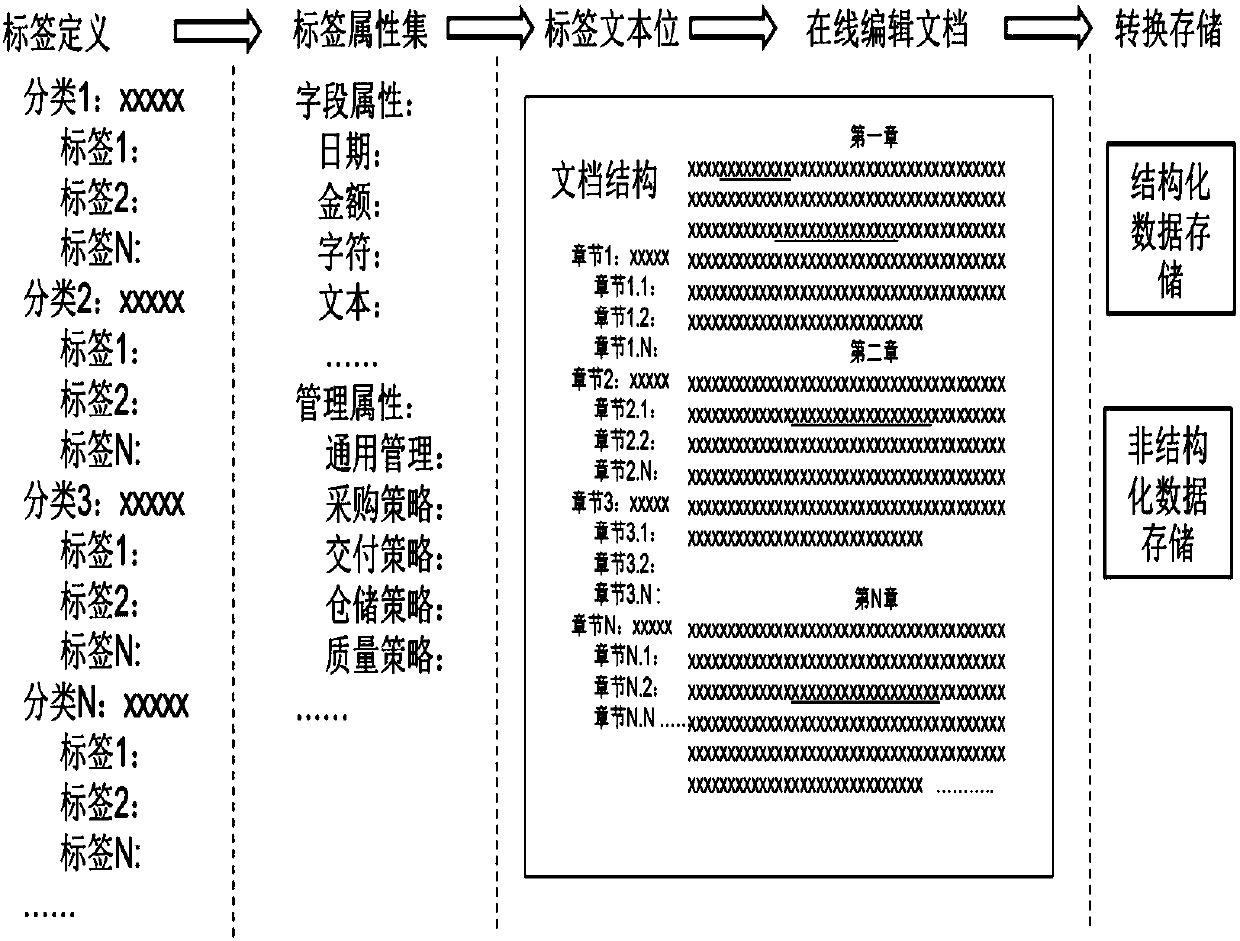

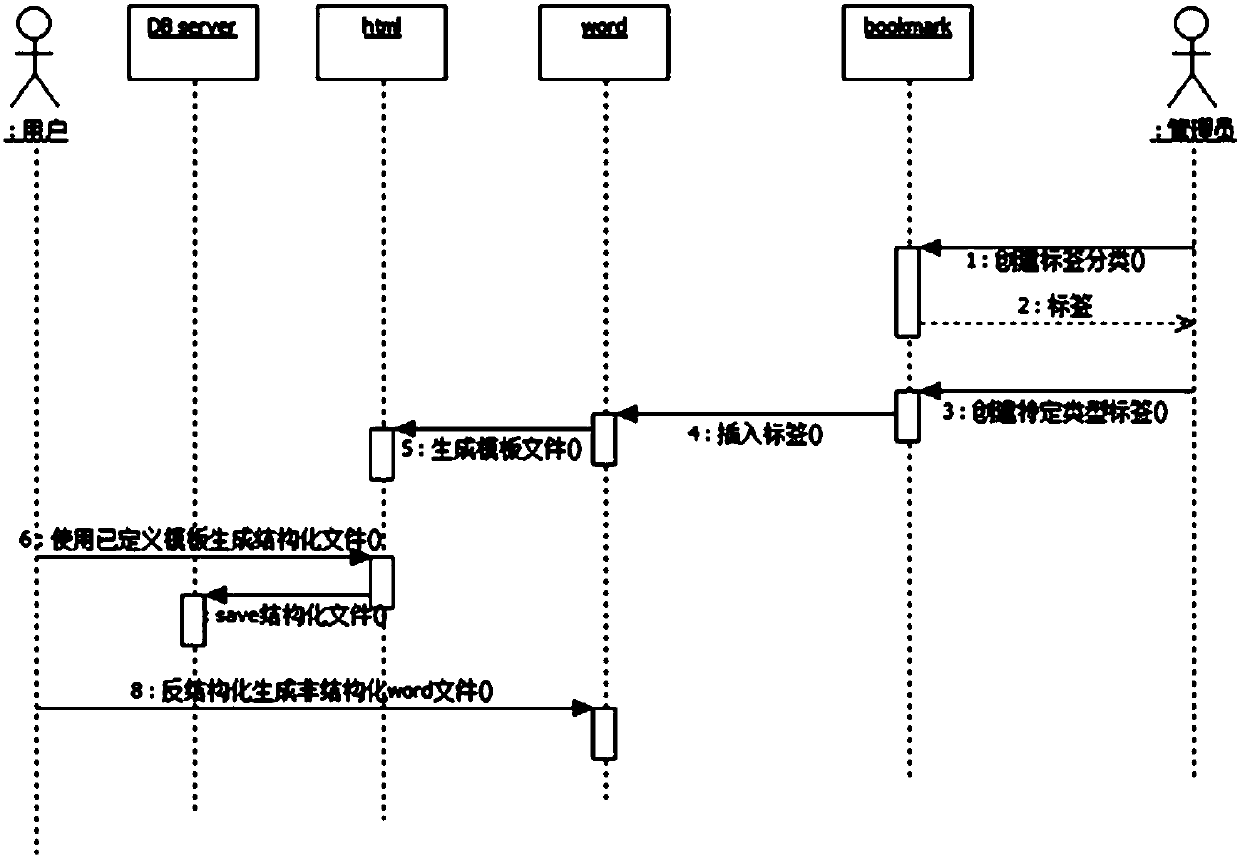

Non-structured data and structured data mutual conversion processing method

ActiveCN108021632AHigh outputPrecise positioningSpecial data processing applicationsText database clustering/classificationInformation processingData file

The invention belongs to the technical field of information processing, and particularly relates to a non-structured data and structured data mutual conversion processing method. The method comprisesthe steps of performing tag classification processing according to a tag realization function; for tags, performing field attribute and management attribute processing; combining to-be-structured datawith the tags, and creating a usage version template; according to the usage version template, converting the non-structured data submitted by a user into static webpage contents, and according to tag types, converting the tags into editable controls and converting the submitted data into structured data; selecting the usage version template to perform structured data online editing; and performing associated storage on the edited data and the corresponding template usage version. Through tag definition and template processing of non-structured data files and generation and conversion storageof non-structured data files, mutual conversion between the non-structured data and the structured data is realized, so that subsequent data analysis processing is facilitated. The method has relatively high application values.

Owner:XINYANG BRANCH HENAN CO LTD OF CHINA MOBILE COMM CORP +1

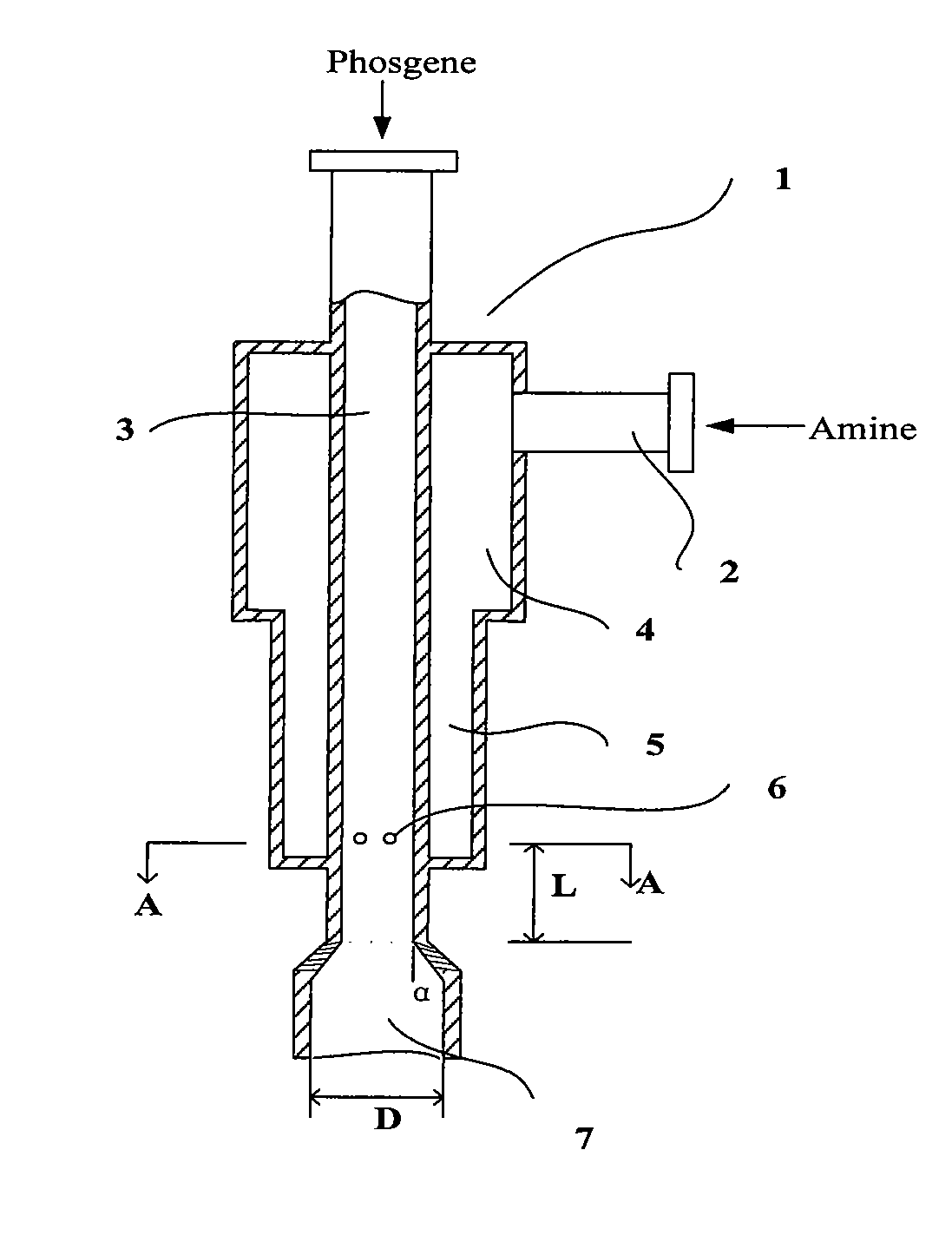

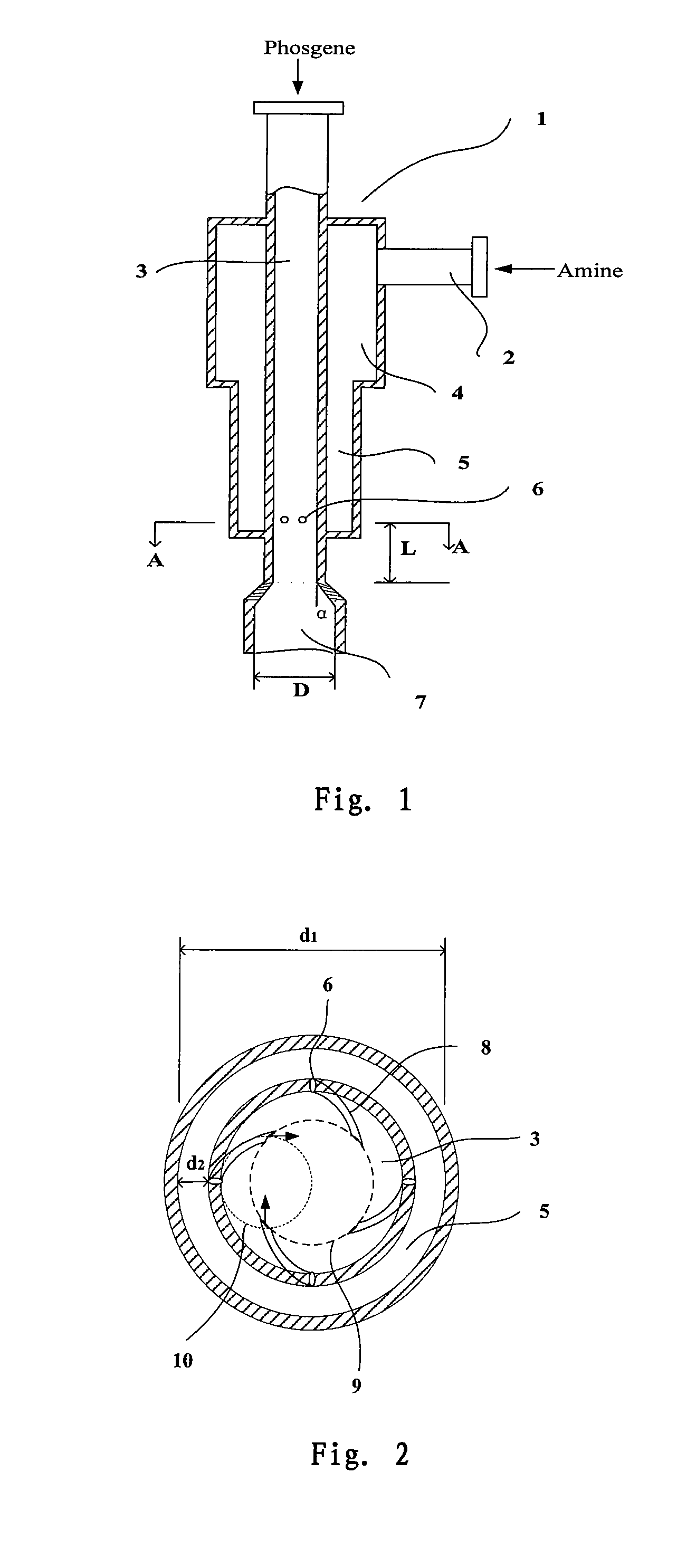

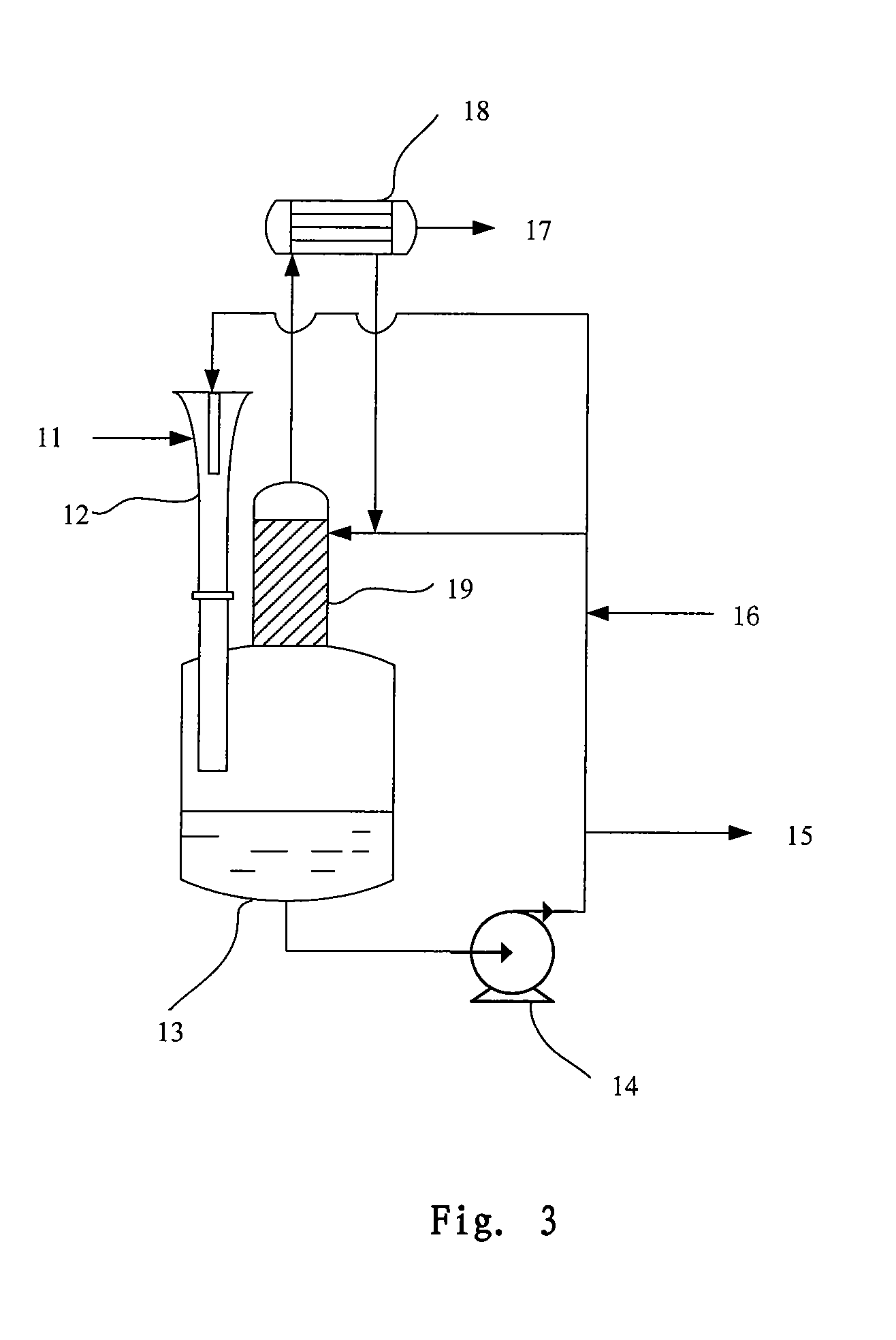

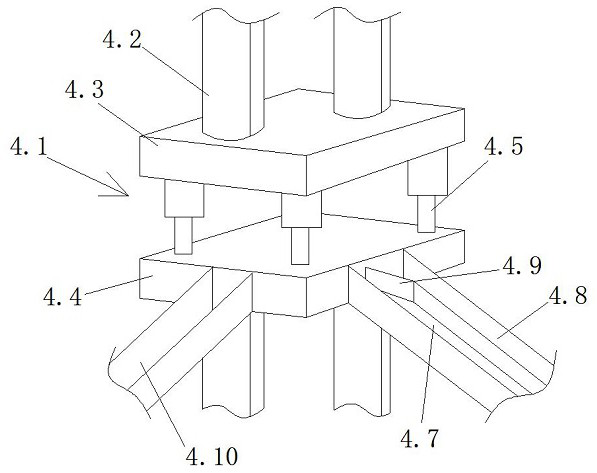

Jet reactor with flow ducts and process for preparing isocyanates using it

ActiveUS20110124907A1Lightweight productionLarge volume flow ratioIsocyanic acid derivatives preparationGaseous chemical processesProcess engineeringPhosgene

The present invention provides a flow duct type jet reactor and a process for preparing isocyanates using it. The flow duct type jet reactor situates flow ducts in inner feed pipe which form whirlpool and reinforce vortex, thereby amine steam rapidly admixes and reacts with phosgene, and the byproducts are reduced. In addition, the present process uses a jet-absorption apparatus which rapidly cools the high temperature gas discharged from the reactor to a temperature at which the product is thermally stable, and at the same time provides negative pressure for the reaction process of the system, and thus saving bulky vacuum system.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD

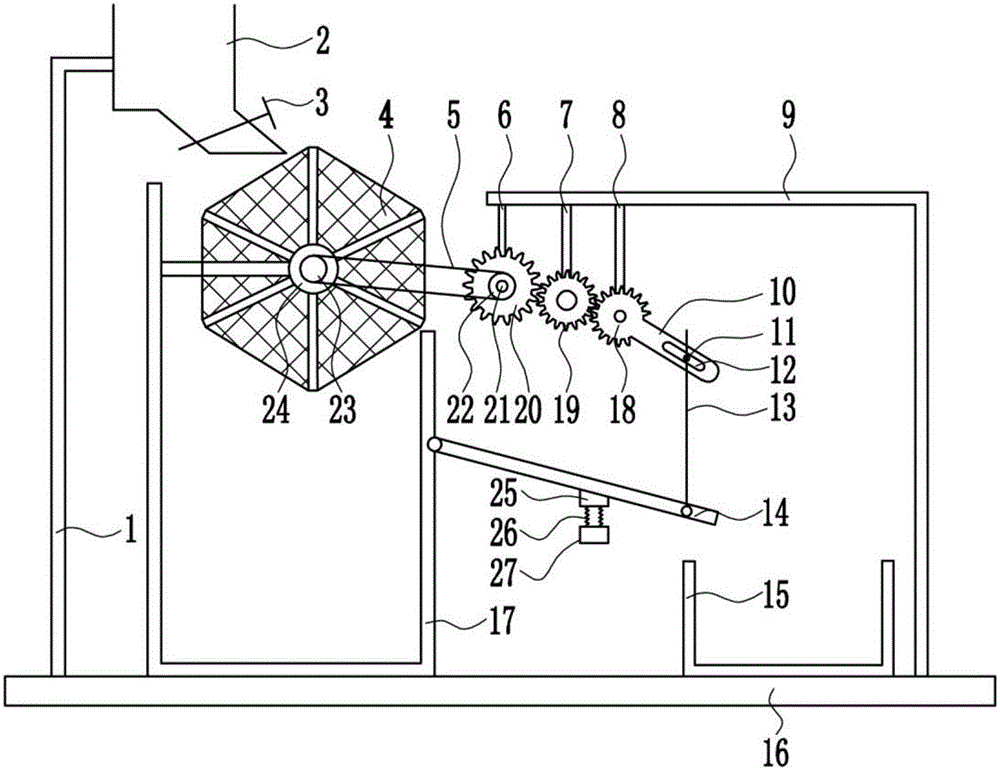

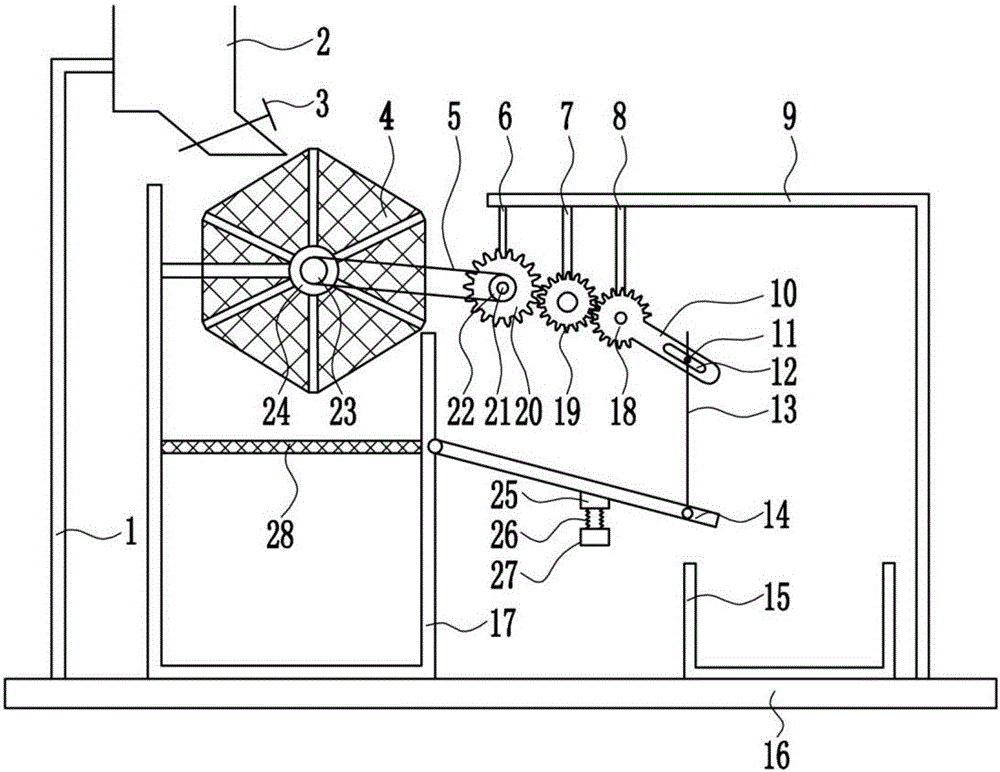

Cosmetic production wastewater after-treatment device

InactiveCN106215487AEasy to cleanImprove post-processing efficiencyMembrane filtersStationary filtering element filtersAfter treatmentLow leakage

The invention relates to a treatment device, in particular to a cosmetic production wastewater after-treatment device, and aims to solve the technical problem of providing the cosmetic production wastewater after-treatment device which is clean in wastewater treatment, easy to operate and low in cost. The cosmetic production wastewater after-treatment device which comprises a left bracket, a lower funnel, an electric control valve, a filter funnel, a flat belt, a first supporting rod, a second supporting rod, a third supporting rod, a right bracket, a swinging rod, a sliding shaft, a lifting rod, a lower leakage tank, a second collecting tank, a bottom plate, a first collecting tank, a third gear, a second gear and the like; the left bracket, the first collecting tank, the second collecting tank and the right bracket are arranged at the top of the bottom plate in sequence from left to right. The cosmetic production wastewater after-treatment device achieves the effects that wastewater is treated cleanly, the operation is simple and the cost is low; cosmetic production wastewater is subjected to after-treatment by utilizing the filter funnel of the device, so that large blocks of waste can be separated quickly.

Owner:张大伟

Preparing method of phenolic fibers

ActiveCN111501114AAchieve blendingRealize spinningSpinning head liquid feederArtificial thread manufacturing machinesFiberPolymer science

The invention discloses a preparing method of phenolic fibers. The method comprises the steps that phenolic resin and a spinning improver are evenly mixed, a mixed material is subjected to melt blending through a dual-screw extruder to form a melt, the melt enters a single-screw extruder, the fibers are sprayed out through a fiber spraying assembly, the fibers are sucked through a fiber sucking device, the fibers are conveyed to a fiber collecting device by a fiber conveying pipe, and phenolic fiber protofilaments are obtained; and the prepared phenolic fiber protofilaments are subjected to apre-crosslinking reaction in a solidifying solution composed of formaldehyde, hydrochloric acid and deionized water, a ladder type heating manner is adopted for carrying out a second-time crosslinkingreaction, and finally, at the high temperature, third-time crosslinking treatment is carried out. The spinning efficiency of the phenolic fiber protofilaments can be effectively improved, the phenolic fiber crosslinking reaction time can be shortened, and the phenolic fibers which are excellent in mechanical property, and high in char yield can be prepared.

Owner:TANGSHAN KAILUAN CHEM TECH CO LTD

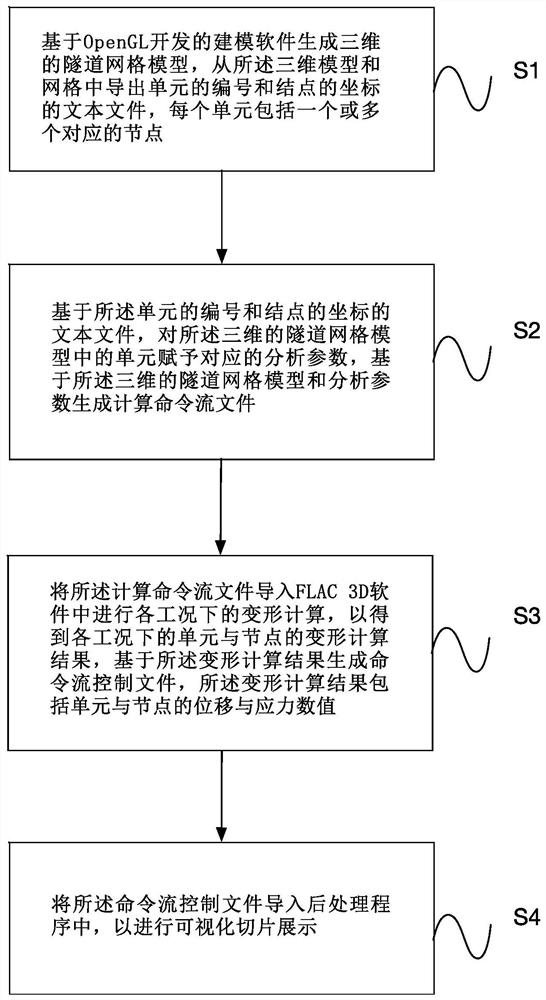

Tunnel deformation simulation calculation method and apparatus

PendingCN112613108AImprove post-processing efficiencyImprove post-optimization processing efficiencyGeometric CADDesign optimisation/simulationModeling softwareModelSim

The invention aims to provide a tunnel deformation simulation calculation method and apparatus, and the method comprises the steps: generating a three-dimensional tunnel grid model through modeling software developed based on OpenGL, and exporting a text file of the number of units and the coordinates of nodes from the three-dimensional tunnel grid model; giving corresponding analysis parameters to units in the three-dimensional tunnel grid model, and a calculation command stream file is generated based on the three-dimensional tunnel grid model and the analysis parameters; importing the calculation command stream file into FLAC 3D software to perform deformation calculation under each working condition so as to obtain deformation calculation results of the units and the nodes under each working condition, and generating a command stream control file based on the deformation calculation results, with the deformation calculation results including displacement and stress values of the units and the nodes; and importing the command stream control file into a post-processing program to perform visual slice display, so that the method can be suitable for numerical simulation users in the field of tunnels, and the post-processing efficiency of tunnel FLAC 3D three-dimensional numerical simulation can be improved and optimized.

Owner:CCCC SHANGHAI THIRD HARBOR SCI RES INST CO LTD +2

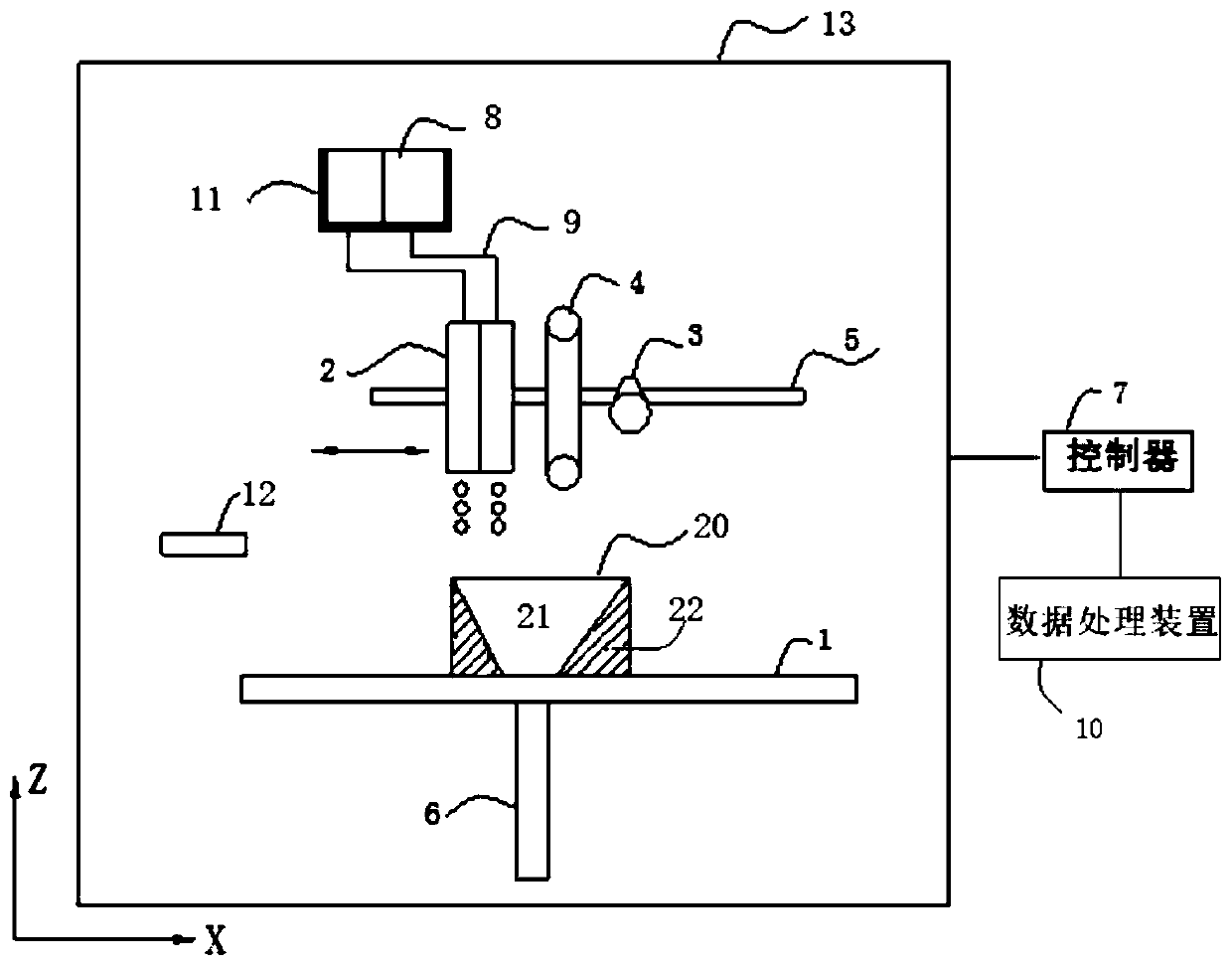

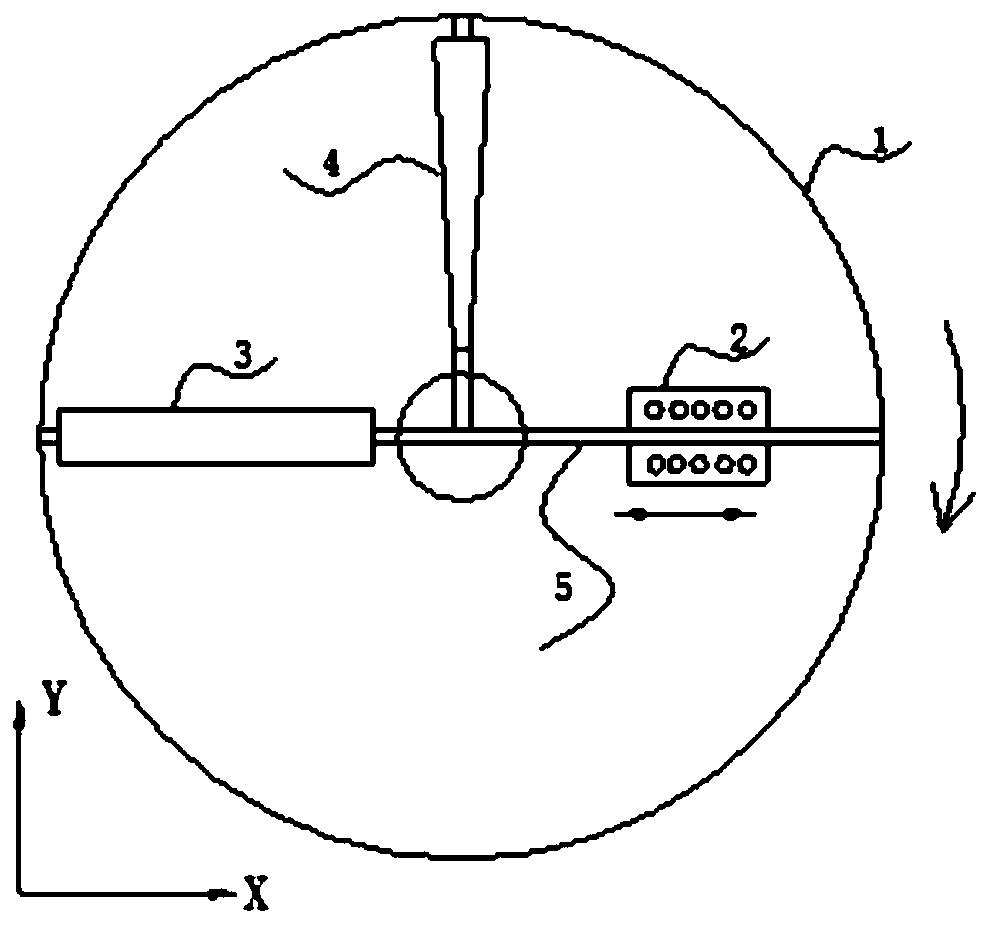

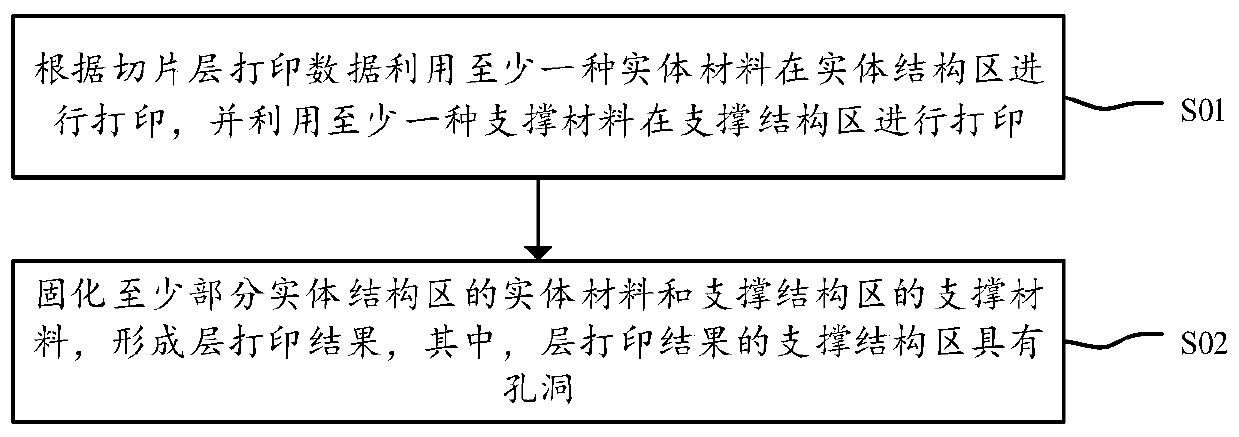

Three-dimensional object and printing method and printing device thereof

ActiveCN111409260AImprove post-processing efficiencyReduce post-processing costsAdditive manufacturing apparatus3D object support structuresSolid structureProcess engineering

The invention provides a three-dimensional object and a printing method and printing device thereof. The method comprises the steps of carrying out the printing in a solid structure region through employing at least one solid material according to slice layer printing data, and carrying out the printing in a supporting structure region through employing at least one supporting material; and solidifying at least part of the solid material of the solid structure region and the supporting material of the supporting structure region to form a layer printing result, wherein the supporting structurearea of the layer printing result is provided with holes. According to the three-dimensional object, when the three-dimensional object is soaked in liquid such as water, a water-based solution or analkaline solution, the liquid enters the supporting structure through the holes, so that the dissolution or swelling rate of the supporting structure is increased, the removal efficiency of the supporting structure is improved, and the treatment cost is reduced.

Owner:ZHUHAI SAILNER 3D TECH CO LTD

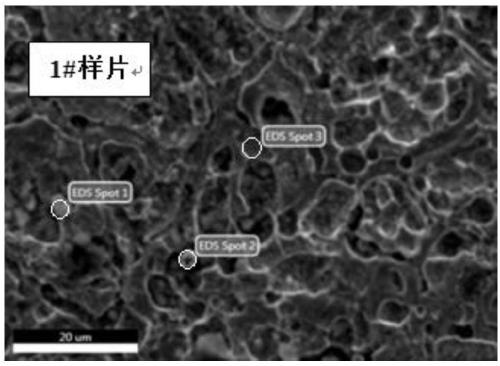

After-treatment equipment for improving surface roughness and strength of 3D printed stainless steel workpiece

ActiveCN108927521AEnhancing Additive Manufacturing BenefitsReduce voidsAdditive manufacturing apparatusSurface roughnessSS - Stainless steel

In a food machine, adopting 3D printed stainless steel workpiece is well required in the market, and therefore after-treatment equipment for improving the surface roughness and the strength of the 3Dprinted stainless steel workpiece is very important. The after-treatment equipment for improving the surface roughness and the strength of the 3D printed stainless steel workpiece comprises a base, ultrasonic power source power assemblies, a workpiece fixing device, an impact device and a roughness testing device. The workpiece fixing device comprises a locating device and a fastening device. Thetreated workpiece is arranged on the workpiece fixing device. The impact device comprises an impact platform, impact pressing heads, force application assemblies and moving mechanisms. The impact platform at least comprises two impact pressing heads. Each impact pressing head is connected with one independent force application assembly and one independent ultrasonic power source power assembly. Apressure sensor and a position clamping device are arranged in each force application assembly. According to the equipment, the ultrasonic impact manner is adopted for carrying out after-treatment onthe 3D printed stainless steel workpiece, the advantage of additional material manufacturing of the 3D printed stainless steel workpiece is further enhanced, and the equipment has a remarkable technology advantage and an application prospect.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

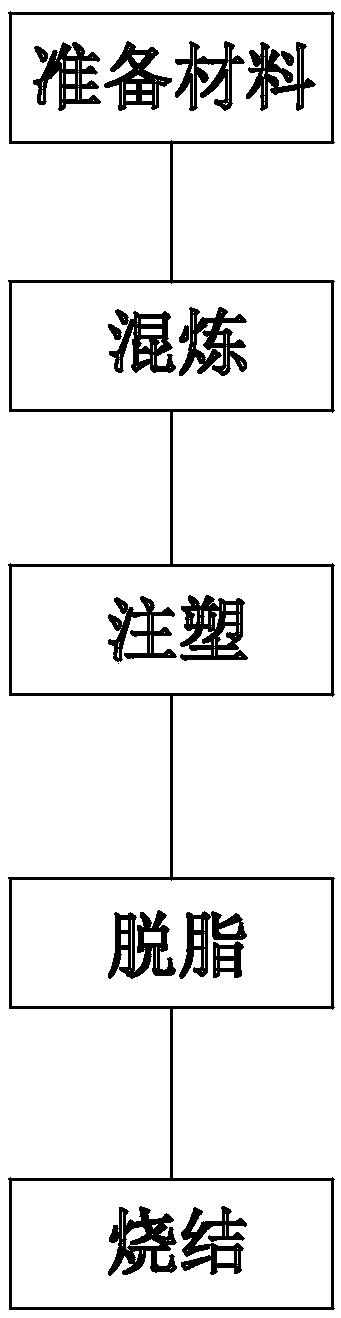

Manufacturing process of golf club head

InactiveCN107790726AHigh precisionTight weight toleranceTransportation and packagingMetal-working apparatusMicrometerAdhesive

The invention discloses a manufacturing process of a golf club head. The manufacturing process of the golf club head includes the following steps of material preparation, specifically, stainless steelpowder with the grain size D90 smaller than or equal to 22 micrometers is adopted, and adhesives are prepared; mixing, specifically, the stainless steel powder is preheated, then the adhesives are added, and banburying is conducted after the adhesives begin to melt; injection molding, specifically, the mixed materials are extruded from a mold cavity to be formed; degreasing, specifically, degreasing is catalyzed through nitric acid, so that the adhesives in a formed product are removed; and sintering, specifically, the degreased product is subjected to high-temperature sintering. According tothe manufacturing process of the golf club head, the final product is obtained through injection molding of the metal powder, degreasing and sintering, and the manufactured product is high in accuracy, small in weight tolerance, good in consistency and higher in post-machining efficiency with only a little post-machining; the product is good in consistency, and the playing experience of golf players is better; and equipment investment involved in the manufacturing process is low, and good economical benefits are achieved.

Owner:陈长春

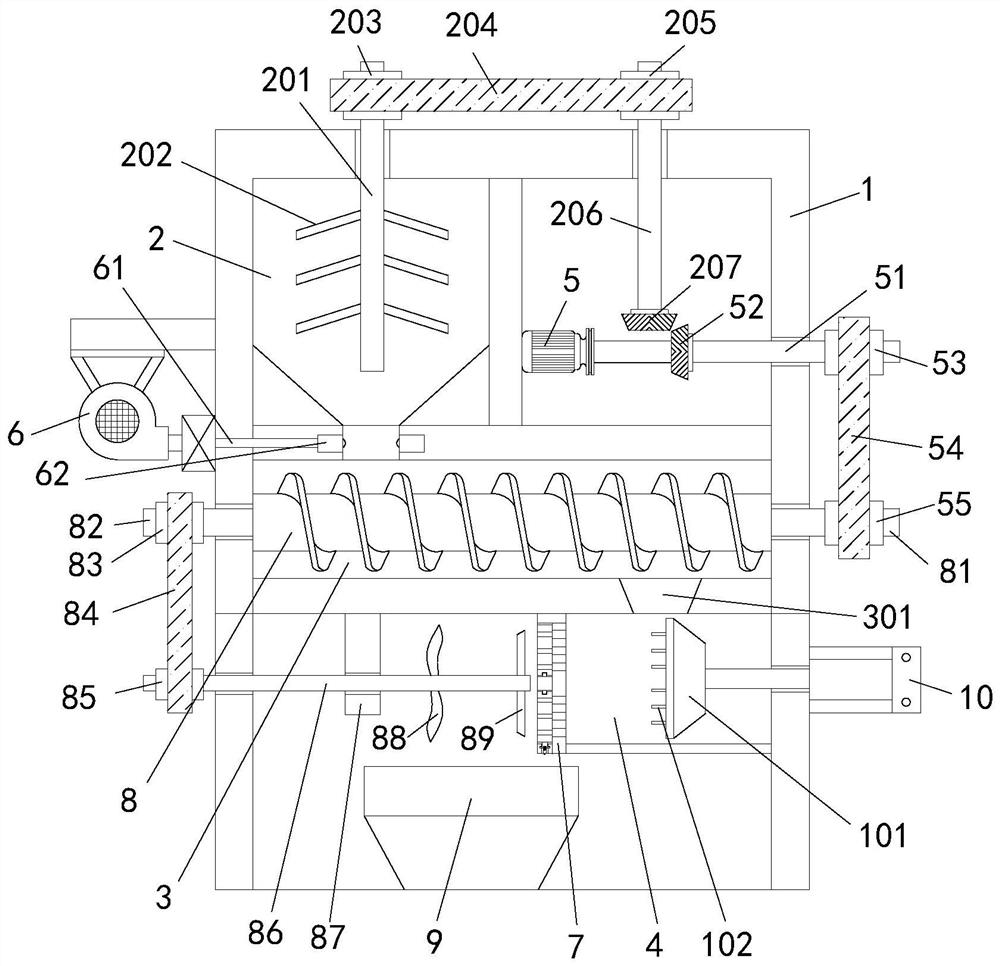

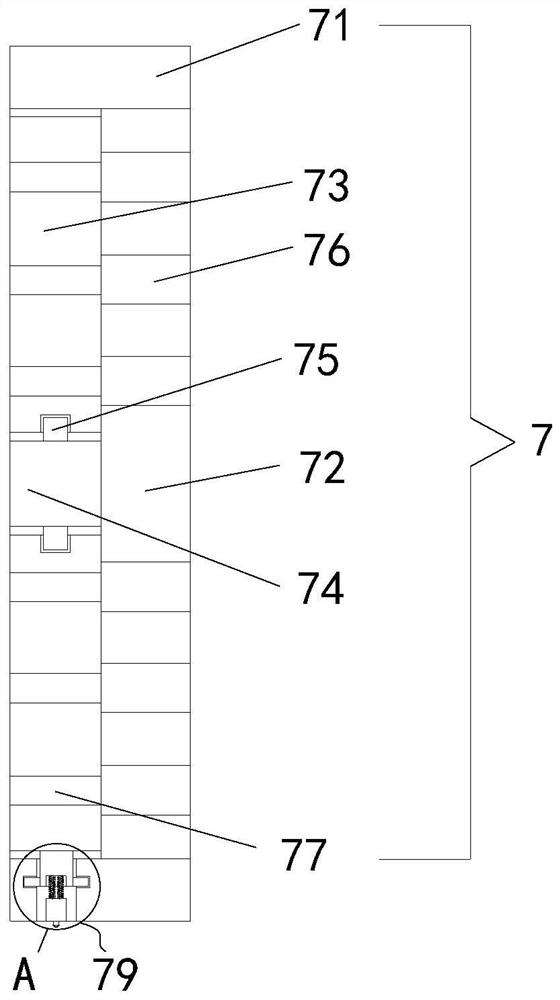

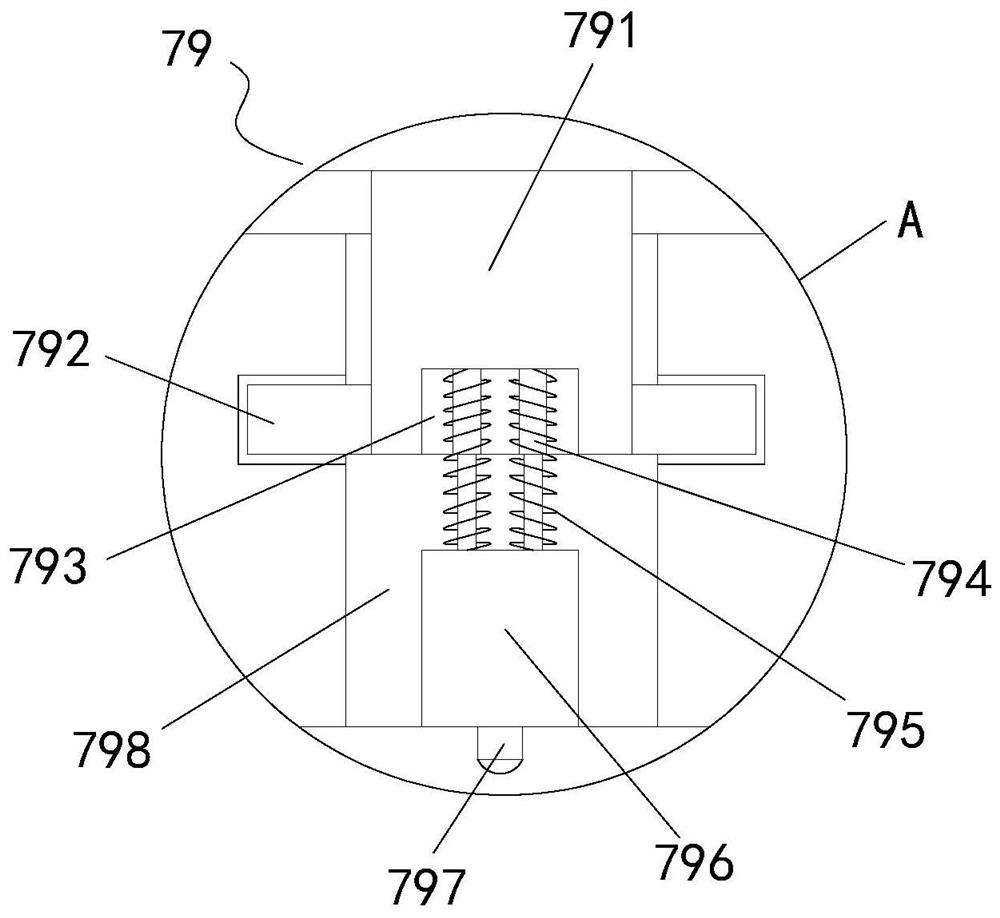

Adjustable granulation device for modified plastic production and processing

The invention discloses an adjustable granulation device for modified plastic production and processing. The adjustable granulation device comprises a device body shell, a stirring chamber, a spiral feeding chamber and a granulation chamber, the stirring chamber, the spiral feeding chamber and the granulation chamber are arranged in the device body shell and sequentially communicate from top to bottom, and a spiral rod is horizontally arranged in the spiral feeding chamber. A first main shaft and a second main shaft are arranged at two ends of the spiral rod correspondingly, and the spiral feeding chamber communicates with the granulation chamber through a discharging opening. An air cylinder is arranged on the outer wall of the granulation chamber, the output end of the air cylinder is connected with a push plate through a piston rod, a plurality of ejector pins are arranged on the side wall of the push plate, and an extrusion adjusting device is arranged at the end, opposite to the air cylinder, of the granulation chamber. According to the device, the defects in the prior art are overcome, the design is reasonable, the granulation of particles with different particle sizes can be achieved by adjusting the extrusion adjusting device under the condition that the device is not disassembled, the production and processing efficiency is greatly improved, and the social use value and the application prospect are relatively high.

Owner:合肥市丽红塑胶材料有限公司

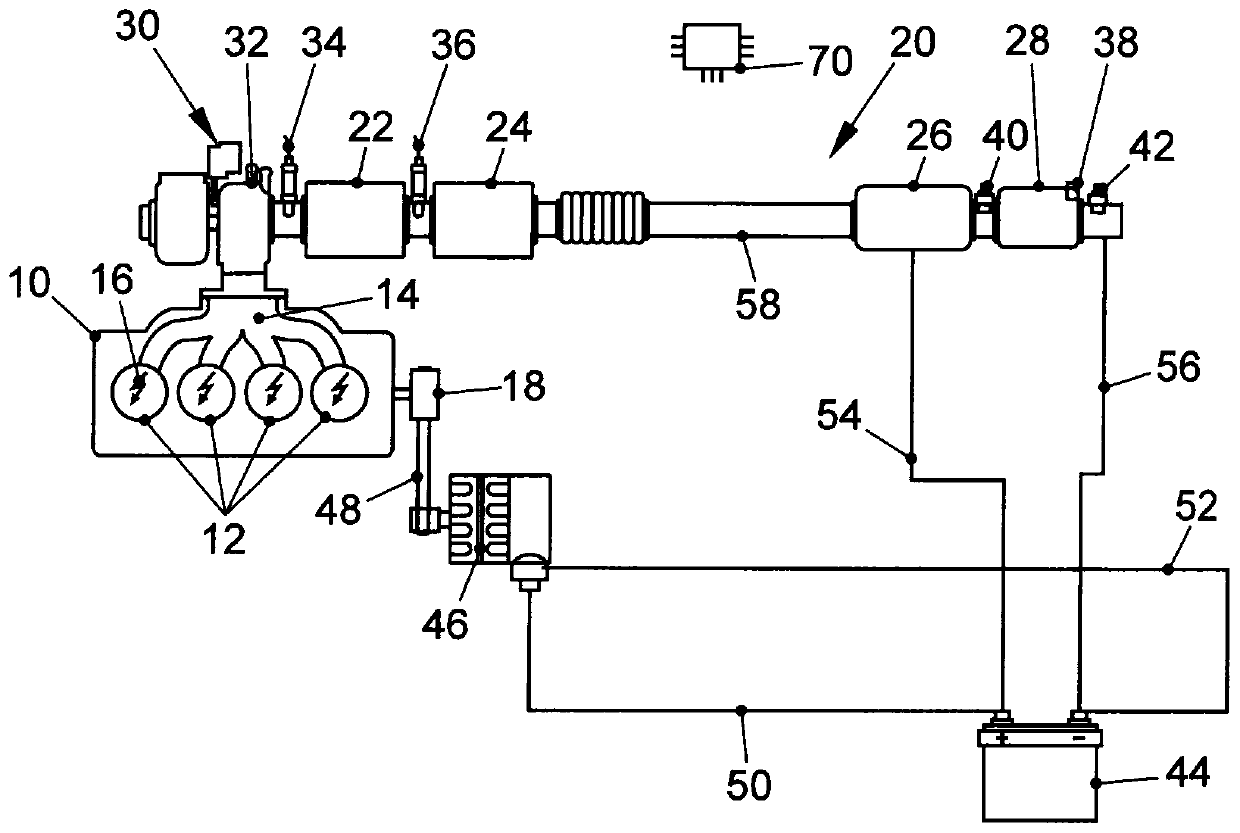

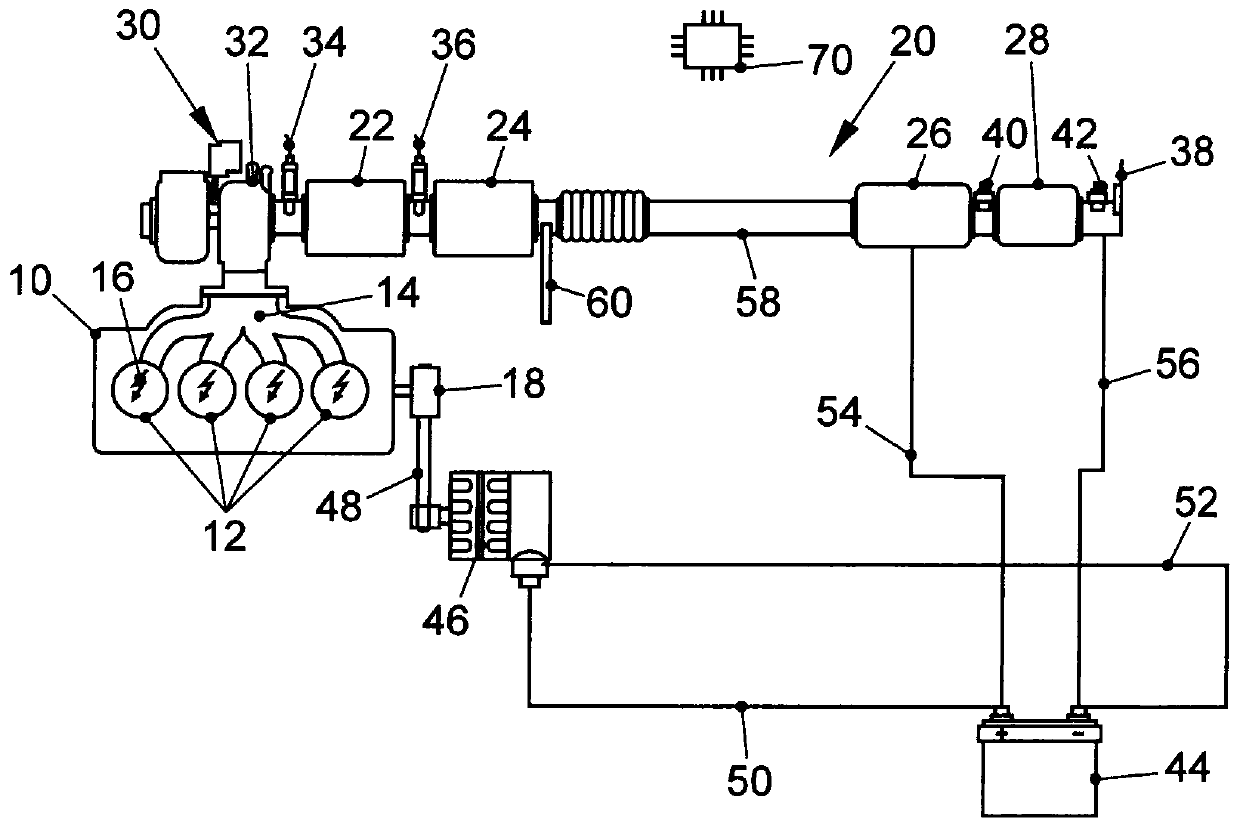

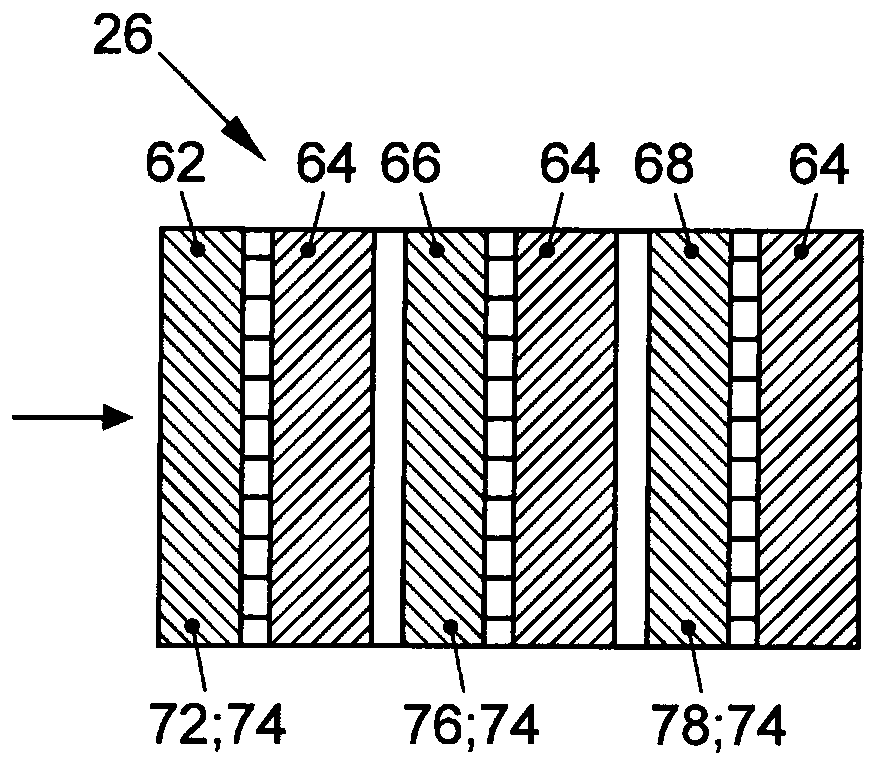

Exhaustion aftertreatment system and method for regenerating a particle filter

ActiveCN110593999AAvoid local overheatingReduced risk of thermal injuryGas treatmentInternal combustion piston enginesParticulatesEngineering

Owner:VOLKSWAGEN AG

Electrochemistry in-situ dirt removing method of radioactive contaminant on surface of metal

ActiveCN109295493AWon't wasteHigh decontamination precisionElectrolysis componentsLiquid wasteLiquid storage tank

The invention discloses an electrochemistry in-situ dirt removing method of radioactive contaminant on the surface of metal. A liquid storage tank is involved in the method. A cathode plate is installed below the liquid storage tank. A guide wire is connected to the cathode plate. A through hole is formed in the bottom of the liquid storage tank. The bottom of the through hole penetrates through the liquid storage tank and the cathode plate sequentially. An anode contactor is detachably connected to the exterior of the liquid storage tank. The anode contactor is provided with a storing cavityused for storing the cathode plate. The anode contactor is provided with a ring-shaped sealing part. The interior of the ring-shaped sealing part and the bottom face of the anode contactor form a washing cavity. An opening is formed in the bottom of the anode contactor. The opening communicates with the storing cavity and the washing cavity. According to the method, for the small contaminant area,fixed-point in-situ dirt removing can be carried out on the radionuclide area by means of the washing cavity formed by the anode contactor and the ring-shaped sealing part, the dirt removing precision is high, the dirt removing effect is good, the electrolyte solution is prevented from being wasted on the surface of the metal which does not need to be washed, the washing cost is saved, and the amount of second-time waste liquid is small.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

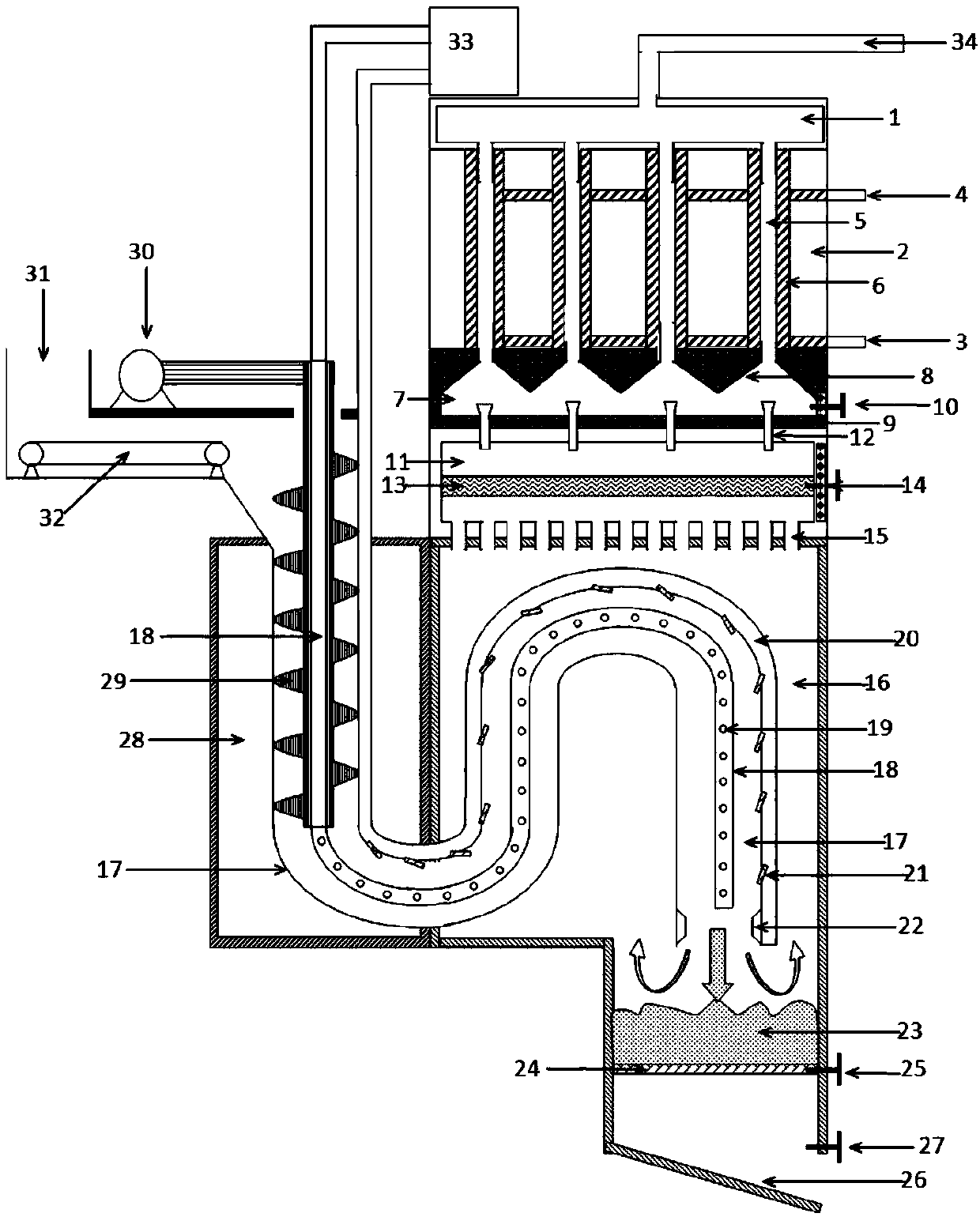

Normal-pressure fixed bed biomass gasification furnace and biomass normal-pressure gasification method

ActiveCN109536207AImprove gasification efficiencyThe overall structure is compactGasification processes detailsCombustible gas productionProcess engineeringFixed bed

The invention provides a normal-pressure fixed bed biomass gasification furnace and a biomass normal-pressure gasification method. The gasification furnace comprises a gas collecting chamber, condensation chambers, a deoiling chamber, a dust removal chamber, a gasification chamber, a doughnut shape-like gasification pipeline, a first gasification agent pipeline, a second gasification agent pipeline, a drying preheating chamber, a screw pushing mechanism, a feeding conveying mechanism and a gasification agent chamber, the doughnut shape-like gasification pipeline is arranged in the drying preheating chamber and the gasification chamber, the screw pushing mechanism is arranged in the doughnut shape-like gasification pipeline, the gasification agent chamber is connected to the first gasification agent pipeline and the second gasification agent pipeline, the first gasification agent pipeline extends along the central axis inside the doughnut shape-like gasification pipeline, the second gasification agent pipeline extends in a manner clinging to the outer wall of the doughnut shape-like gasification pipeline, each of the first gasification agent pipeline and the second gasification agent pipeline is provided with a plurality of gasification agent outlets, the dust removal chamber is arranged above the gasification chamber, the deoiling chamber is arranged above the dust removal chamber, the condensation chambers are arranged above the deoiling chamber, and the gas collecting chamber is arranged above the condensation chambers. The gasification furnace has the advantages of integral integration, high gasification efficiency and wide application range.

Owner:GUANGDONG LOONGCHING ENERGY SAVING ENVIRONMENTAL PROTECTION TECH

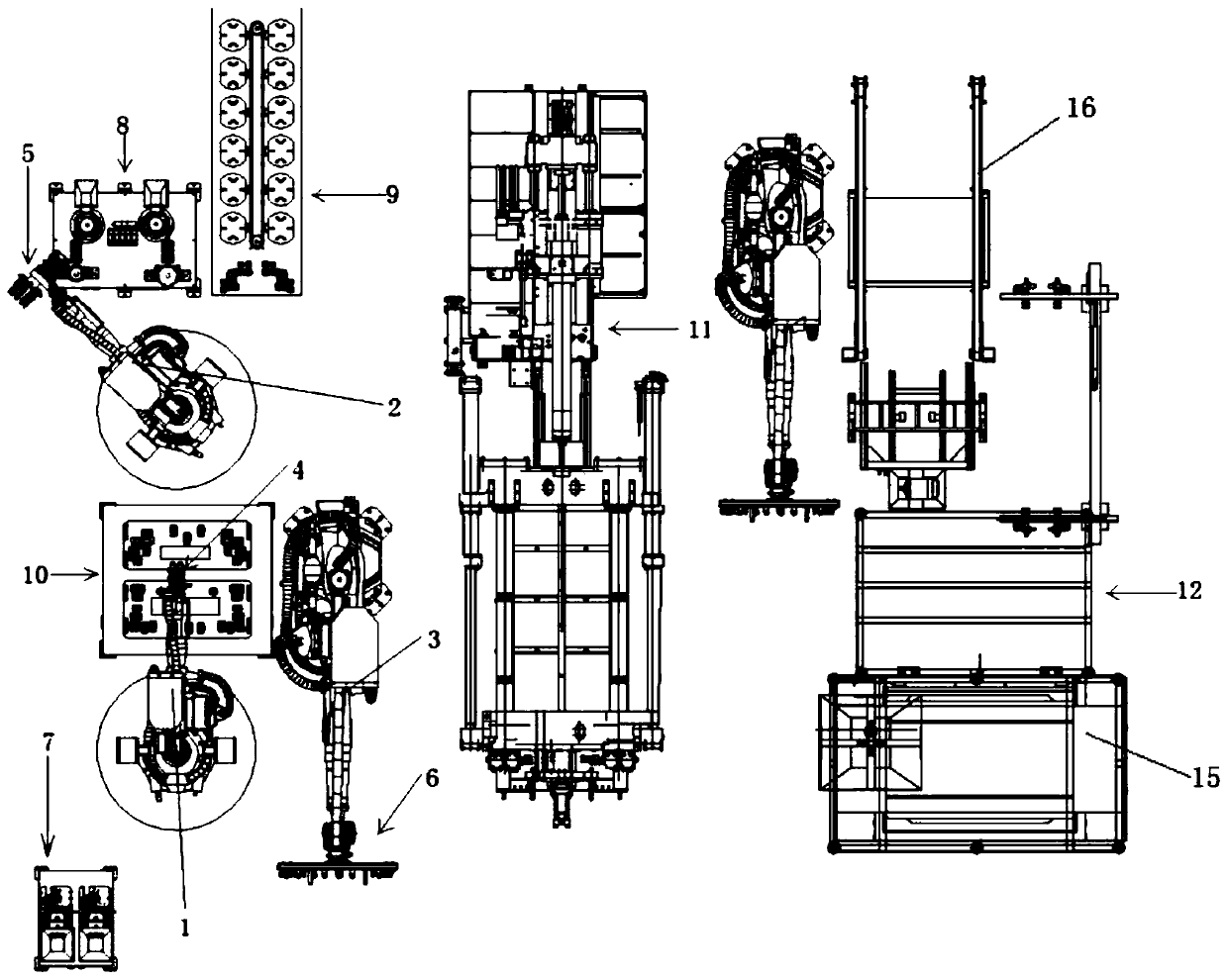

Automatic production equipment of automobile injection molding parts

The invention relates to an insert installing mechanism in automatic production equipment of an automobile injection molding parts. The complete automation of an insert clamping and placing process is realized, labor is saved, production efficiency is improved, possible manual errors are effectively avoided, and meanwhile, product quality and production stability are improved; the injection molding parts are rapidly conveyed among all stations of the post-treatment, so that the post-treatment efficiency is improved, the space occupation is small, the cost is low, the machining and transferring of all after-treatment stations can be completed by only one mechanical arm, and the efficiency is improved; and after the injection molding parts are produced, the injection molding parts are placed on a multi-layer storage rack through a special forklift, the injection molding parts can be separately placed, the forklift is convenient and rapid to transport, and the occupied space is reduced.

Owner:江阴名旭模塑有限公司

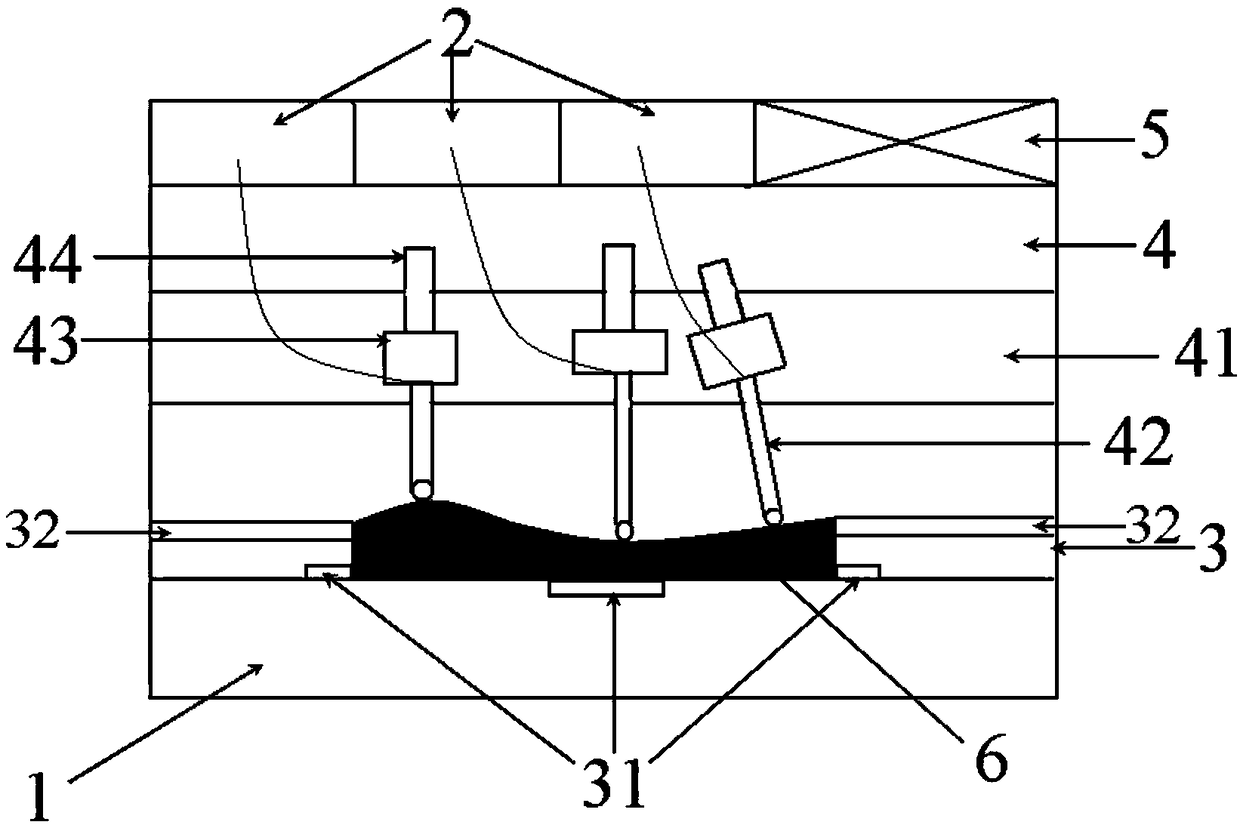

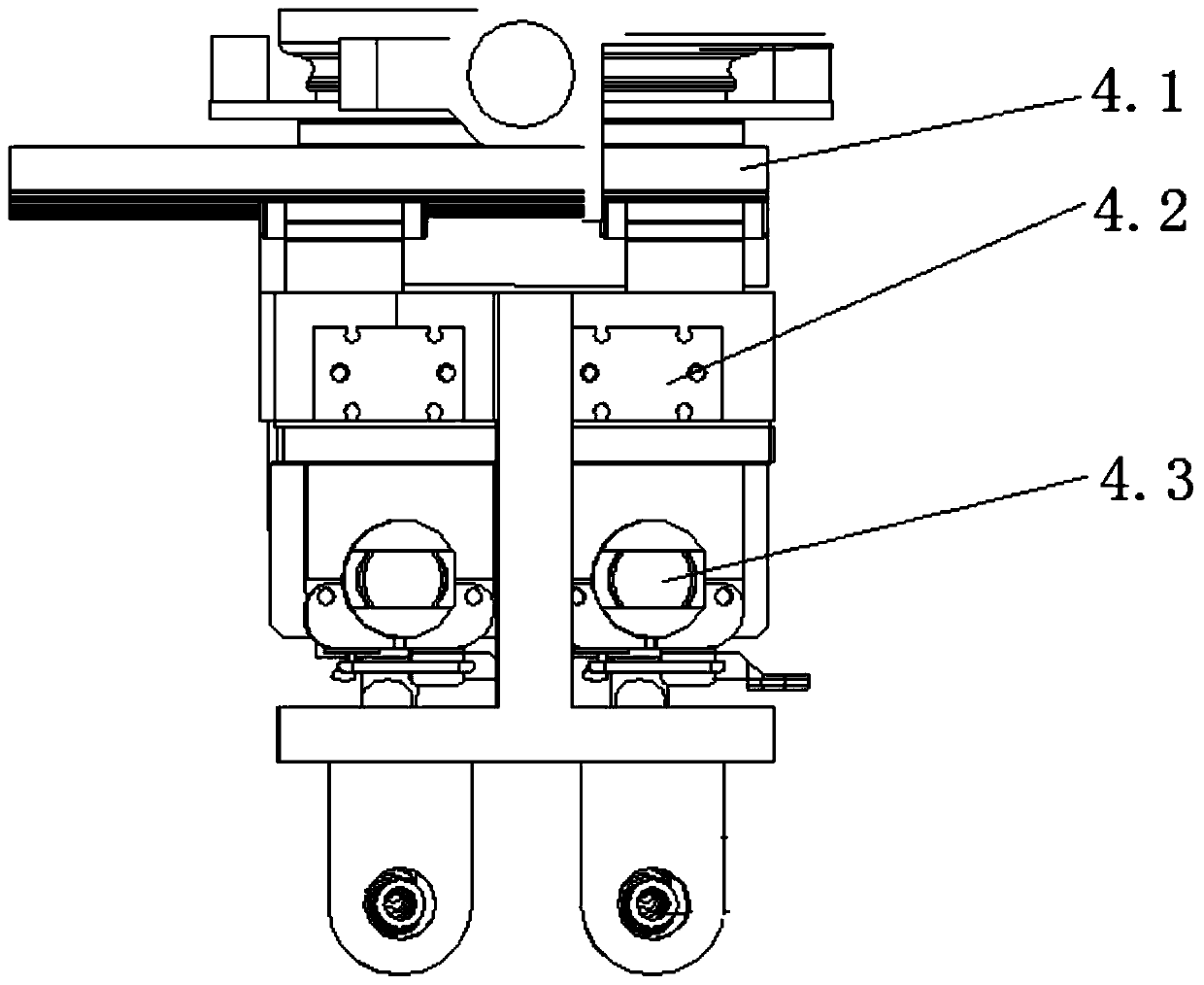

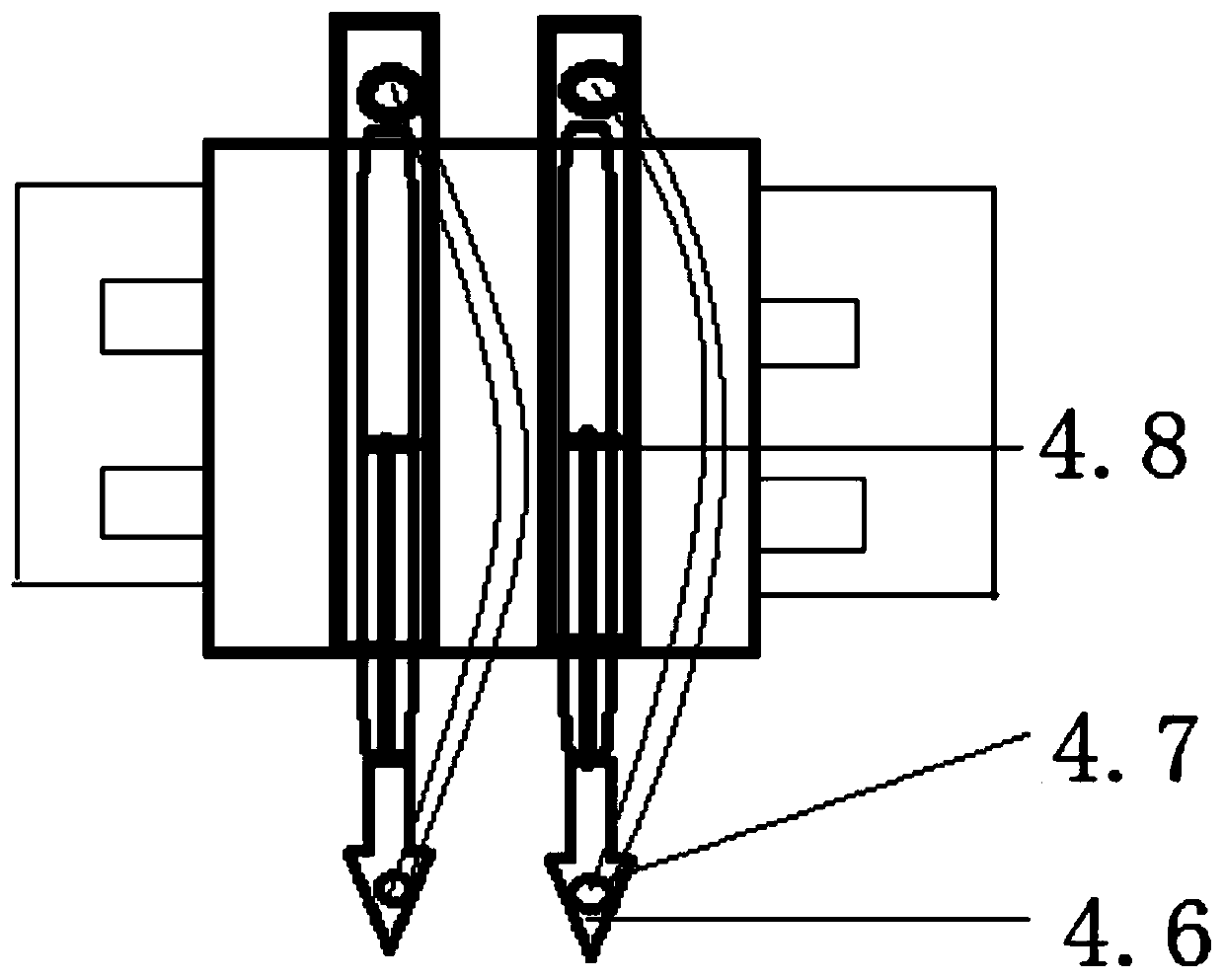

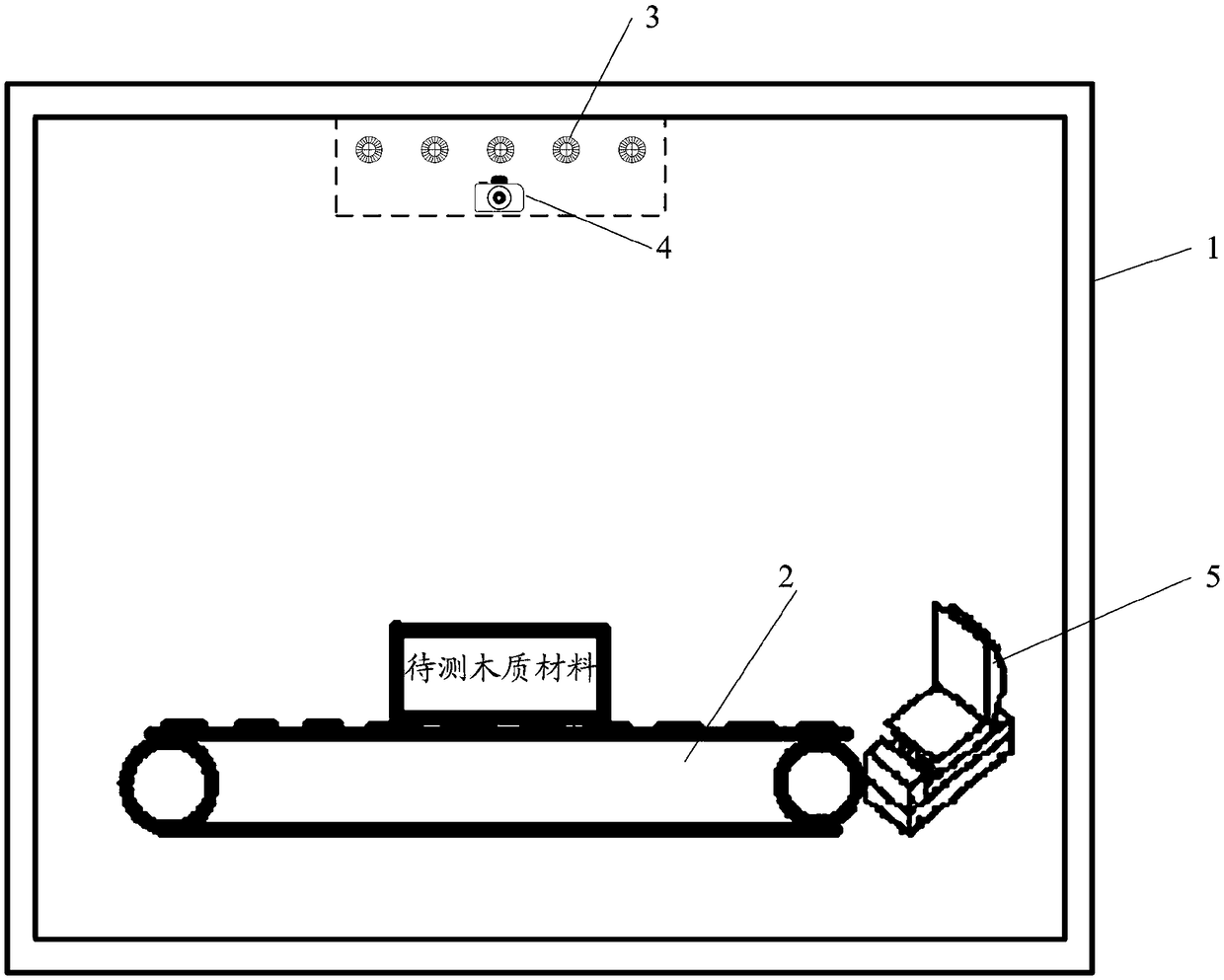

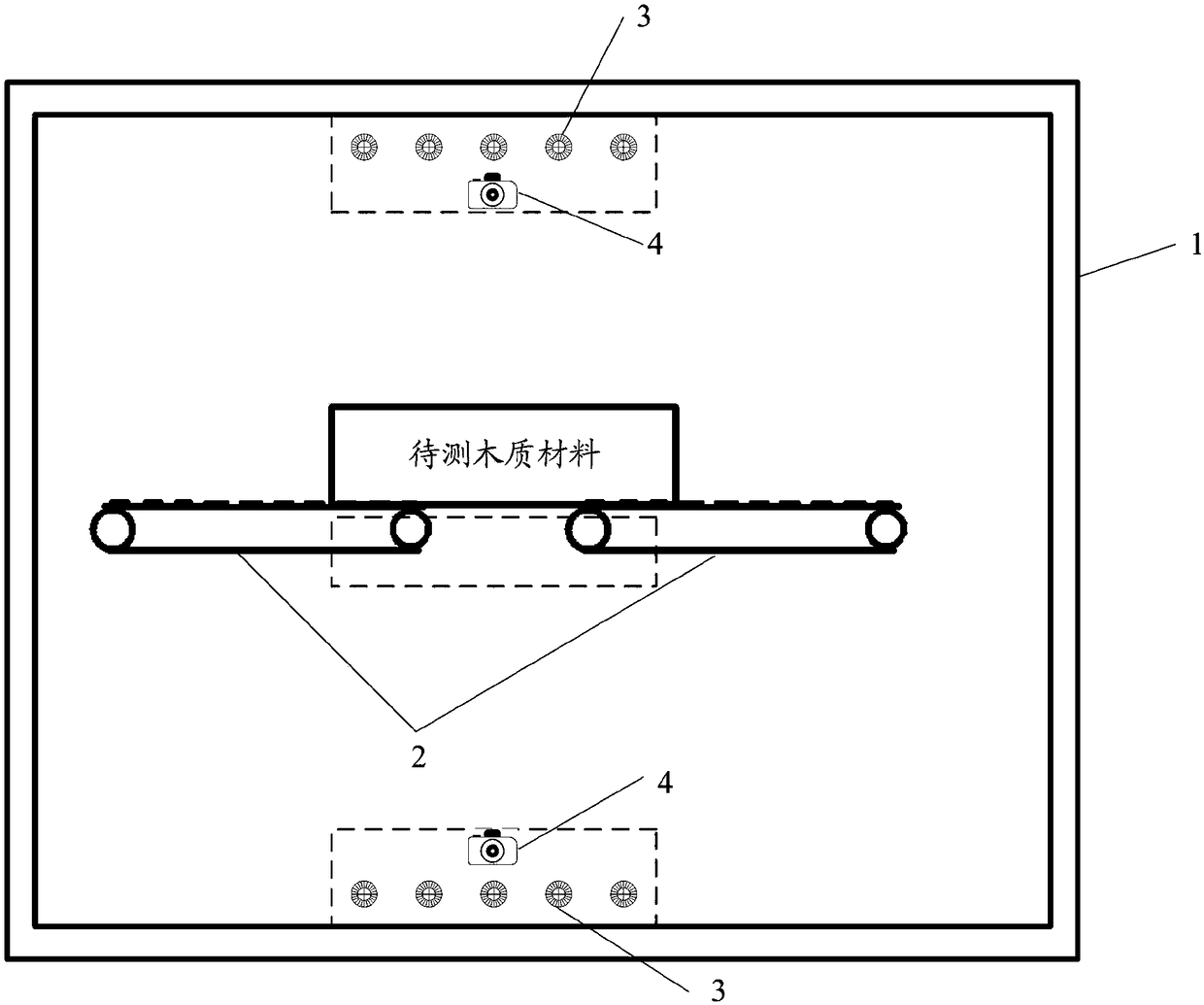

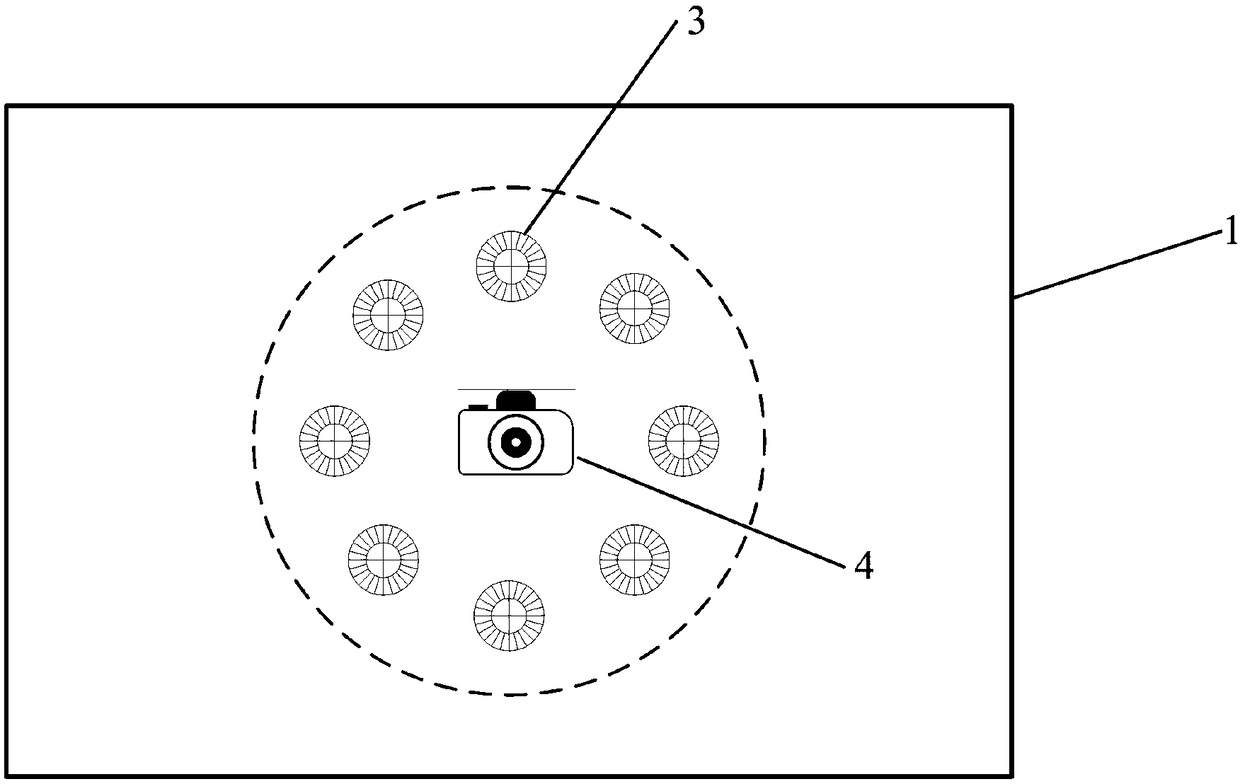

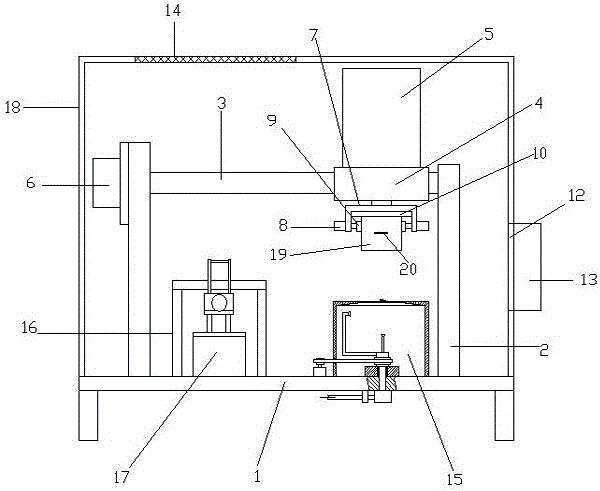

Wood material defect detection apparatus and method thereof

PendingCN108398431ARealize double-sided detectionQuality improvementOptically investigating flaws/contaminationMaterial defectEngineering

The invention discloses a wood material defect detection apparatus and a method thereof. The apparatus comprises a detection tank body, a conveyor belt, a lamp source, a camera, and a controller; theconveyor belt, the lamp source and the camera are placed in the detection tank body, the lamp source and the camera are fixed over the conveyor belt, a detection area is indicated at the conveyor belt, the detection area are also indicated at an end surface of the detection tank body, the lamp source is fixed in the detection area of the detection tank body, the lamp source number is multiple, andthe lamp sources are uniformly distributed in the detection area, and the lamp sources are used for providing light with equal brightness for the detection area of the conveyor belt while detecting;the camera is fixed in the detection area at the end surface of the detection tank body, an output terminal of the camera is connected with the input terminal of a controller, the camera is used for taking pictures of a to-be-detected wood material, and transmitting the pictures to the controller for processing; and the controller is used for obtaining a defect parameter of the to-be-detected woodmaterial according to the pictures transmitted by the camera. The apparatus and the method can increase the detection precision and efficiency.

Owner:BEIJING FORESTRY UNIVERSITY +1

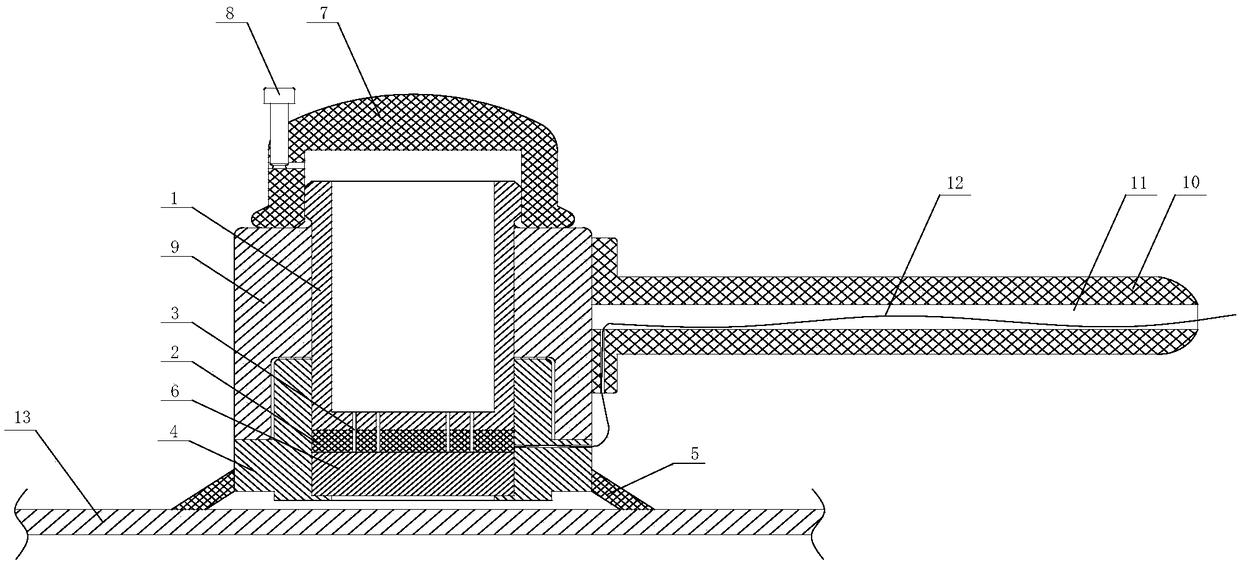

Magnetic core after-treatment device

ActiveCN105903850AImprove post-processing efficiencyImprove processing efficiencyLiquid surface applicatorsSpraying apparatusMagnetic coreAfter treatment

The invention relates to the technical field of magnetic core manufacturing and discloses a magnetic core after-treatment device. The magnetic core after-treatment device comprises a base plate. Supporting plates are arranged at the two ends of the base plate. A sliding rail is arranged between the upper ends of the supporting plates. A sliding seat is arranged on the sliding rail. A main air cylinder is arranged on the sliding seat. A main threaded rod is arranged between the supporting plates. A main motor used for driving the main threaded rod to rotate is arranged on one of the supporting plates. A U-shaped plate is arranged at the shaft end of the main air cylinder. Horizontal clamping air cylinders are arranged on the two sides of the U-shaped plate. A clamping block is arranged at the shaft end of each clamping air cylinder. An automatic paint spraying mechanism is arranged at the right end of the base plate. A supporting seat is arranged at the left end of the base plate. An electrode bending mechanism is arranged below the supporting seat. The base plate is further provided with a dust cover. An air inlet is formed in the top of the dust cover. A filter screen is arranged in the position of the air inlet. An exhaust port is formed in the side face of the dust cover. An exhaust fan is arranged in the position of the exhaust port. The magnetic core after-treatment device has the beneficial effects that automatic paint spraying can be achieved before bending of a magnetic core electrode, the electrode is automatically bent after paint spraying, and the magnetic core after-treatment efficiency is improved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Positive and negative end orientation picking machine used for lithium battery recovery

ActiveCN111017512AEasy to handle differentlyImprove post-processing efficiencyConveyorsControl devices for conveyorsStructural engineeringElectrical and Electronics engineering

The invention discloses a positive and negative end orientation picking machine used for lithium battery recovery. The picking machine comprises a machine body. A shaking device is arranged on the upper side of the interior of the machine body. A shaking cavity with an upward opening is formed in the shaking device. A shaking box is arranged in the shaking cavity in a left-right sliding mode. A storage cavity provided with an upward opening and used for storing a battery is formed in the shaking box. A falling outlet with a downward opening is formed in the right end of the lower wall of the storage cavity in a communicating mode. A falling channel is formed in the position, right facing the lower side of the falling outlet, of the lower wall of the shaking cavity. A picking device is arranged on the lower side of the interior of the machine body. According to the positive and negative end orientation picking machine used for lithium battery recovery, recovered batteries fall one by one in a shaking mode and are sorted, then the lithium batteries with different positive and negative pole orientations are picked, the batteries with the same positive and negative orientation are classified, conveyed and collected separately, accordingly, the batteries are effectively recovered and sorted, different treatment on positive and negative poles when the batteries are treated in a laterperiod is facilitated, and the post-treatment efficiency is improved.

Owner:徐州储盈电子科技有限公司

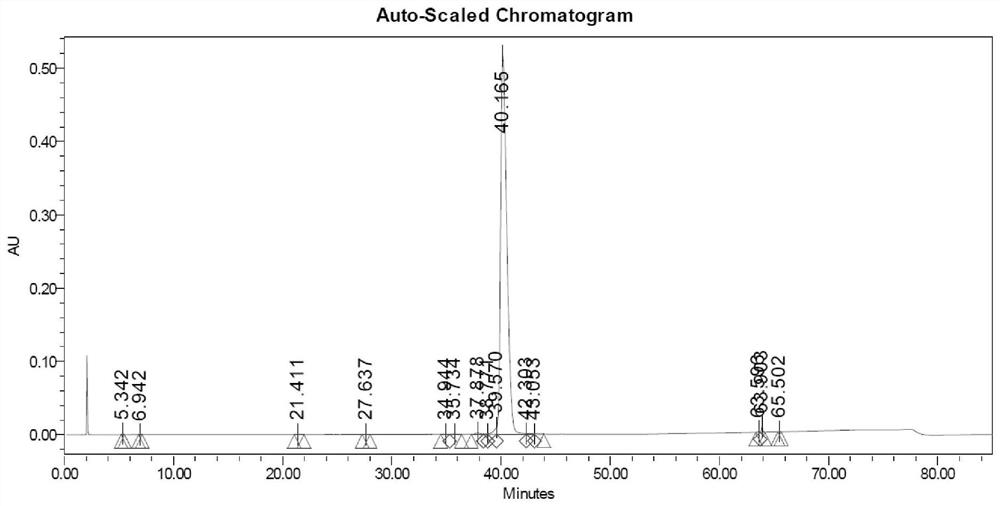

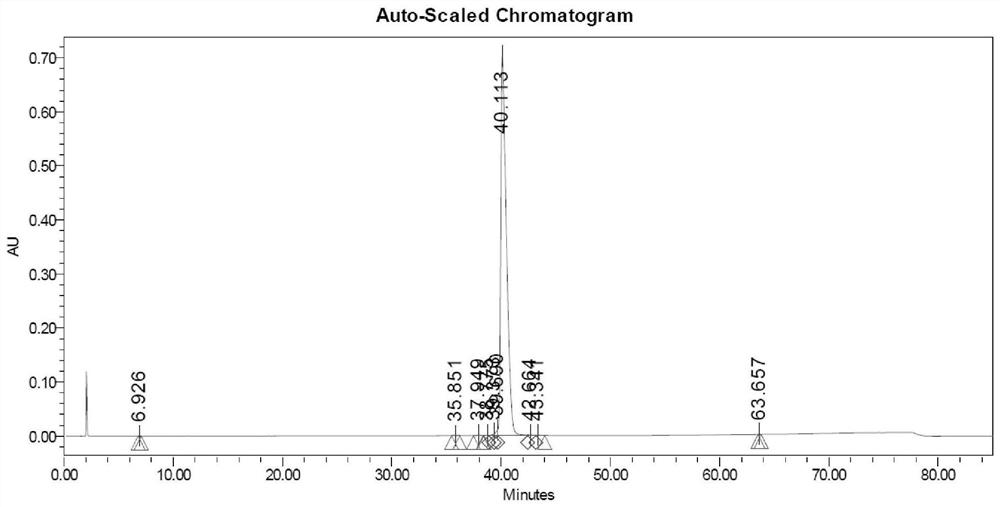

Method for purifying semaglutide

InactiveCN111848777AReduce typesImprove chromatographic conditionsPeptide preparation methodsGlucagonsOrganosolvFreeze dry

The invention relates to the field of purification of polypeptide drugs, in particular to a purification preparation method for synthesizing semaglutide by a solid-phase fragment method. According tothe preparation method, column chromatography is combined with a membrane separation technology to obtain higher product purity and yield and solve the technical problem of large-scale preparation atpresent. The preparation method comprises the following steps: dissolving crude semaglutide synthesized by a solid-phase fragment method into an acetic acid aqueous solution; filtering by using a ceramic membrane, separating and purifying by using a reversed-phase C8 filler, collecting a semaglutide fraction, recovering the organic solvent at low temperature and reduced pressure to obtain a purified solution of semaglutide, removing salt and redundant acid radical ions by using a membrane system, further concentrating to a concentration suitable for freeze-drying, freeze-drying and packaging to obtain a high-quality semaglutide raw material.

Owner:SHENZHEN READLINE BIOTECH CO LTD

Pre-cleaning device and pre-cleaning method for glass production and processing

InactiveCN112371679AGuarantee the firmness of the bondImprove post-processing efficiencyDirt cleaningFlexible article cleaningDust controlElectric machinery

The invention discloses a pre-cleaning device and a pre-cleaning method for glass production and processing. The pre-cleaning device comprises a supporting frame, a transmission mechanism, a film covering mechanism and a cleaning mechanism, wherein the transmission mechanism is arranged in an inner cavity of the supporting frame; the film covering mechanism comprises two supporting blocks, two supporting columns, two hinge rods, a first driving motor, two transmission rods, a cleaning roller and two extending mounting rods; and the cleaning mechanism comprises a waste liquid collecting box, two supporting rods and a rectangular hollow box. According to the pre-cleaning device and the pre-cleaning method for glass production and processing provided by the invention, manual assistance is conveniently replaced to quickly remove dust from glass to be coated in batches, so that the bonding firmness of glass coating is ensured, and the later processing efficiency of glass coating is improved.

Owner:韩秀忠

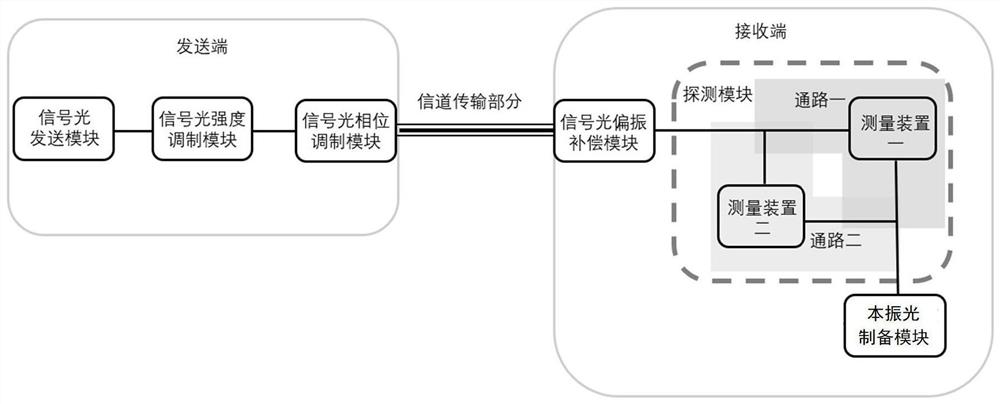

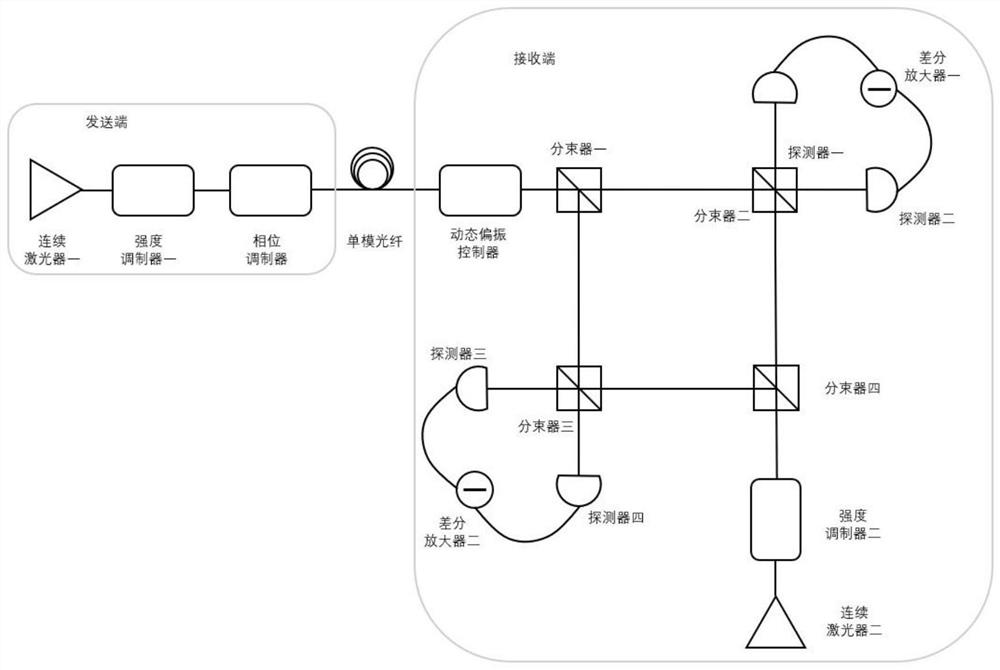

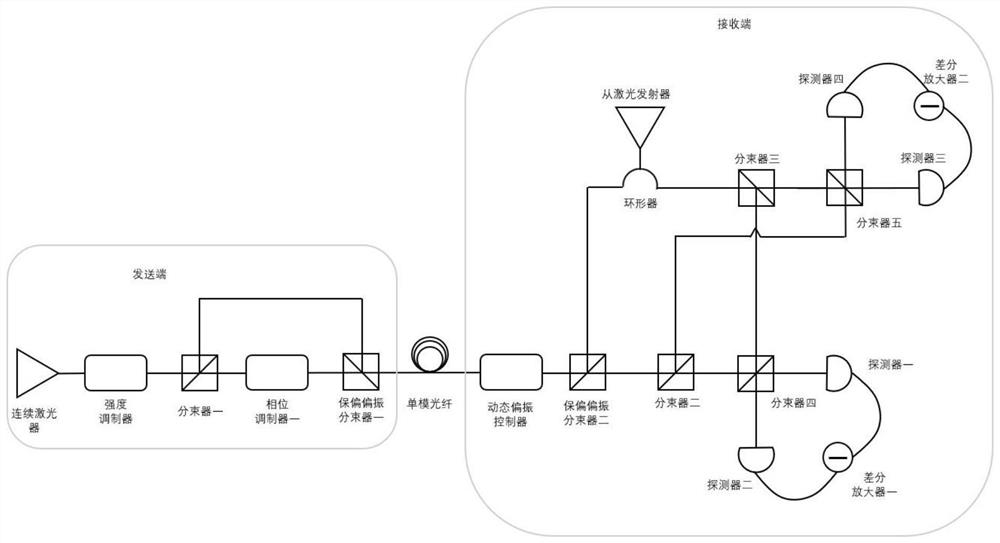

Four-state continuous variable quantum key distribution method and system of local oscillator

InactiveCN112887091ASimplify the coordination processReduce operational complexityKey distribution for secure communicationElectromagnetic receiversSoftware engineeringLocal oscillator

The invention provides a four-state continuous variable quantum key distribution method and system of a local oscillator. According to the invention, four-state modulation is used, but the phase between the signal light and the local oscillator light is not required to strictly meet the angle of 0, pi, but an additional fixed phase difference is allowed to exist within a period of time of coding and unconditionally safe coding rate estimation is given through a quasi-Newton algorithm. In addition, the system sends the local oscillation light through the receiving end, so that the local oscillation light can be prevented from going through a quantum channel and suffering additional attacks, so that higher safety is obtained.

Owner:NANJING UNIV

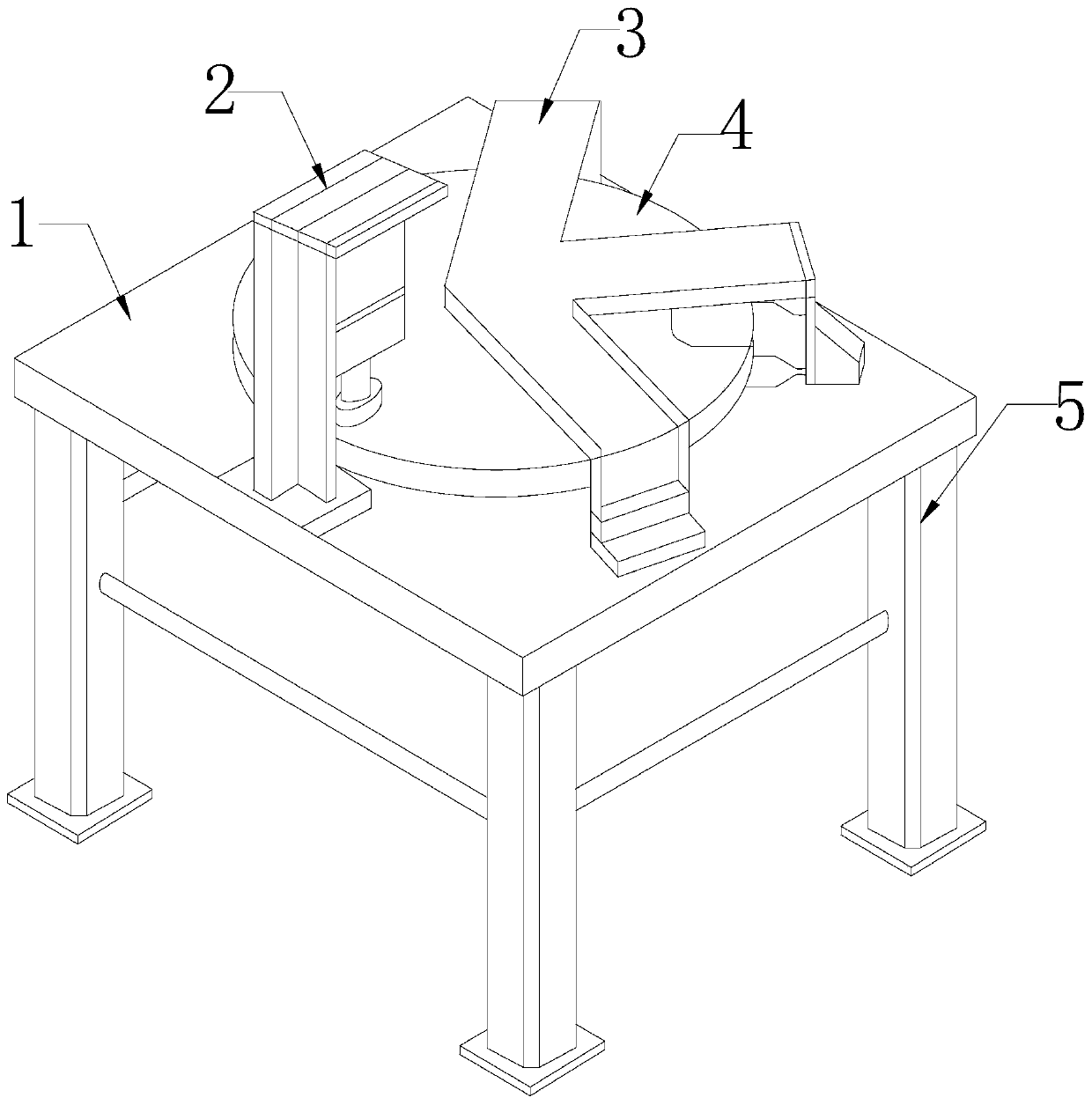

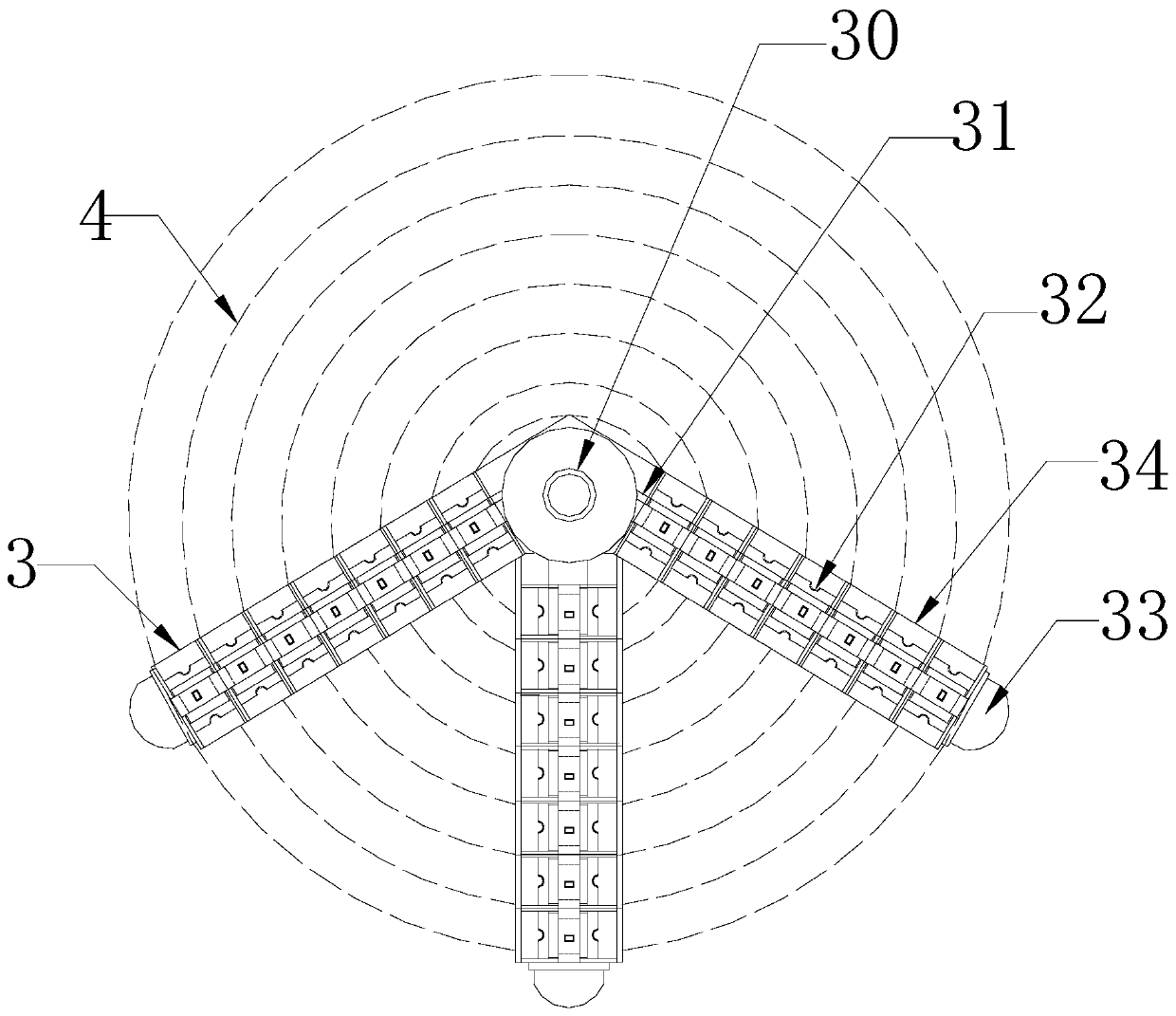

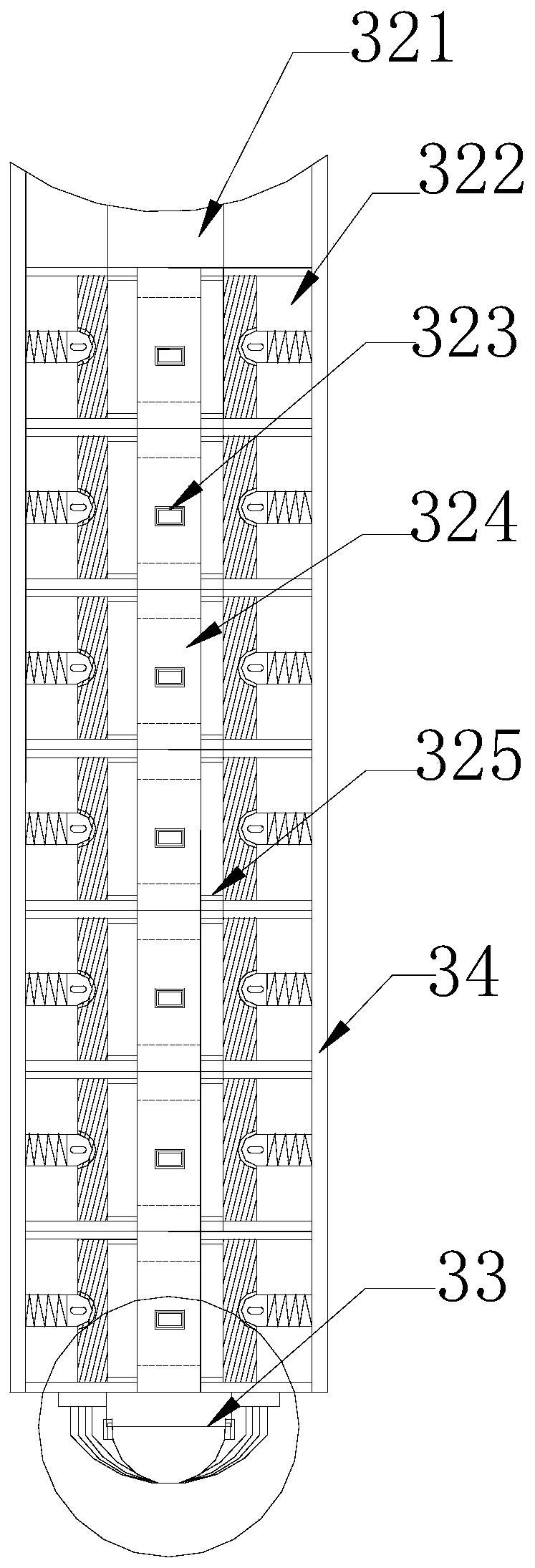

Chip screening equipment

The invention discloses chip screening equipment. The chip screening equipment is characterized by structurally comprising a workbench, a detecting table, a sorting mechanism, a test board and supporting legs, wherein the bottom of the workbench is equipped with four supporting legs; the upper end of the workbench is provided with the detecting table and the test board; the test board is matched with the detecting table and the sorting mechanism; the sorting mechanism is of a three-foot type, and consists of a rotary shaft, a pushing plate, sorting guide parts, a transfer joint and plate racks, the rotary shaft is connected to the three plate racks, the plate racks are horizontally and linearly equipped with two or more sorting guide parts, and the transfer joint is mechanically connectedto the other ends, opposite to the rotary shaft, of the plate racks. The sorting mechanism is provided with the three plate racks, so that distinguishing can be achieved according to different screening grades, and therefore, efficiency is higher; the pushing plate, the sorting guide parts and the transfer joint, which are arranged on each plate rack, are mutually matched, the transfer joint is connected to a transfer belt, the pushing plate is matched on the plate racks, and workpieces screened out by the sorting guide parts are timely fed out to process, so that existing mechanical hand clamping type is changed, graded sorting and batch feeding are realized, and efficiency is high.

Owner:江苏爱矽半导体科技有限公司

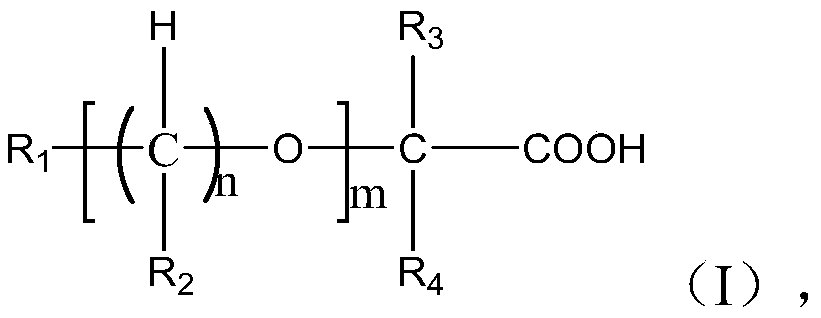

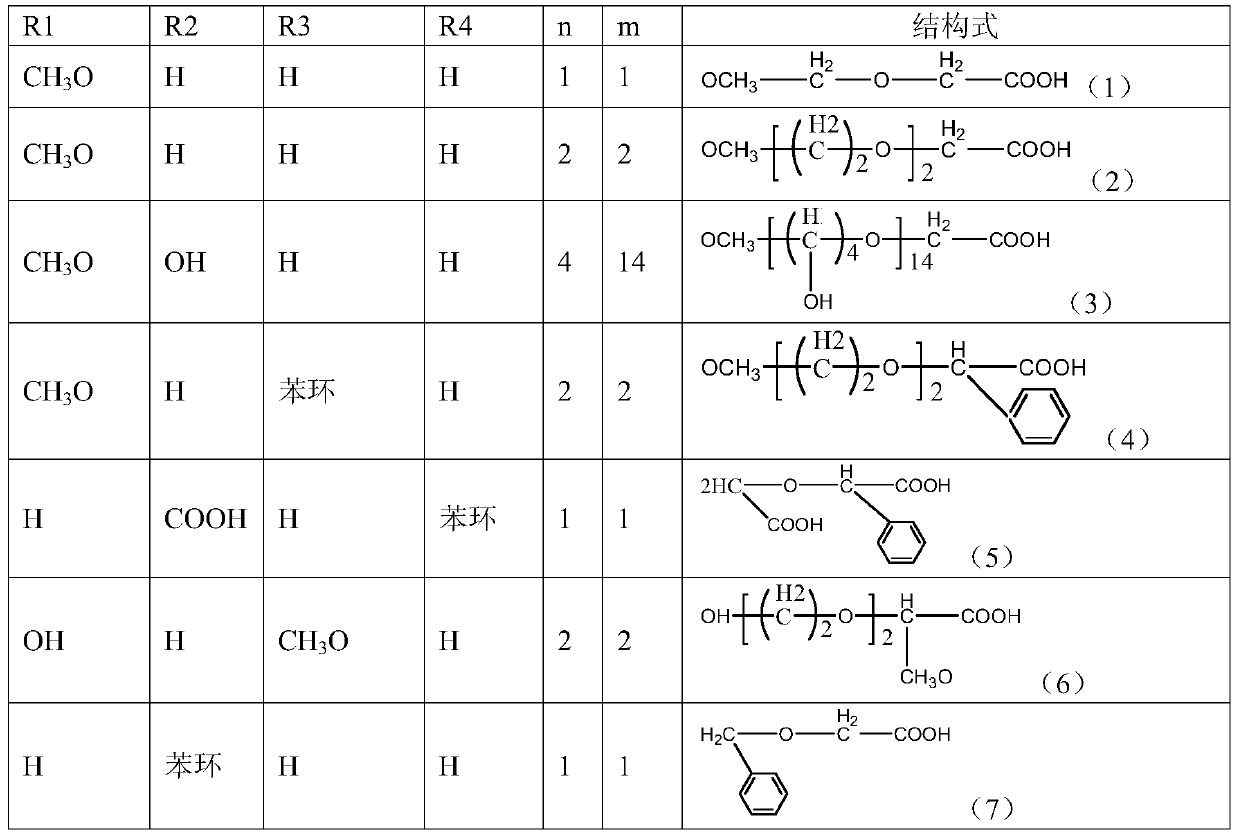

Composition for 3D ink-jet printing supporting structure and preparation method thereof

ActiveCN111004491AIncrease dissolution rateImprove support strengthAdditive manufacturing apparatusInksCarboxyl radicalMaterials science

The invention provides a composition for a 3D ink-jet printing supporting structure and a preparation method of the composition. The composition comprises the following components in parts by weight:18-40 parts of a photo-curable main material, 2-30 parts of a functional reaction promoting material, a non-curable water-miscible material, a photo-initiator and an auxiliary agent, wherein the molecular structure of the functional reaction promoting material contains carboxyl and active hydrogen, and the active hydrogen can react with peroxide free radicals. The invention also provides a preparation method of the composition. The composition provided by the invention has the advantages that the photo-curing reaction conversion rate is obviously improved, and the photo-curing product also hasobviously improved dissolution rate in an alkaline solution while the support strength is increased.

Owner:ZHUHAI SAILNER 3D TECH CO LTD

Convenient and automatic motor iron core production process

ActiveCN112570985AQuality assuranceIncrease profitManufacturing dynamo-electric machinesProduction linePunch press

The invention relates to a convenient and automatic motor iron core production process. The process is characterized in that a silicon steel strip is unwound at an unwinding machine and then is conveyed to a leveling machine to be leveled; the silicon steel strip at a discharge part of the leveling machine is leveled, and conveyed to a slitting machine to be slit into silicon steel sheets with required sizes; them the silicon steel sheets are conveyed into a punch press for punch forming; formed rotors are fed into a riveting pressing machine from a rotor channel, the multiple rotors are subjected to riveting pressing fixing after overlapping is completed, and the rotors are fed into a aftertreatment device after riveting pressing is completed, and clamped into a discharging channel afteraftertreatment is completed; formed stators are fed into a welding device from a stator channel, and fed into the discharging channel after welding is completed; the stators and rotors are grabbed through a gripper of a conveying mechanism, the stators are placed on a stator feeding channel, the rotors are placed on a rotor feeding channel, and finally the stators and the rotors are conveyed intoa packaging area, so that production of motor iron cores is completed. According to the convenient and automatic motor iron core production process, the production line is continuous, automatic feeding is achieved, the labor is saved, and the production efficiency is improved.

Owner:JIANGYIN CHUANGJIA ELECTRICAL APPLIANCE

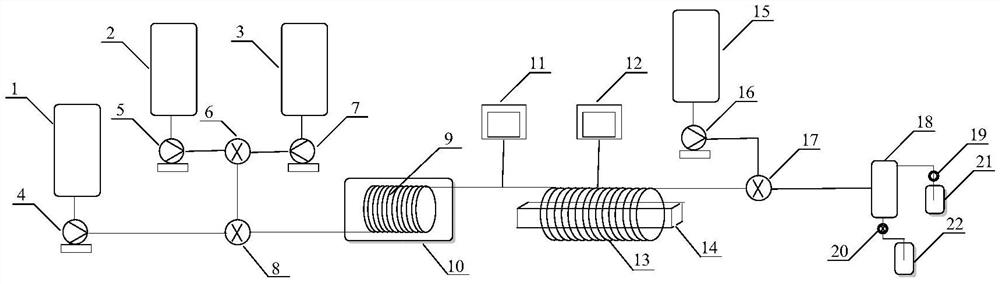

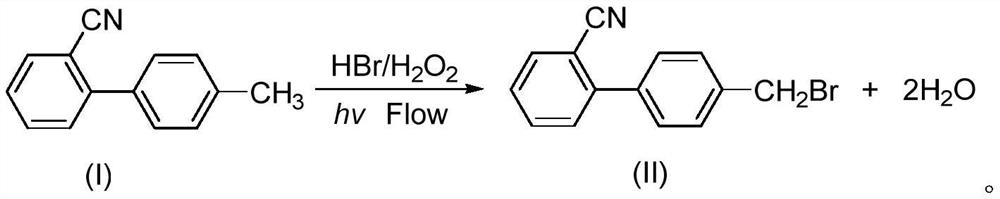

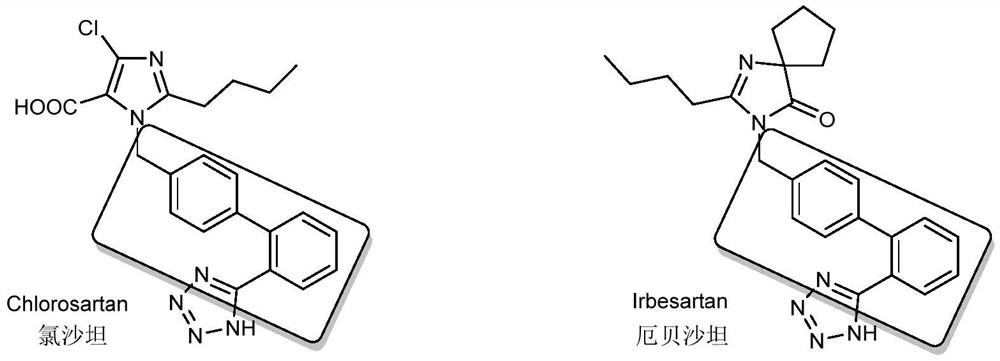

Continuous flow method for synthesizing p-bromo-methyl biphenyl carbonitrile and reaction device thereof

PendingCN111960967AImprove post-processing efficiencyScientific and reasonable designOrganic compound preparationCarboxylic acid nitrile purification/separationProcess engineeringMetering pump

The invention discloses a continuous flow method for synthesizing p-bromo-methyl biphenyl carbonitrile and a reaction device for synthesizing p-bromo-methyl biphenyl carbonitrile. P-methyl biphenyl carbonitrile is used as a raw material; bromine generated by oxidizing hydrobromic acid through hydrogen peroxide is used as a bromination reagent; materials are continuously input into an efficient mixer through a metering pump to be mixed and then enter a pipeline reactor; and temperature control and illumination on reactants in the pipeline reactor are carried out to complete bromination reaction, quenching of a reaction liquid in the pipeline reactor is carried out, continuous liquid separation, and drying, concentration and recrystallization purification on the obtained organic phase are carried out to obtain the pure p-bromo-methyl biphenyl carbonitrile product. The bromination reaction has the advantages of high bromine atom utilization rate, fewer byproducts and fewer solid wastes, and conforms to the concept of green chemistry; the continuous flow synthesis method has the advantages of good safety, convenience in intelligent control, short reaction time, high post-treatment efficiency and the like, and has industrial production and application values.

Owner:ZHEJIANG KINGLYUAN PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com