Normal-pressure fixed bed biomass gasification furnace and biomass normal-pressure gasification method

A biomass and fixed bed technology, applied in the field of atmospheric fixed bed gasifier and its gasification, atmospheric fixed bed biomass gasifier and biomass atmospheric gasification, can solve the problem of low gasification efficiency and control Inconvenient layout and other problems, to achieve the effect of high gasification efficiency, compact overall structure and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention more clearly, but the protection scope of the present invention is not limited thereby.

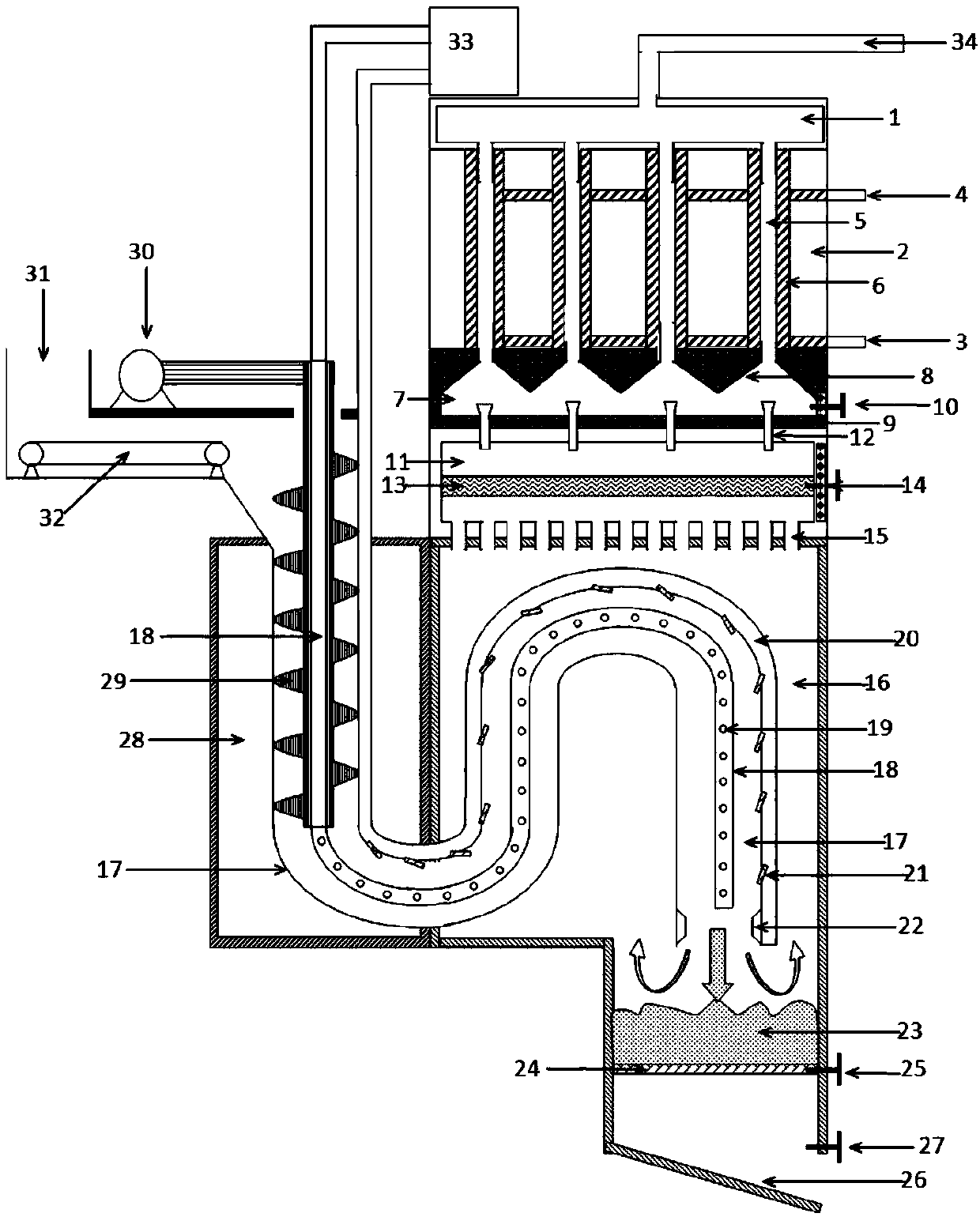

[0033] The normal pressure fixed bed biomass gasifier of the present invention, as attached figure 1 As shown, it includes a gas collection chamber 1, a condensation chamber 2, an oil removal chamber 7, a dust removal chamber 11, a gasification chamber 16, a circular gasification pipeline 17, a first gasification agent pipeline 18, and a second gasification agent pipe Road 20, drying preheating chamber 28, screw pusher mechanism 29, pusher drive motor 30, feed conveying mechanism 32 and gasification agent chamber 33, and described feed conveying mechanism 32 is arranged at feed inlet 31, is used for producing Material feed transportation, the drying preheating chamber 28 and the gasifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com