After-treatment equipment for improving surface roughness and strength of 3D printed stainless steel workpiece

A technology of workpiece surface, 3D printing, applied in the direction of additive processing, etc., can solve the problem of non-planar surface shape, achieve the effect of high surface strength, reduce voids, and improve surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

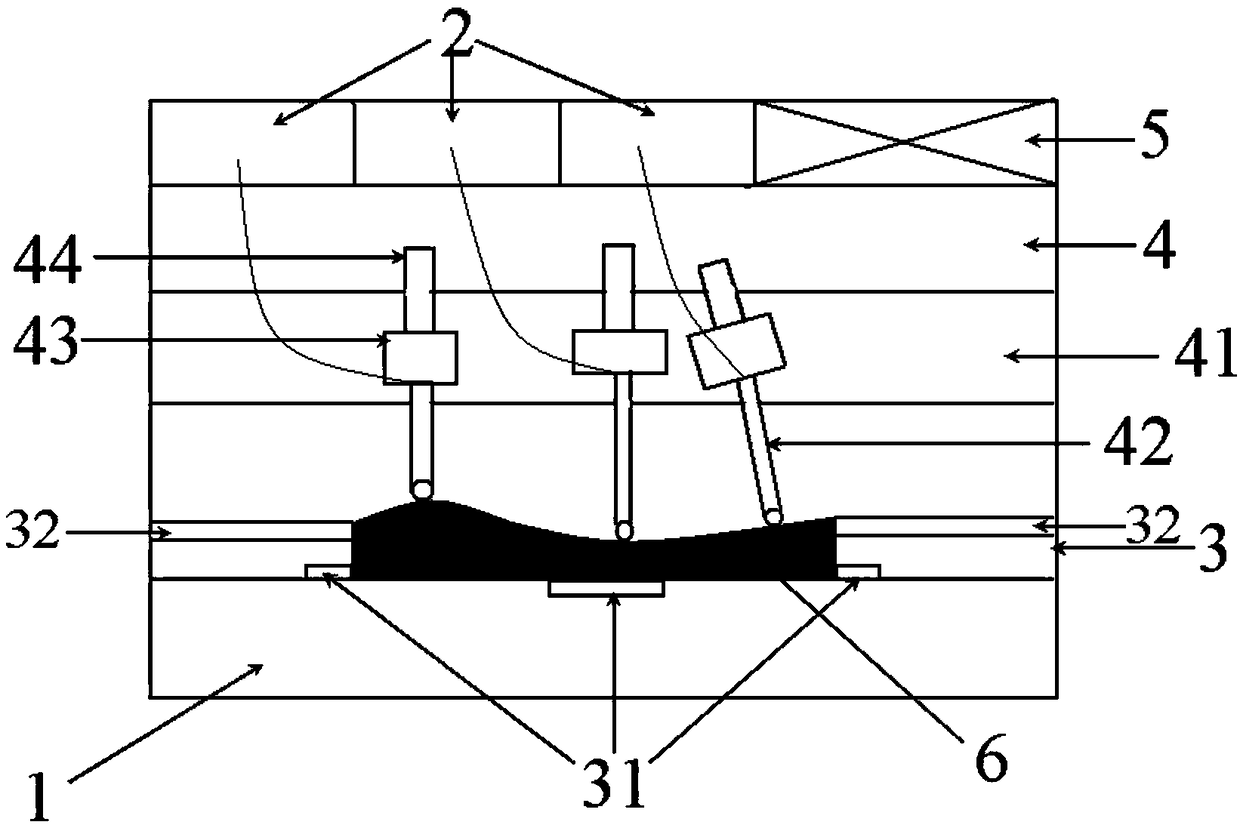

[0026] see figure 1 According to the post-processing equipment for improving the surface roughness and strength of 3D printing stainless steel workpieces provided by the present invention, it includes a base 1, an ultrasonic power supply power assembly 2, a workpiece fixing device 3, an impact device 4 and a roughness testing device 5, the workpiece The fixing device 3 includes a positioning device 31 and a fastening device 32, the processed workpiece 6 is placed on the workpiece fixing device 3, and the impact device 4 includes an impact platform 41, an impact pressure head 42, a force applying component 43 and a moving mechanism 44 , the impact platform 41 includes at least two impact indenters 42, and each of the impact indenters 42 is respectively connected to a separate force applying assembly 43 and a separate ultrasonic power supply assembly 2 , the force applying component 43 has a pressure sensor and a locking device.

[0027] The impact head 42 can freely rotate on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com