Automatic winding device integrating winding, packing and unloading

A winding device and automatic technology, applied in the directions of packaging, transportation and packaging, winding strips, etc., can solve the problems of differences in winding shapes and packaging methods, low design inspiration, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

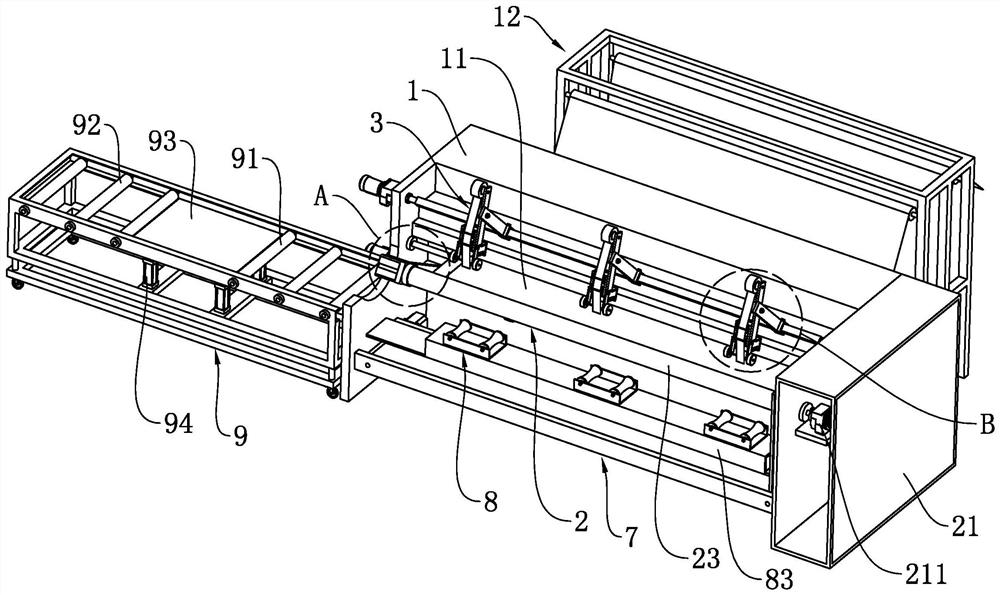

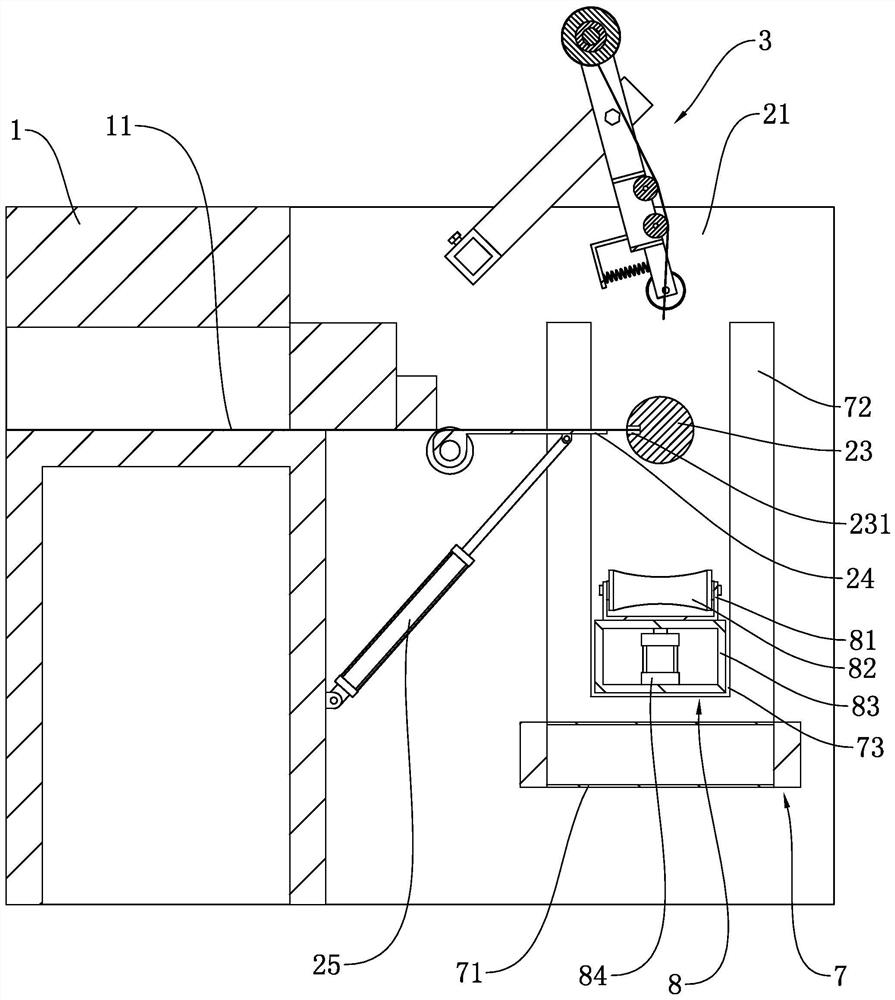

[0062] refer to figure 1 , the present invention discloses an automatic rolling device integrating rolling, packing and unloading, comprising a cloth storage machine 12, a frame 1 and a blanking platform 9, and the produced and processed sheet 11 enters through the cloth storage machine 12 Frame 1; Frame 1 is provided with winding module 2, packaging module 3 and unloading module 7, and winding module 2 is used for winding sheet 11, and cloth storage machine 12 can be according to the speed of winding module 2 winding The tension of the adjusted sheet 11; the packing module 3 is used to pack the rolled sheet 11 after the winding is finished, and after the sheet 11 is packed, the unloading module 7 starts to push the rolled sheet 11 to On the blanking platform 9.

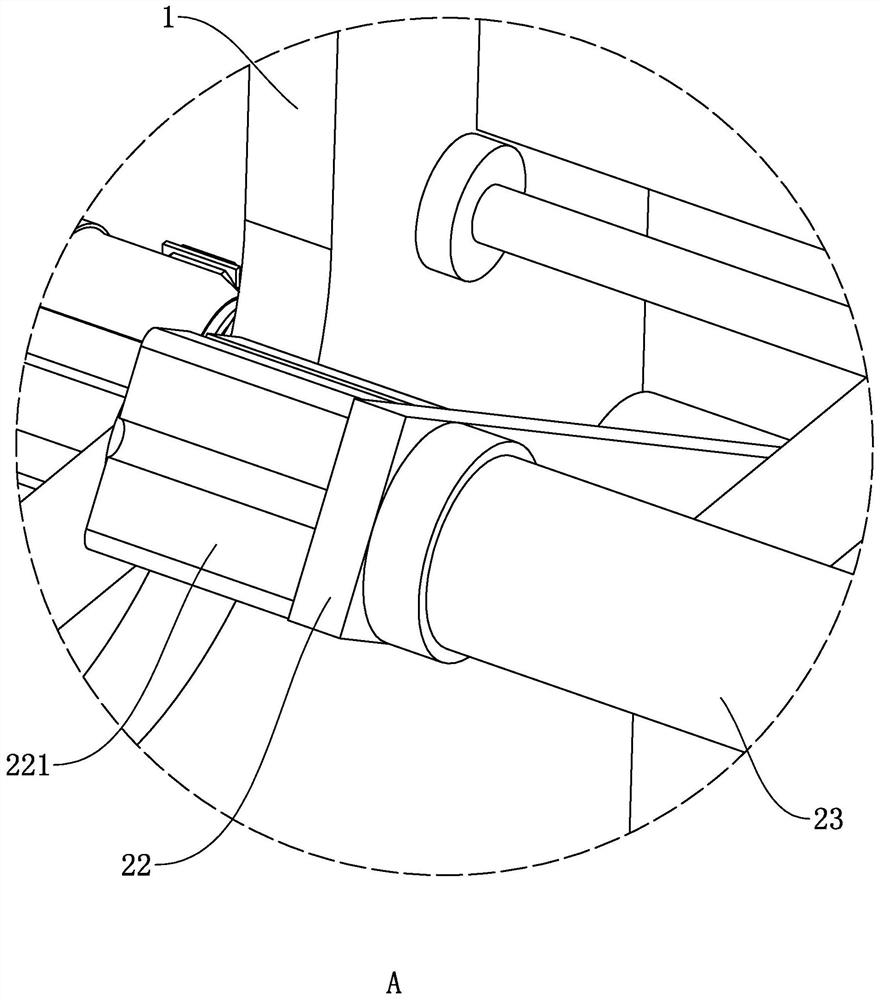

[0063] refer to figure 1 and figure 2 , the winding module 2 comprises a support plate 21, a transmission motor 211, a clamping shaft 23 and a rocker arm 22, the support plate 21 is located at one end of the leng...

Embodiment 2

[0086] An automatic winding device integrating winding, packing and unloading, refer to Figure 6 and Figure 7 , the difference from Embodiment 1 is that the linear drive in this embodiment adopts two sets of transmission chains 74 that are driven simultaneously, the transmission chains 74 are horizontally arranged and reciprocated from the support plate 21 to the rocker arm 22, and the pusher Two vertically arranged push rods 75 are adopted, one end of the push rod 75 is welded to the top surface of the transmission chain, the other end extends between the rolled sheet 11 and the support plate 21, and the clamping shaft 23 and the roller assembly 8 are all located between the push rods 75. The two sets of transmission chains 74 are simultaneously driven, driving the push rod 75 to abut against the rolled sheet 11 toward the side of the support plate 21, and steadily push the sheet 11 away from the clamping shaft 23 gradually, and then the transmission chain 74 drives the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com