Method and device for recovering oligomers for polyphenylene sulfide production

A recovery method, polyphenylene sulfide technology, applied in the field of chemical production, can solve the problems of lack of easy-to-operate, low-cost and high-efficiency methods, and achieve the effects of reducing costs, reducing emissions, and avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

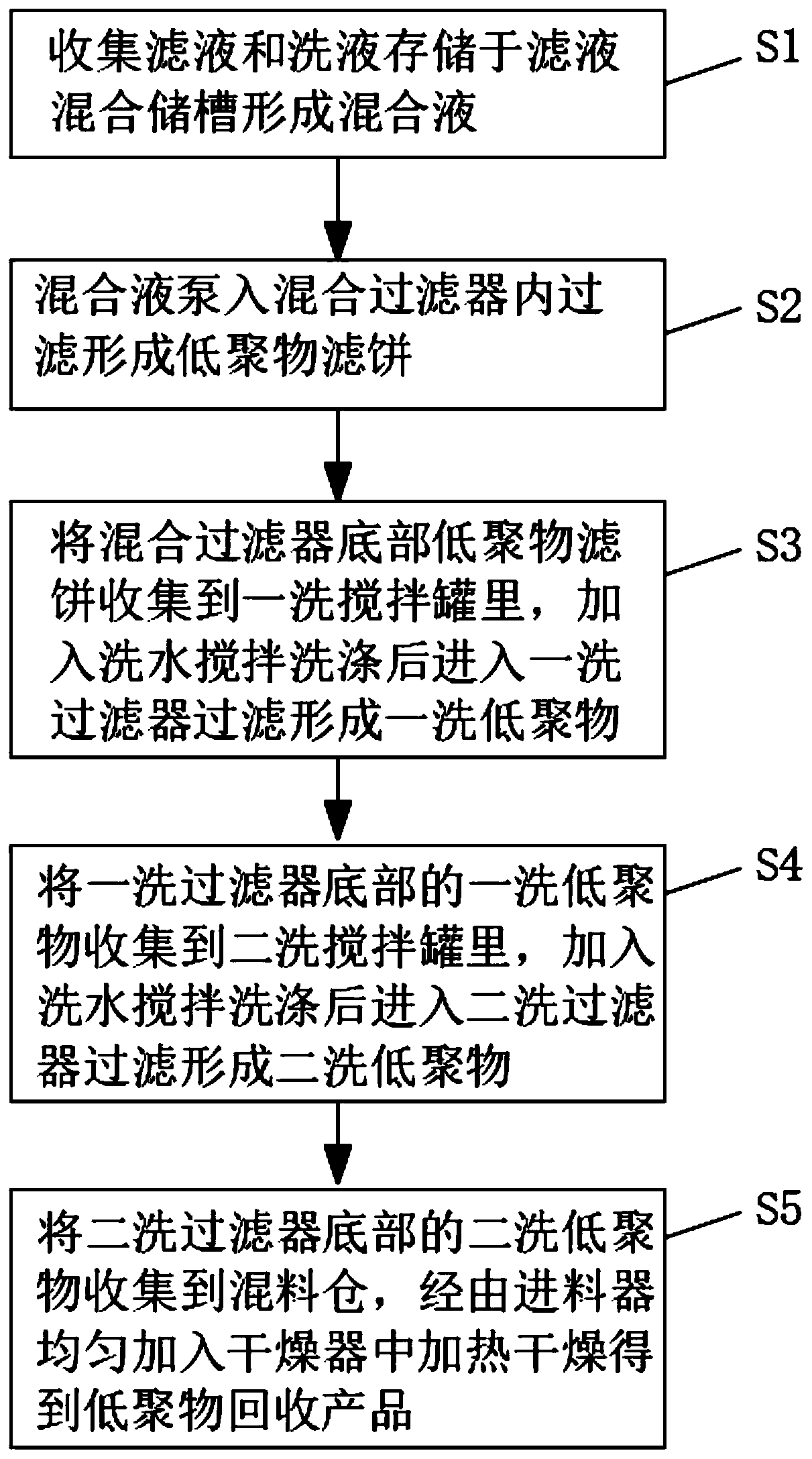

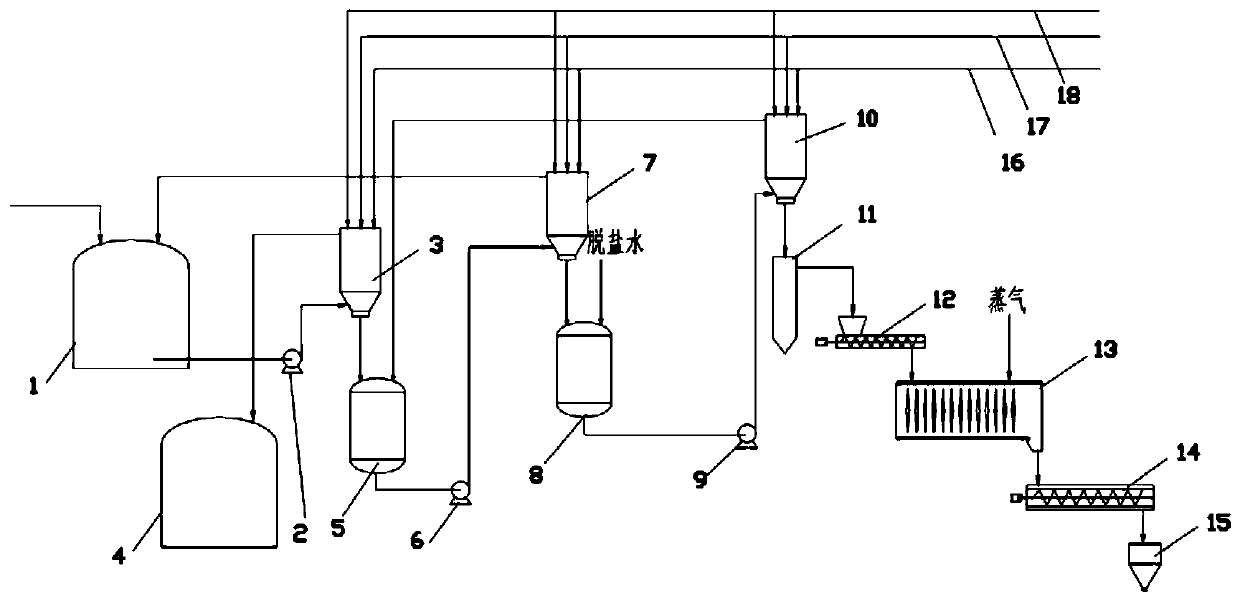

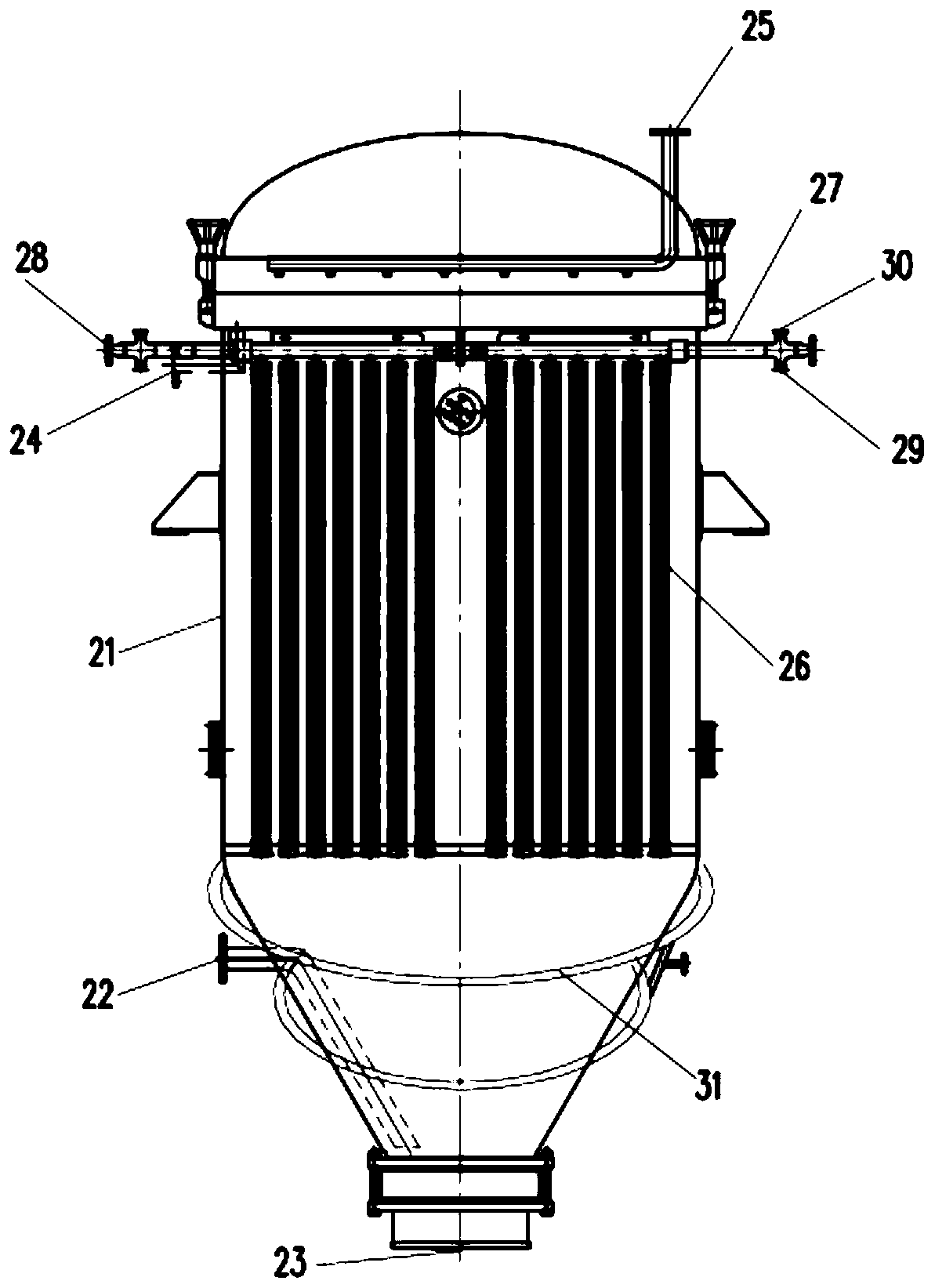

[0037] combine Figure 1-3 Shown, a kind of polyphenylene sulfide production oligomer recovery method comprises the following steps:

[0038] S1: Collect the filtrate and washing liquid and store them in the filtrate mixing storage tank 1 to form a mixed liquid;

[0039] S2: The mixed liquid is pumped into the mixing tube by the mixed liquid pump 2 and filtered to form an oligomer filter cake;

[0040] S3: Collect the oligomer filter cake at the bottom of the mixing tubular filter 3 into a washing mixing tank 5, add washing water to stir and wash, and then enter the first washing tubular filter 7 to filter to form a washing oligomer;

[0041] S4: Collect the first-wash oligomers at the bottom of the first-wash tubular filter 7 into the second-wash mixing tank 8, add washing water to stir and wash, and then enter the second-wash tubular filter 10 to filter to form the second-wash oligomers;

[0042] S5: Collect the secondary-washed oligomers at the bottom of the secondary-was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com