Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Meet the environmental protection requirements of energy saving and emission reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

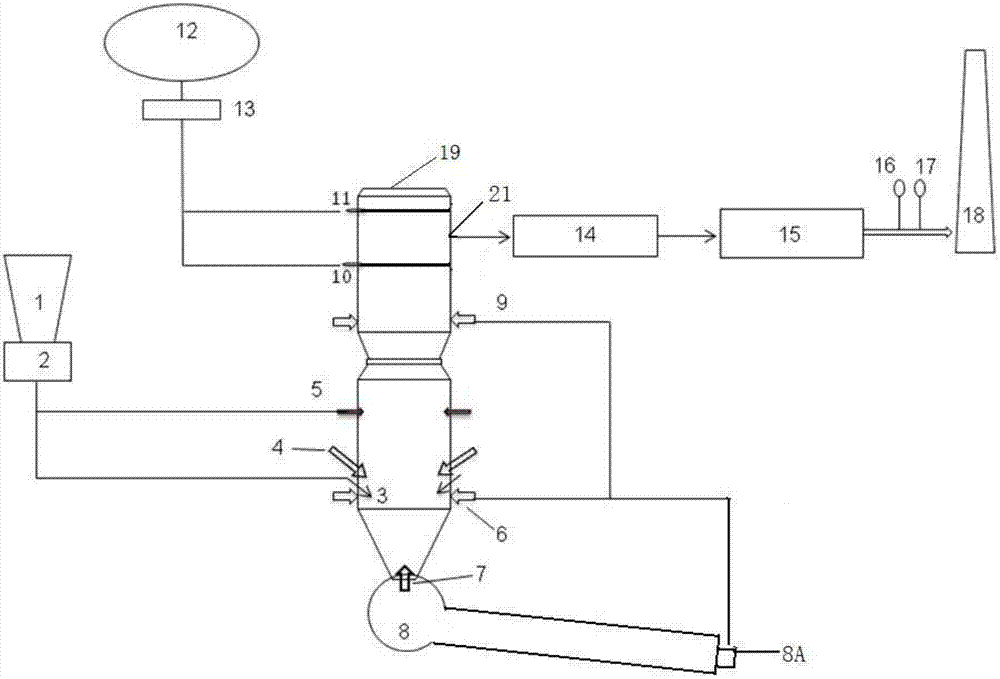

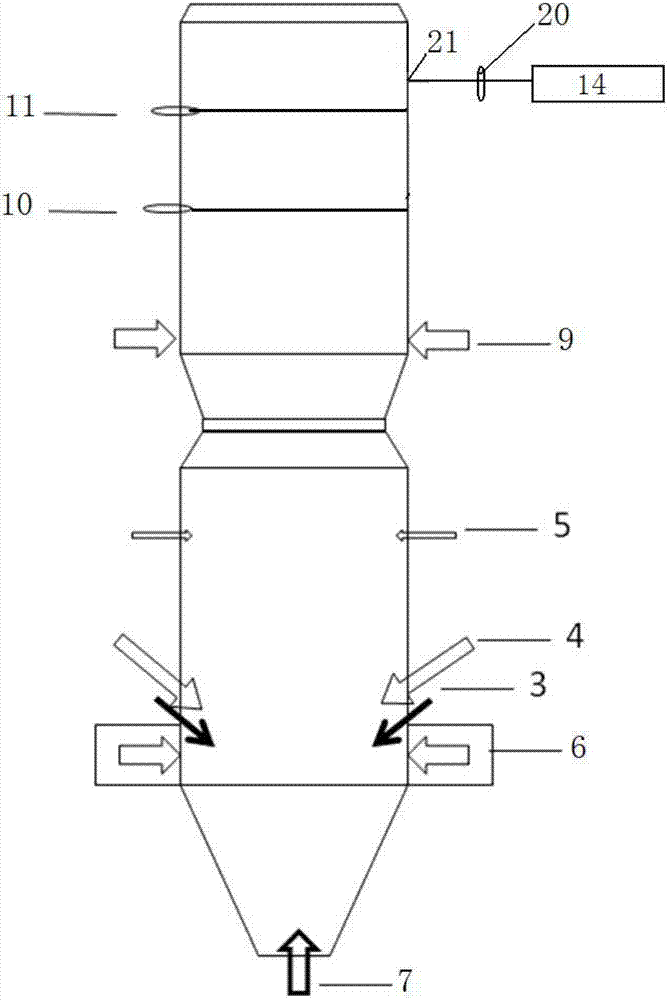

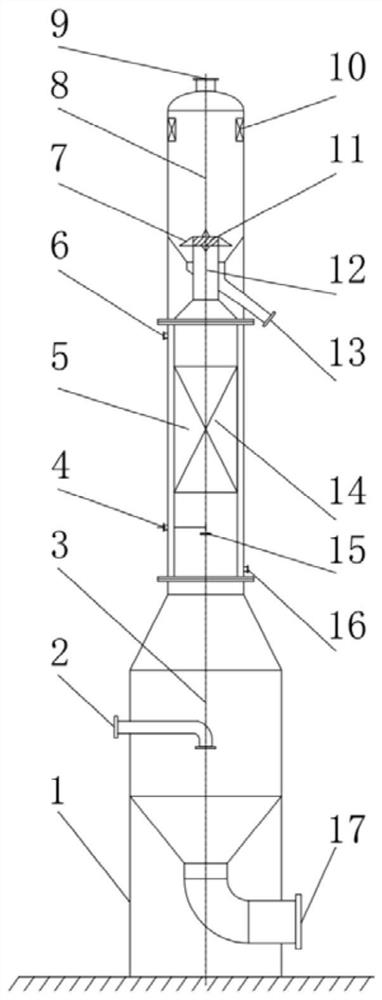

Efficient reburning denitrification device and technical method

ActiveCN103206865AImprove removal efficiencyMeet emission standardsIncreasing energy efficiencyWaste heat treatmentWater storage tankEngineering

The invention discloses an efficient reburning denitrification device which comprises a decomposing furnace. The bottom of the decomposing furnace is provided with a secondary air inlet and is connected with a rotary cement kiln. The decomposing furnace comprises a main low-nitrogen burner and a reburning burner on the lower portion from bottom to top, and a raw material inlet is arranged at the position of the main low-nitrogen burner. Coal powder in a coal powder bunker enters the decomposing furnace from the main low-nitrogen burner and the reburning burner. A tertiary air inlet is arranged below the raw material inlet and connected with a cooler of the rotary cement kiln. The decomposing furnace comprises an overfire air inlet and an SNCR (selective non-catalytic reduction) spray gun on the upper portion from bottom to top. The overfire air inlet is connected with the tertiary air inlet and the cooler of the rotary cement kiln. The SNCR spray gun is connected with a centrifugal pump and an ammonia water storage tank device. A smoke outlet is arranged at the upper section of the decomposing furnace and connected with a cyclone preheater, an electric dust collector and a chimney. The invention further provides a technical reburning denitrification method by the efficient reburning denitrification device. By the efficient reburning denitrification device and the technical reburning denitrification method, NOx removal efficiency can be improved, sprayed ammonia water is reduced, and denitrification cost of cement enterprises is lowered.

Owner:上海三融环保工程有限公司

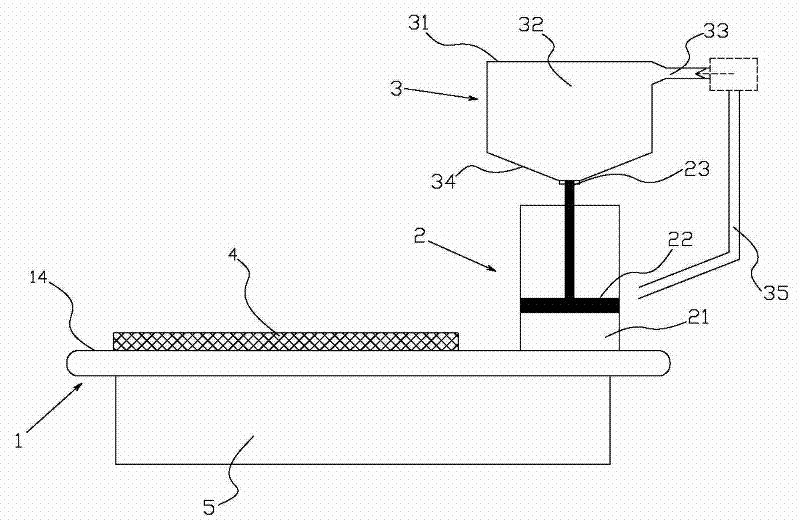

Synthetic jet heat radiating device

InactiveCN102364712AExtend your lifeImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesReciprocating motionEngineering

The invention discloses a synthetic jet heat radiating device comprising a heat exchange element, a piston cylinder and a synthetic jet device, wherein the heat exchange element is provided with an inner cavity, and an outer wall corresponding to the inner cavity can be used for installing a heating source and a heat radiating element; the piston cylinder is arranged on the outer wall and is provided with a piston cavity clinging to the outer wall and a piston assembled in the piston cavity; the synthetic jet device comprises a shell in which at least one chamber with an opening is arranged, the chamber is provided with a thin film wall with elasticity, and the thin film wall is in transmission connection with the piston through a piston rod; the piston drives the thin film wall to reciprocate through the piston rod by using heat from a heating source transmitted by the heat exchange element so that compression and expansion periodical change is generated in the chamber and jet is generated at the opening. In the invention, a passive heat radiation mechanism and an active heat radiation mechanism without power consumption are combined, so that a better heat radiating effect can beachieved; in addition, the environment friendly requirements for energy saving and emission reduction are met, therefore, compared with the traditional active synthetic jet device, the synthetic jet heat radiating device has the advantage that the service life of an element is longer.

Owner:ZHONGSHAN WEIQIANG TECH

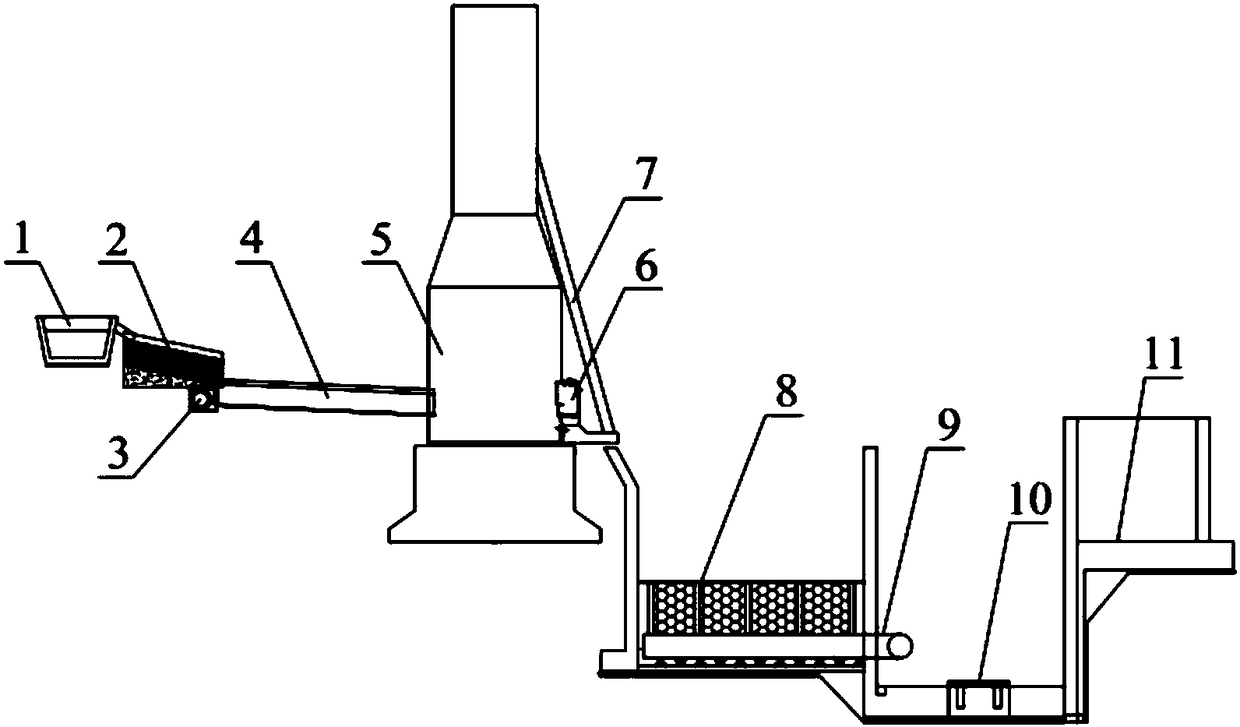

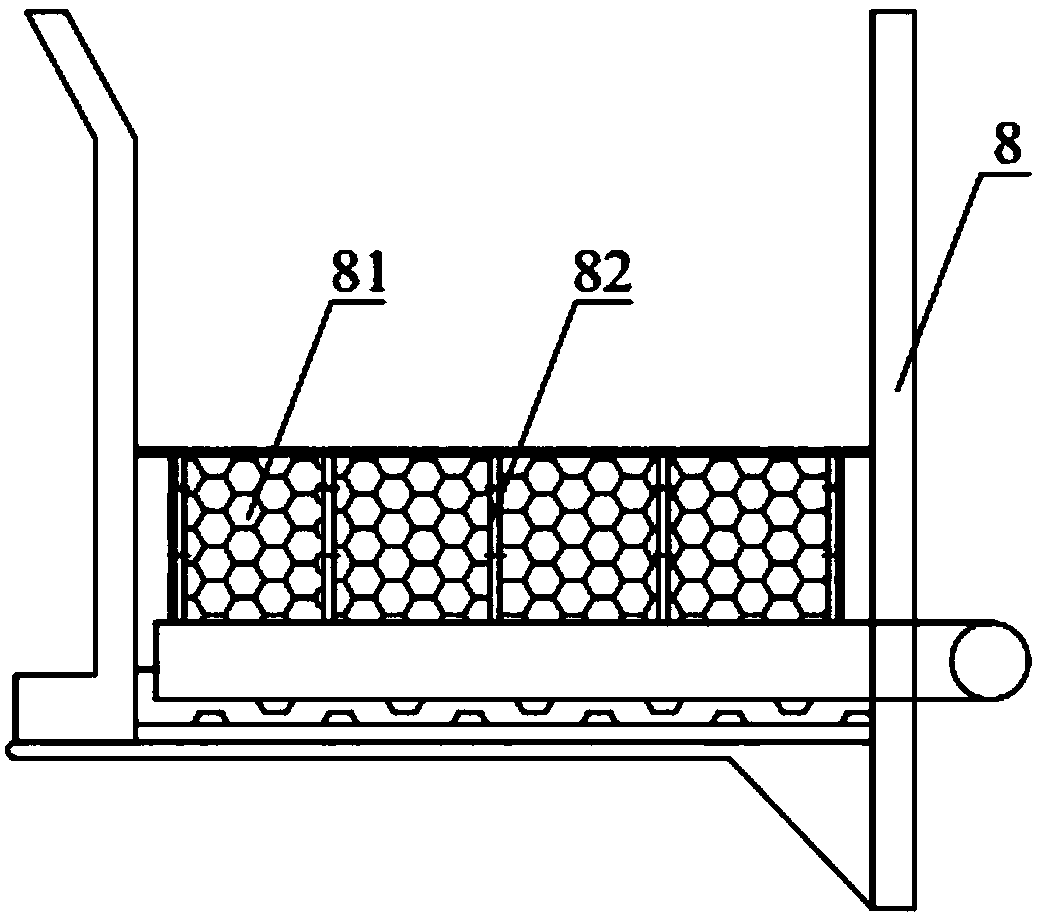

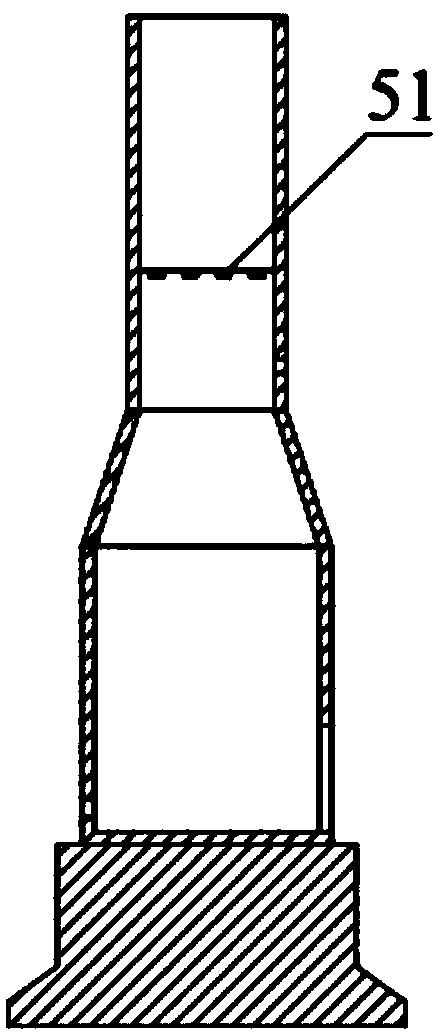

Bottom-filtration-process slag treatment method for ferroalloy submerged arc furnace

ActiveCN108220511AImprove granulation effectReduce generationRecycling and recovery technologiesPunchingFiltration

The invention discloses a bottom-filtration-process slag treatment method for a ferroalloy submerged arc furnace and belongs to the technical field of ferroalloy submerged arc furnace. The method comprises the following steps of making molten slag overflow into a molten slag ditch via a slag tank; performing crushing, water quenching and pelletizing on the slag which flows from the molten slag ditch into a waste slag ditch by high-speed water flow sprayed out of a punching box; making a slag and water mixture flow from the water granulated slag ditch into a buffer tower and continuing to coolthe slag and water mixture; making the slag and water mixture inside the buffer tower directly flow into a filter tank via an outlet device; filtering the water inside the filter tank by using a filter pipe, and conveying the water to a slag treatment water pool by using a water pump; conveying the water inside the water pool to the punching box in order to realize slag punching and cyclic utilization; and grabbing out the water granulated slag from the filter tank by using a water granulated slag grabbing hopper. The method disclosed by the invention is simple in process and reasonable in procedures, commendably guarantees the granulation degree of the slag, realizes more complete slag and water separation, greatly reduces emission of steam, reduces environmental pollution and realizes simple industrial implementation.

Owner:马钢集团设计研究院有限责任公司

Method for preparing zinc stearate having hydrophilicity

InactiveCN101914006AImprove hydrophilicityHydrophilic size controllableCarboxylic acid salt preparationSocial benefitsPolymer science

The invention relates to the technical field of plastic processing auxiliary agents, in particular to a method for preparing zinc stearate. The obtained product is mainly used as isolating agents in a rubber industry and lubricating and releasing agents in amino molding materials. The method comprises the following steps of: putting stearic acid into a reaction kettle under normal pressure and heating the stearic acid to 125 to 175 DEG C; adding zinc oxide into the reaction kettle in two steps; reacting the mixture under the action of a catalyst, then adding a modifying auxiliary agent into the obtained product and stirring; then discharging, wherein the temperature in the whole reaction process is kept to be 125 to 175 DEG C; and finally crushing the obtained product to obtain the finished product. The zinc stearate prepared by the method has excellent hydrophilicity which is unreachable to an ordinary direct process; moreover, by the method, the magnitude of the hydrophilicity of the zinc stearate is controllable; and the catalyst and the modifying auxiliary agent have no pollution on the environment so as to meet the environment protection requirements of energy saving and emission reduction. The process is simple and easy to implement and has extremely high economic and social benefits, and the application field of the zinc stearate is expanded by the process.

Owner:DONGGUAN CHNV TECH CO LTD

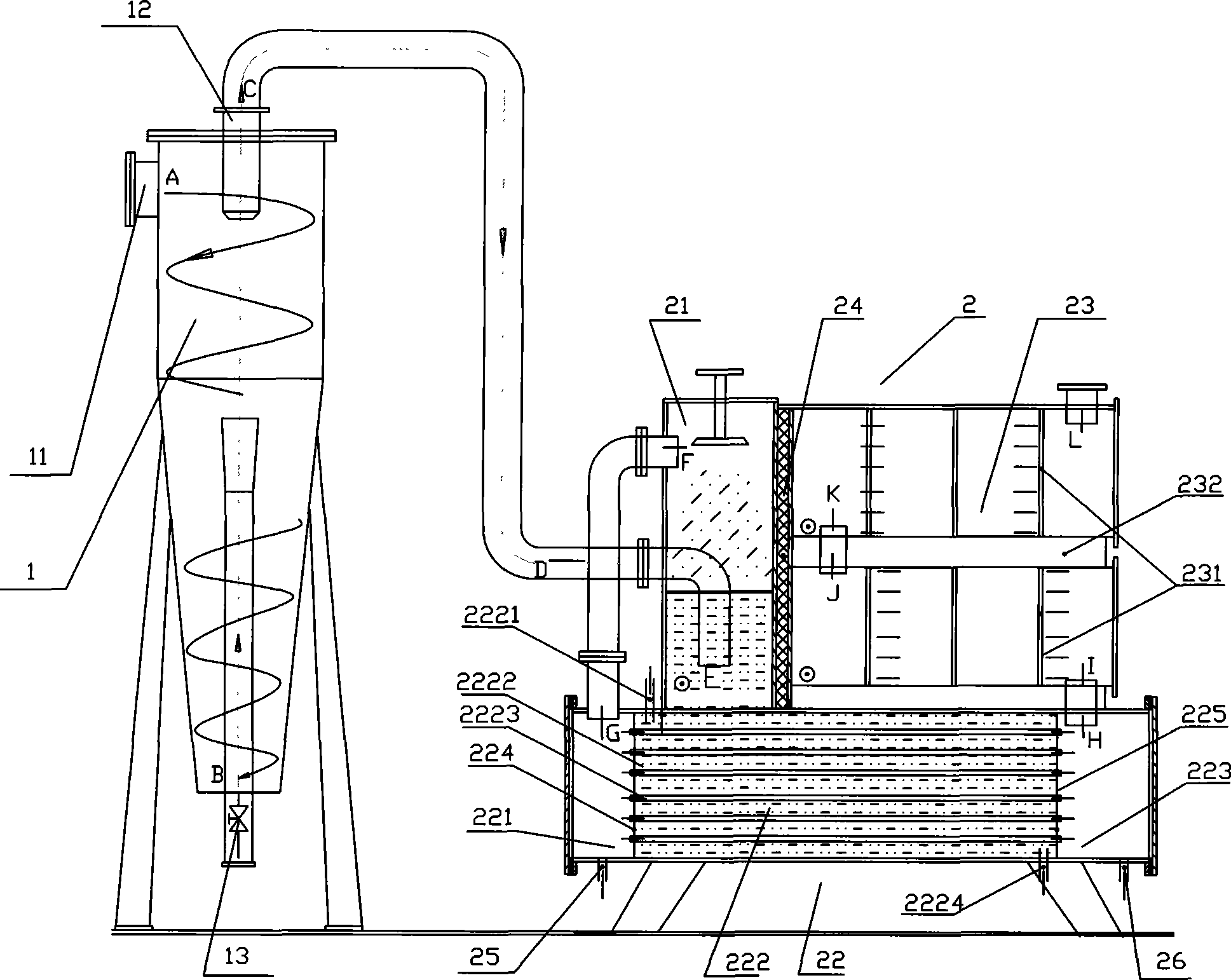

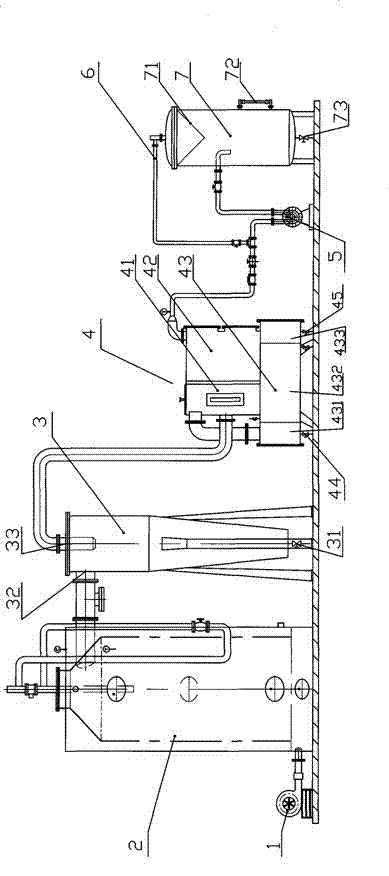

Biomass gas purification equipment and process

InactiveCN101440311ASimple structureDesign scienceGas purification by liquid washingWater bathsFiltration

The invention relates to a biomass fuel gas purification apparatus and a purification process, wherein the purification apparatus comprises a composite filter and is characterized by further comprising a cyclone separator. The cyclone separator is communicated with the composite filter through a gas pipeline; the cyclone separator and the bottom of the composite filter are provided with a sewage outfall respectively; and the composite filter has an integral composite structure comprising a water bath spray thrower, a heat exchanger and a dry-type filter. The biomass fuel gas purification apparatus integrates gas purification and filtration, has the advantages of more reasonable and more compact structure, small occupied area for the apparatus, simple process, scientific design, energy conservation and emission reduction, and in particular achieves fuel gasification and canalization for rural biomass waste materials as soon as possible so that the rural civilians can use clean and convenient fuel gas as urban poeple.

Owner:张建超 +1

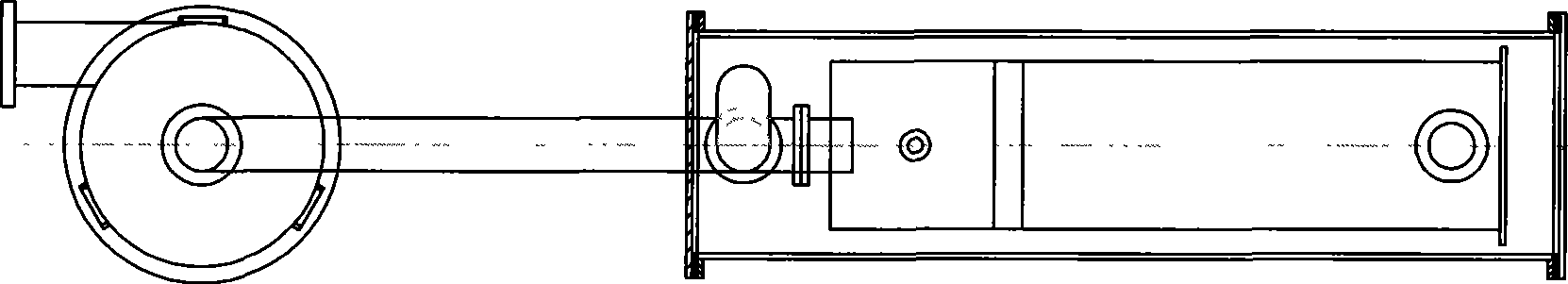

Method for preparing feed-grade calcium hydrophosphate by wet-process phosphoric acid organic extraction and purification raffinate

The invention discloses a method for preparing feed-grade calcium hydrophosphate by wet-process phosphoric acid organic extraction and purification raffinate. Raffinate acid used for organic solvent extraction and purification in a wet-process phosphoric acid preparing process is used as the raw material of the feed-grade calcium hydrophosphate, wherein the raffinate acid contains 20-25% of P2O5 and 0.3% of F ions; the feed-grade calcium hydrophosphate is prepared by the three-stage neutralization reaction technology, wherein the first-stage neutralization reaction is neutralization reaction with calcium carbonate, and the second-stage neutralization reaction and the third-stage neutralization reaction are neutralization reaction with lime milk; the raffinate acid can be comprehensively utilized by segmentation and multi-grade neutralization reaction; and the byproduct fertilizer-grade calcium hydrophosphate of the feed-grade calcium hydrophosphate is produced. Compared with the prior art, the method disclosed by the invention is characterized in that condensation is omitted when the raffinate acid is used, energy consumption is low, the raffinate acid is fully reused, the whole technical process is free from high-temperature heating, the reaction is environmentally friendly, and the technical process conforms to the environment-friendly requirement of energy saving and emission reduction.

Owner:KUNMING CHUAN JINNUO CHEM IND

Method for preparing high-temperature resistant zinc stearate

InactiveCN101914007AImprove long-term high temperature performanceNo pollution in the processCarboxylic acid salt preparationProcedure AgentsAntioxidant

The invention relates to the technical field of plastic processing aids, in particular to a method for preparing high-temperature resistant zinc stearate. An obtained product is mainly taken as a lubricating mold release agent in the plastic industry for processing at the high temperature. The method comprises the following steps of: putting stearic acid into a reaction kettle under normal pressure to heat the stearic acid to 130 to 180 DEG C; adding zinc oxide and a catalyst in two steps; reacting, adding an antioxidant, stirring and discharging the reaction product, wherein temperature is kept between 130 and 180 DEG C in an entire reaction process; and smashing to obtain a zinc stearate product. The acid value of free stearic acid in the high-temperature resistant zinc stearate prepared by the method is less than 0.5 percent and the whiteness of the product is enhanced greatly after heat is preserved at the temperature of 220 DEG C for 2 hours. Moreover, the zinc stearate has the advantages of stable process control, stable product quality, small fluctuation, no pollution of the used catalyst and the antioxidant on the environment and capability of meeting the environmental protection requirements of energy conservation and emission reduction; and the process has the advantages of simpleness, easy implementation, contribution to expanding the application field of the zinc stearate and very high economic benefit and social benefit.

Owner:DONGGUAN CHNV TECH CO LTD

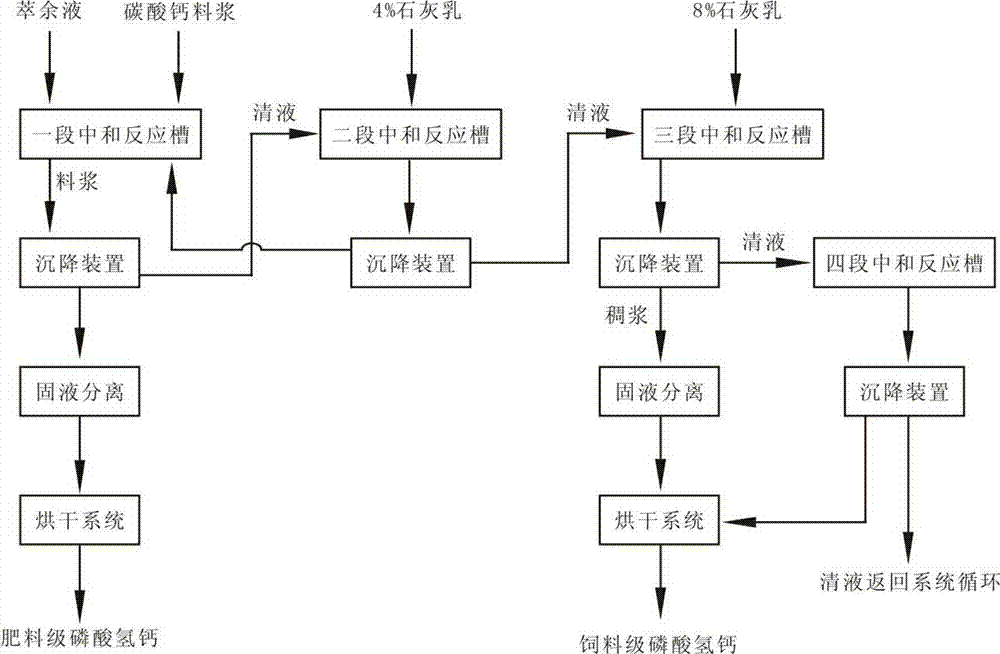

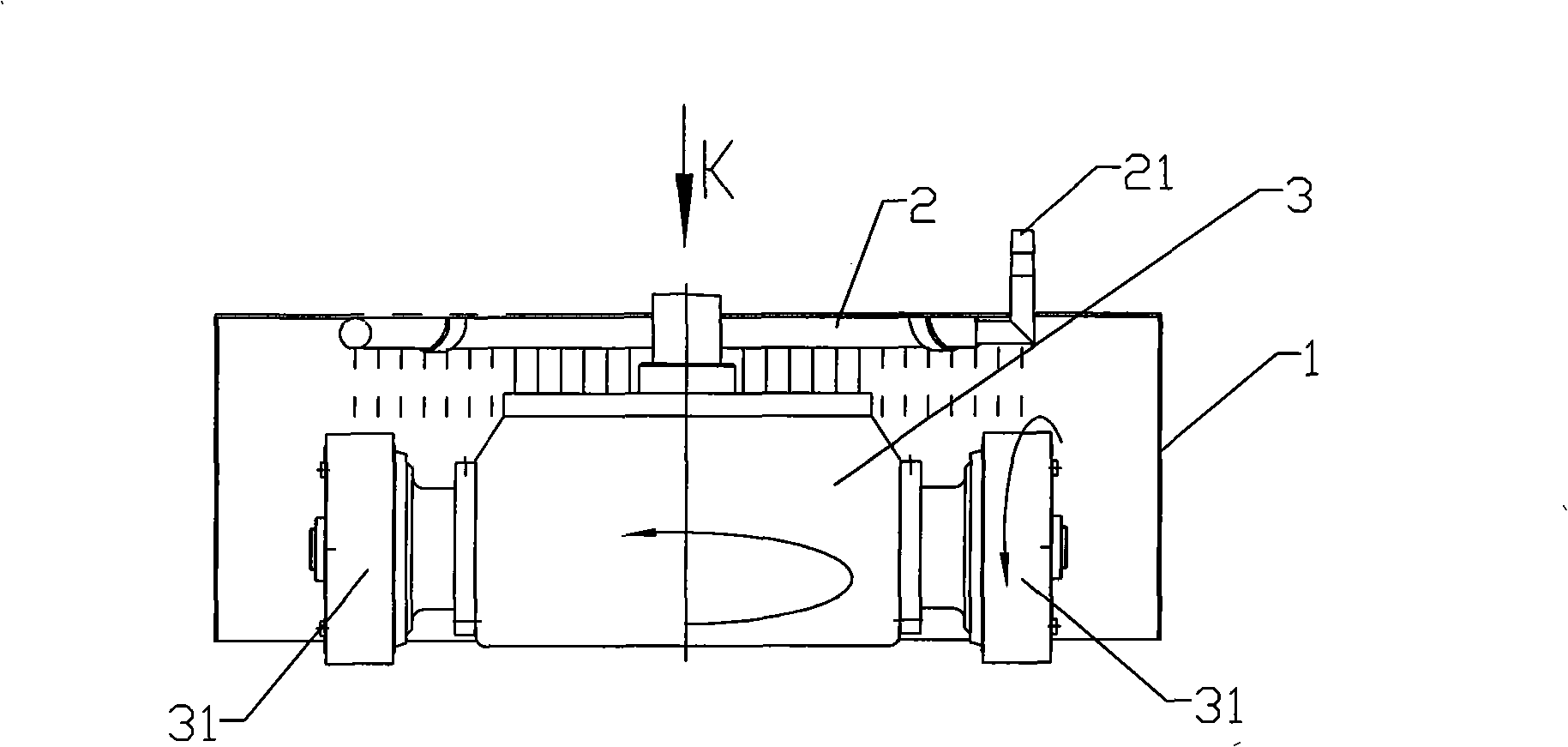

Low-order coal dry distillation device

InactiveCN101935534AEliminate transmissionTake advantage ofDirect heating destructive distillationSpecial form destructive distillationThermal energyHeat carrier

The invention relates to a low-order coal dry distillation device, comprising a hopper, a dry distillation chamber, a heating chamber, a thermal insulation chamber, a discharging channel, a gas distributor, a thermal insulation structure and a hot gas circulating pipe. As for the device, the dry distillation chamber is arranged in a heating gas environment, and the gas heat carrier inlet temperature of the dry distillation chamber is equal to the temperature of gas heat carrier outside the dry distillation chamber, thus no heat exchange occurs between the dry distillation chamber and the outside. The invention is also provided with the hot gas circulating pipe which is used for communicating the thermal insulation chamber with the heating chamber so as to lead the hot gas in the thermal insulation chamber to enter into the heating chamber in a circulation mode, thus saving the gas hot carrier and making full use of the heat energy of the gas hot carrier.

Owner:TAIYUAN UNIV OF TECH

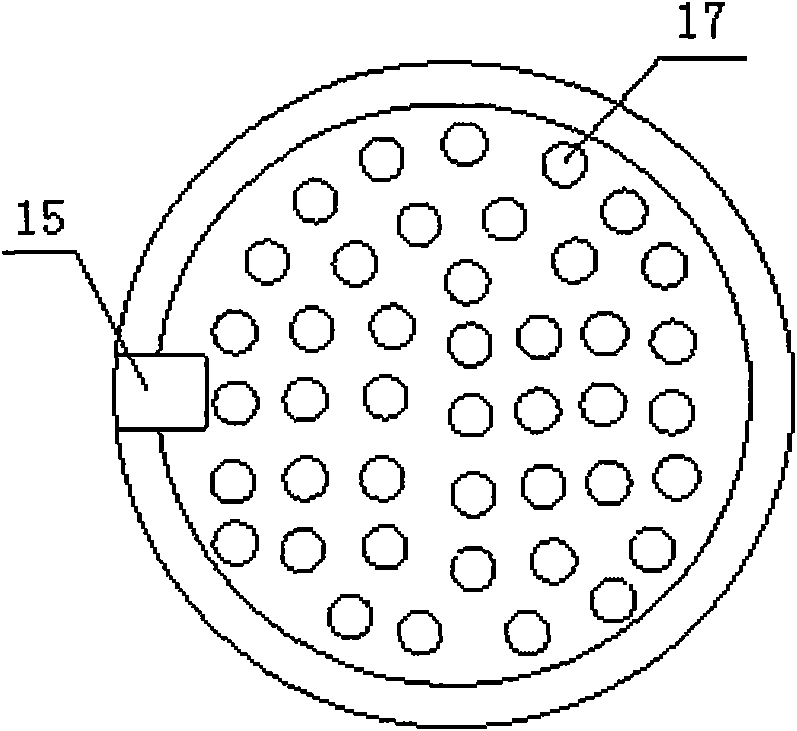

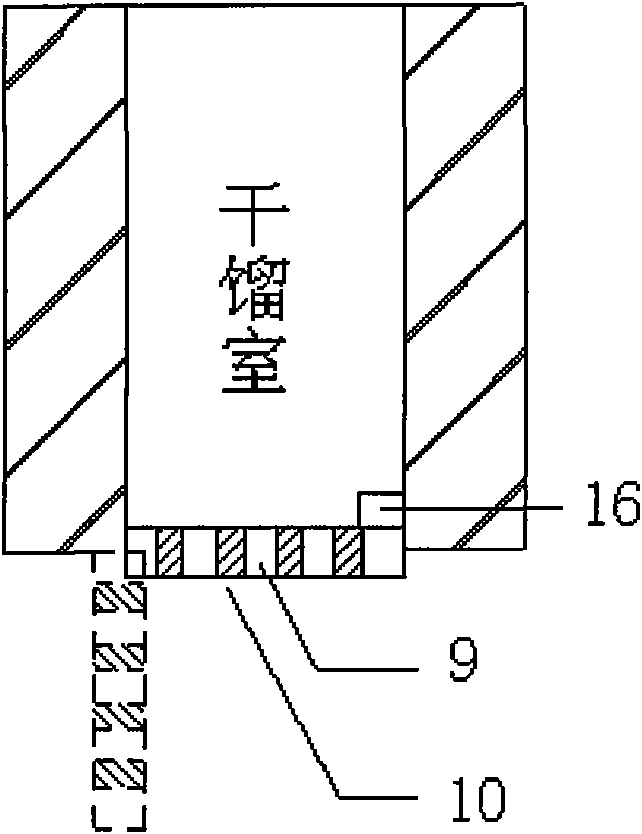

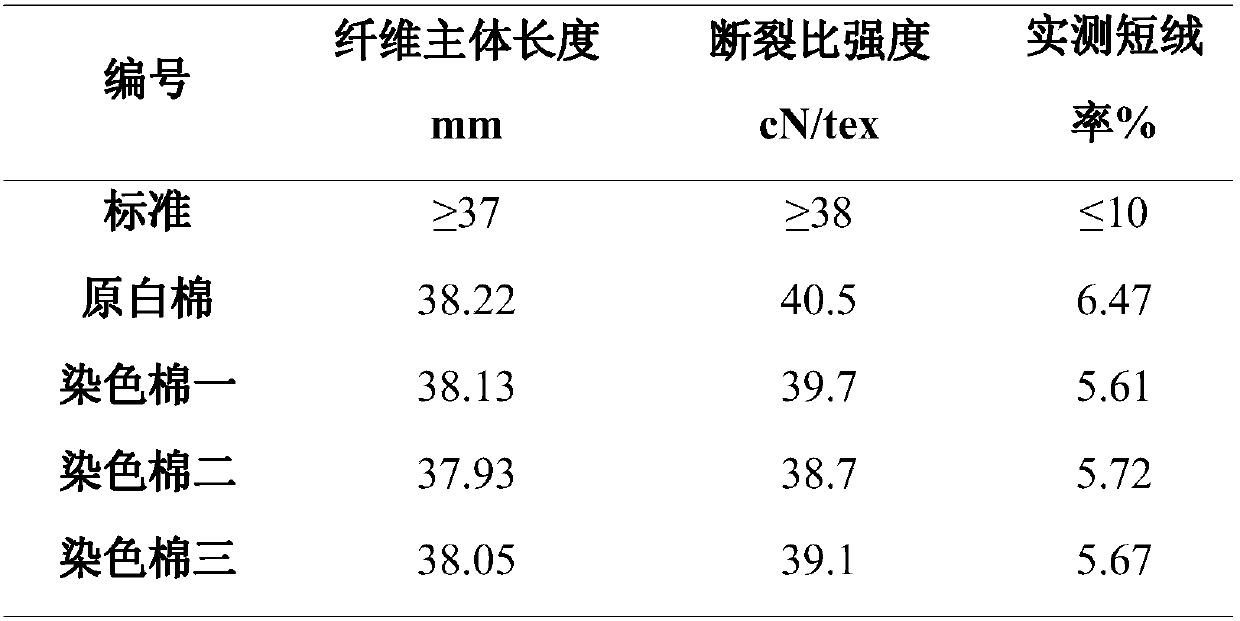

Cotton fiber continuously-dyeing method

The invention discloses a cotton fiber continuously-dyeing method. The method comprises the following steps: (1) preparing combed sliver; (2) dyeing; (3) washing with water. The dyed cotton fiber prepared through the method is higher than a standard value in main body length and breaking specific strength. According to the method, on one hand, a proper dyeing material and a proper low temperaturecondition are selected in order to lower the strength loss of the cotton fiber after being dyed, and improve the spinning property of dyed cotton, so that the breaking specific strength of the dyed cotton is lowered; meanwhile, in the technical scheme, the liquid rate of the combed sliver is 70 to 100 percent, in the dyeing process of the cotton sliver, water consumption is low; dyeing liquid is free from salt, so that salt content in waste water is low in a discharging process; on the other hand, in the dyeing process, the combed cotton sliver is soaked in the dye liquid, and is piled at thetemperature of 20 to 35 DEG C, so that energy consumption is low, and environment requirement on energy saving and emission reduction is met.

Owner:SHANDONG HUANGHE DELTA INST OF TEXTILE SCI & TECH RES INST

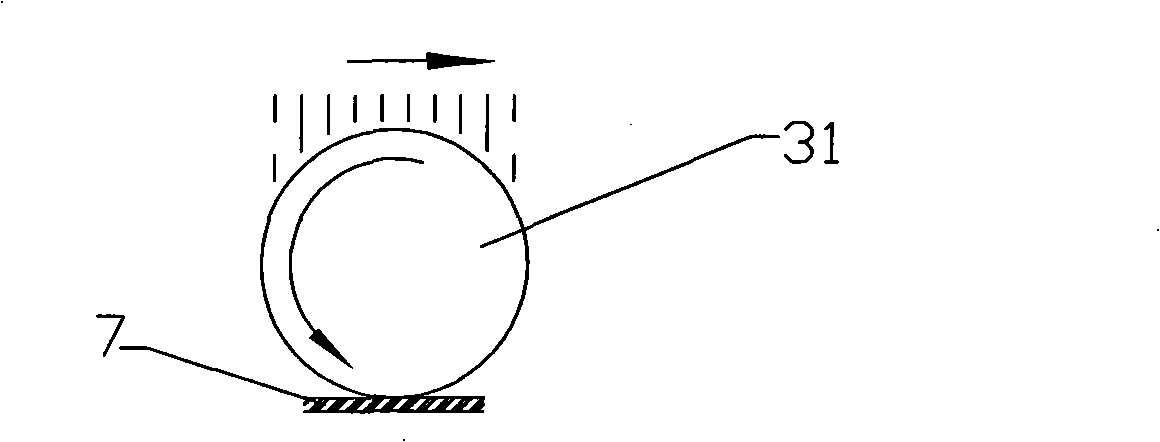

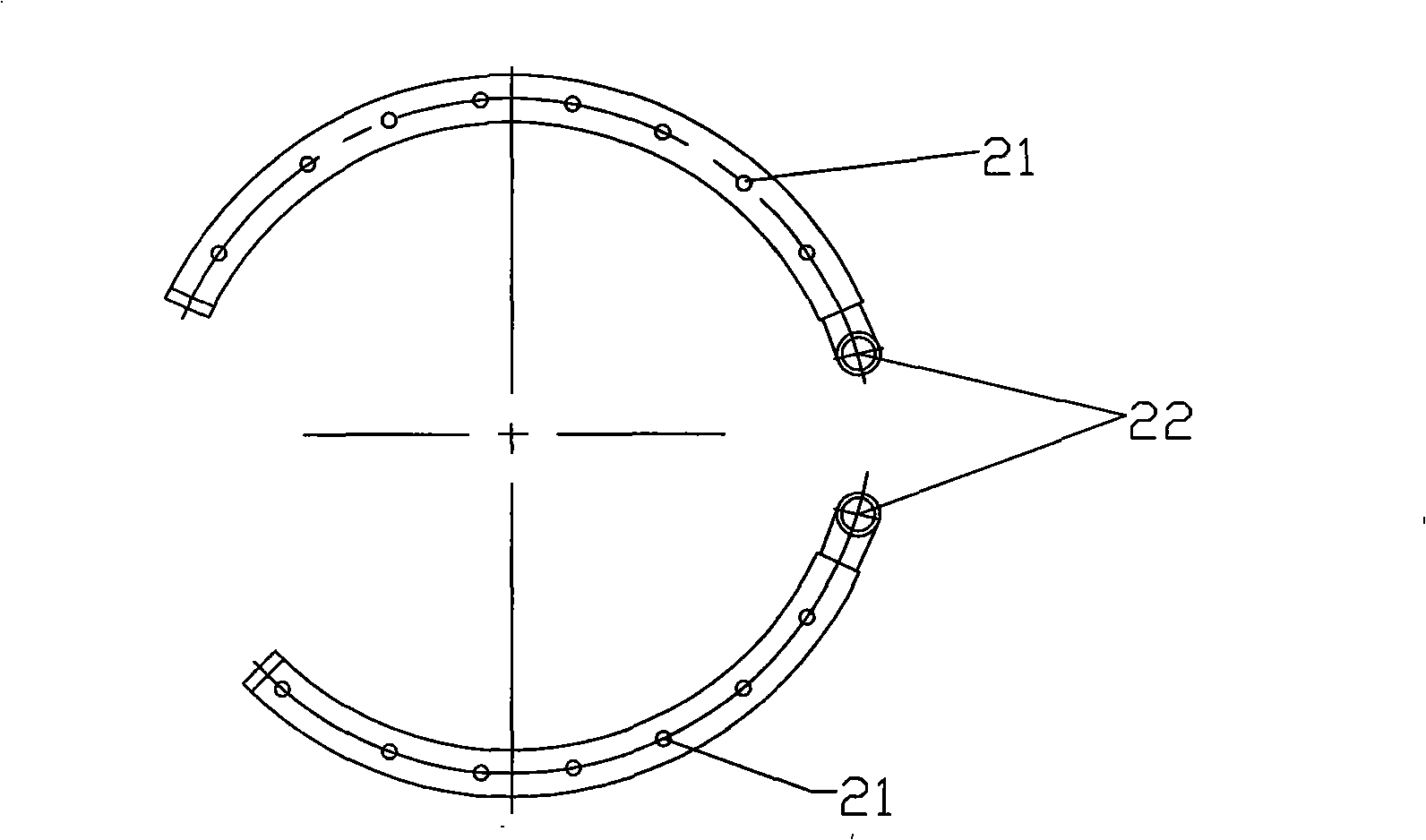

Novel rough coarse-grinding head cooling water supply facility

InactiveCN101332586AExtended service lifeWashed away in timeGrinding/polishing safety devicesEngineeringWater cooling

The invention relates to a water cooling and supply device, in particular to a water cooling and supply device for coarse grinding heads of ceramic tiles (stone material). The water supply device comprises a water cover surrounding a grinding wheel, the water cover is provided with at least one water outlet which can lead cooling water to a grinding point of the grinding wheel. The water cooling and supply device has simple structure, the grinding wheel is surrounded by the water cover provided with the water outlet, the water outlet can purposely lead the cooling water to the grinding point of the grinding wheel, the grinding wheel is well cooled and grinding swarf is washed away in time, which improves the grinding efficiency, prolongs the service life of the grinding wheel, improves the grinding quality, saves a great deal of cooling water, and meets the environmental protection requirement of energy conservation and emission reduction.

Owner:KEDA INDUSTRIAL GROUP CO LTD

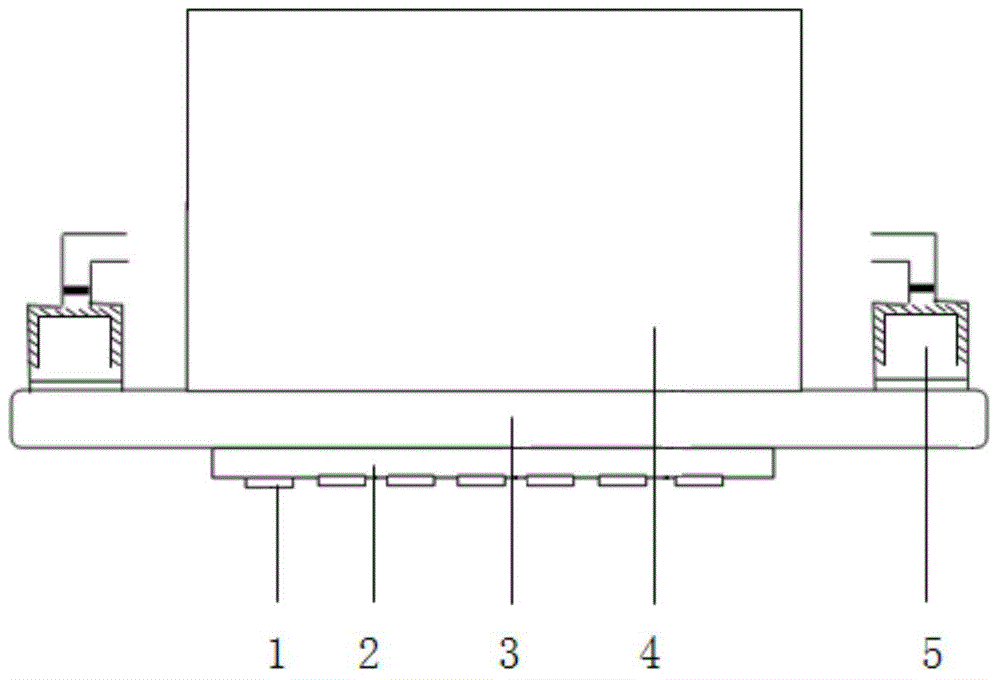

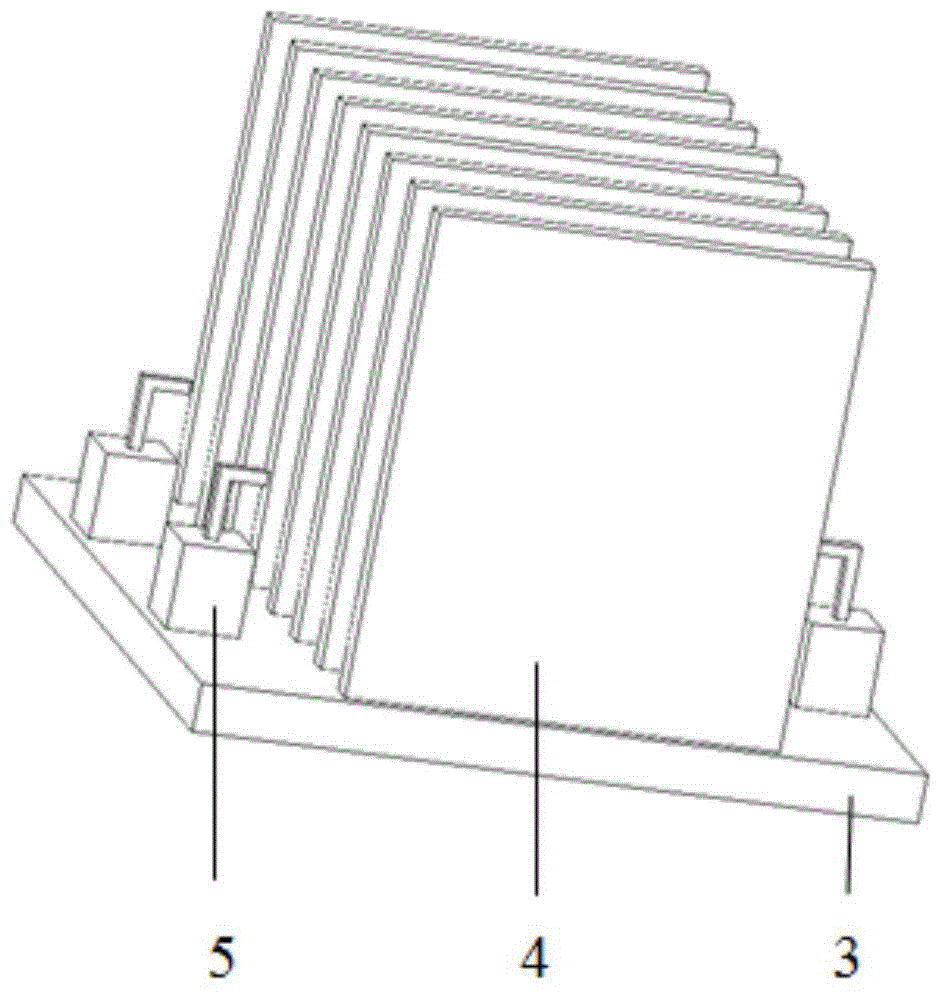

Double-heat-dissipation device of LED street lamp

InactiveCN104132318AImprove cooling effectReasonable designPoint-like light sourceLighting heating/cooling arrangementsEngineeringHeat spreader

The invention discloses a double-heat-dissipation device of an LED street lamp. The double-heat-dissipation device comprises LED integrated chips, a substrate, a heat exchange element, synthetic jet radiators and an insert radiator. The LED integrated chips are fixed onto the substrate, the substrate is fixed onto the heat exchange element, the insert radiator is arranged at the center of the top surface of the heat exchange element, the left side and the right side of the insert radiator are respectively provided with the same number of the synthetic jet radiators, and the synthetic jet radiators are installed on the top surface of the heat exchange element. The double-heat-dissipation device of the LED street lamp increases the heat exchange coefficient between air jets and cooling fins and greatly improves the heat dissipation performance.

Owner:SOUTH CHINA UNIV OF TECH

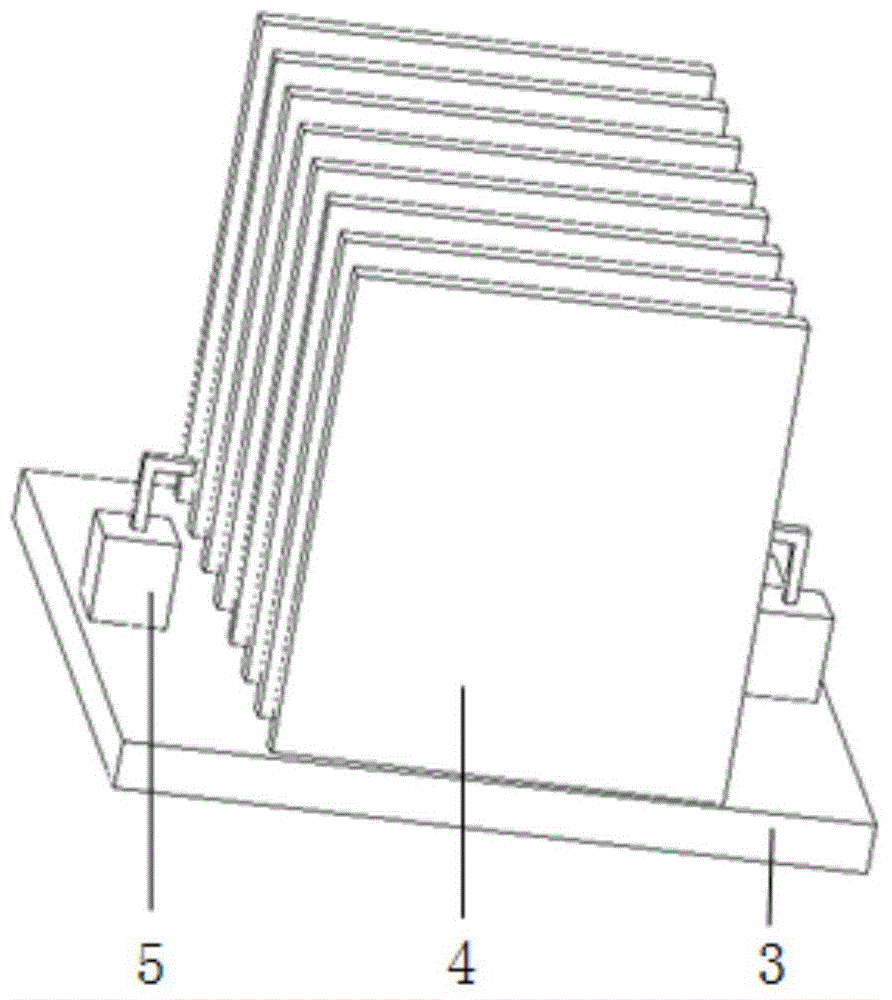

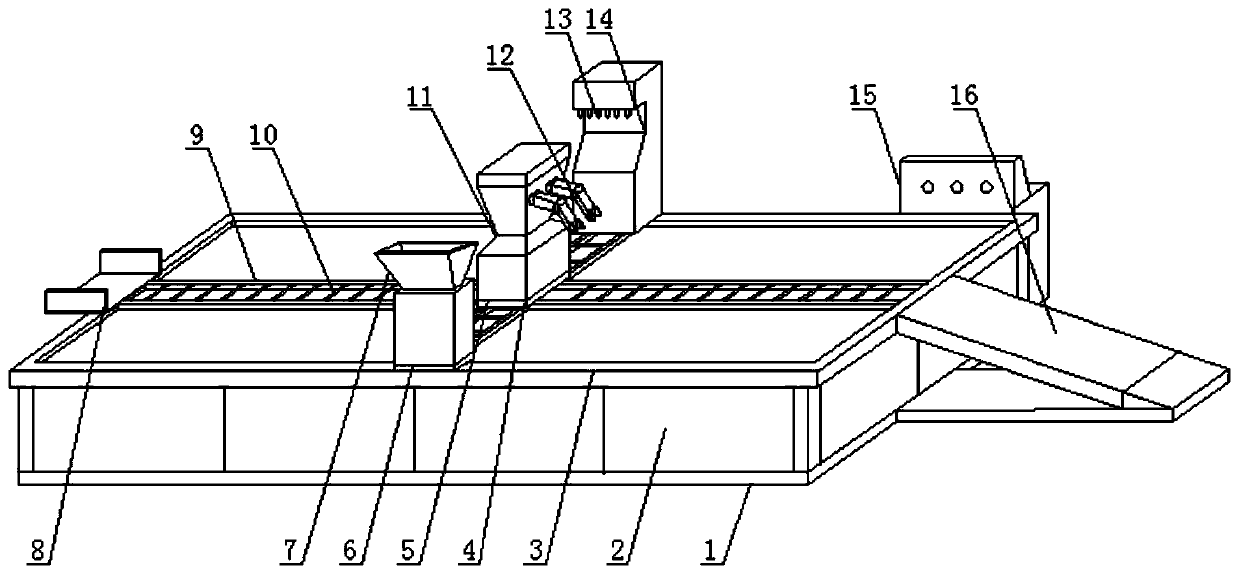

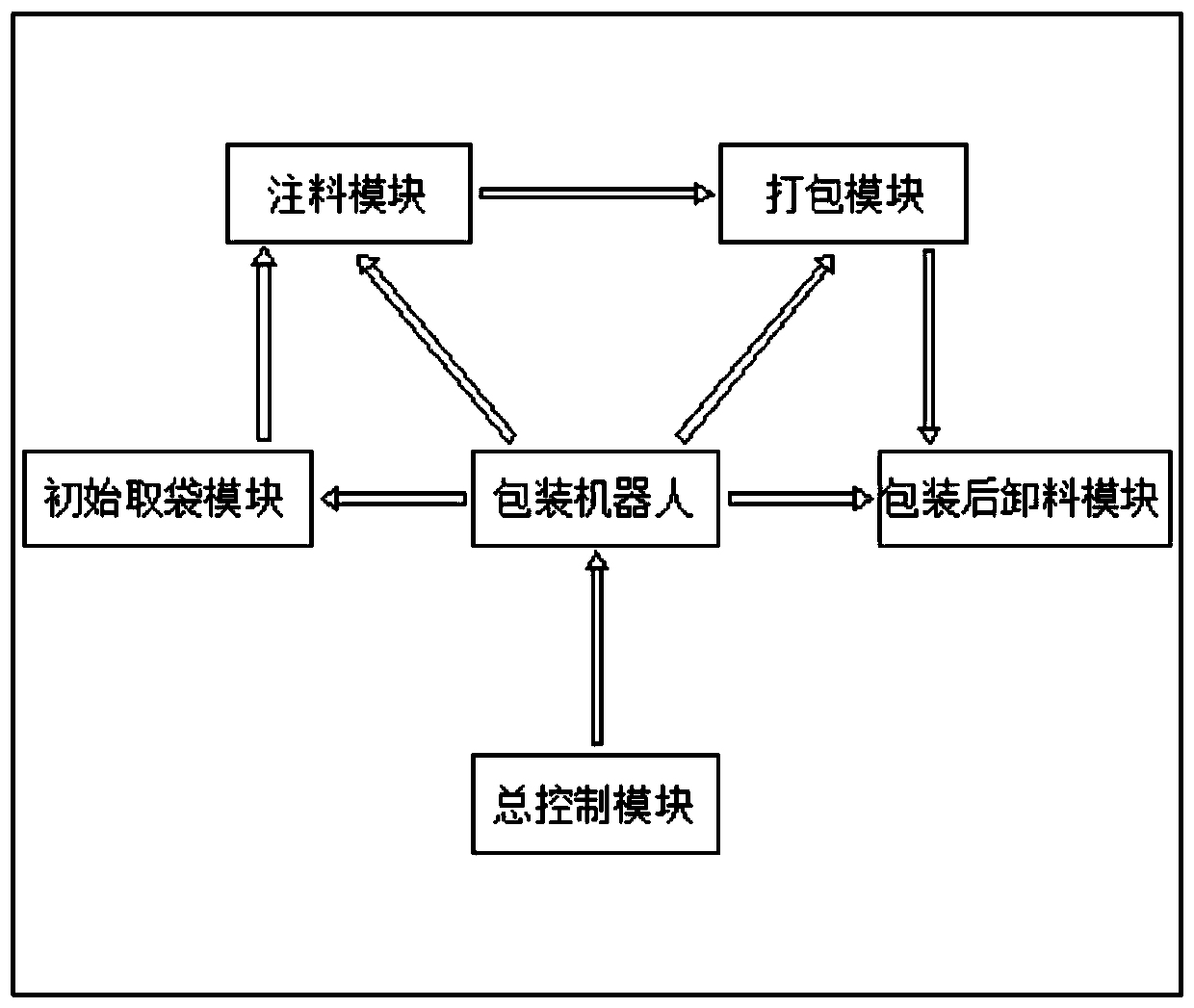

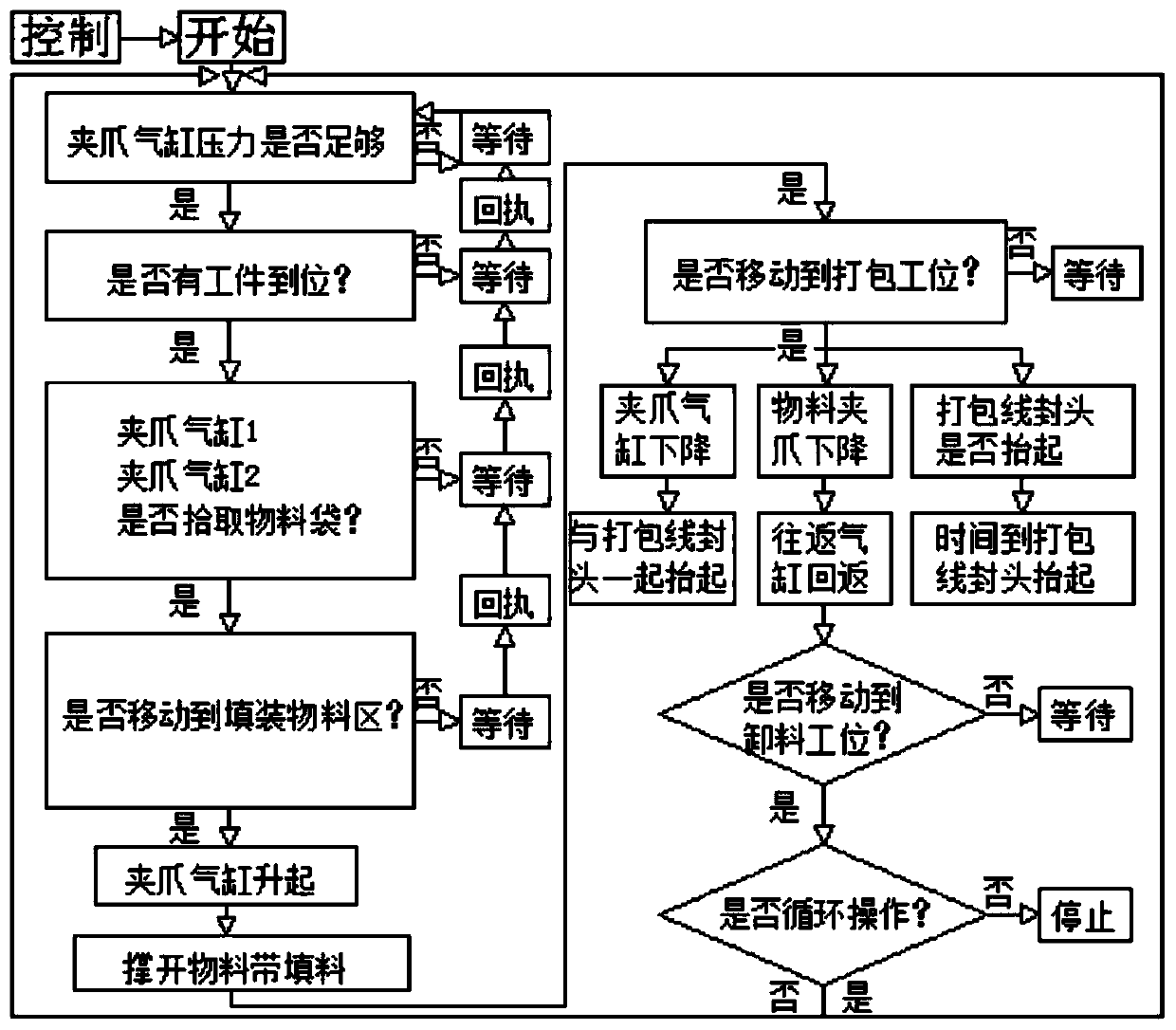

Robot type intelligent flexible packaging machine

The invention discloses a robot type intelligent flexible packaging machine. The machine comprises a placing base and a working platform; the working platform is mounted at the upper end of the mounting base; and the working platform and the placing base are fixedly connected through welding. According to the robot type intelligent flexible packaging machine of the invention, the guarantee mode ofa traditional intelligent flexible packaging machine is changed. The novel packaging robot is used for carrying out the working procedures of material taking, material injecting, packaging and discharging. Different from a traditional stiff intelligent flexible packaging mode, a mode adopting the packaging robot to perform packaging makes a whole packaging process more flexible and an operation stroke shorter. In this way, compared with the traditional intelligent flexible packaging machine, the robot type intelligent flexible packaging machine has higher packaging efficiency and a lower error rate, and can rapidly complete a whole packaging process only by installing a set track through two material clamping jaws.

Owner:合肥浩普智能装备科技有限公司

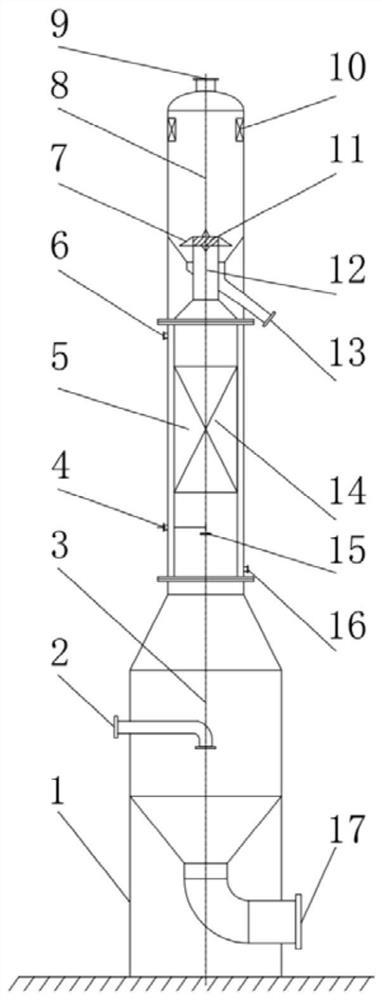

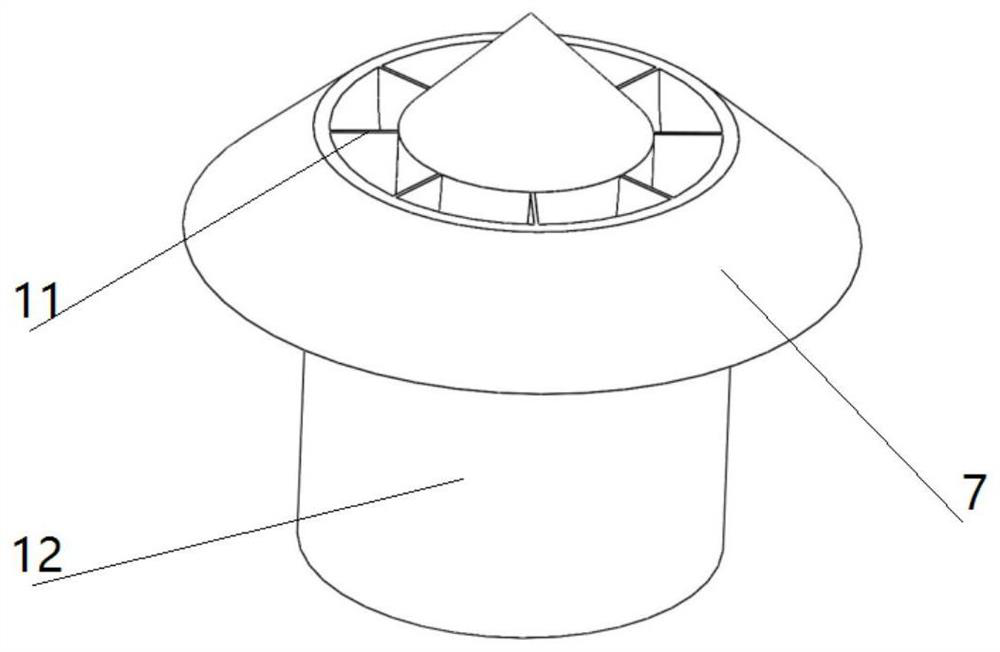

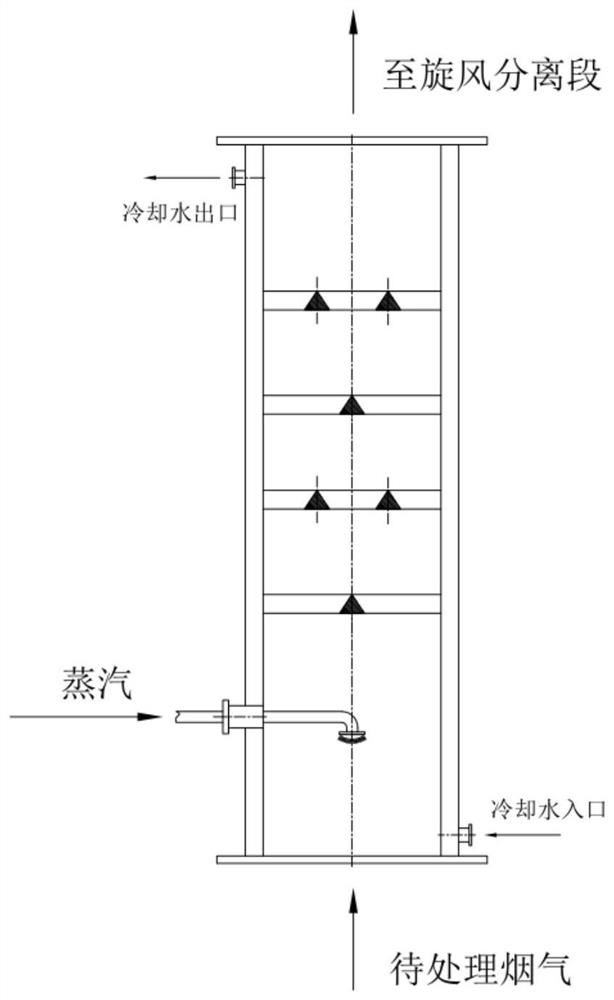

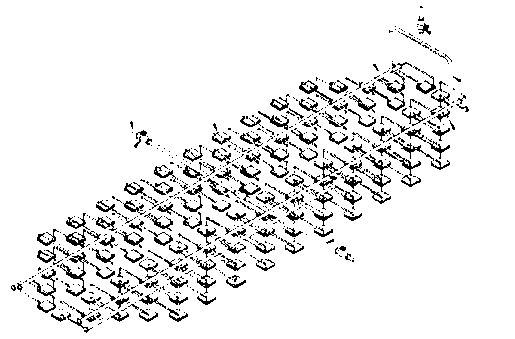

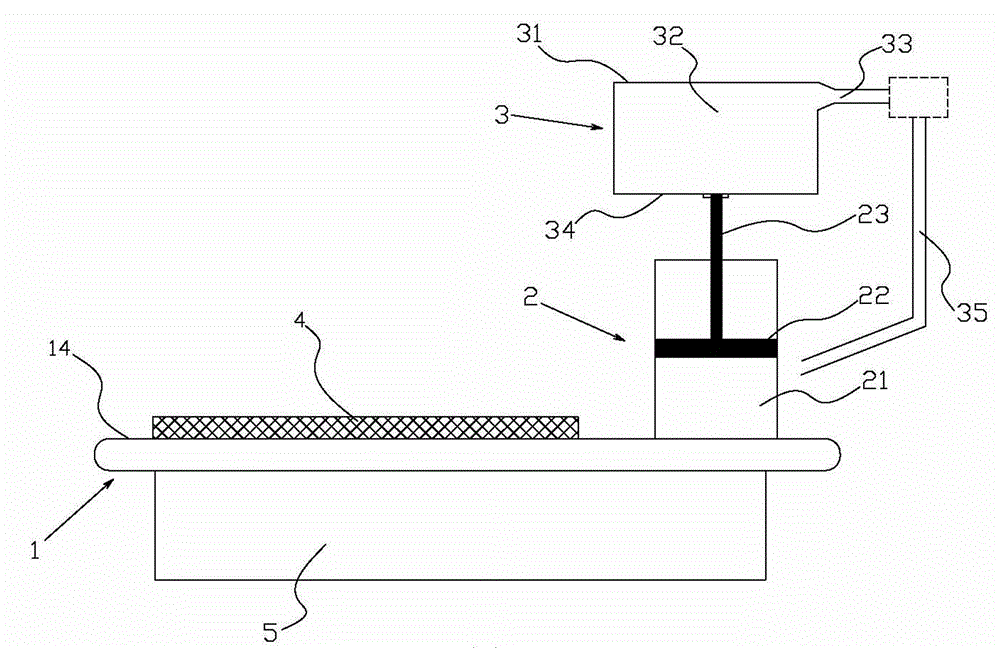

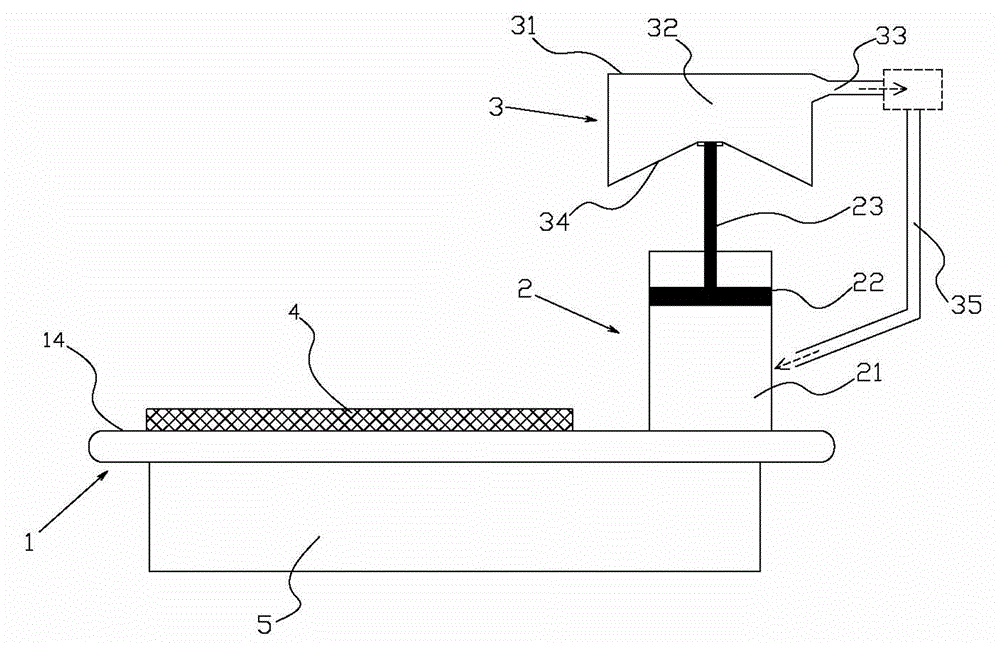

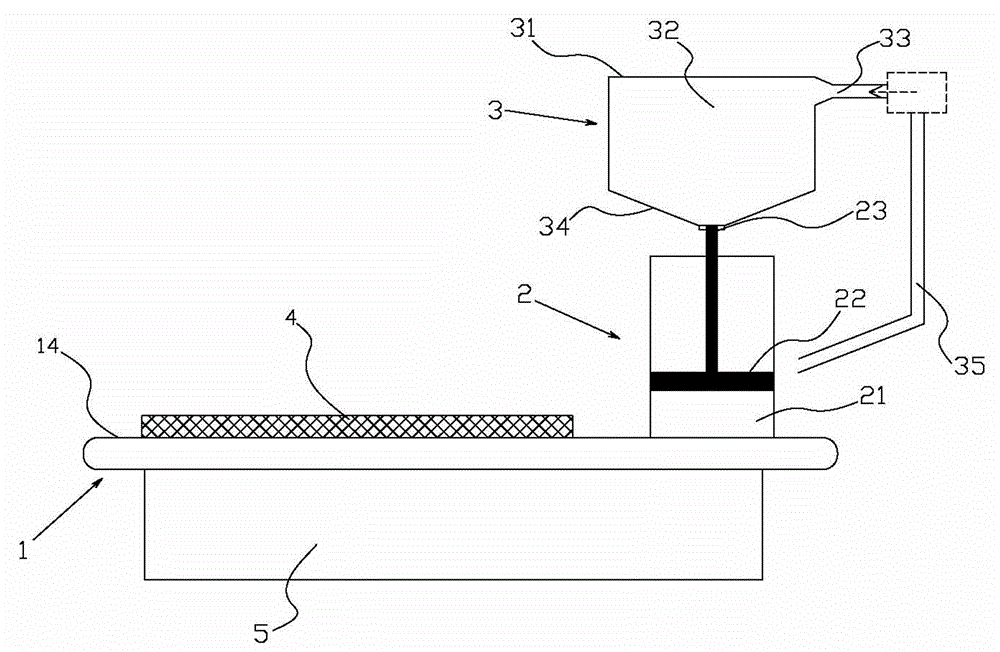

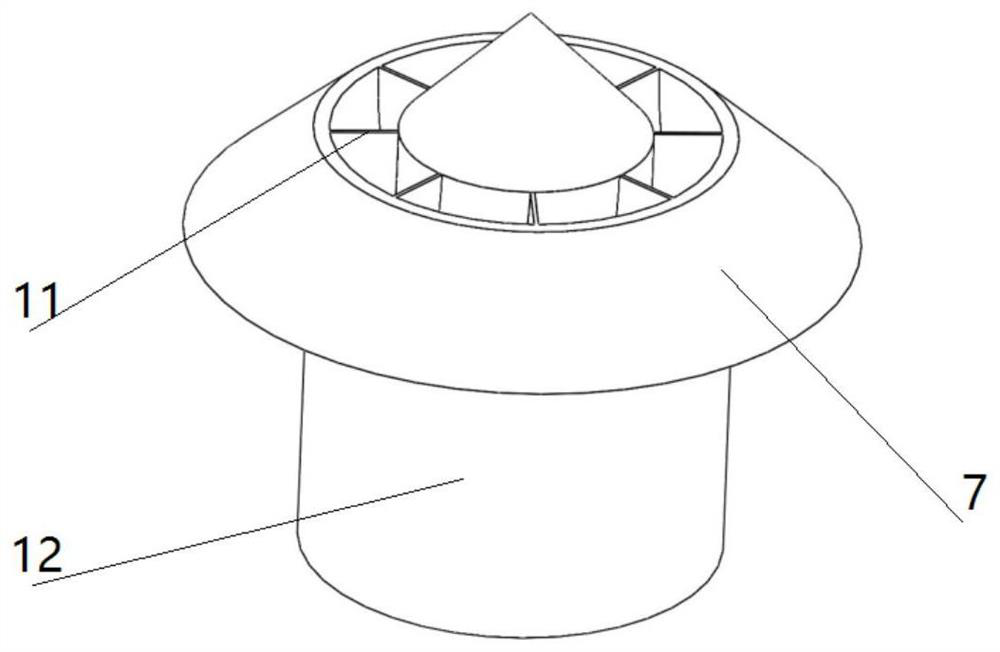

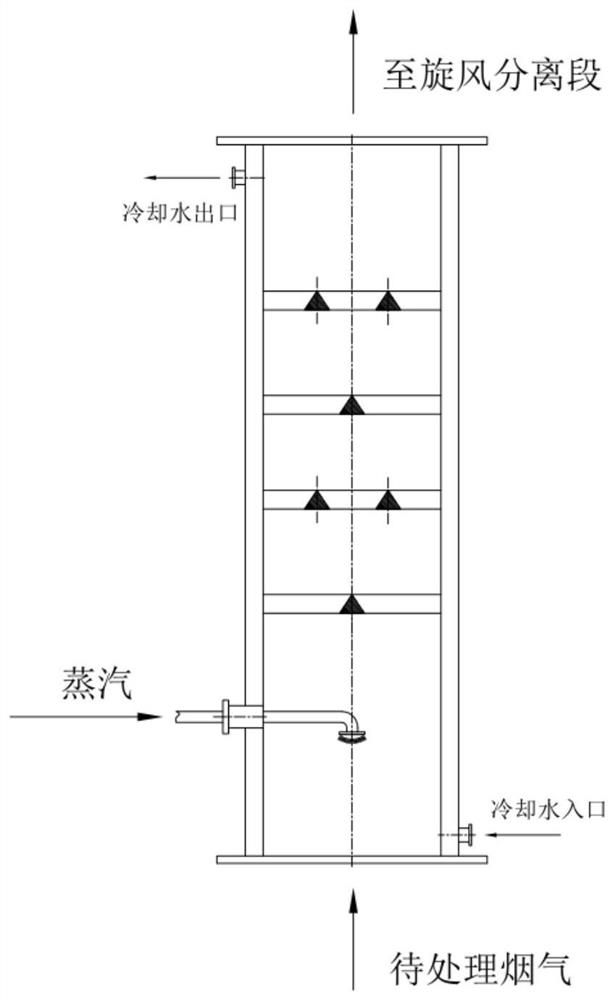

Compact industrial tail gas fine particle efficient removing and cooling device and method

ActiveCN112316570AMeet environmental protection requirementsImprove the separation effectHuman health protectionDispersed particle separationExhaust gasPollutant

The invention provides a compact industrial tail gas fine particle efficient removing and cooling device and method, the device comprises a flue gas pretreatment unit and a cyclone separating unit, the flue gas pretreatment unit comprises a gravity settling chamber and a steam phase change chamber, the lower end of the steam phase change chamber is communicated with the upper part of the gravity settling chamber, wherein the steam phase change chamber is divided into a steam phase change section and a turbulence agglomeration section from bottom to top, the device adopts an integrated design of a particle pretreatment unit and the cyclone separating unit, and particularly, a steam phase change agglomeration and turbulence agglomeration treatment technology is firstly fused into the particle pretreatment unit, so that the removal of coarse particles and the agglomeration and growth of fine particles in dust-containing tail gas are realized; the cyclone separating unit adopts an axial flow type cyclone separator structure with a reflecting screen, so that the fine particle removal efficiency is effectively improved; and the device is compact in overall structure, small in occupied area and convenient to operate, and the purpose of efficiently removing fine particle pollutants in industrial tail gas in an energy-saving mode is achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

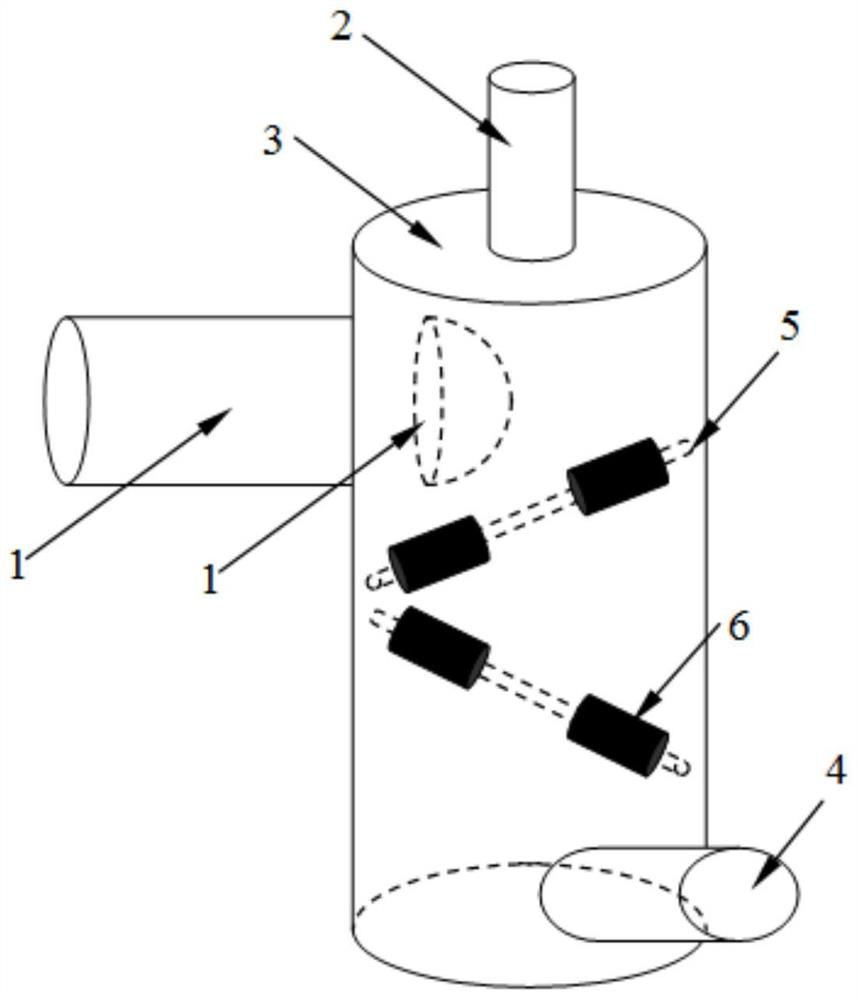

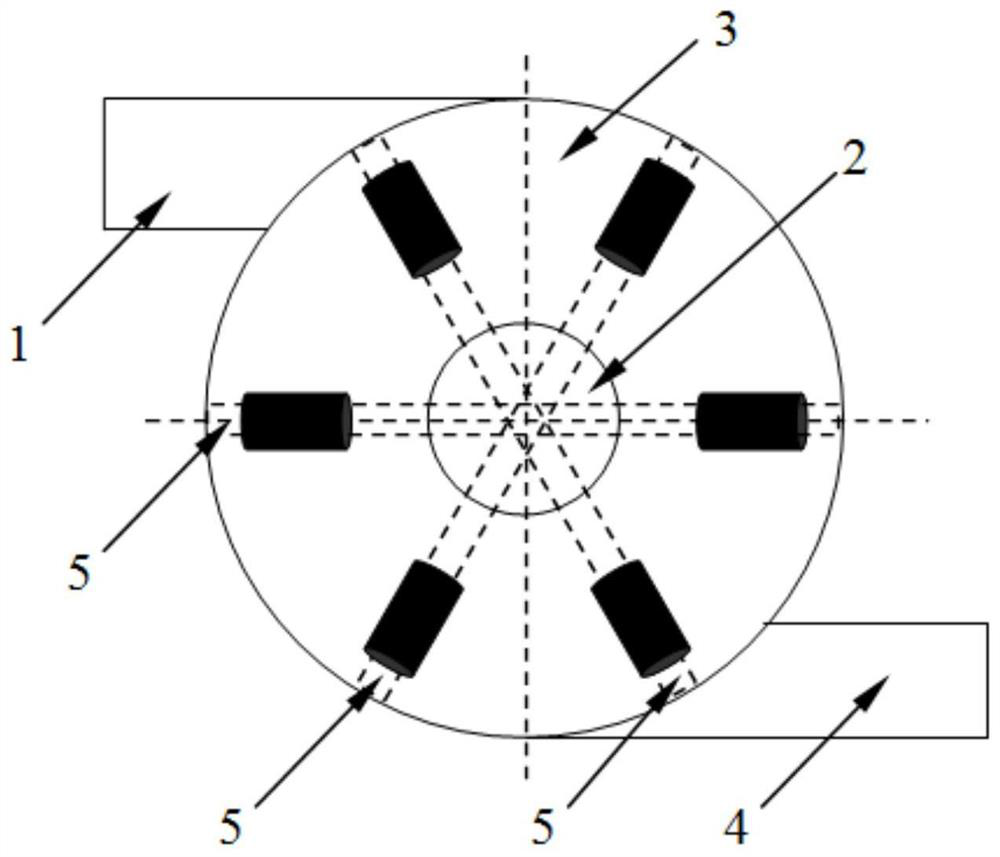

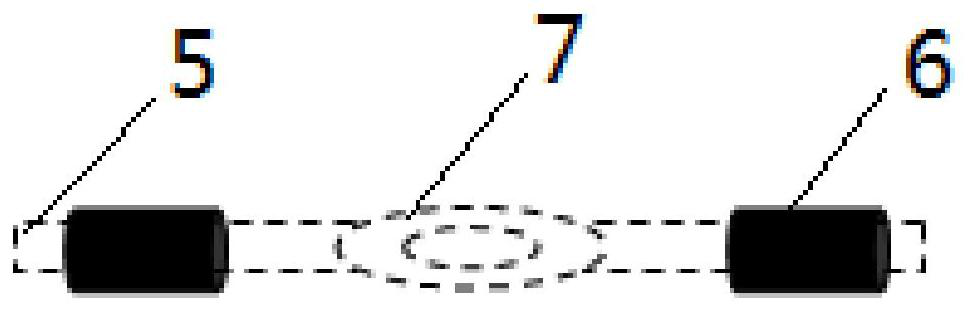

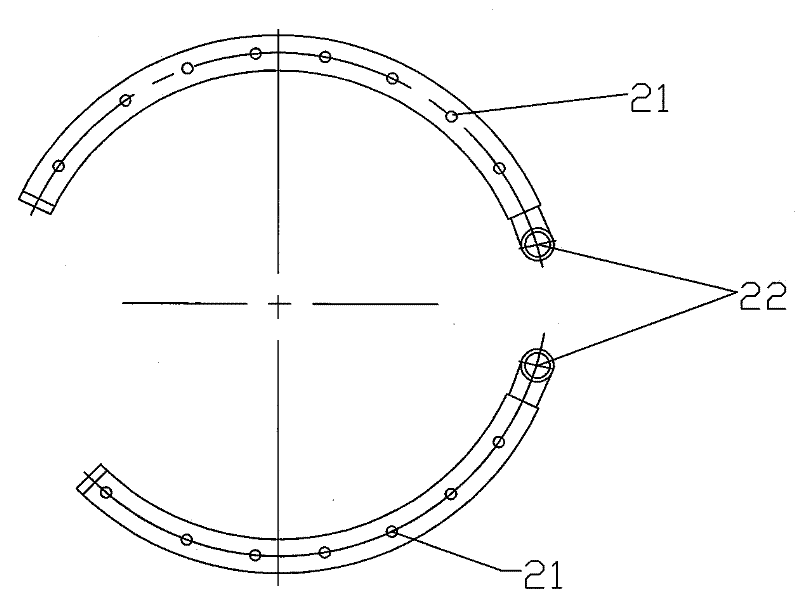

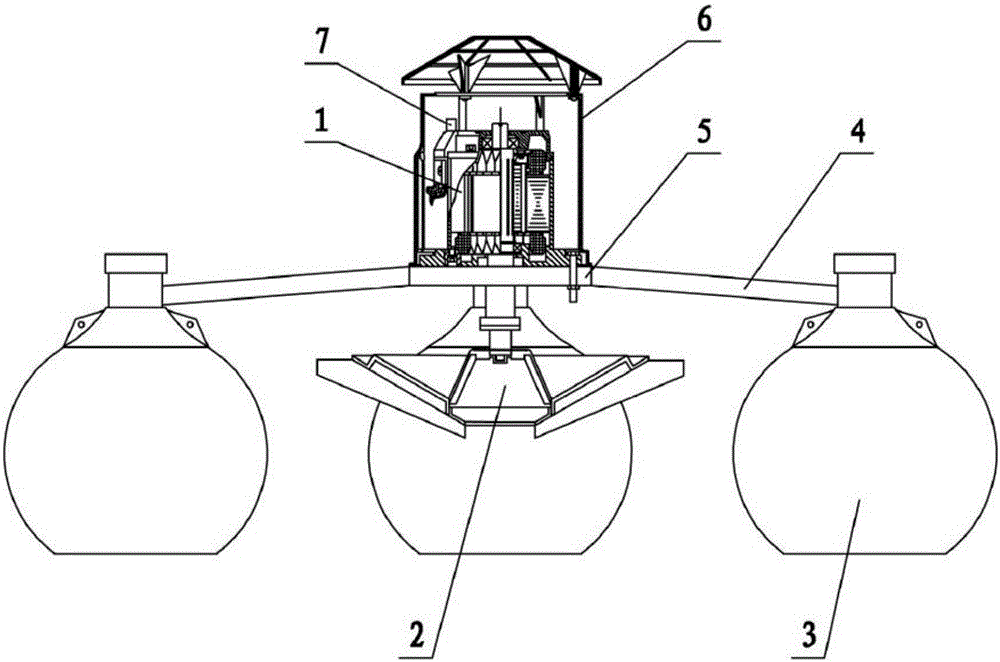

Auxiliary quick floating device of water surface floating building and application method thereof

InactiveCN103101608AQuick floatNo consumptionVessel salvagingSocial benefitsEnvironmental engineering

The invention provides an auxiliary quick floating device of a water surface floating building and an application method thereof. The auxiliary quick floating device of the water surface floating building consists of water storing devices (1), vent pipe systems (2) and environmental water communicating pipe systems (3), wherein the vent pipe systems (2) and the environmental water communicating pipe systems (3) are connected with all the water storing device. The auxiliary quick floating device of the water surface floating building further comprises a main pipe for gathering all the pipe systems, a ventilation valve (4), outboard valves (5), communicating valves (6) on the both sides of the environmental water communicating pipe systems, and outboard pipes (7). The auxiliary quick floating device is applied to the large-size water surface floating building; and after the auxiliary quick floating device is constructed or grounded in the other conditions, the floating building realizes the quick secondary floatation through simple and easy operation. The auxiliary quick floating device can be directly applied to improvement and upgrade of a newly-built water surface building or the conventional building. The auxiliary quick floating device is simple in structure, can carry out quick floatation in a non-power driving manner, and has good social benefits.

Owner:NANTONG DAODA MARINE ENG

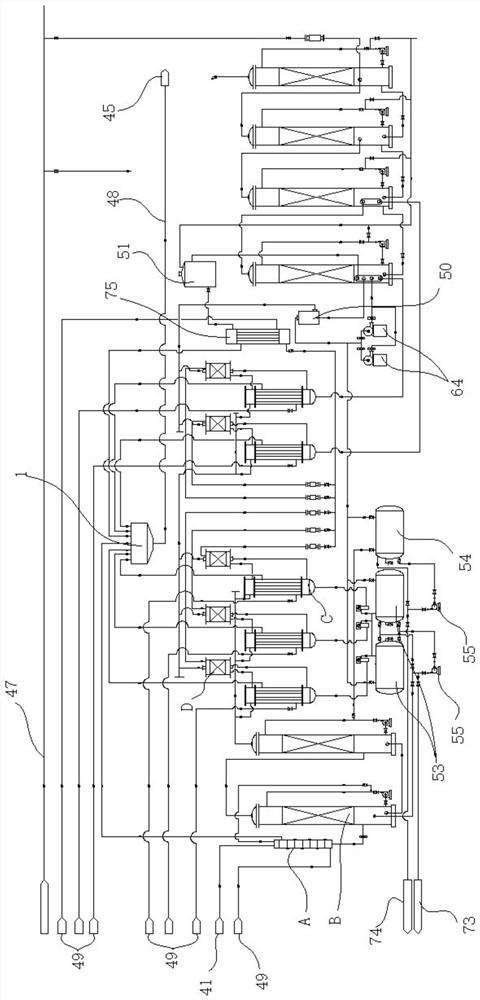

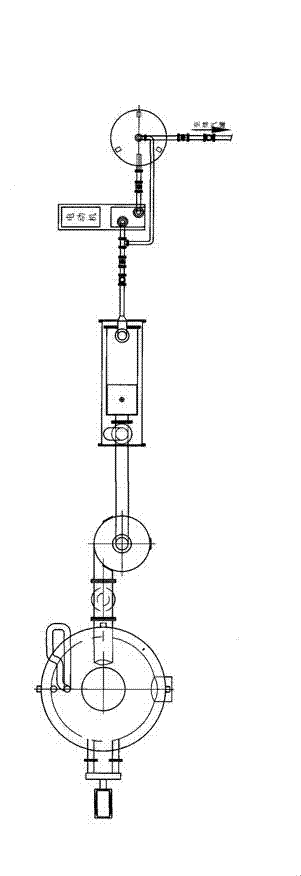

Method and device for recovering oligomers for polyphenylene sulfide production

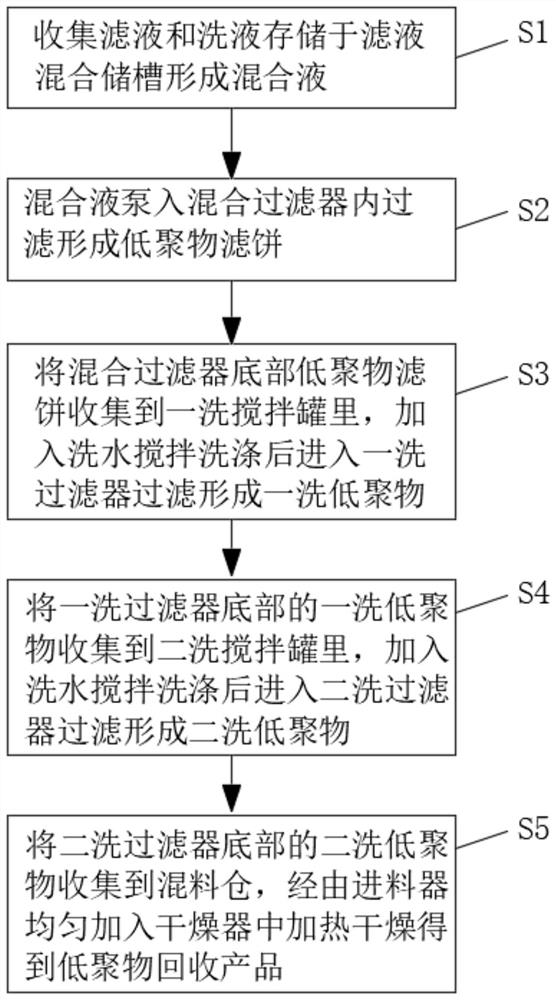

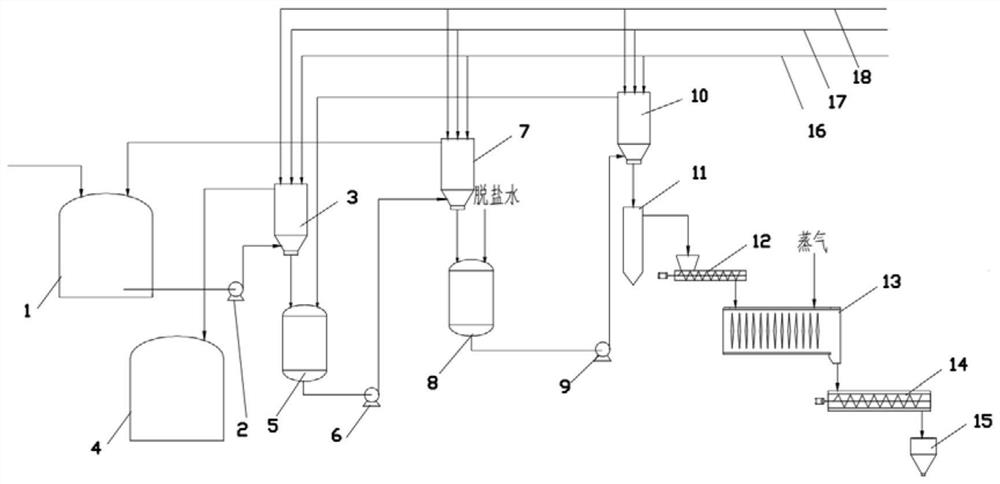

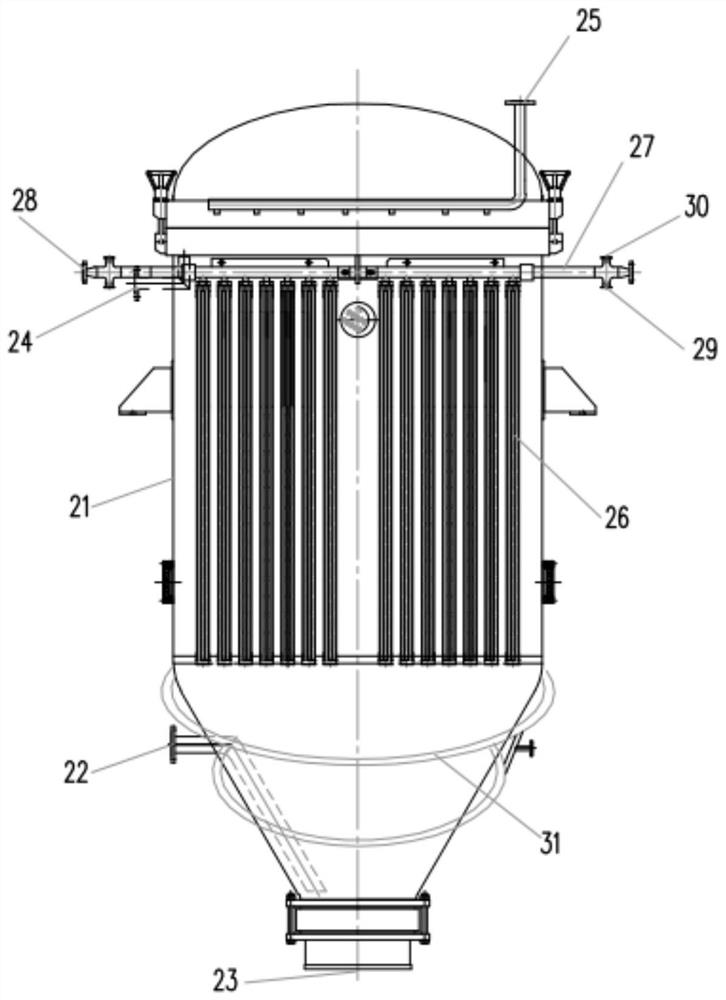

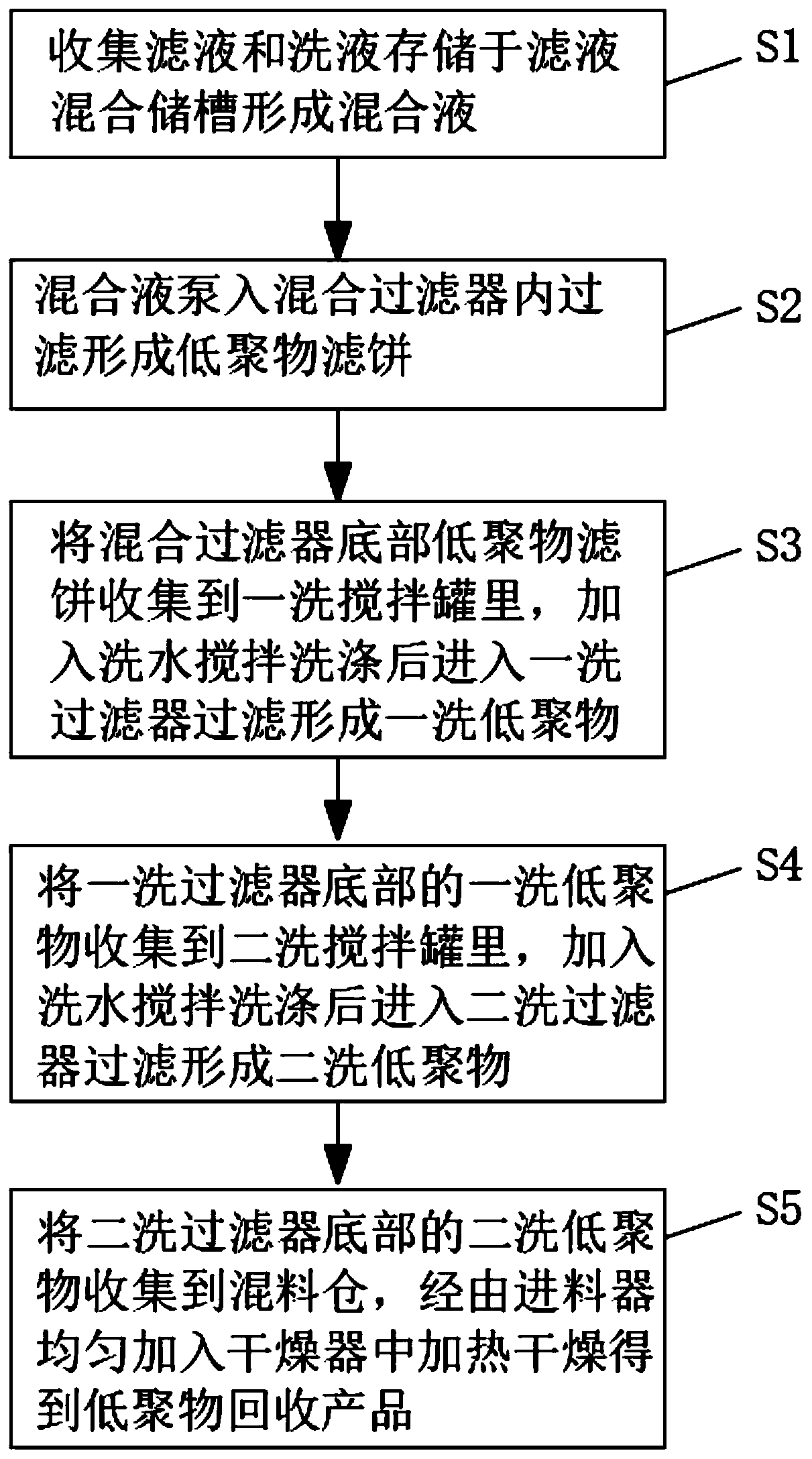

The invention discloses a polyphenylene sulfide oligomer recovery method. The method comprises the following steps: S1, collecting a filtrate and a washing liquid, and storing the filtrate and the washing liquid in a filtrate mixing storage tank to form a mixed liquid; S2, pumping the mixed liquid into a mixing filter, and carrying out filtering to form an oligomer filter cake; S3, collecting theoligomer filter cake at the bottom of the mixing filter into a primary-washing stirring tank, adding washing water, carrying out stirring and washing, and allowing the filter cake to enter a primary-washing filter to undergo filtering so as to form a primary-washing oligomer; S4, collecting the primary-washing oligomer at the bottom of the primary-washing filter into a secondary-washing stirring tank, adding washing water, carrying out stirring and washing, and allowing the filter cake to enter a secondary-washing filter to undergo filtering so as to form a secondary-washing oligomer; and S5,collecting the secondary-washing oligomer at the bottom of the secondary-washing filter into a mixing bin, uniformly adding the secondary-washing oligomer into a dryer through a feeder, and performingheating and drying to obtain a recovered oligomer product. According to the method, the oligomer with a certain economic value in the filtrates are recycled through filtering, washing and drying, meanwhile, solid waste emission is reduced, and the environmental protection requirements for energy conservation and emission reduction are met.

Owner:CHONGQING JUSHI NEW MATERIAL TECH CO LTD

Method and device for recovering oligomers for polyphenylene sulfide production

The invention discloses a polyphenylene sulfide oligomer recovery method. The method comprises the following steps: S1, collecting a filtrate and a washing liquid, and storing the filtrate and the washing liquid in a filtrate mixing storage tank to form a mixed liquid; S2, pumping the mixed liquid into a mixed filter, and filtering to form an oligomer filter cake; S3, collecting the oligomer filter cake at the bottom of the mixed filter into a primary washing stirring tank, adding washing water, stirring, washing, and filtering in a primary washing filter to form a primary washing oligomer; S4, collecting the primary-washing oligomer at the bottom of the primary washing filter into a secondary washing stirring tank, adding washing water, stirring, washing, and filtering in a secondary washing filter to form a secondary washing oligomer; and S5, collecting the secondary washing oligomer at the bottom of the secondary washing filter into a mixing bin, uniformly adding the secondary washing oligomer into a dryer through a feeder, heating and drying to obtain an oligomer recovery product. According to the method, the oligomer with a certain economic value in the filtrate is recycled through filtering, washing and drying; meanwhile, solid waste emission is reduced, and the environmental protection requirements for energy conservation and emission reduction are met.

Owner:CHONGQING JUSHI NEW MATERIAL TECH CO LTD

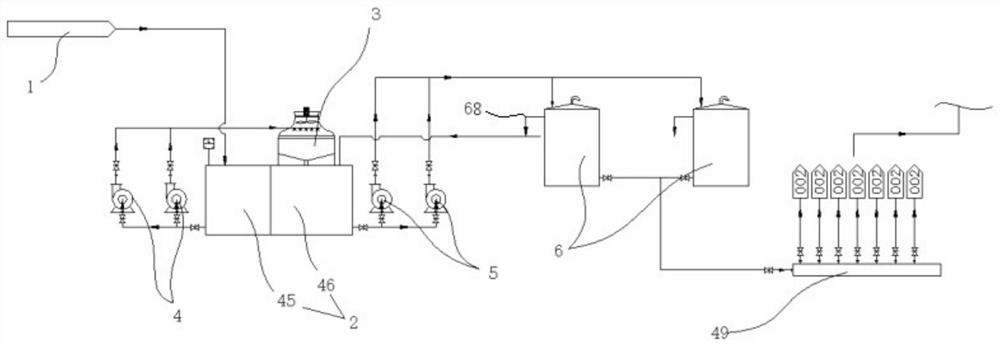

Drying, tentering and setting process

InactiveCN105040339AIncrease profitMeet the environmental protection requirements of energy saving and emission reductionHeating/cooling textile fabricsStretchingCold airProcess engineering

The invention relates to a drying, tentering and setting process. The drying, tentering and setting process comprises the following steps: feeding a fabric in a rope shape or an open width; feeding the fabric to a feeding trough; rolling the fabric through a padder; conveying the fabric to a drying machine; feeding the dried fabric to an intermediate-pressure high-temperature steam heating and setting machine and carrying out setting and tentering; then feeding the fabric into a master over-feed device, a selvedge uncurler, a left small over-feed device, a right small over-feed device and a needle yielding plate or tongs in sequence; then feeding the fabric to multi-connected setting high-temperature hot air circularly sprayed up and down; conveying the fabric to a high-temperature drying oven, and then carrying out cold air cooling and needle or tongs removing in sequence; then feeding the fabric to a water-cooling roller, and finally fabric crossing or curling and taking the fabric out. According to the drying, tentering and setting process disclosed by the invention, an old process having a large amount of heat energy wastes is changed, the energy can be saved by about 35 percent under the conditions of the same fabric, the same yield and the same quality, the product quality and the equipment utilization rate are greatly improved, and the environment-friendly requirements of energy saving and emission reduction are achieved.

Owner:ZHEJIANG JINGBAO MACHINERY

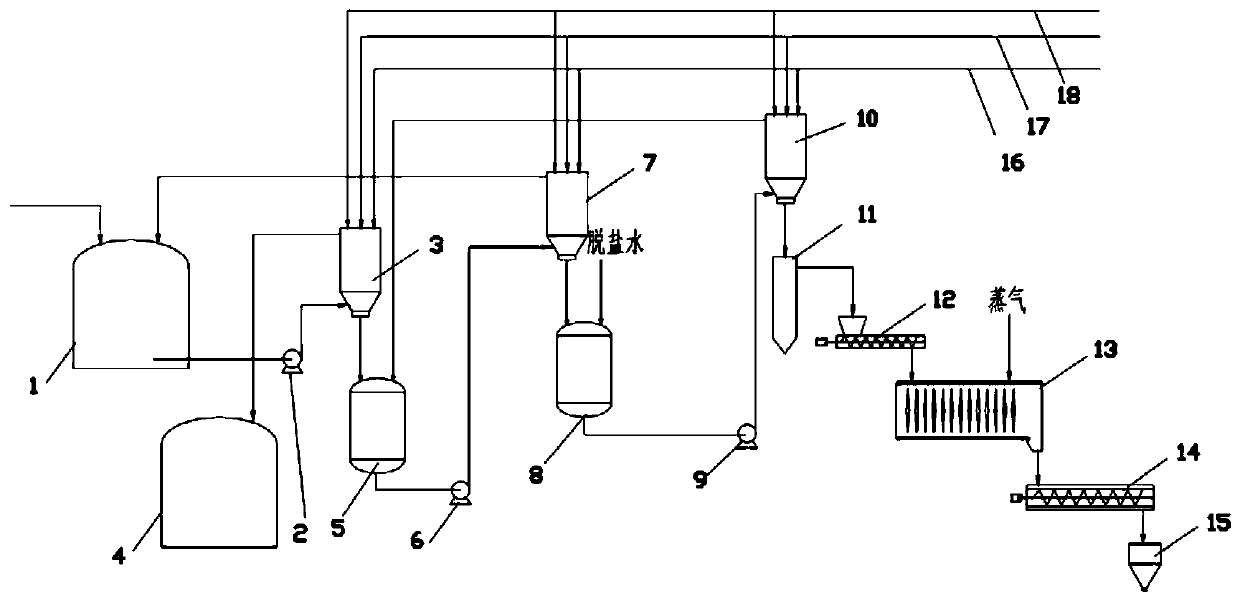

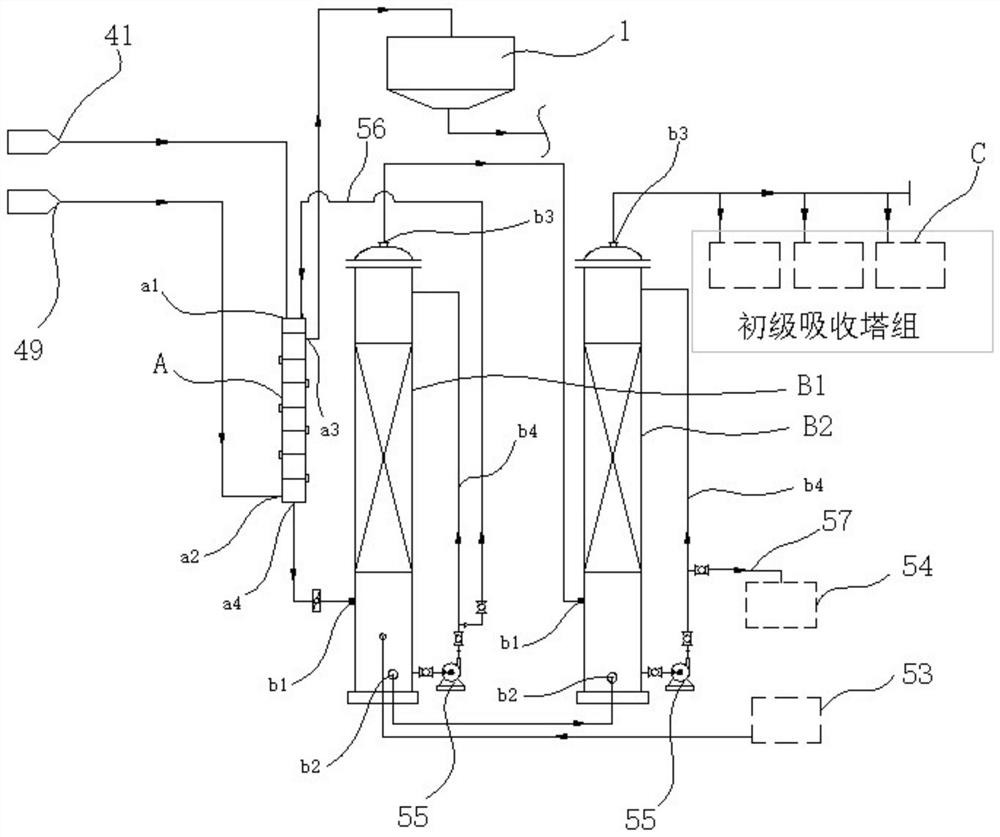

An environmentally friendly process for purifying tail gas from potassium sulfate production

ActiveCN109758874BHigh yieldRaise the gradeChlorine/hydrogen-chloride purificationDispersed particle separationVapor–liquid separatorEnvironmental engineering

The invention proposes an environmentally friendly process for purifying the tail gas produced by potassium sulfate. The tail gas is treated through tail gas treatment equipment. The tail gas treatment equipment includes a tail gas transportation pipeline, a graphite cooler, a primary scrubber group, a secondary scrubber group, and a primary absorption tower group. , secondary absorption tower group, gas-liquid separator, acid making bucket, hydrochloric acid intermediate tank and water circulation cooling assembly. The process flow of the environmentally friendly process includes tail gas cooling, B acid production, A acid production, dilute hydrochloric acid production and cooling water circulation. The present invention In view of the problems existing in the existing tail gas treatment, development and improvement can be carried out to produce multi-specification hydrochloric acid. The hydrochloric acid yield rate is high, the grade is high, the quality is good, and the market is good. The hydrogen chloride tail gas treated by the present invention has a high absorption rate and meets the emission requirements. The combination of process water and circulating water saves the enterprise's water, which meets the enterprise's low-cost and high-efficiency production requirements, and also meets the environmental protection requirements of energy conservation and emission reduction.

Owner:崔立军

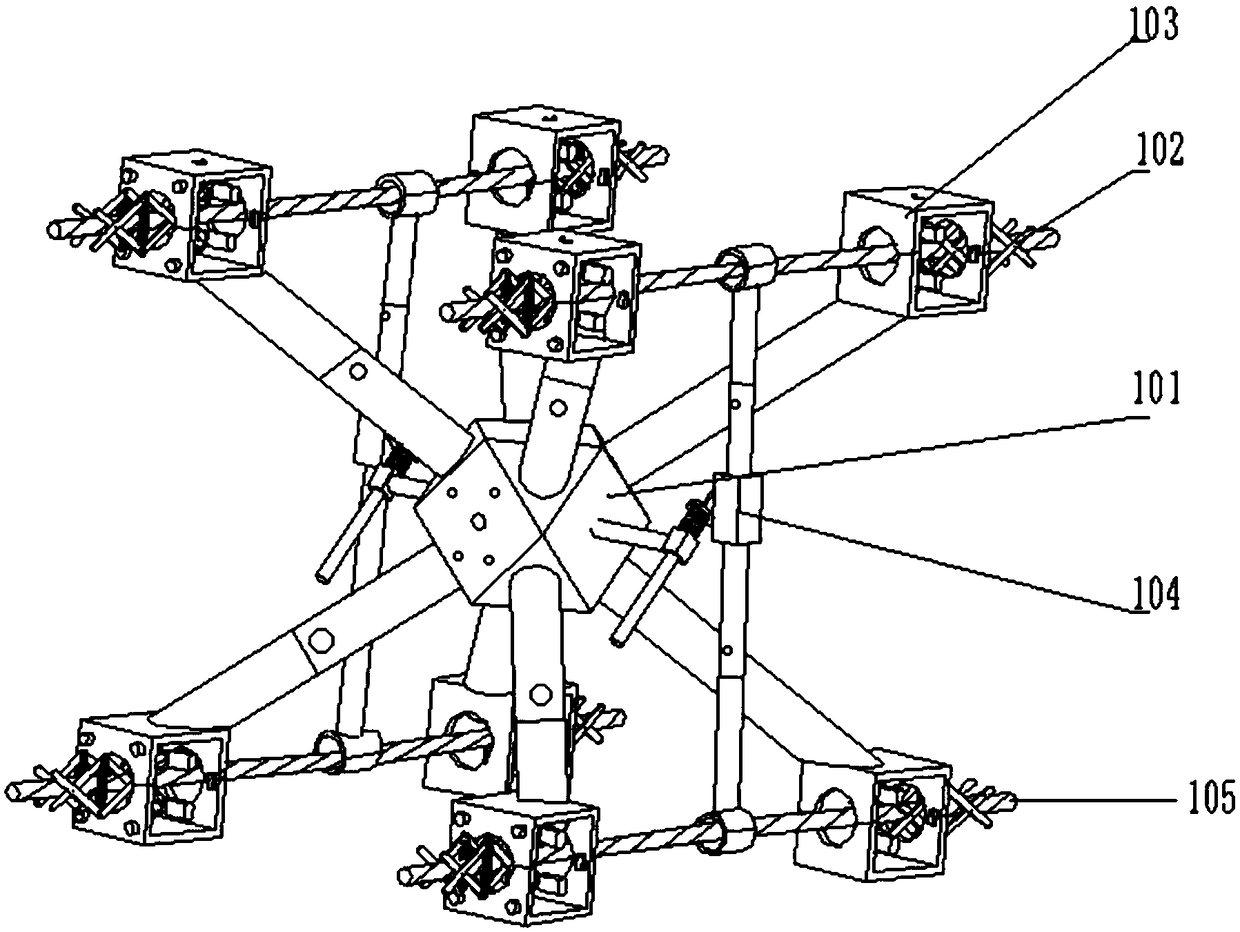

Automatic patrol-inspection and cleaning device for ultrahigh-pressure four-split power line

ActiveCN109047082ARealize automatic secondary cleaningIncreased cleansing powerCleaning using toolsPhotovoltaic energy generationComputer moduleElectric power

Owner:HEBEI UNIV OF TECH

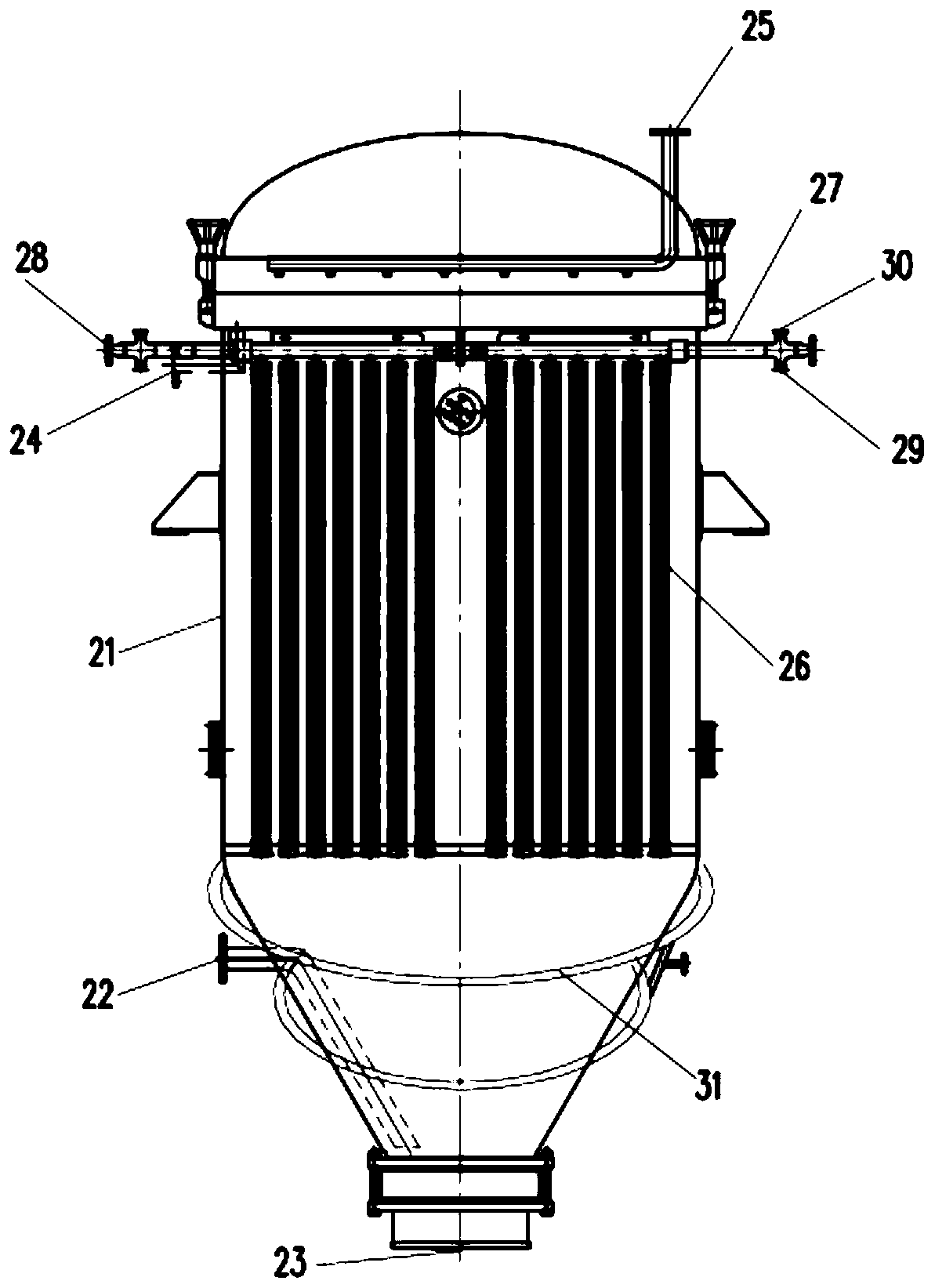

Environment-friendly preparation technology for composite material

The invention discloses an environment-friendly preparation technology for a composite material. The environment-friendly preparation technology comprises the following steps: preparing a mould; preparing a gel coat layer; performing leakage-proof shaping on the mould; assembling the mould; paving a reinforcing rib and a reinforcing layer; paving vacuum accessories and a runner; packaging a vacuumfilm; introducing a resin in vacuum; curing and recycling styrene; de-molding; cutting and shaping; recycling slitter edges and dust. When styrene is recycled, styrene is under gaseous state; a fin tubular type styrene condenser is adopted for recycling styrene; desalted water is used as a cooling medium; the recycled styrene material is served as a resin material introduced in vacuum. Accordingto the invention, the manner of condensation recycling is adopted for solving the problem of serious benzene and alkene pollution of the prior art. The recycled styrene is used as the resin material again, so that the pollution is reduced and the cost is greatly lowered.

Owner:常州市可可环保科技有限公司

Extraction method of liquiritin compounds

InactiveCN105769983AHigh process yieldShort processPlant ingredientsHigh concentrationChromatographic separation

The invention discloses an extraction method of liquiritin compounds.Radix glycyrrhiza serves as the raw material for extraction production.The extraction method includes the steps of 1, cleaning, wherein cold water or industrial purified water is adopted for rinsing; 2, breaking and milling, wherein rinsed glycyrrhiza is broken and milled to break cells; 3, serum separation, wherein a filter press or a centrifuge is adopted for separation, and glycyrrhiza cell serum is obtained; 4, enzyme deactivation, wherein a superhigh-temperature flash sterilization device process is adopted to perform superhigh-temperature flash sterilization on the glycyrrhiza cell serum; 5, purification, a macroporous resin adsorption and chromatographic separation process is adopted to adsorb and purify active materials such as liquiritin compounds in glycyrrhiza extract, and adsorption separation and purification are further performed to obtain high-concentration extraction liquor containing active ingredients such as liquiritin compounds; 6, concentration, wherein a vacuum concentration process is adopted to obtain concentrated liquor; 7, drying, wherein the concentrated liquor is atomized to obtain concentrate; 8, cooling, wherein the dry concentrate is cooled and subjected to agglomerating granulation, and the product can be obtained.

Owner:刘良贵

Disinfection and pest-killing mixture

The invention relates to a disinfection and pest-killing mixture. The disinfection and pest-killing mixture is characterized by being prepared by taking pynamin and permethrin as principal raw materials through processes of glue binding, micro emulsion and compounding. According to the disinfection and pest-killing mixture, the physical property that an insecticide is insoluble in water is solved, the drug mixing problem that the chemical properties of a disinfectant and the insecticide are antagonistic with each other is solved, a series of technical problems such as the composition of a surfactant are solved, and a complex formula becomes reality, so that the technical support and the research and development idea are provided for the development of a new generation of the disinfection and pest-killing mixture.

Owner:王福建

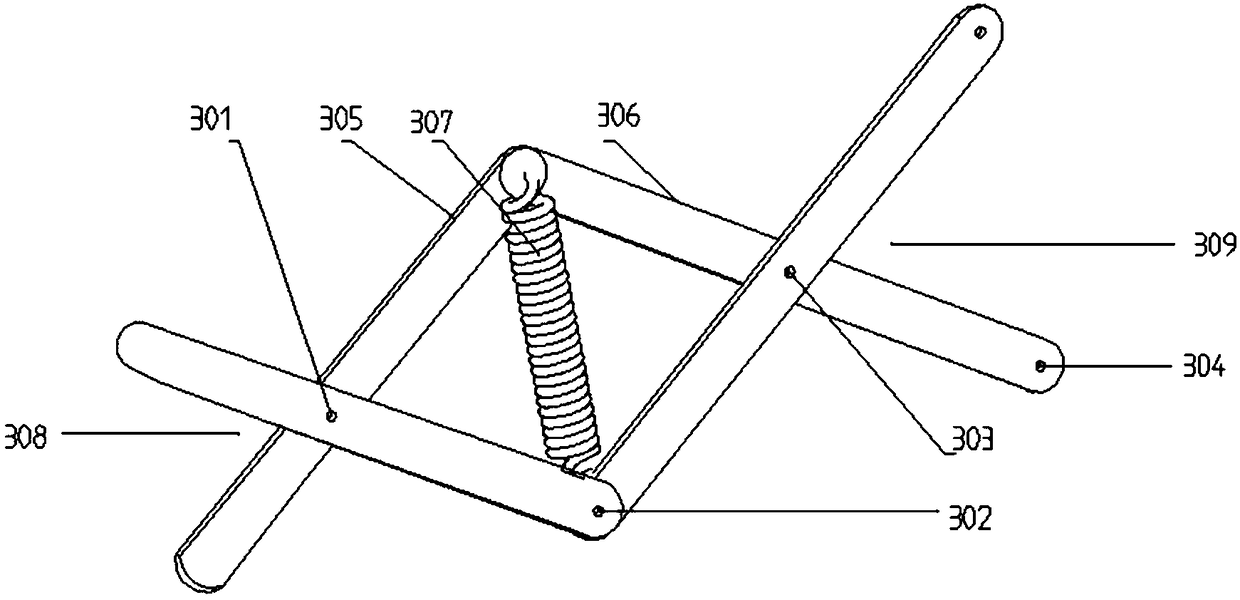

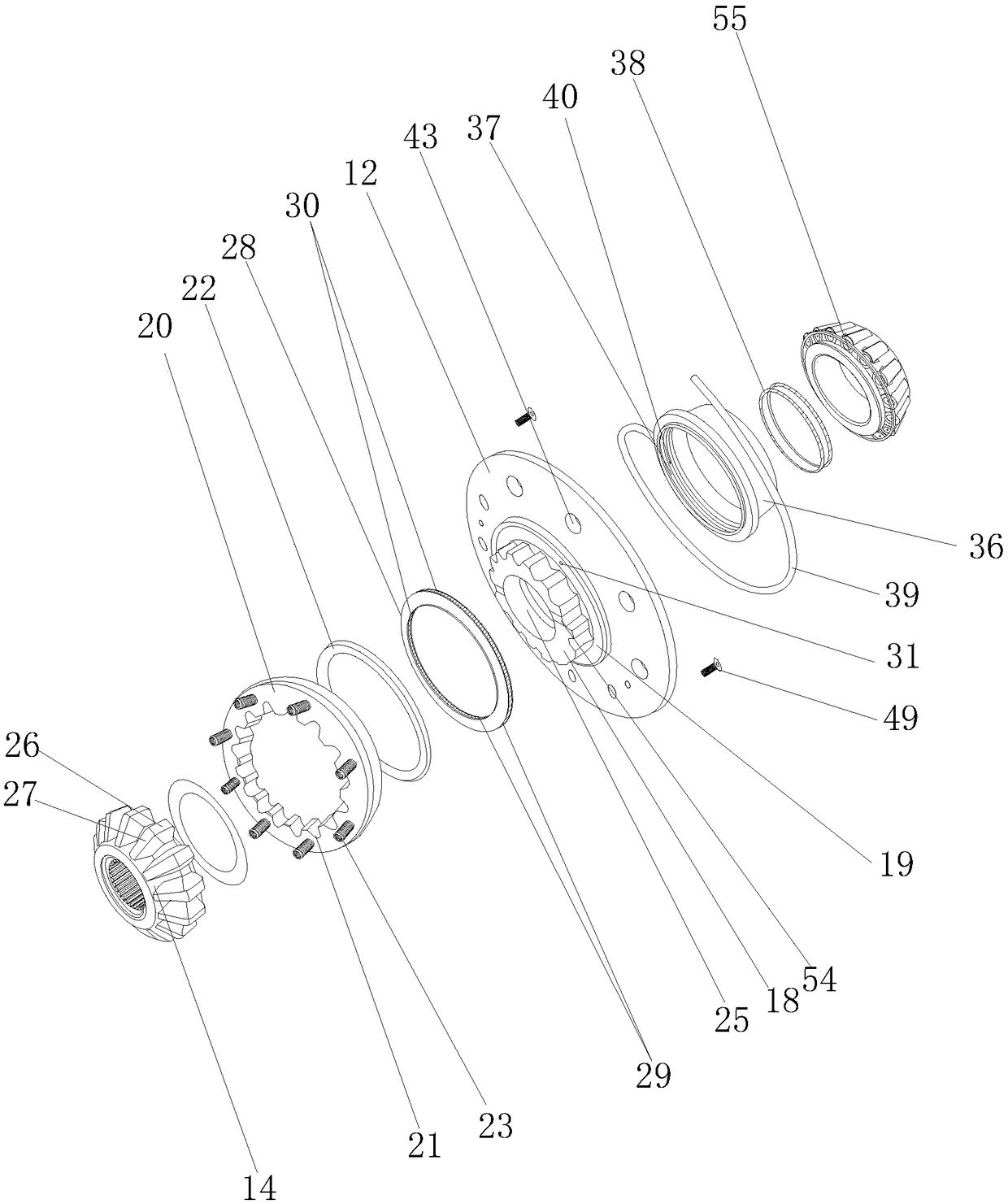

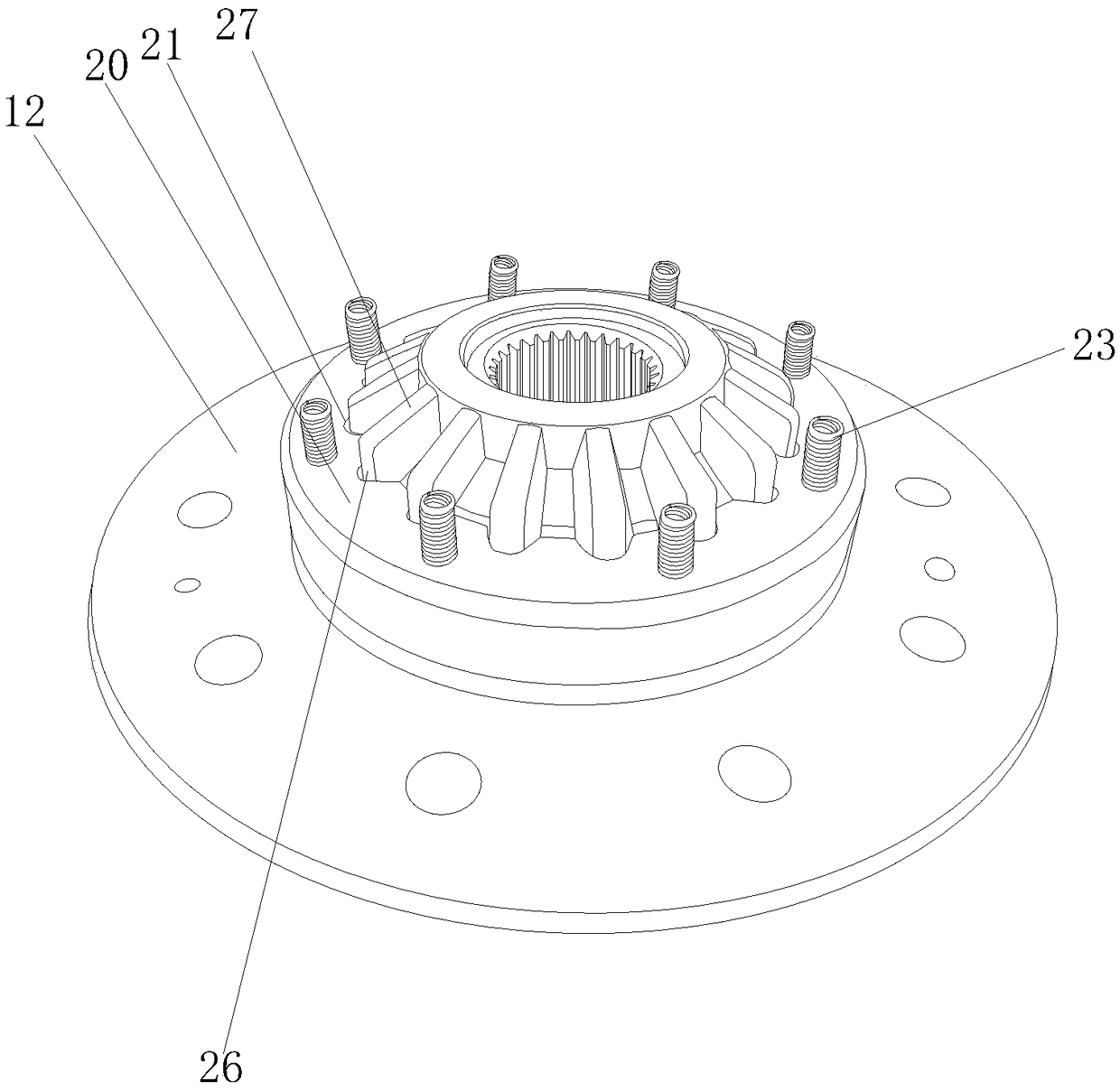

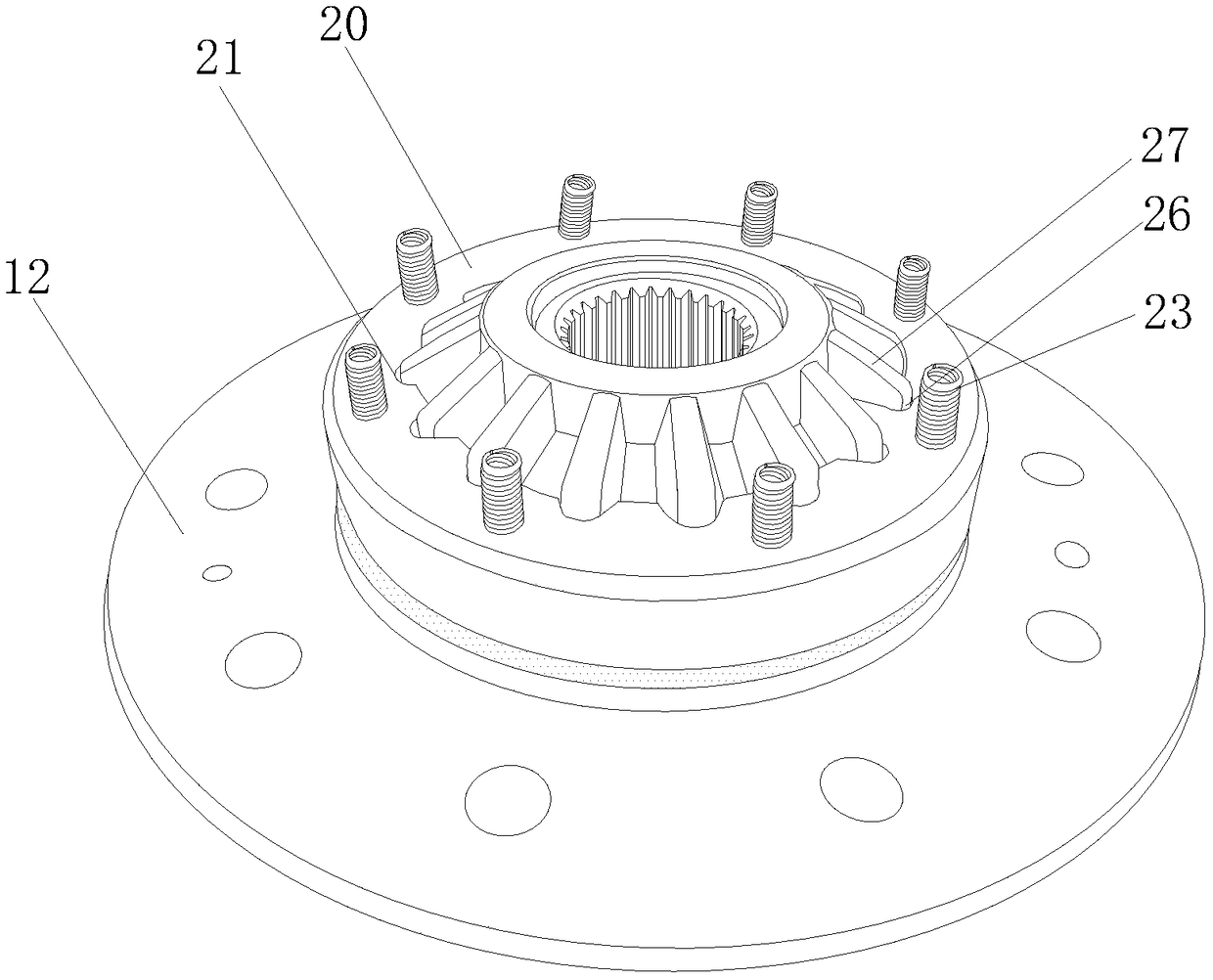

Self-locking type limited slip differential mechanism

PendingCN109372968AImprove passabilityIngenious and reasonable structureGear lubrication/coolingDifferential gearingsLimited-slip differentialSelf locking

The invention discloses a self-locking type limited slip differential mechanism. The self-locking type limited slip differential mechanism comprises a shell, half axle gears and a planet gear. The shell is covered with a flange cover assembly. The flange cover assembly is provided with an outer tooth meshing guiding structure and an annular groove, the outer tooth meshing guiding structure is sleeved with a meshing locking tooth sleeve internally provided with the inner circle provided with an inner spline, and the inner spline and outer straight teeth on the half axle gear II can be in clamping sleeving fit for locking. A spring hole is formed in the side face of the meshing locking tooth sleeve and internally provided with a reset spring in an abutting manner. A pushing piece is arrangedin the annular groove and can be pushed and ejected out in the annular groove, and an air outlet hole is formed in the bottom of the annular groove. An air pipe is used for air conveying, air entersan air inlet hole through an air cavity, the air pressure is output through the air outlet hole, the pushing piece is pushed through the air pressure, the meshing locking tooth sleeve is subjected tobutting pressing, so that the meshing locking tooth sleeve and the half axle gear II are in a locking state, the differential mechanism is forced to be in a locking state, the differential mechanism has an automatic locking slip limiting function, the weight is reduced, stability is extremely high, and the vehicle passing capability is improved.

Owner:李世奇

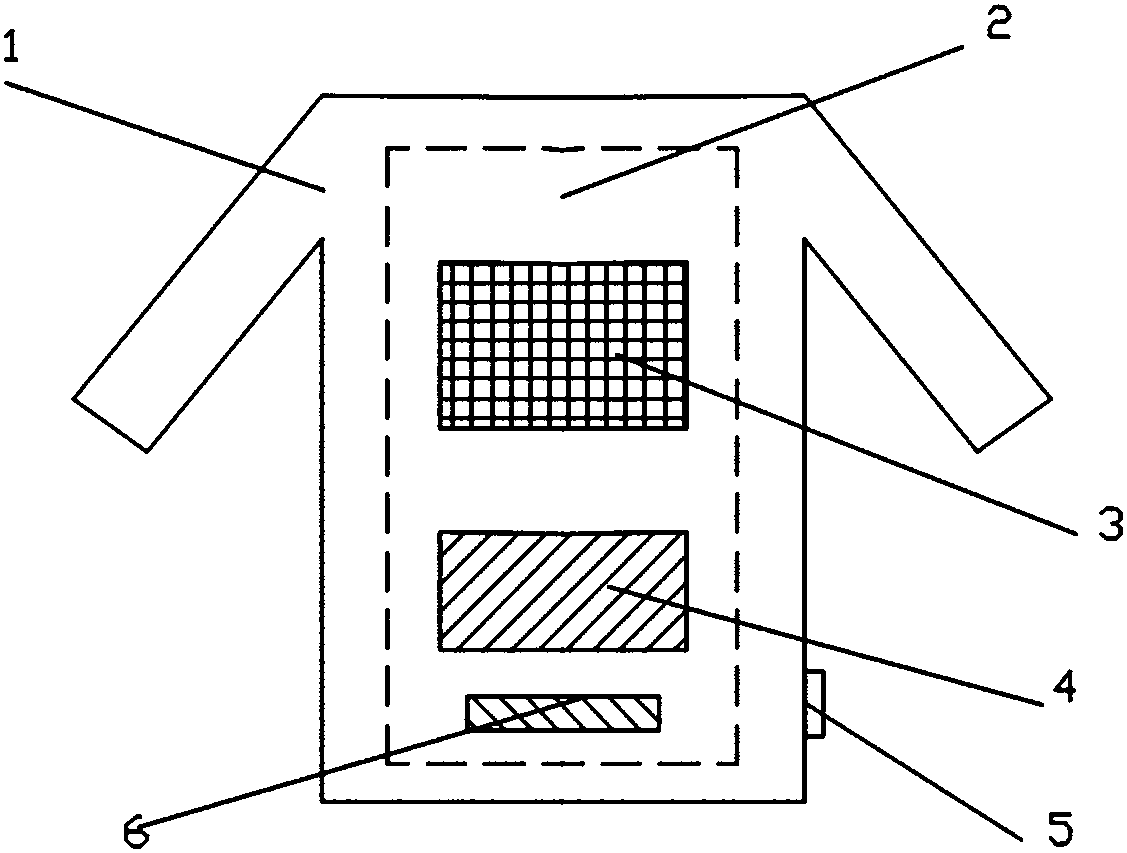

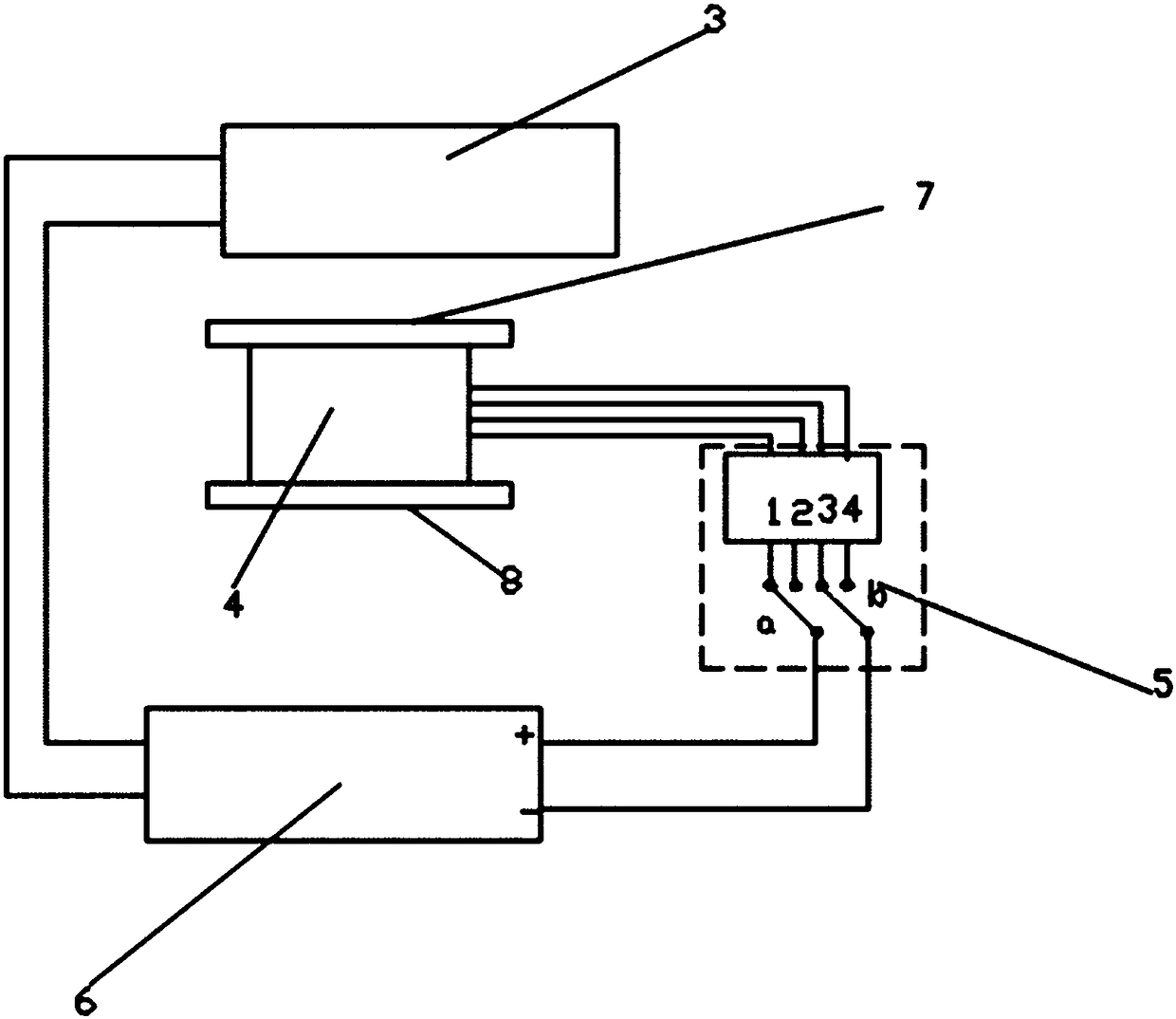

Work clothes based on solar semiconductor refrigeration

PendingCN108433209ARealize the cooling effectRealize the heating effectProtective garmentActive coolingHeating effect

The invention discloses work clothes based on solar semiconductor refrigeration. The work clothes comprise a solar cell panel, a semiconductor refrigeration sheet, a charging battery and a current direction control device, wherein the solar cell panel, the semiconductor refrigeration sheet, the charging battery and the current direction control device are installed on the outer surface of the clothes, foil heat exchangers are installed on the inner surface of the clothes, the solar cell panel is connected with the charging battery through a wire, the charging battery is connected with the current direction control device through a wire, the wire coming out of the current direction control device is connected with a positive electrode and a negative electrode of the semiconductor refrigeration sheet respectively, and the foil heat exchangers are arranged at both the cold end and the hot end of the semiconductor refrigeration sheet. The semiconductor refrigeration sheet is added into thework clothes, the active cooling or heating effect of the clothes is achieved, and solar energy is utilized to provide energy for a refrigeration system and is clean, renewable and free of pollution;a compression and throttling part is not needed, the system is exquisite and light, the work is free of noise, a greenhouse effect or ozone depletion cannot be caused, and the work clothes are environmentally friendly; the current direction control device is utilized to achieve free switch of refrigeration and heating.

Owner:TIANJIN UNIV OF COMMERCE

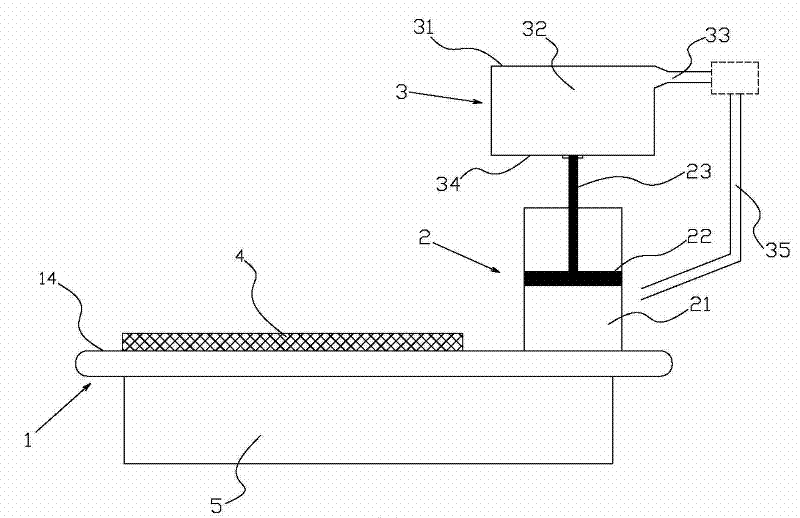

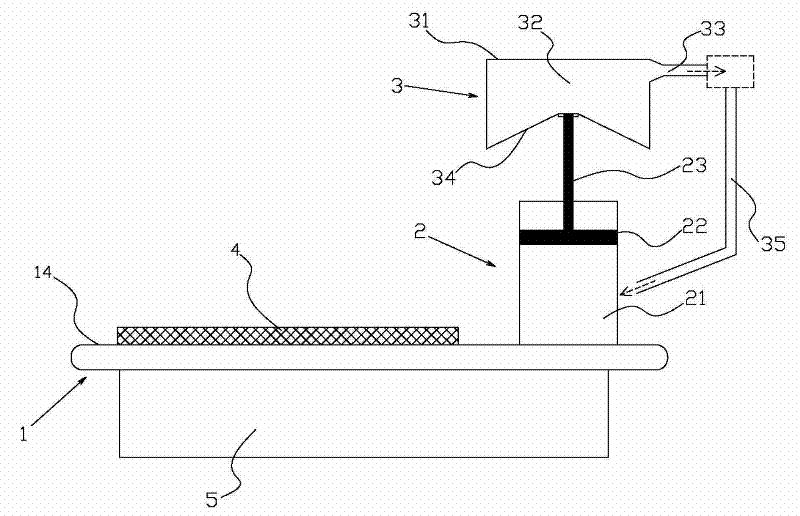

Synthetic jet heat radiating device

InactiveCN102364712BExtend your lifeImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesEnvironmental resistanceReciprocating motion

The invention discloses a synthetic jet heat radiating device comprising a heat exchange element, a piston cylinder and a synthetic jet device, wherein the heat exchange element is provided with an inner cavity, and an outer wall corresponding to the inner cavity can be used for installing a heating source and a heat radiating element; the piston cylinder is arranged on the outer wall and is provided with a piston cavity clinging to the outer wall and a piston assembled in the piston cavity; the synthetic jet device comprises a shell in which at least one chamber with an opening is arranged, the chamber is provided with a thin film wall with elasticity, and the thin film wall is in transmission connection with the piston through a piston rod; the piston drives the thin film wall to reciprocate through the piston rod by using heat from a heating source transmitted by the heat exchange element so that compression and expansion periodical change is generated in the chamber and jet is generated at the opening. In the invention, a passive heat radiation mechanism and an active heat radiation mechanism without power consumption are combined, so that a better heat radiating effect can be achieved; in addition, the environment friendly requirements for energy saving and emission reduction are met, therefore, compared with the traditional active synthetic jet device, the synthetic jet heat radiating device has the advantage that the service life of an element is longer.

Owner:ZHONGSHAN WEIQIANG TECH CO LTD

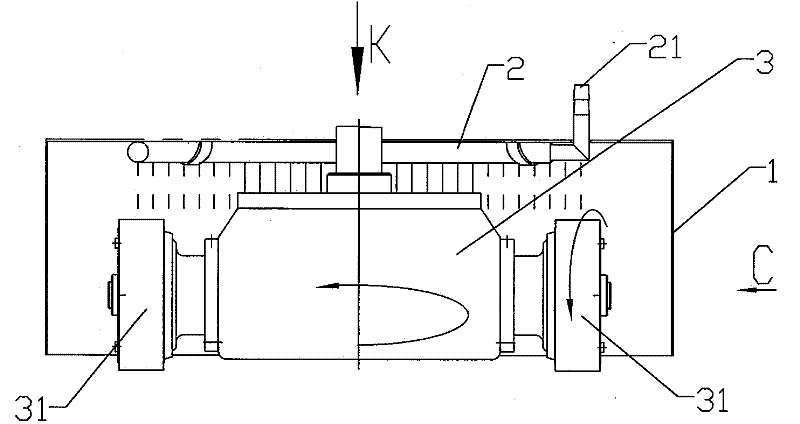

Symmetrical gas-liquid separator

InactiveCN113318485AShort separation timeSimple structureLiquid degasificationEngineeringVapor–liquid separator

The invention discloses a symmetric gas-liquid separator; the symmetric gas-liquid separator comprises a main body pipeline and a plurality of acceleration rotation assemblies, and each acceleration rotation assembly comprises at least one acceleration rotation device; a cavity is formed in the main body pipeline, the plurality of acceleration rotation assemblies are arranged in the cavity, and each acceleration rotation assembly is arranged in the radial direction of the main body pipeline; on the axial projection surface of the main body pipeline, the plurality of acceleration rotation assemblies are distributed in a staggered manner; the transverse section, in the axial direction of the main body pipeline, of the acceleration spiral flow generator is of a symmetrical structure relative to the radial direction of the main body pipeline; and the acceleration spiral flow generator comprises a plurality of acceleration spiral flow generator sets, and the two acceleration spiral flow generators in each acceleration spiral flow generator set are symmetrical about the axial direction of the main body pipeline. The symmetric gas-liquid separator solves the problem that in the prior art, gas-liquid separation is not ideal when gas content is high or gas treatment capacity is high.

Owner:丛俊余

Novel rough coarse-grinding head cooling water supply facility

InactiveCN101332586BExtended service lifeWashed away in timeGrinding/polishing safety devicesEngineeringWater cooling

The invention relates to a water cooling and supply device, in particular to a water cooling and supply device for coarse grinding heads of ceramic tiles (stone material). The water supply device comprises a water cover surrounding a grinding wheel, the water cover is provided with at least one water outlet which can lead cooling water to a grinding point of the grinding wheel. The water cooling and supply device has simple structure, the grinding wheel is surrounded by the water cover provided with the water outlet, the water outlet can purposely lead the cooling water to the grinding point of the grinding wheel, the grinding wheel is well cooled and grinding swarf is washed away in time, which improves the grinding efficiency, prolongs the service life of the grinding wheel, improves the grinding quality, saves a great deal of cooling water, and meets the environmental protection requirement of energy conservation and emission reduction.

Owner:KEDA INDUSTRIAL GROUP CO LTD

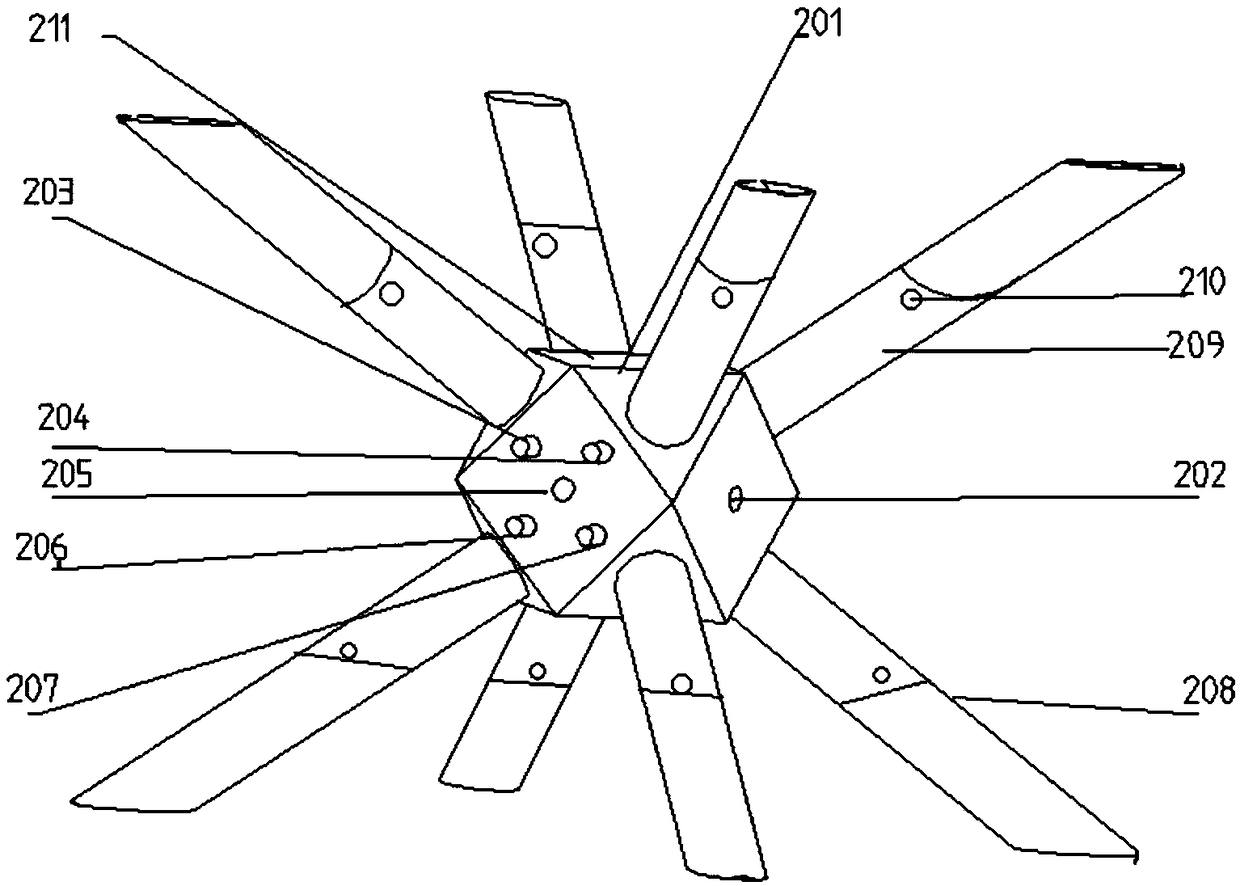

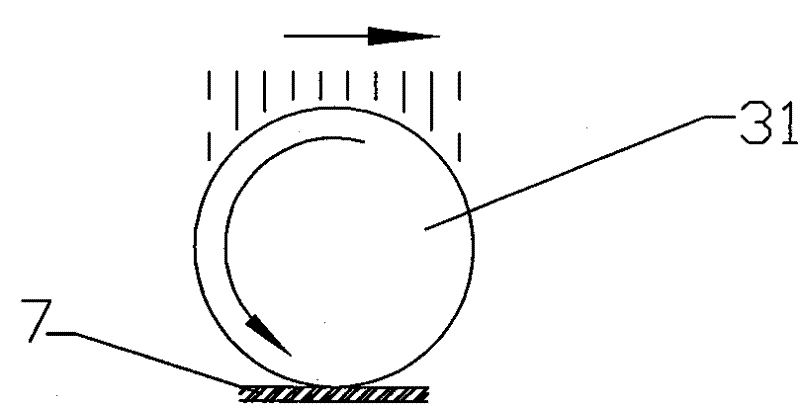

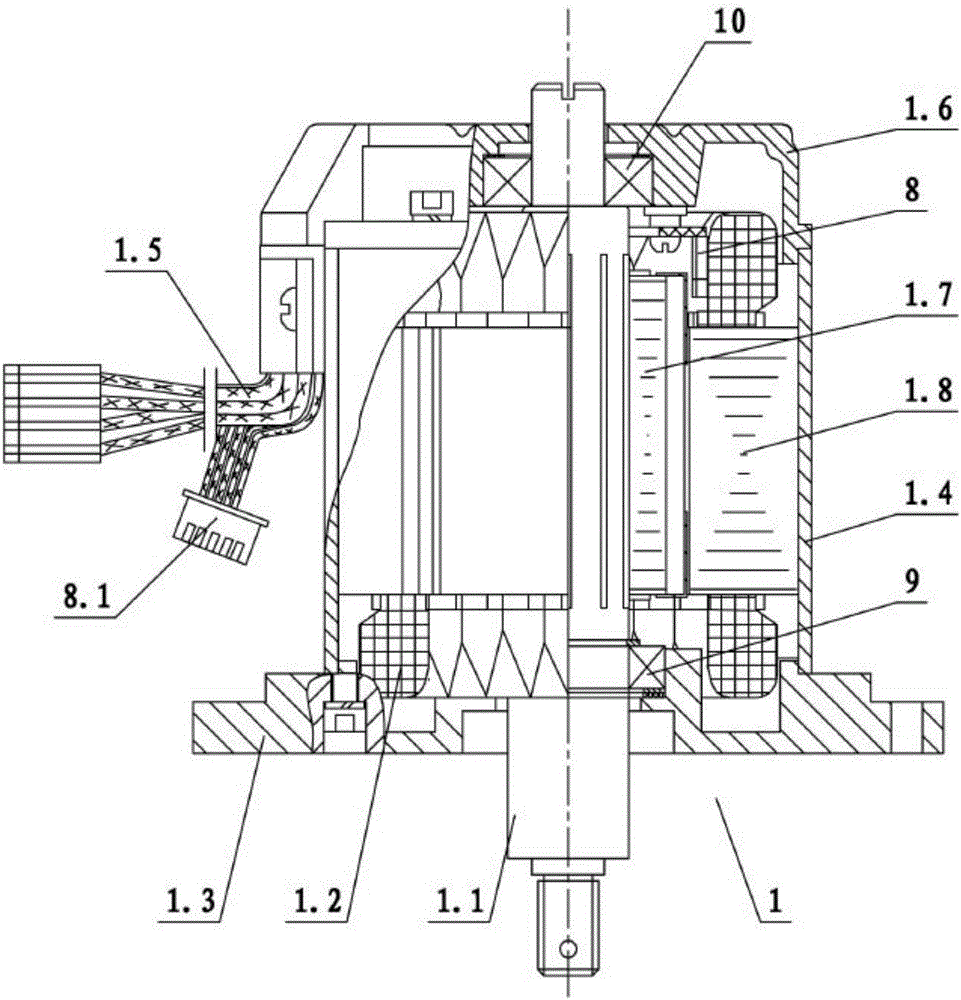

Improved aerator

InactiveCN106330012AWaste of power resourcesReduce noiseSingle motor speed/torque controlPisciculture and aquariaBrushless motorsImpeller

The invention discloses an improved aerator, which comprises an impeller, floating bodies and a motor base, wherein the motor is connected with the floating bodies through a bracket, the motor base is provided with a DC brushless motor, and a motor shaft is connected with the impeller. The impeller is coated with a metal anti-corrosion coating, wherein the metal anti-corrosion coating comprises a copper aluminum alloy bottom layer, a nickel aluminum metal middle layer and a sealing paint surface layer, the thickness of the copper aluminum alloy bottom layer is 120 microns, the thickness of the nickel aluminum metal middle layer is 140 microns, and the thickness of the sealing paint surface layer is 160 microns; and the sealing paint is polyurethane top paint. The improved aerator adopts the DC brushless motor to act as a driving motor of the impeller, thereby enabling the equipment to be lower in noise in operation, less in energy consumption and higher in efficiency, and conforming to environmental protection requirements of energy conservation and emission reduction at present.

Owner:WUXI SHUANGNENGDA TECH

Biomass gasification device and gasification technology

InactiveCN101445735BAvoid stickingReduce maintenance costsSpecial form destructive distillationProcess engineeringComposite filter

Owner:大连鑫宝生物质能有限公司

A compact industrial tail gas fine particulate matter removal and cooling device and method

ActiveCN112316570BRealize benign complementarityMeet the environmental protection requirements of energy saving and emission reductionHuman health protectionDispersed particle separationCyclonic separationFine particulate

The invention provides a compact industrial tail gas fine particulate matter removal and cooling device and method, comprising a flue gas pretreatment unit and a cyclone separation unit, the flue gas pretreatment unit includes a gravity settling chamber and a steam phase change chamber, the The lower end of the steam phase change chamber communicates with the upper part of the gravity settling chamber. The steam phase change chamber is divided into a steam phase change section and a turbulent flow agglomeration section from bottom to top. The device adopts an integrated design of a particle pretreatment unit and a cyclone separation unit, especially It is the first time that steam phase change agglomeration and turbulent flow agglomeration treatment technologies are integrated into the particle pretreatment unit, which realizes the removal of coarse particles and the agglomeration of fine particles in the dusty tail gas, and the cyclone separation unit of the present invention adopts a reflective screen The advanced axial-flow cyclone separator structure can effectively improve the removal efficiency of fine particles; the overall structure of the device is compact, the floor space is small, and the operation is convenient, which solves the problem of high-efficiency and energy-saving removal of fine particle pollutants in industrial tail gas.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com