Convenient and automatic motor iron core production process

A production process and iron core technology, applied in the field of motor iron core production technology, can solve the problems of affecting the quality of slitting and shearing, low equipment utilization, low post-processing efficiency, etc., to improve equipment utilization and save labor. The effect of the process of handling and reducing manual transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

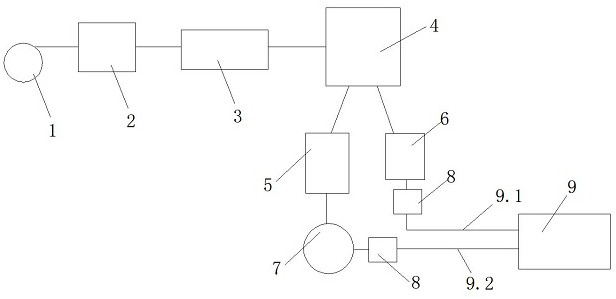

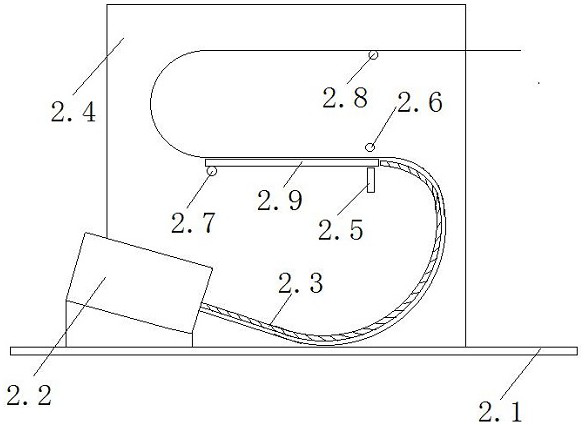

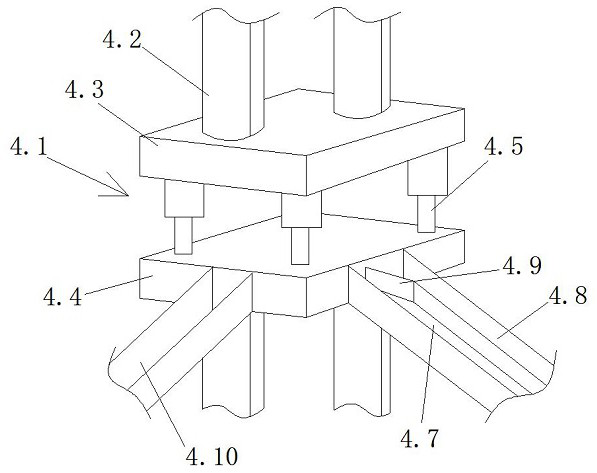

[0032] see Figure 1 to Figure 7 , the present invention relates to a convenient and automatic motor core production process. After the silicon steel strip is uncoiled from the unwinder 1, it is sent to the leveling machine 2 for leveling. After the silicon steel strip is output from the roller box 2.2, it is attached to the arc The lower end of the plate 2.3 is transported to the upper end of the arc-shaped plate 2.3 and passes between the support frame 2.5 and the bar 2.6, then transported to the support plate 2.9, then transported to the upper end of the transmission roller 2.8, and finally passes through the transmission Roller 2.8 makes the silicon steel strip at the output of the leveling machine smooth, and is transported to the slitting machine 3 to be cut into silicon steel sheets of required size, and then sent to the punching machine 4, and the stamping die 4.2 in the punching machine 4 simultaneously A stator or rotor is punched, and the silicon steel sheet is punche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com