Glass light guide plate injection mold and light guide plate injection molding process

A glass light guide plate, injection mold technology, applied in optical components, household appliances, other household appliances, etc., can solve the problems of warpage, low production efficiency, shortened mold service life, etc., to improve stability and reduce molding. Cycle time and production costs, the effect of structural simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

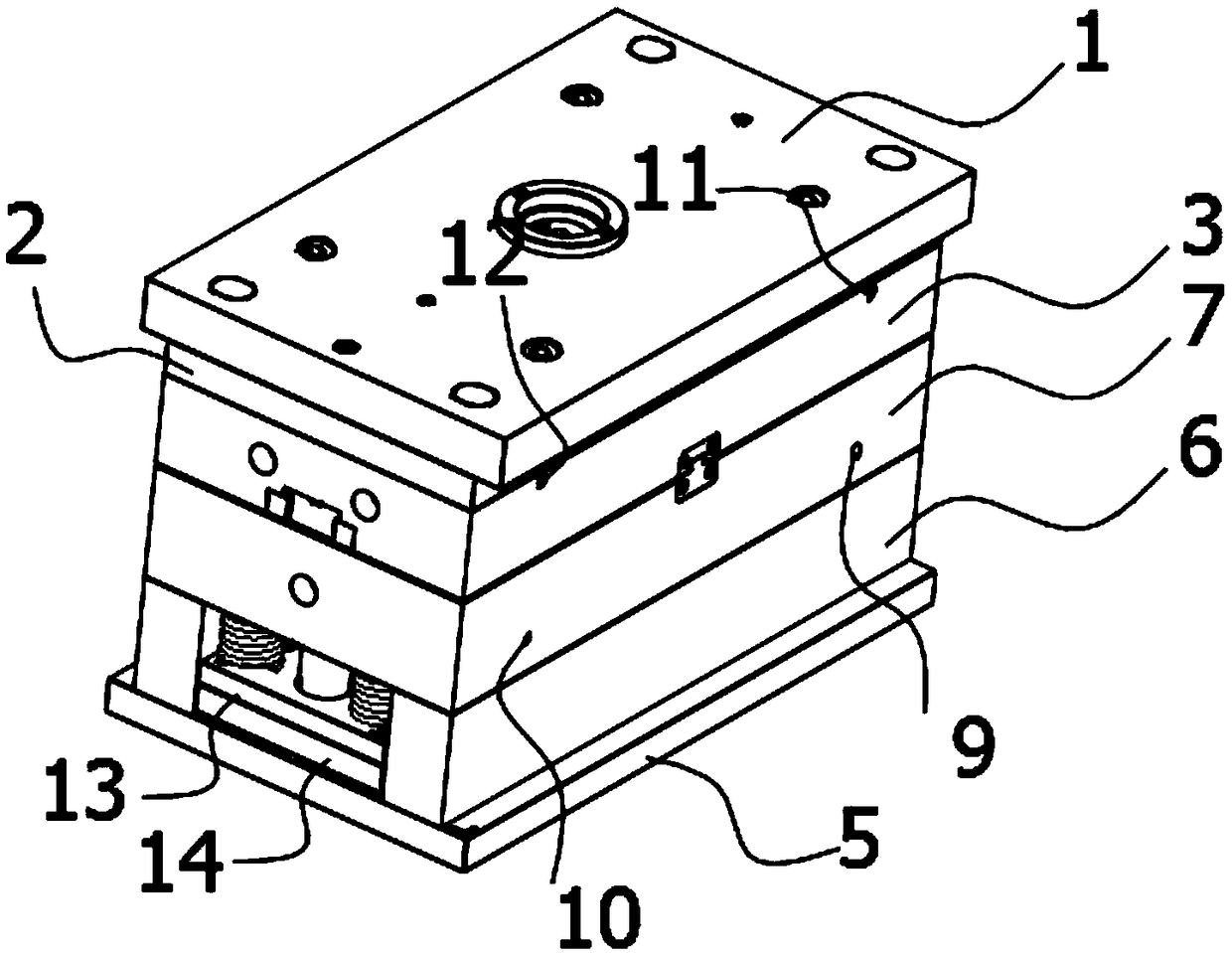

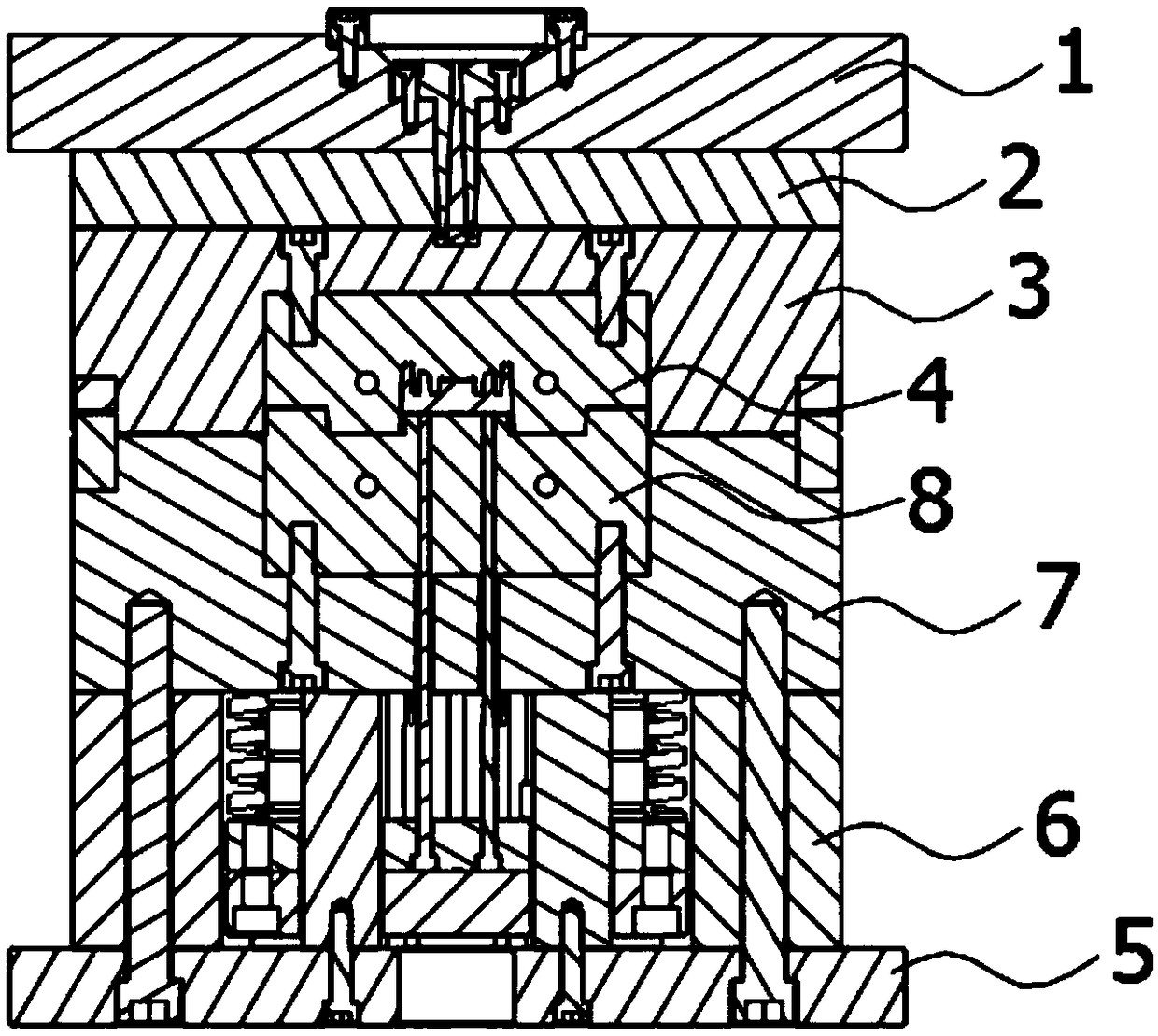

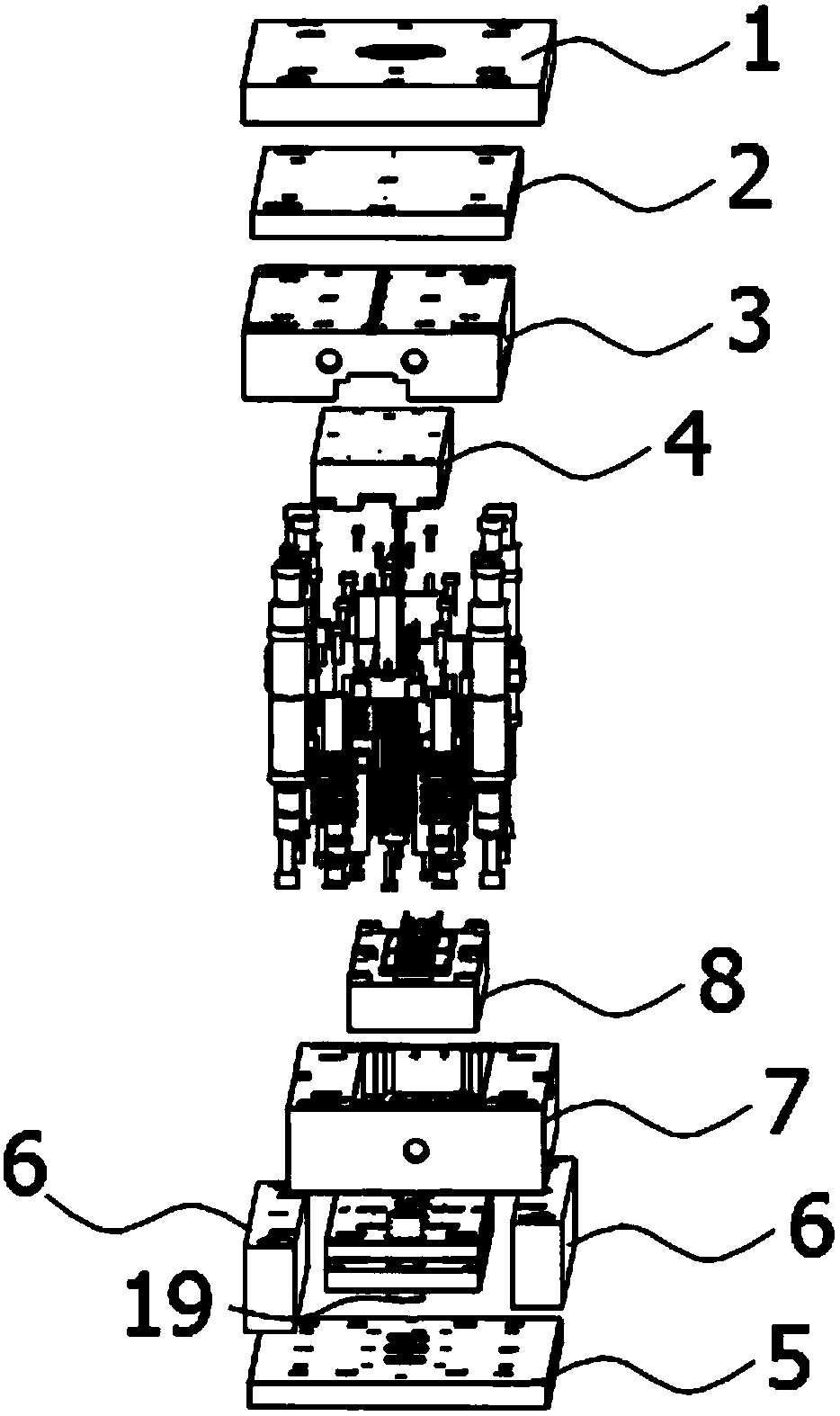

[0052] Embodiment: a kind of glass light guide plate injection mold and light guide plate injection molding process, such as Figure 1-Figure 7 As shown, it includes a male mold base and a female mold base used in conjunction with each other; the female mold base includes a panel 1, a nozzle plate 2, a female template 3 and a female mold core 4, and the panel, the nozzle plate and the female mold base The three templates can be separated and connected, and the female mold core is fixed on the inner side of the female template; the male mold seat includes a base plate 5, a die foot 6, a male template 7 and a male mold core 8, and the base plate, mold feet and male template The three are fixedly connected, the male mold core is fixed on the inner side of the male template; the cavity of the light guide plate is formed between the female mold core and the male mold core; the female mold base has a glue inlet; the male mold core The seat has an ejection structure for ejecting the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com