Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85 results about "Sulfide production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This medium contains ferrous ammonium sulfate and sodium thiosulfate, which together serve as indicators for the production of hydrogen sulfide. Hydrogen sulfide production is detected when ferrous sulfide, a black precipitate, is produced as a result of ferrous ammonium sulfate reacting with H2S gas.

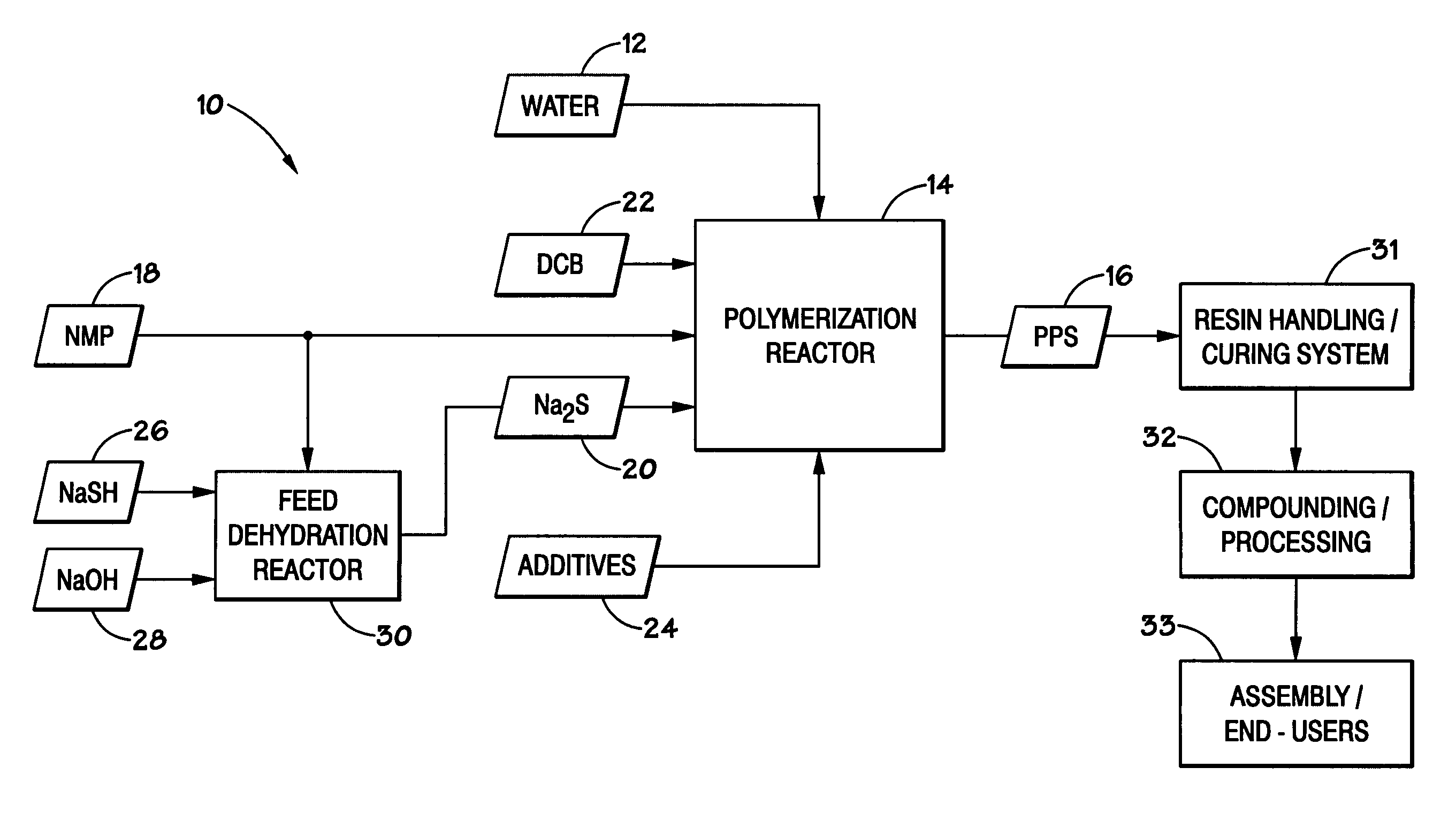

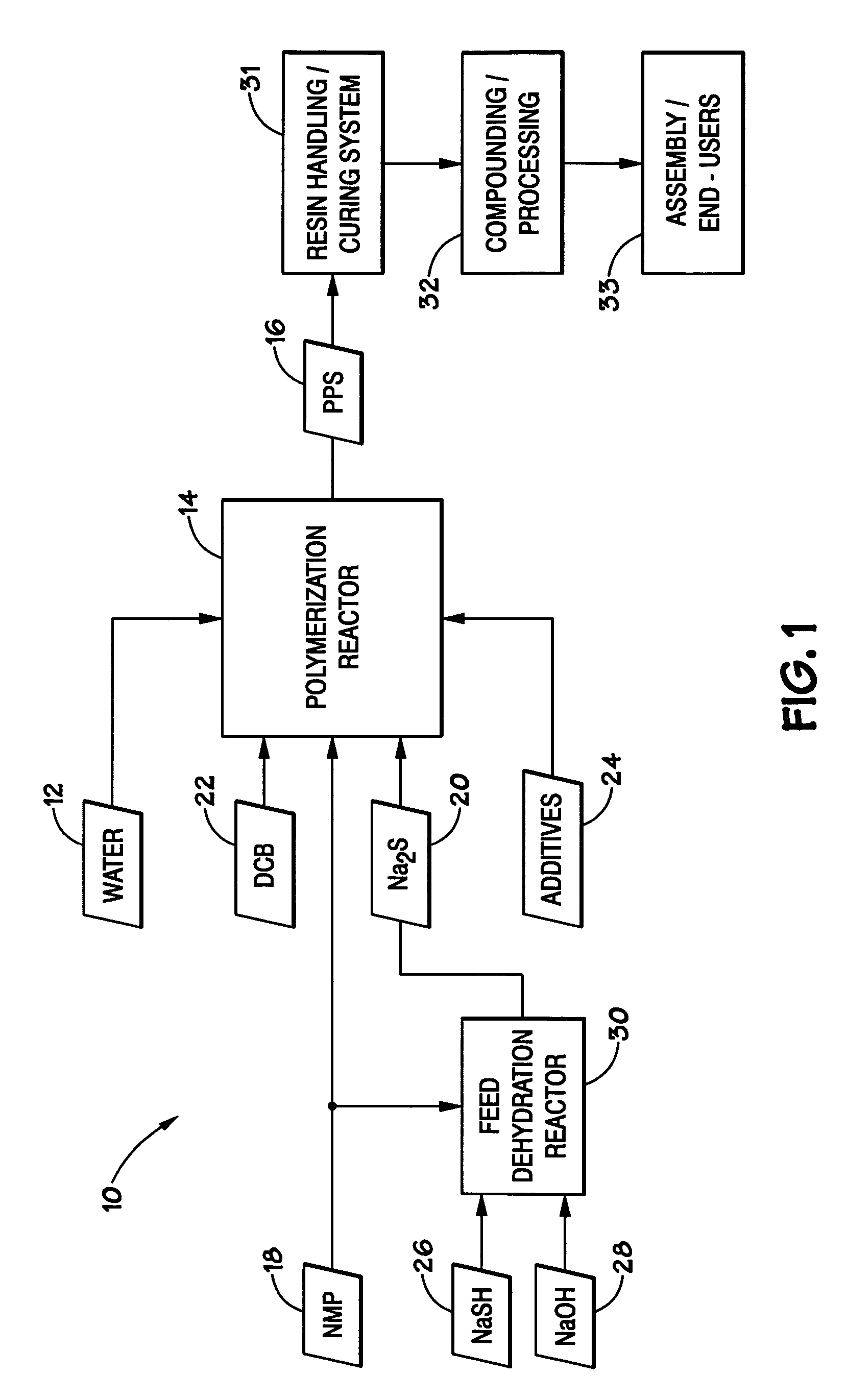

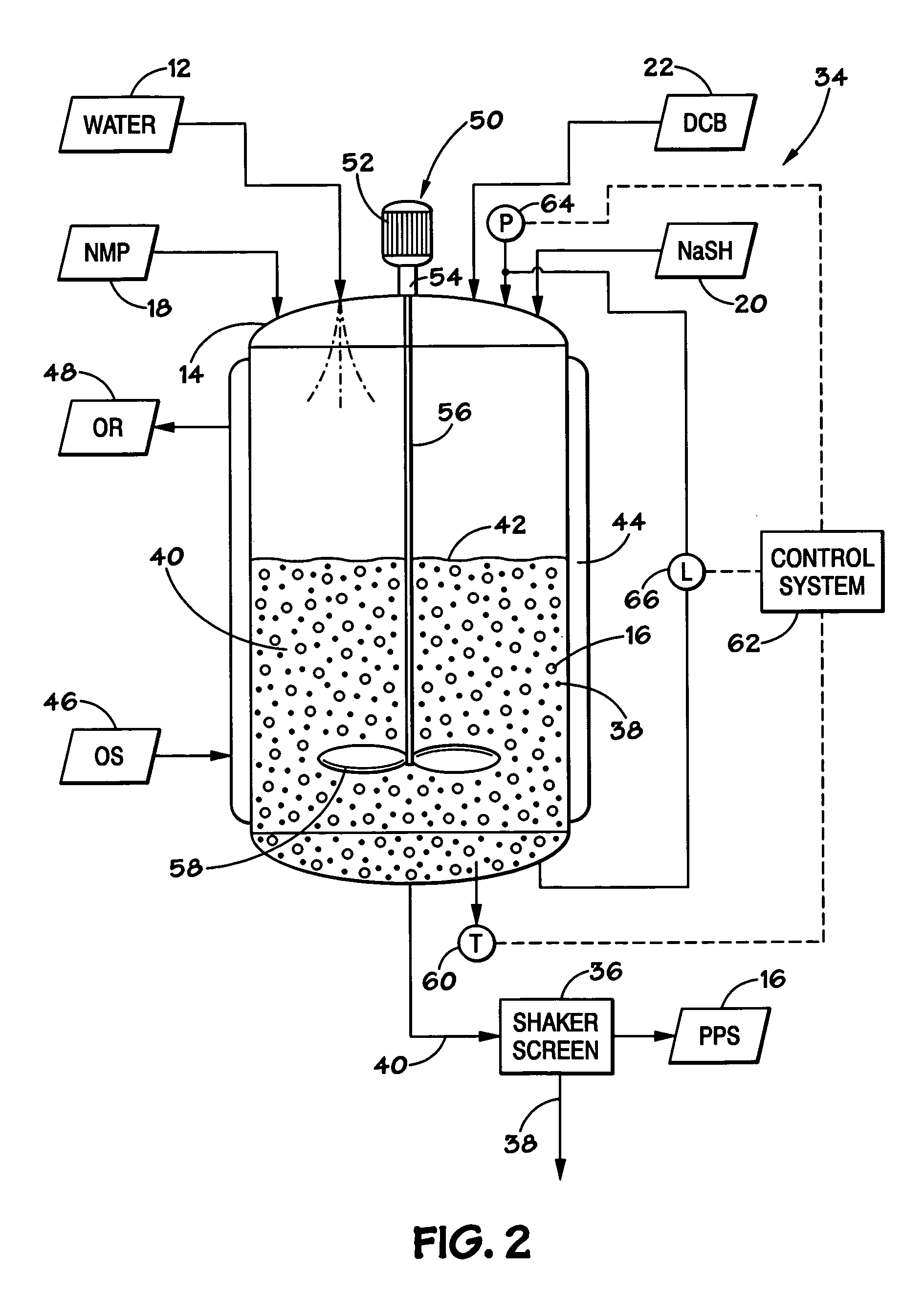

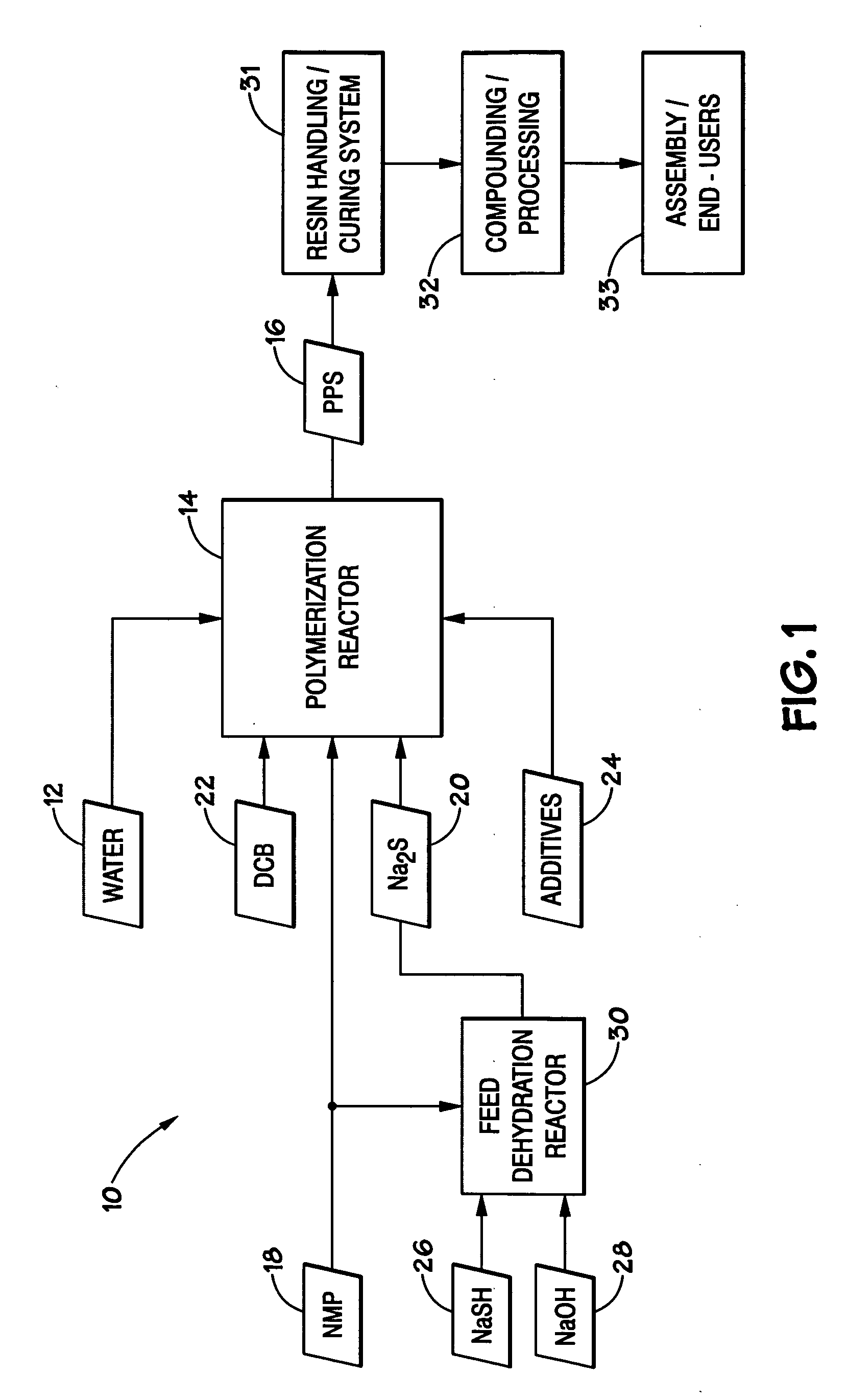

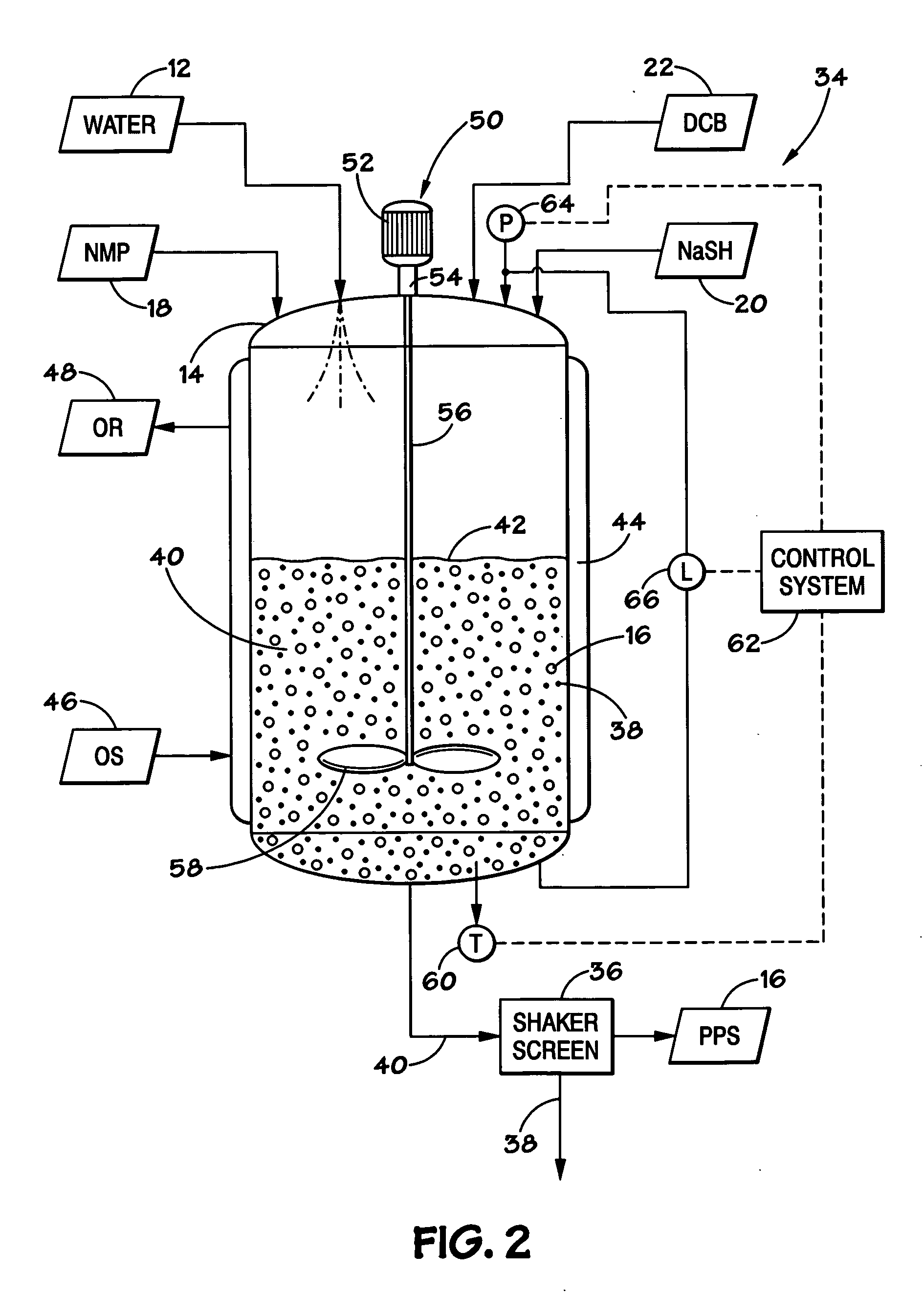

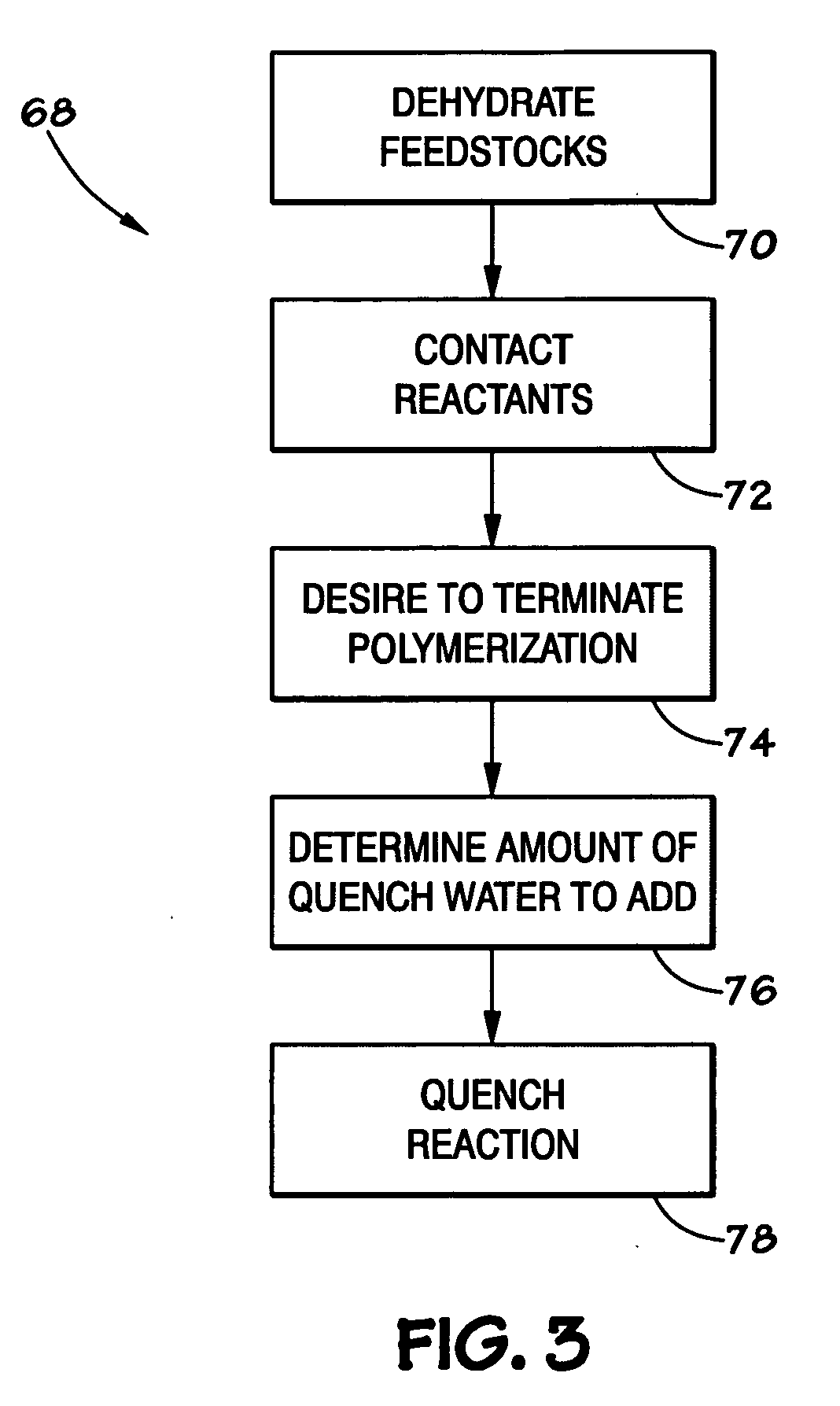

Inferred water analysis in polyphenylene sulfide production

A method for producing polyphenylene sulfide (PPS) polymer, including polymerizing reactants in a reaction mixture in a vessel to form PPS polymer in the vessel, measuring values of operating variables of the vessel and / or PPS process, and determining the amount of quench fluid to add to the vessel based on the values of the operating variables. The technique may rely on the vapor liquid equilibrium (VLE) of the mixture to calculate the concentration of water existing in the reactor prior to quench, and accounts for the effectiveness of the upstream dehydration process and in the amount of water produced during the polymerization. The technique is a striking improvement over the trial-and-error estimation of the amount of quench water based on human operating experience, and avoids direct measurements of the existing water concentration in the reactor. The result is improved control of PPS particle size and other properties.

Owner:SOLVAY SA

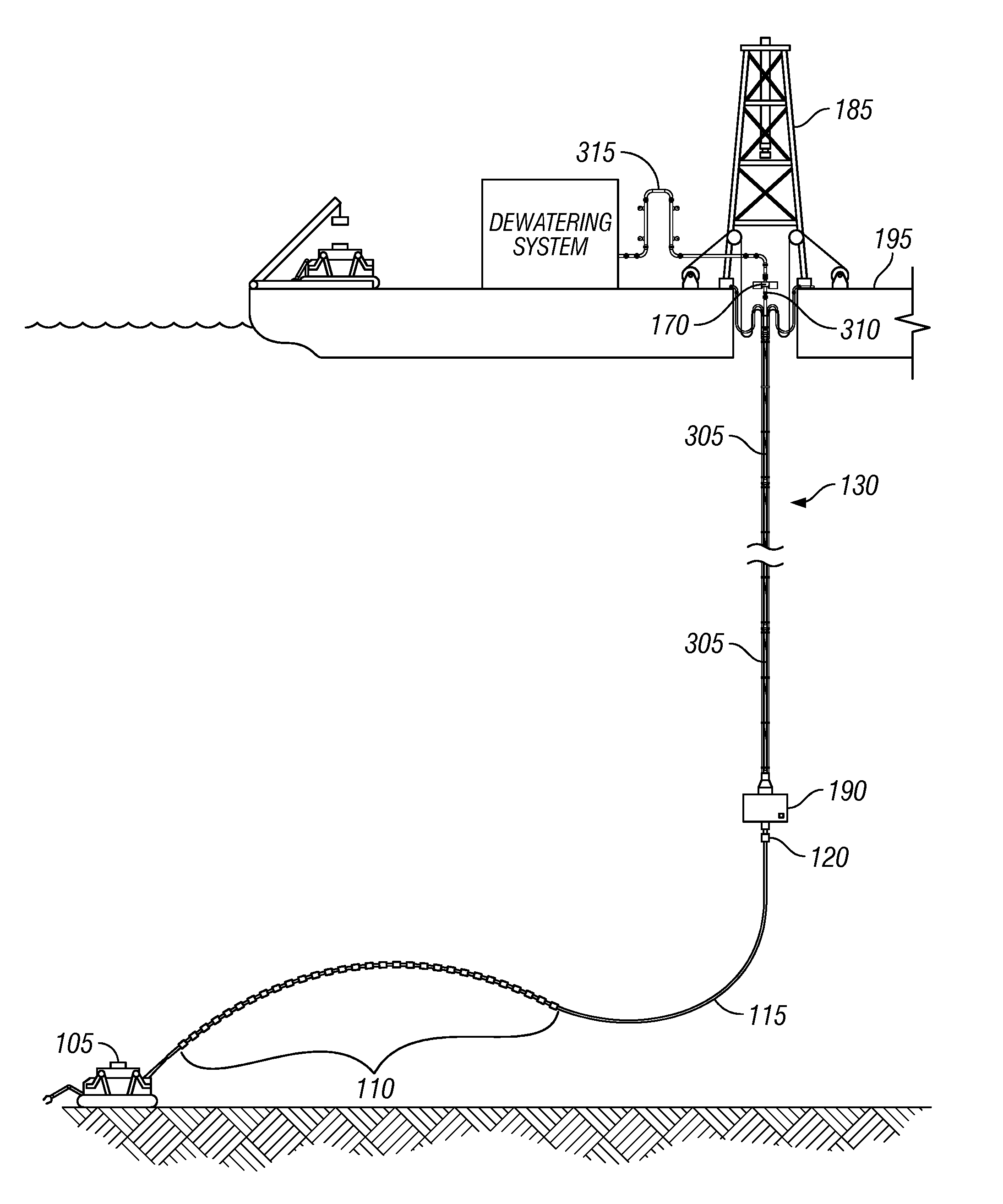

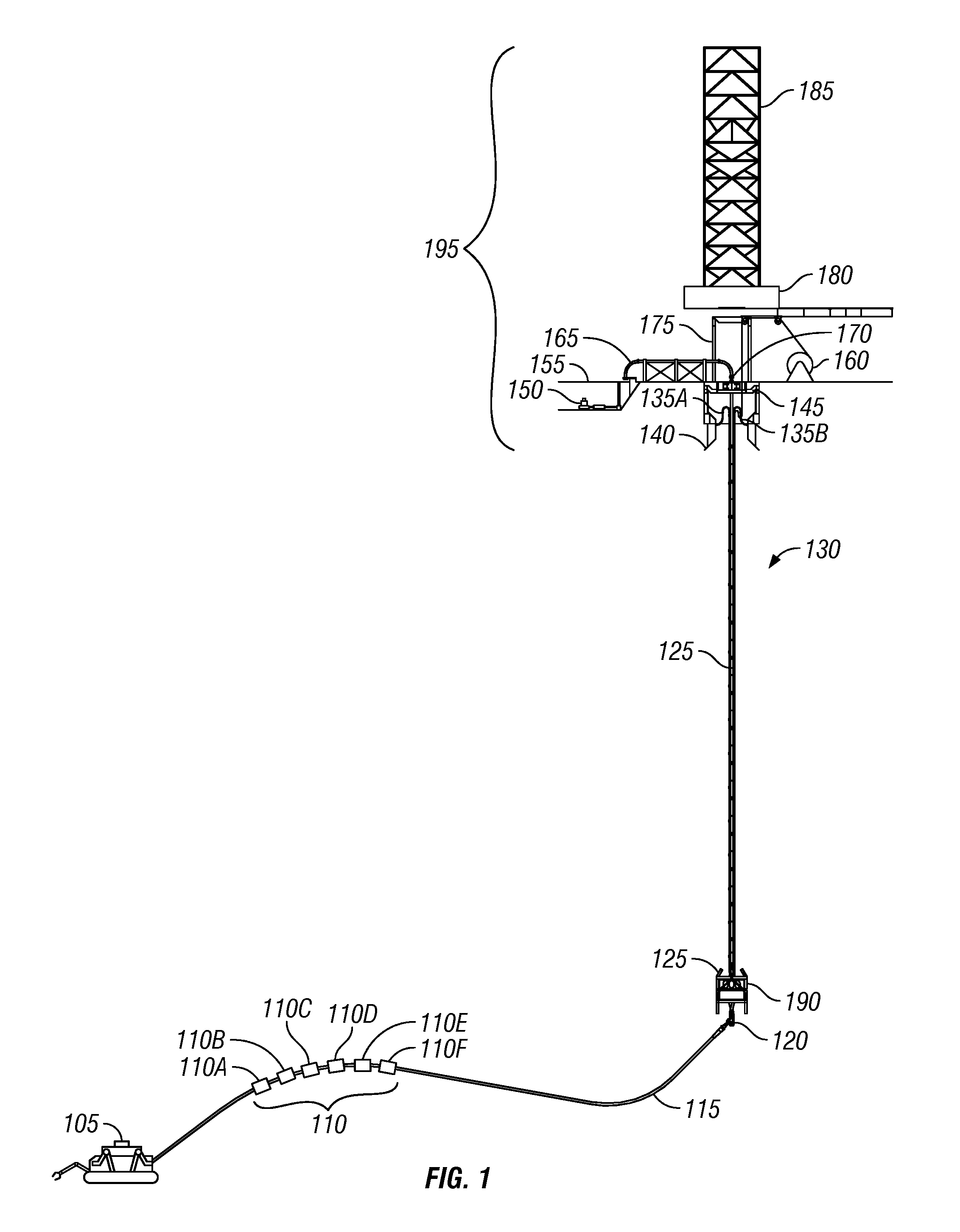

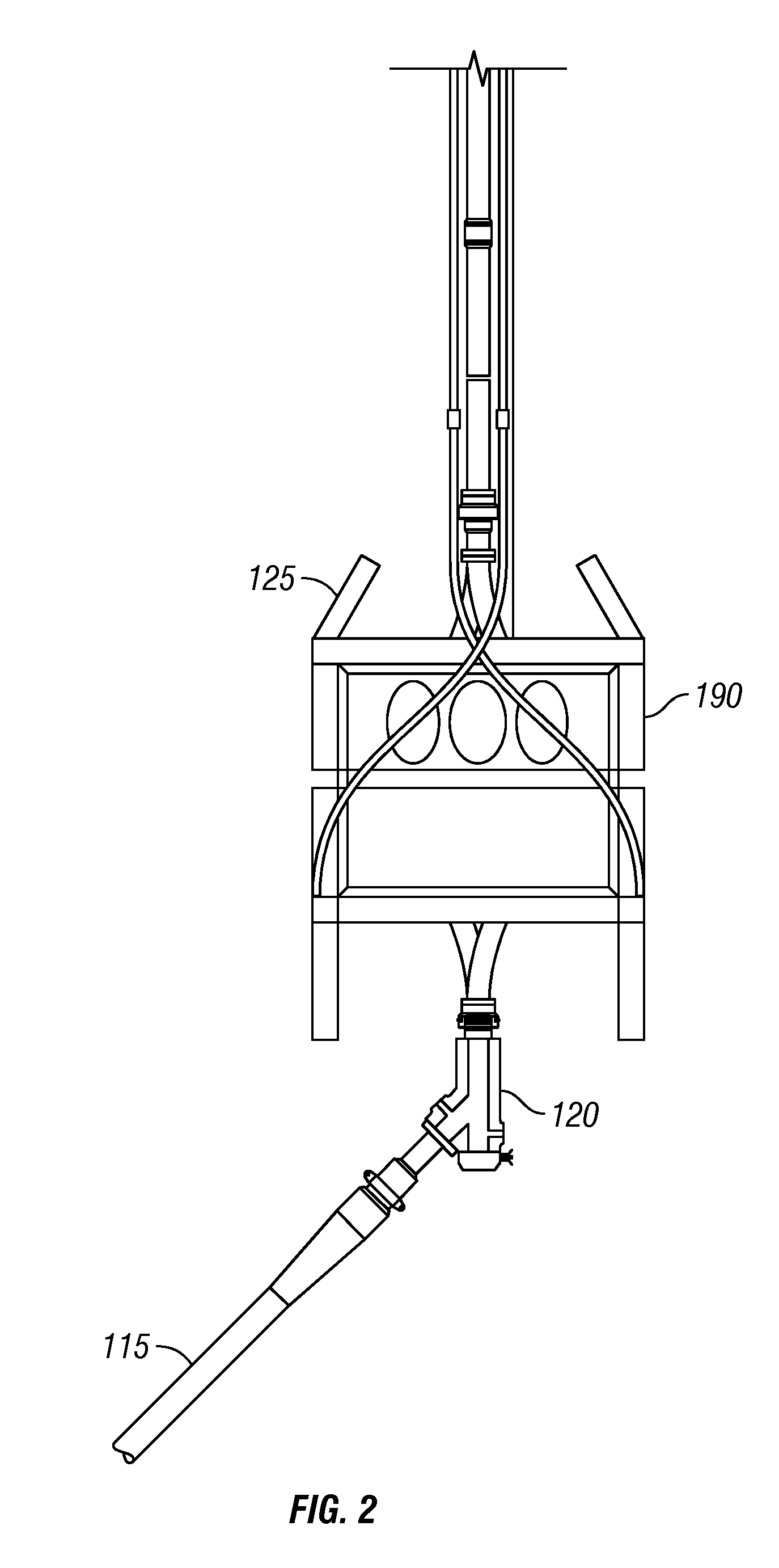

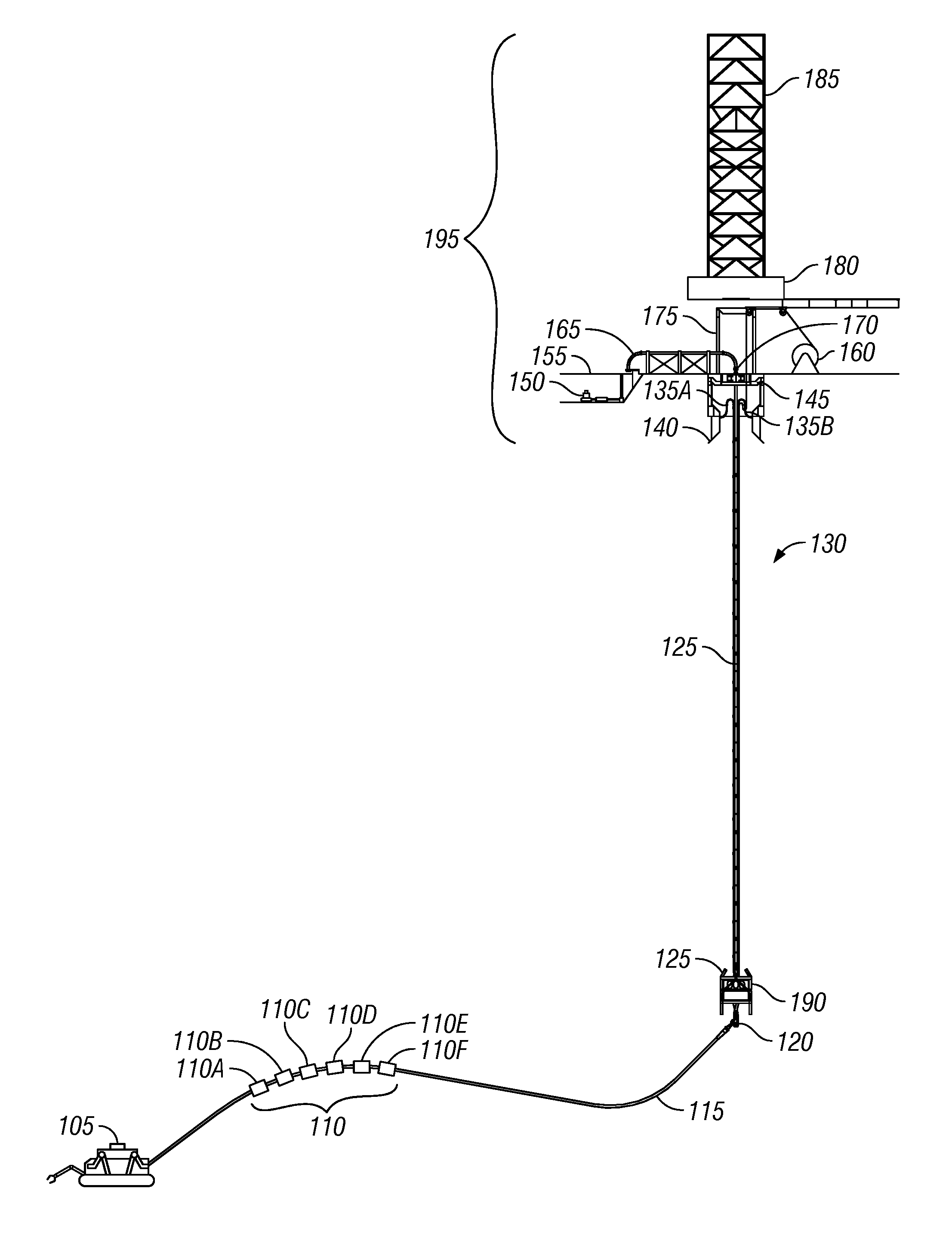

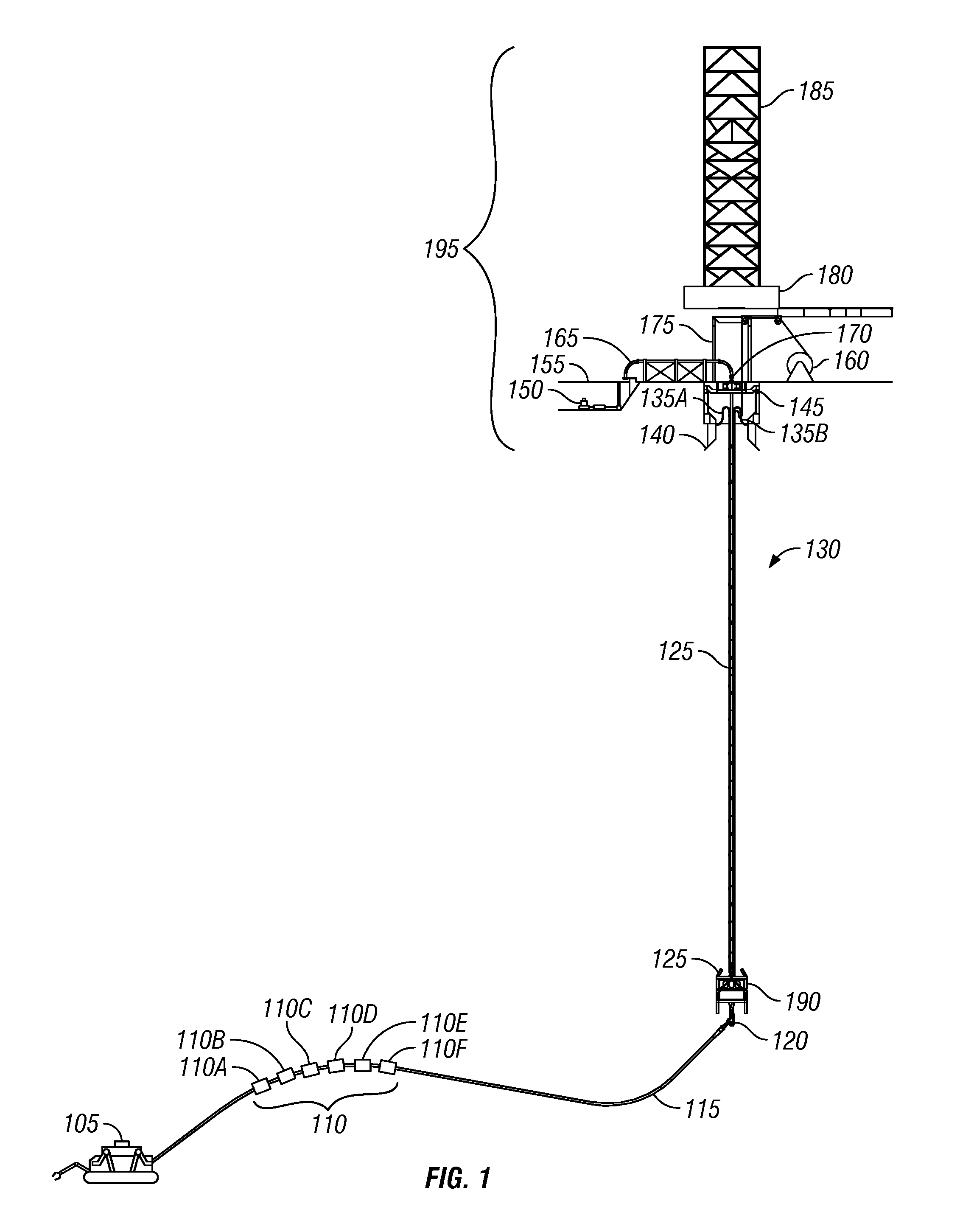

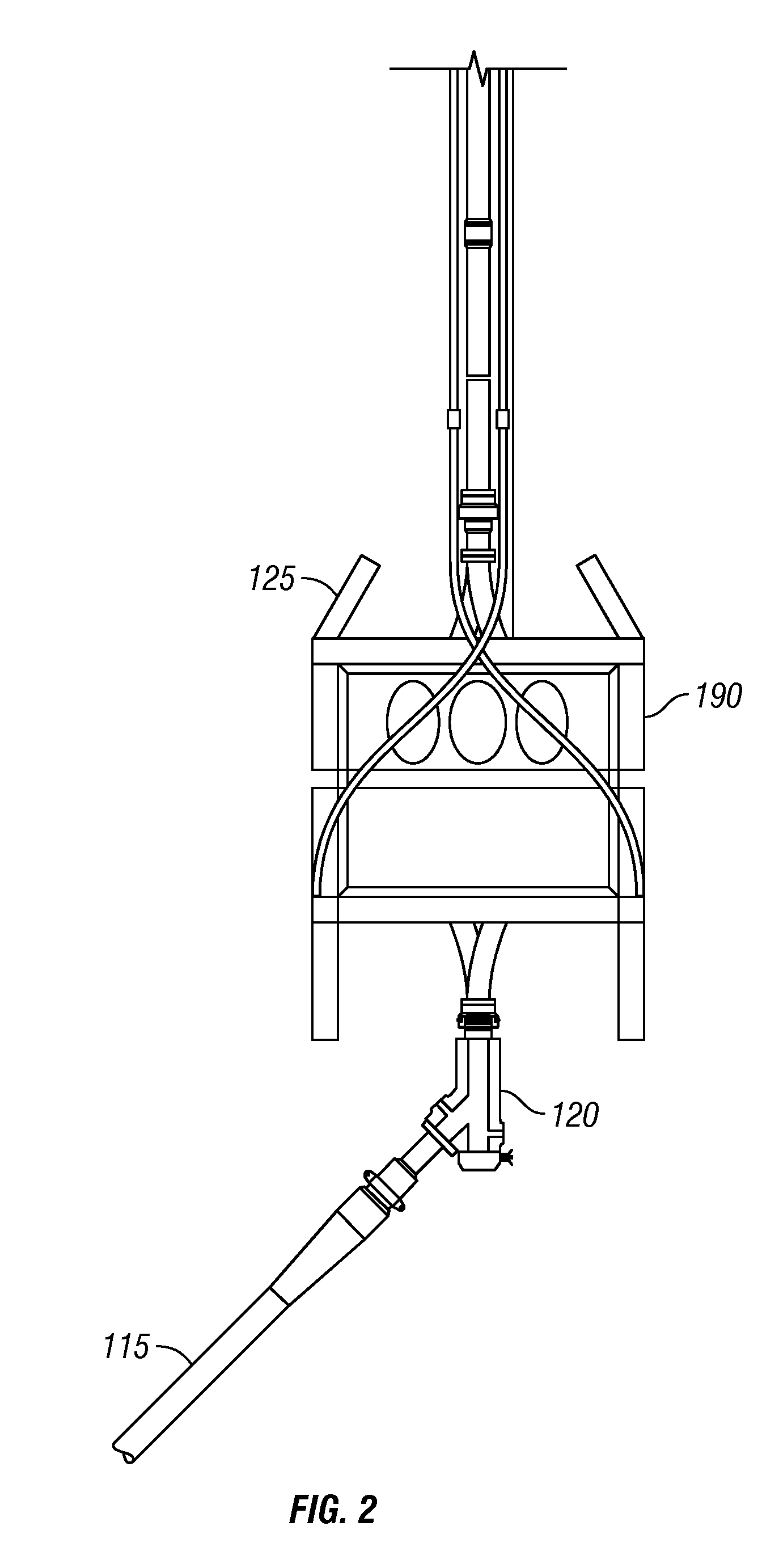

System and method of utilizing monitoring data to enhance seafloor sulfide production for deepwater mining system

Applicants have created a method and system of deep sea mining comprising mining SMS deposits from the sea floor with a subsea miner, pumping the solids from the subsea miner through a jumper and pumping the solids from the jumper up a riser to a surface vessel. Further, applicants have created a method of deploying a deep sea mining system, comprising stacking a riser hangoff structure on top of a subsea pump module forming an assembly; picking up the assembly by a hanging mechanism, hanging the assembly on a moon pool, attaching a first riser joint; disconnecting the riser hangoff structure from the assembly; and attaching at least one second riser joint to form the riser.

Owner:EDA KOPA SOLWARA

A kind of separation and recovery method of NMP and catalyst lithium chloride in polyphenylene sulfide production

The invention relates to a separation and recovery method for n-methylpyrrolidone (NMP) and a lithium chloride catalyst during polyphenylene sulfide producing. The method is characterized by: directly carrying out vacuum distillation for a polyphenylene sulfide polycondensation mother liquid until the polyphenylene sulfide polycondensation mother liquid is dried to recover a solvent of the NMP, wherein the NMP can be used in the next recycling production; adding water to the distilled residues, then heating to a temperature of 40 DEG C, carrying out stirring and completely dissolving the distilled residues, carrying out filtering and washing the filter residues, mixing the resulting filtrate and the washing solution, and analyzing lithium content in the mixed solution; adding the mixed solution to a phosphoric acid solution or a sodium aluminate solution, wherein the phosphoric acid solution or the sodium aluminate solution has a lithium reaction equivalent of 105-115%, then completely stirring to enable lithium phosphate or lithium aluminate to be precipitated completely, then carrying out steps of filtering, washing, drying for the lithium phosphate or the lithium aluminate to recover the lithium salt having a purity more than 97%. According to the present invention, the operation of the method is simple; the cost is low; the recovered NMP and the recovered lithium salt havehigh purities.

Owner:NANJING UNIV

Inhibition of biogenic sulfide production via biocide and metabolic inhibitor combination

ActiveUS20050238729A1Inhibit productionInhibit sulfide productionHeavy metal active ingredientsBiocideSulfide productionSulfate-reducing bacteria

Biogenic sulfide production is synergistically inhibited by treating sulfate-reducing bacteria (SRB) with a biocide and a metabolic inhibitor. The biocide directly kills a first portion of the SRB. The metabolic inhibitor inhibits sulfate-reducing growth of a second portion of the SRB without directly killing the second portion of the SRB. The treatment of SRB with both a biocide and a metabolic inhibitor provides effective biogenic sulfide inhibition at significantly lower concentrations than would be required if the biocide or metabolic inhibitor was used alone.

Owner:UNIV TECH INT +1

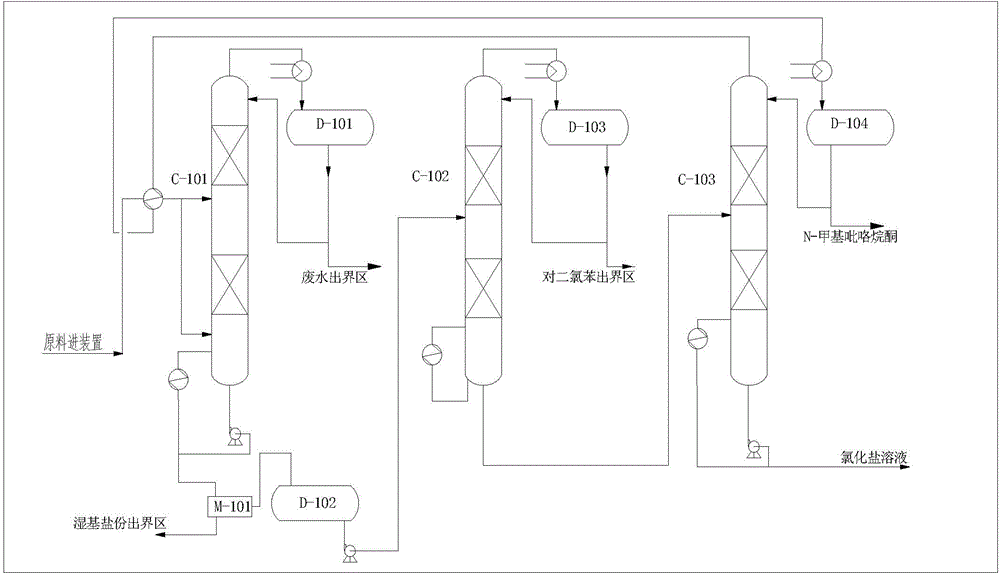

Continuous recycling method of NMP (N-methyl pyrrolidone) solvent for polyphenylene sulfide production device

ActiveCN104447480AAvoid lostReduce lossesOrganic chemistryChemical industryHigh concentrationRecovery method

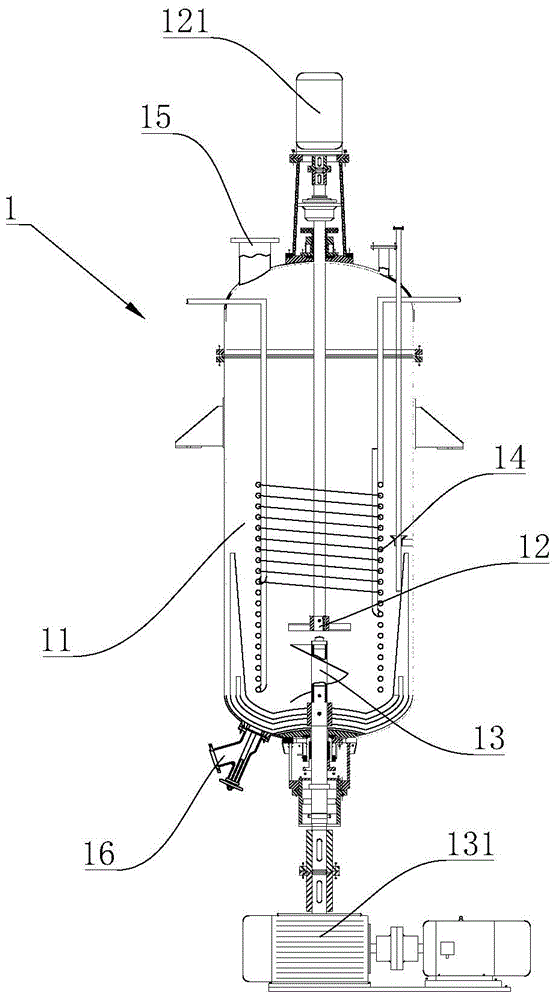

The invention discloses a novel continuous recycling method of an NMP (N-methyl pyrrolidone) solvent for a polyphenylene sulfide production device. The polyphenylene sulfide production device comprises three vacuum rectifying towers, a heat exchanger, a centrifuge machine, a storage tank, a pump and relevant pipelines. In an existing polyphenylene sulfide solvent recycling process, pipelines are easily blocked by salt crystals in a dehydration process, so that the halt maintenance needs to be frequently carried out, the rate of equipment utilization is low, and the solvent loss is high. According to the novel continuous recycling method of the NMP (N-methyl pyrrolidone) solvent for the polyphenylene sulfide production device, a novel technological process device is developed; by virtue of forced circulation of high-concentration salt fraction at the tower bottoms, solid salt formed after water and the solvent are removed can be adequately stirred and circulated, and the blockage, caused by the salt crystals, of valves of the pipelines is avoided, so that the heating efficiency of the column bottoms is increased, the yield of NMP is improved, the quality of an recycled NMP product can reach 99.5% or above, recycling requirements of a system are met, and meanwhile, the long-period, stable and efficient operation of the device are guaranteed.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

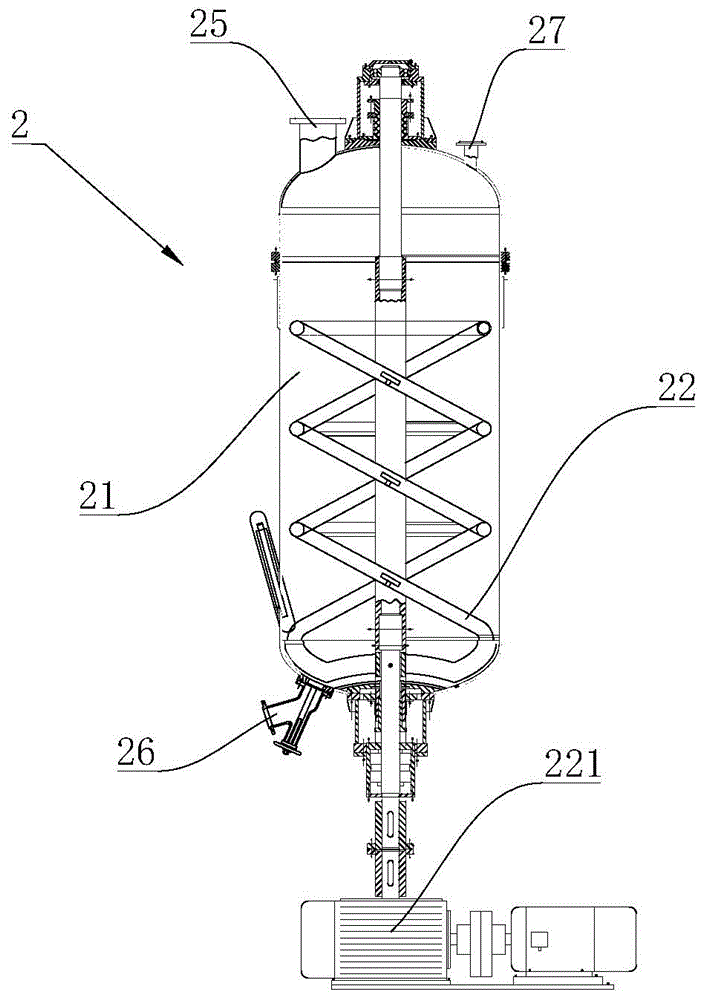

Continuous washing method for product in polyphenylene sulfide production

The invention discloses a method for continuously washing products generated in the process of production of polyphenylene sulfide, which can improve the production efficiency, reduce the energy consumption and provide a stable material flow for subsequent technologies. The method comprises the following steps: firstly, a mixture required to be washed after polymerization is sent into a horizontal helical discharging sedimentation centrifuge for filtration, and separated solid substances, namely coarse products of polyphenylene sulfide resin, are directly sent into a disposable washing kettle; secondly, the coarse products of the polyphenylene sulfide resin are mixed with washing water in the disposable washing kettle, and fully stirred, and enters into a second horizontal helical discharging sedimentation centrifuge for filtration and separation, and separated solid substances are sent into a second washing kettle for secondary washing; and thirdly, washing and centrifugal separation are continuously performed until the purity of the polyphenylene sulfide resin meets the standards, wherein washing and centrifugal separation each time is a washing period.

Owner:JIANGSU XINZHONG INVESTMENT

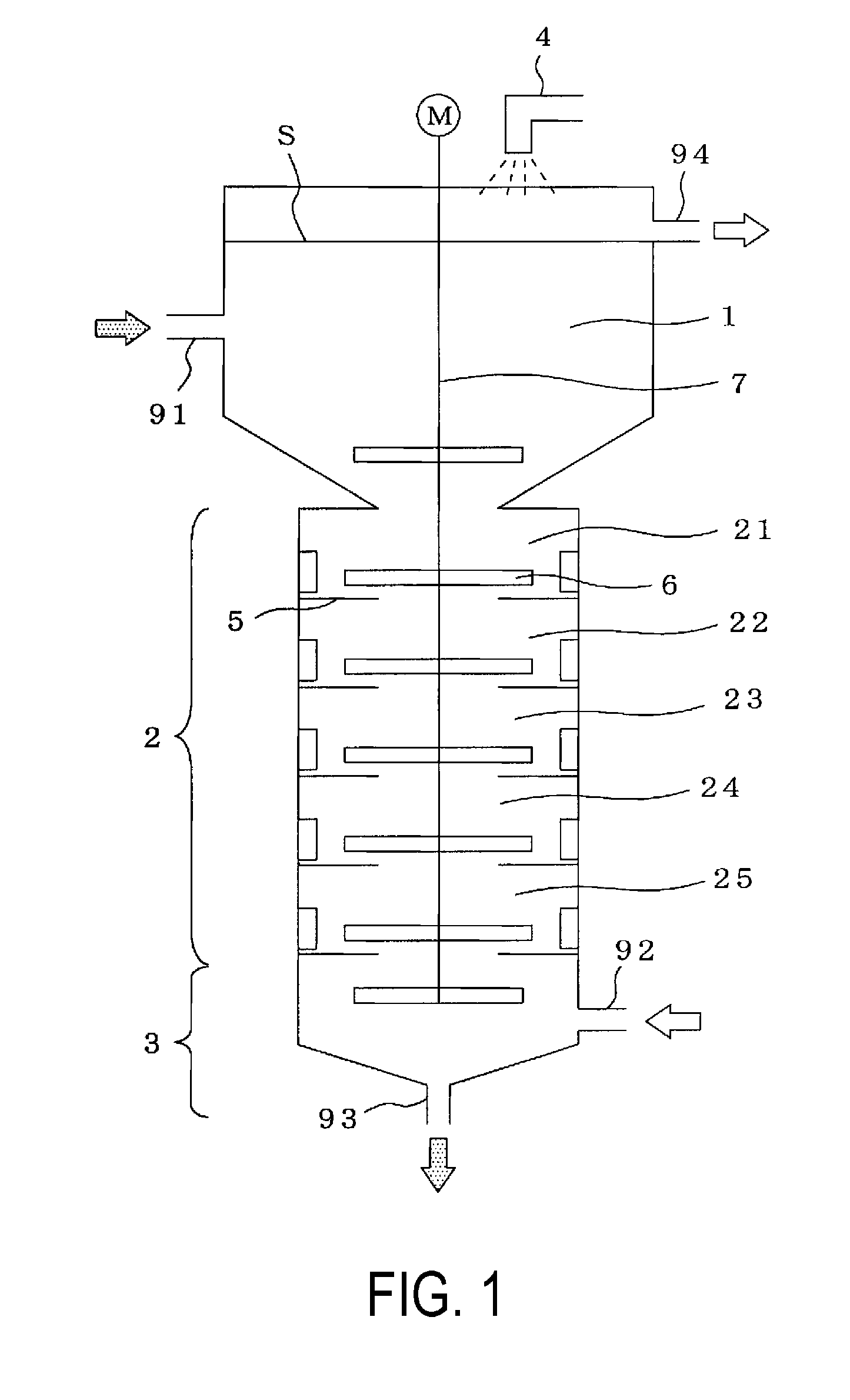

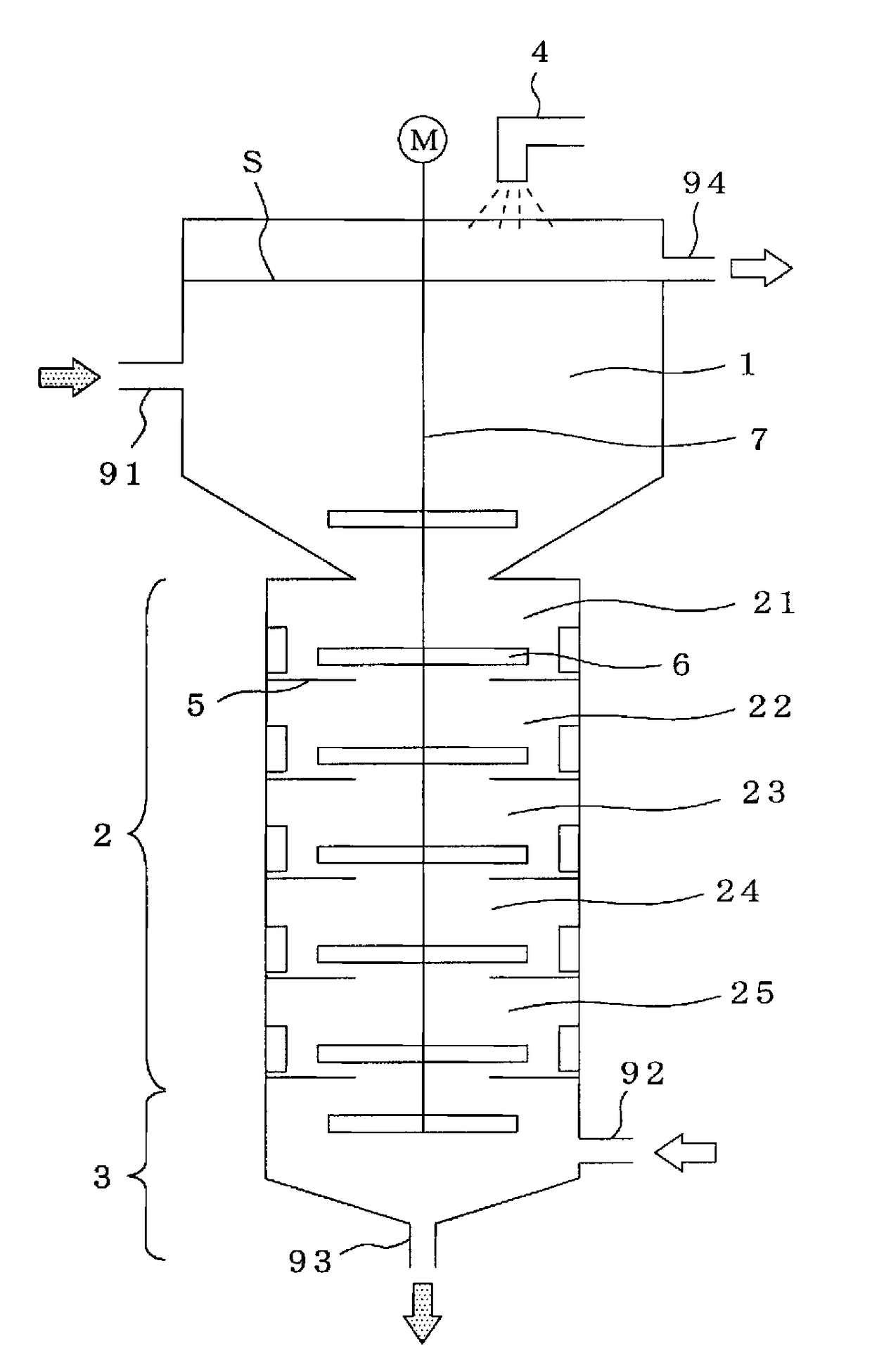

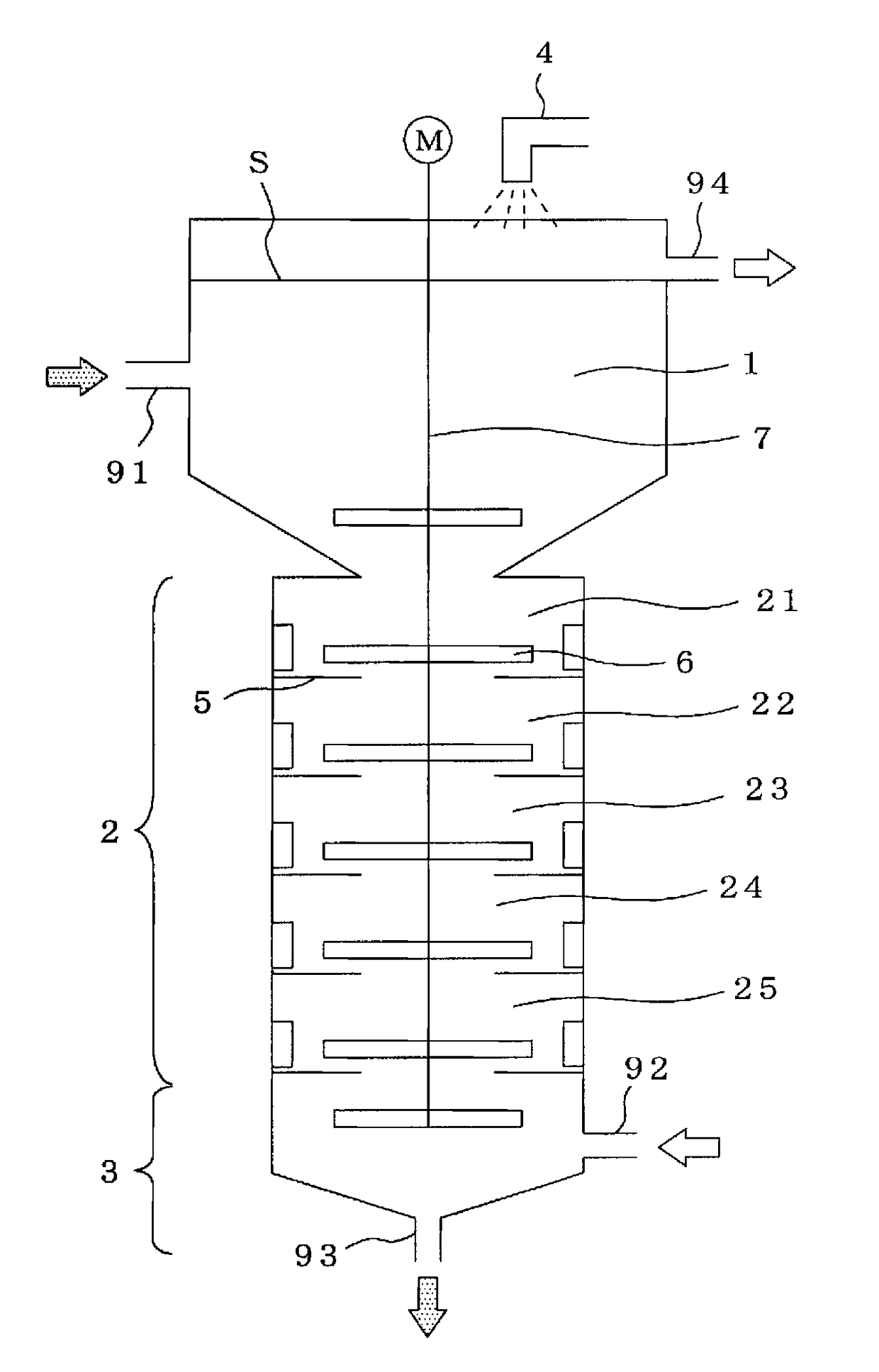

Polyarylene sulfide production method and polyarylene sulfide production apparatus

ActiveUS20170029570A1Stable productionImprove production yieldCleaning using liquidsStationary filtering element filtersSulfide productionSlurry

The present invention provides a production method and a production apparatus for a polyarylene sulfide (PAS), thus the formation of a floating polymer and the leakage of the floating polymer to the outside of the vessel in a washing step are prevented, to achieve steady production of the polymer with high quality, to improve the yield of the polymer and to reduce environmental load, wherein the floating polymer refers to a particles of the polymer which are floating on the surface of a washing solution, in the upper part of the inside of a washing vessel, as a result of the adhesion of a gas onto the surface of the particles of the polymer.The present invention provides a production method for a PAS comprising step (I), performing polymerization, step (II), separating and collecting a polymer, step (III), washing a slurry, and step (IV), collecting the polymer after washing, wherein an aqueous medium is sprayed onto a PAS floating on the surface of the aqueous washing solution in the upper part of the inside of the washing vessel in step (III) (step (IIIa), washing a slurry using a counter current, and / or step (IIIb), treating a slurry with acid using a counter current, or the like); and a production apparatus for a PAS comprising a washing device (counter current washing device and / or a counter current contact / acid treatment device or the like) having an aqueous medium spray means.

Owner:KUREHA KAGAKU KOGYO KK

Inferred water analysis in polyphenylene sulfide production

A method for producing polyphenylene sulfide (PPS) polymer, including polymerizing reactants in a reaction mixture in a vessel to form PPS polymer in the vessel, measuring values of operating variables of the vessel and / or PPS process, and determining the amount of quench fluid to add to the vessel based on the values of the operating variables. The technique may rely on the vapor liquid equilibrium (VLE) of the mixture to calculate the concentration of water existing in the reactor prior to quench, and accounts for the effectiveness of the upstream dehydration process and in the amount of water produced during the polymerization. The technique is a striking improvement over the trial-and-error estimation of the amount of quench water based on human operating experience, and avoids direct measurements of the existing water concentration in the reactor. The result is improved control of PPS particle size and other properties.

Owner:SOLVAY SA

Inhibition of biogenic sulfide production via biocide and metabolic inhibitor combination

ActiveUS7833551B2Inhibit productionInhibition productionHeavy metal active ingredientsBiocideSulfide productionSulfate-reducing bacteria

Owner:UNIV TECH INT +1

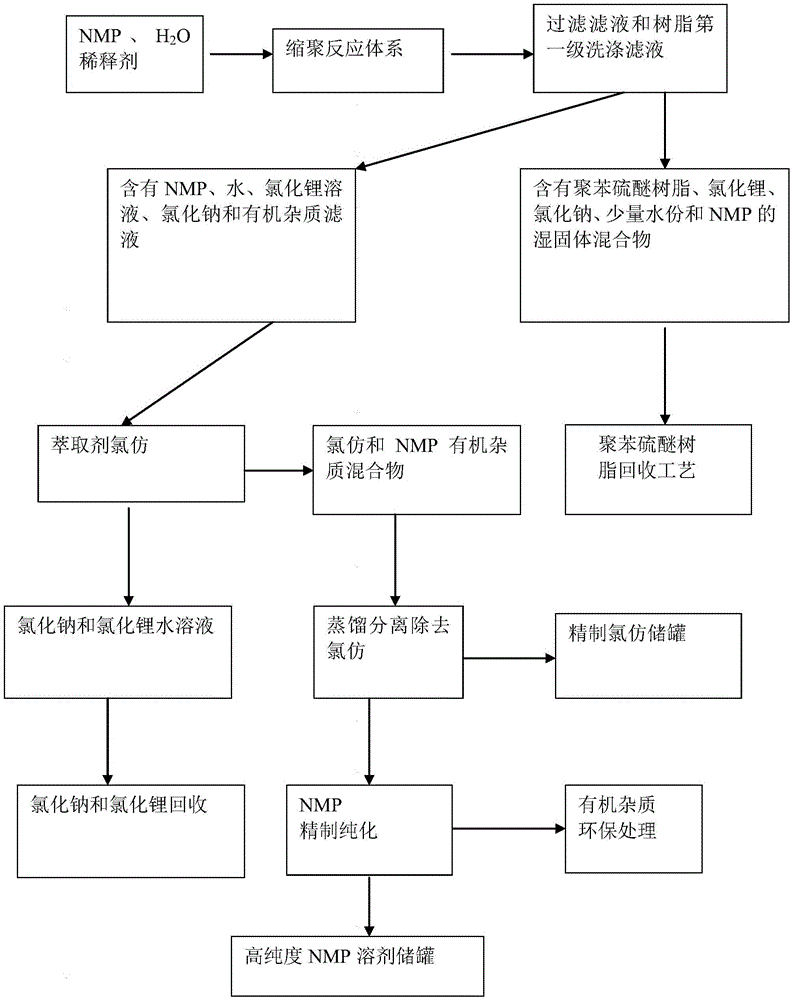

Solvent recycling technology adopted in polyphenylene sulfide production

The invention relates to a solvent recycling technology adopted in polyphenylene sulfide production. According to the technology, sodium sulfide and paradichlorobenzene which contain a certain amount of crystallization water are adopted as raw materials, lithium chloride is adopted as cosolvent, and N-methyl pyrrolidone is adopted as solvent, so that polyphenylene sulfide resin is synthecized; after a polycondensation reaction is completed, the solvent for synthesizing and producing the polyphenylene sulfide resin is recycled, meanwhile, a certain amount of fresh NMP solvent and oxygen-free deionized water need to be added to a polycondensation reaction system to dissolve the cosolvent and a by-product (sodium chloride) generated in the synthesis technological process, thereby a mixture system containing the polyphenylene sulfide resin, NMP, the cosolvent, the by-product and organic impurities is formed, and immediately the mixture system is input into a centrifugal machine for solid-liquid separation. According to the solvent recycling technology, the high boiling point solvent and the oxygen-free deionized water are adopted as diluent of the polycondensation reaction system, and the solvent recycling technology aims at lowering the viscosity of the polycondensation reaction system, raising the velocity of solid-liquid separation, further raising the production rate of the polyphenylene sulfide resin, lowering production cost of whole polyphenylene sulfide resin, shortening the washing process flow at the same time and reducing equipment investment of the washing process flow.

Owner:何展潮

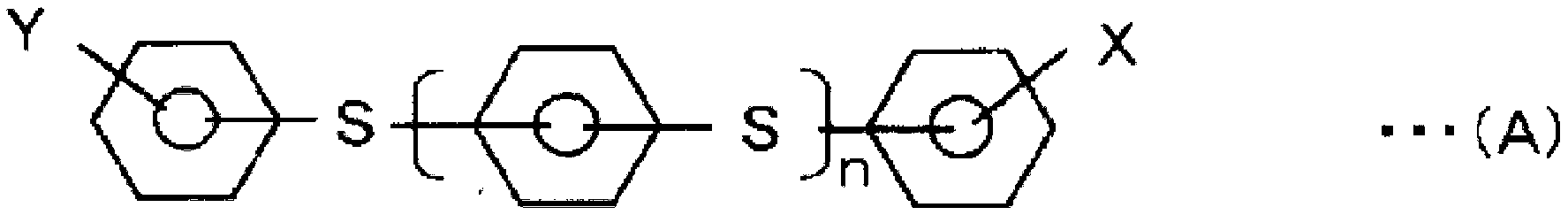

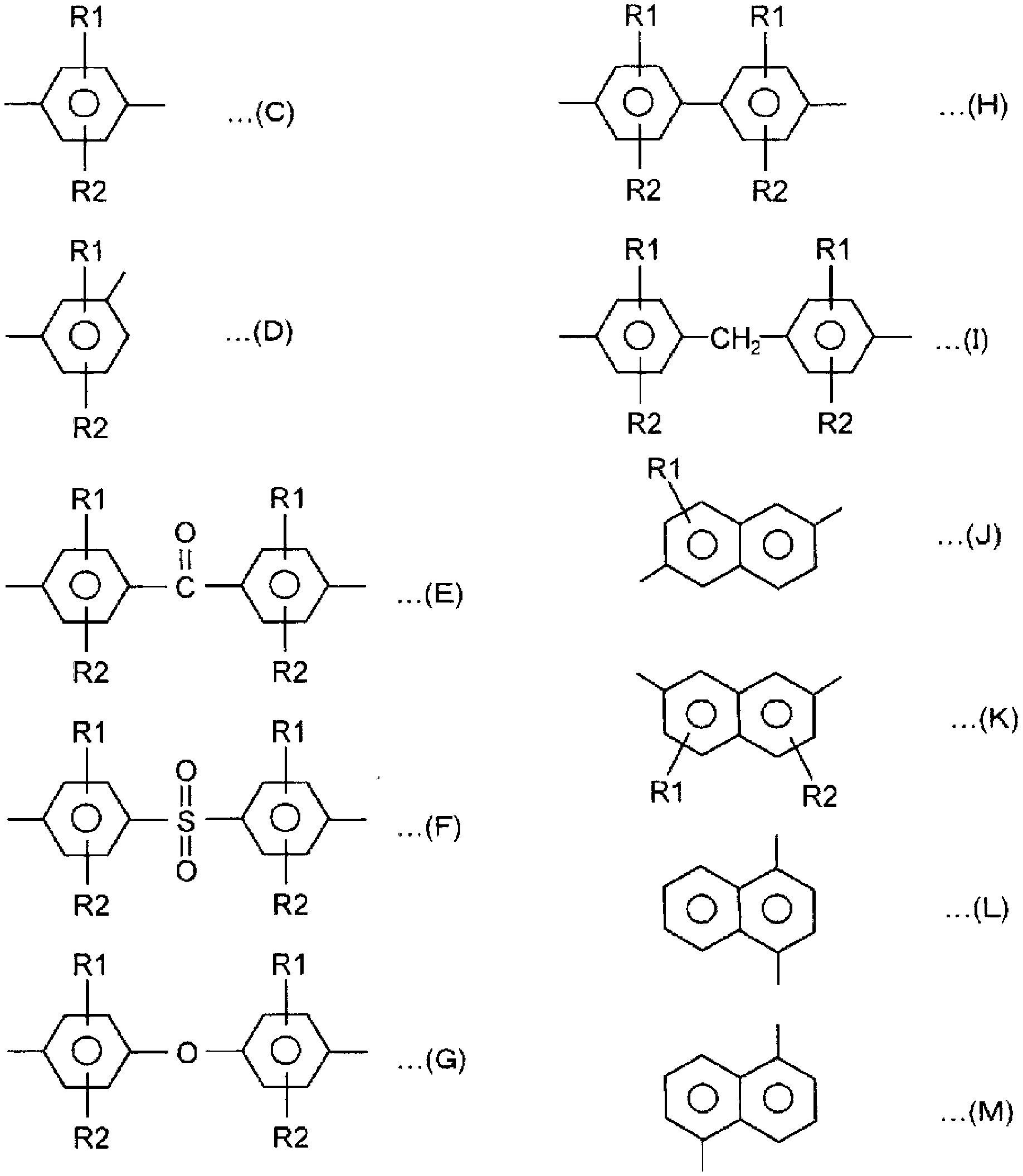

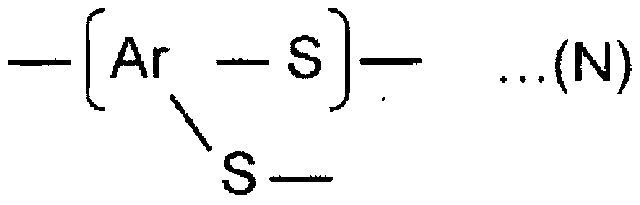

Polyarylene sulfide production method and polyarylene sulfide

A polyarylene sulfide containing reactive functional groups with a narrow dispersity and low amount of generated gas is produced by heating a cyclic polyarylene sulfide composition in the presence, with respect to 1 mole of arylene sulfide structural units, of 0.1 mole% to 25 mole% of a sulfide compound having reactive functional groups selected from amino groups, carboxyl groups, hydroxyl groups, acid anhydride groups, isocyanate groups, epoxy groups, silanol groups and alkoxysilane groups.

Owner:TORAY IND INC

Lithium salt recovery method

The invention discloses a lithium salt recovery method which comprises the following steps of: firstly, carrying out a sulfohydrogenation reaction between a hydrosulfide and a lithium salt existing in an N-methylpyrrolidinone system in an inert gas environment, thereby converting the lithium salt into lithium hydrosulfide, and then performing solid-liquid separation; after solid-liquid separation, heating a N-methylpyrrolidinone solution containing the lithium hydrosulfide in the inert gas environment and decomposing and converting the lithium hydrosulfide into lithium sulfide precipitate, and collecting the lithium sulfide precipitate after solid-liquid separation. The method has the advantages that the production process is safer and more convenient because no high-risk hydrogen sulfide gas is utilized, and the recovery process is short, the investment is saved, the efficiency is high and the recovery rate of the lithium salt is higher than 99%. As the solvent NMP does not need to be evaporated at a high temperature, high-temperature decomposition of the solvent is also avoided. For polyarylene sulfide production, the lithium salt recovery method is suitable for different preparation processes / routes; and the recovered lithium sulfide can be recycled directly for polyarylene sulfide preparation.

Owner:SHANDONG MINGHUA NEW MATERIAL CO LTD

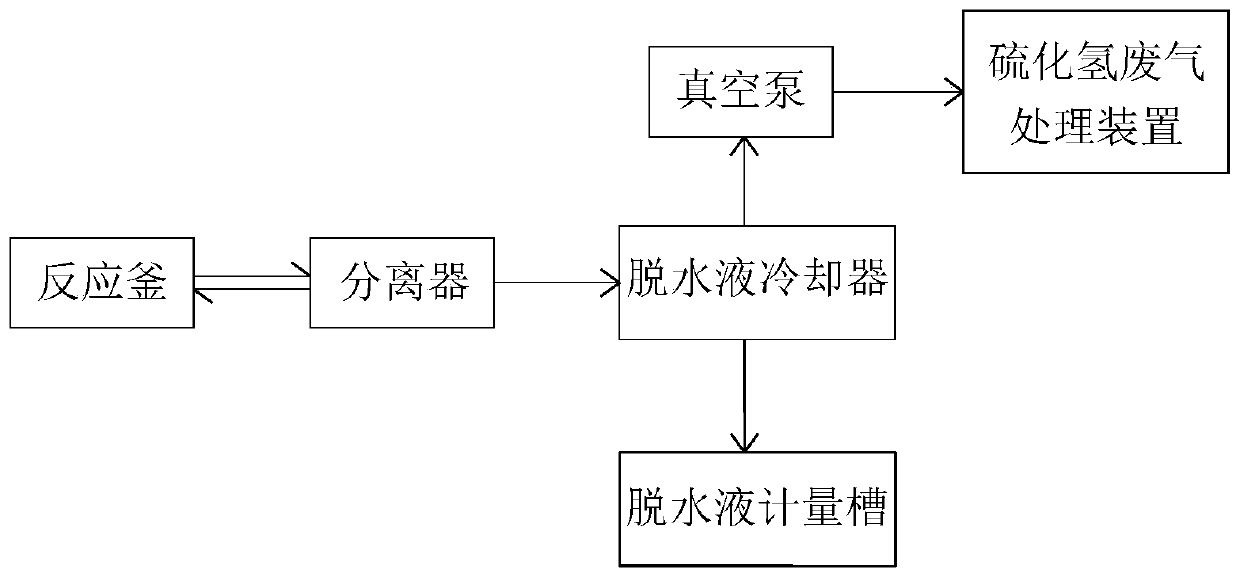

Method for dehydrating sodium sulfide polyhydrate in polyphenylene sulfide production

The invention relates to the technical field of sodium sulfide dehydration, particularly to a method for dehydrating sodium sulfide polyhydrate in polyphenylene sulfide production. The specific schemeis that the method comprises: adding sodium sulfide polyhydrate, NMP, an auxiliary agent and sodium hydroxide into a reaction kettle, and heating and dehydrating the materials in the reaction kettle;making the mixed steam generated by the dehydrating enter a separator, separating, returning the separated liquid returns to the reaction kettle, and carrying out condensation recovery and waste gastreatment on the separated gas; and adding molten p-dichlorobenzene into the reaction kettle, and carrying out a step-by-step heating reaction on the mixed solution in the reaction kettle to finally obtain the polyphenylene sulfide product. In the prior art, the existing PPS production is high in dehydration temperature, performs two-section evaporation dehydration by requiring steam and other energy sources, is instable, and does not have the fixed dehydration time, and the process control is instable during dehydration to cause a large amount of liquid carrying so as to cause the high NMP content in the dehydrated water. According to the invention, the problem in the prior art is solved.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

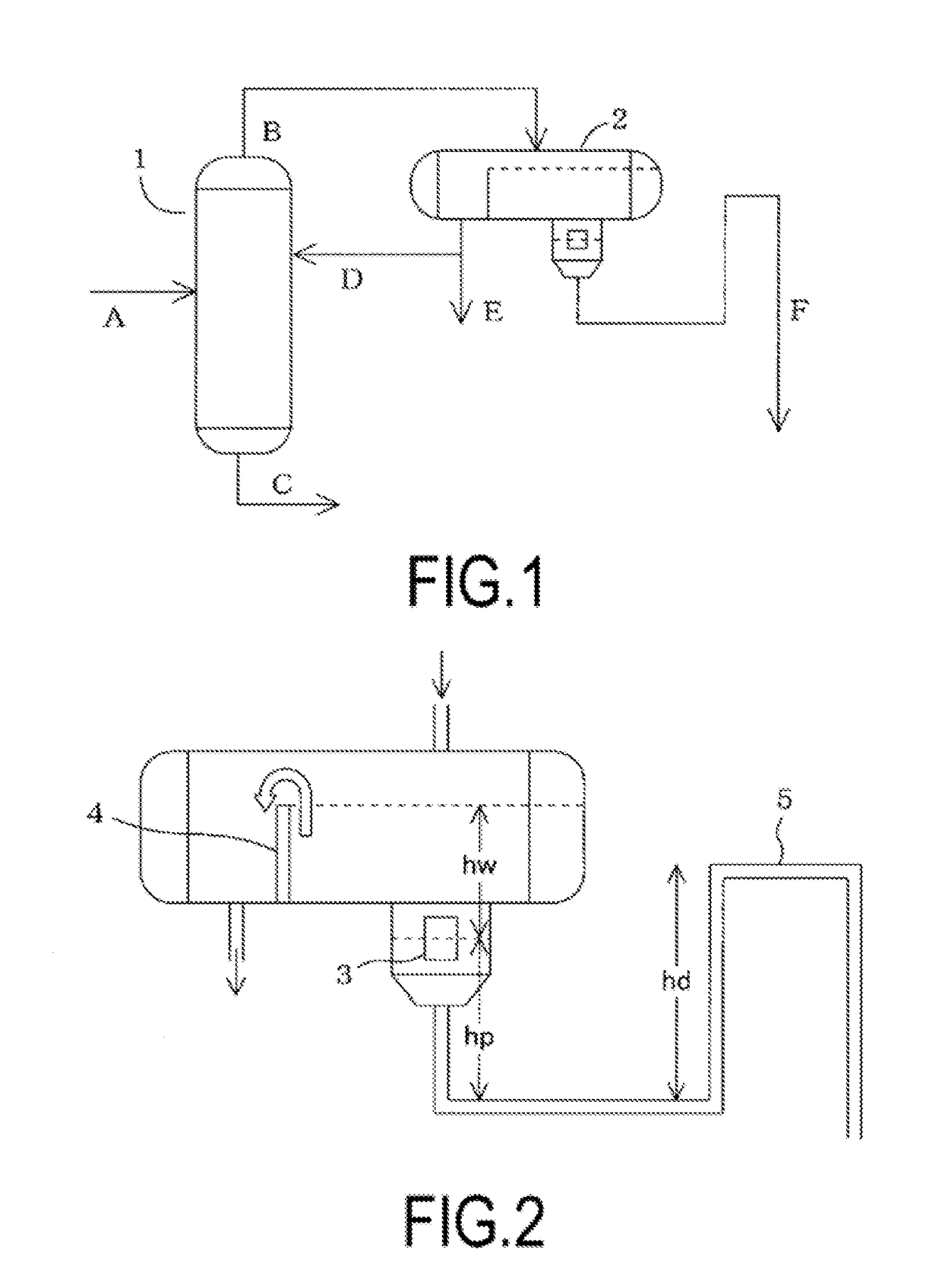

Polyarylene sulfide production method and polyarylene sulfide produced using production method

The present invention is a production method for producing polyarylene sulfide, wherein an unreacted dihalo aromatic compound is recovered and reused.The present invention is a production method for producing polyarylene sulfide, the method include: (a) a polymerization step; (b) a separation step; and (c) a recovery step of recovering an unreacted dihalo aromatic compound from a water-containing mixture in the form of a water-containing liquid mixture containing the separated liquid by steam distillation entailing adjusting the reflux ratio of water in the steam distillation column without adding water other than the refluxed water. Alternatively, the present invention is a production method for producing polyarylene sulfide, the method include: (a) a polymerization step; (d) a dehydration step; and (c) a recovery step of recovering an unreacted dihalo aromatic compound from a water-containing mixture in the form of a water-containing liquid mixture and / or a water-containing steam mixture containing a raw material mixture and / or a polymerization reaction solution by steam distillation entailing adjusting the reflux ratio of water in the steam distillation column without adding water other than the refluxed water in the dehydration step.

Owner:KUREHA KAGAKU KOGYO KK

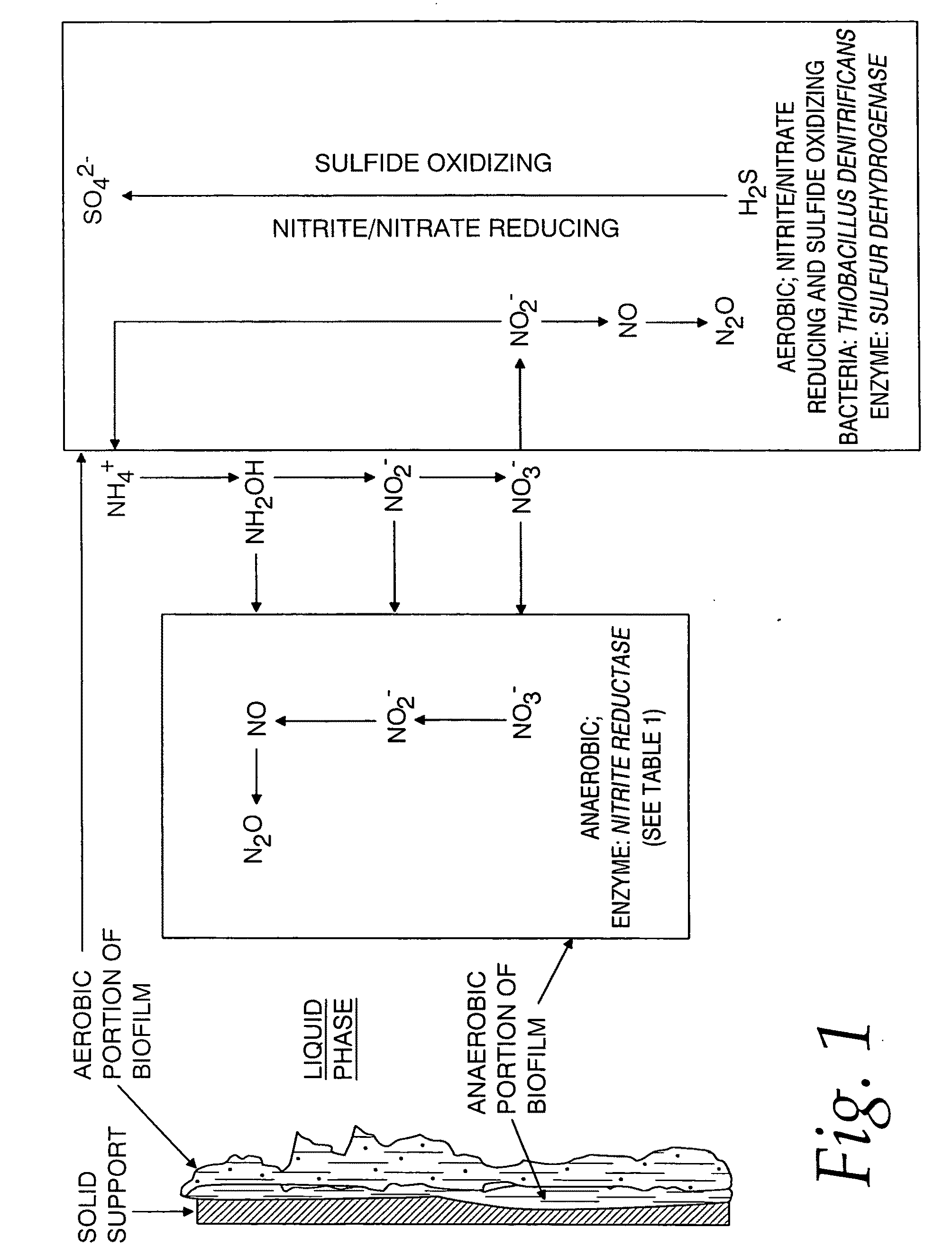

Method for the use of nitrate reducing bacteria and phages for mitigating biogenic sulfide production

Owner:MULTI CHEM GRP

Polyphenylene sulfide production method

The invention discloses a polyphenylene sulfide production method, which comprises the following active ingredients: water-containing sodium sulfide, p-dichlorobenzene, phase solvent, solvent, and auxiliaries, wherein the phase solvent adopts 2-dimethyl benzoyl isocyanate, and the auxiliaries adopt chlorinated polyethylene. The polyphenylene sulfide production method concretely comprises the following steps: firstly, drying and dewatering the water-containing sodium sulfide, phase solvent, solvent, and auxiliaries, wherein the dewatering time lasts 30-50min, and the temperature is at 150-175DEG C; adding the p-dichlorobenzene after drying and dewatering, filtering after filtering, adding washing liquor while filtering, and filtering and rying to obtain polyphenylene sulfide. Through the mode, the invention can provide a polyphenylene sulfide production method, which is simple in operation steps, and easy to realize, the purity of polyphenylene sulfide can be controlled to the greatest extent during reaction, more refuses cannot be generated during reaction, and thus the environment can be effectively protected.

Owner:SUZHOU NEW DISTRICT HUASHIDA ENG PLASTICS

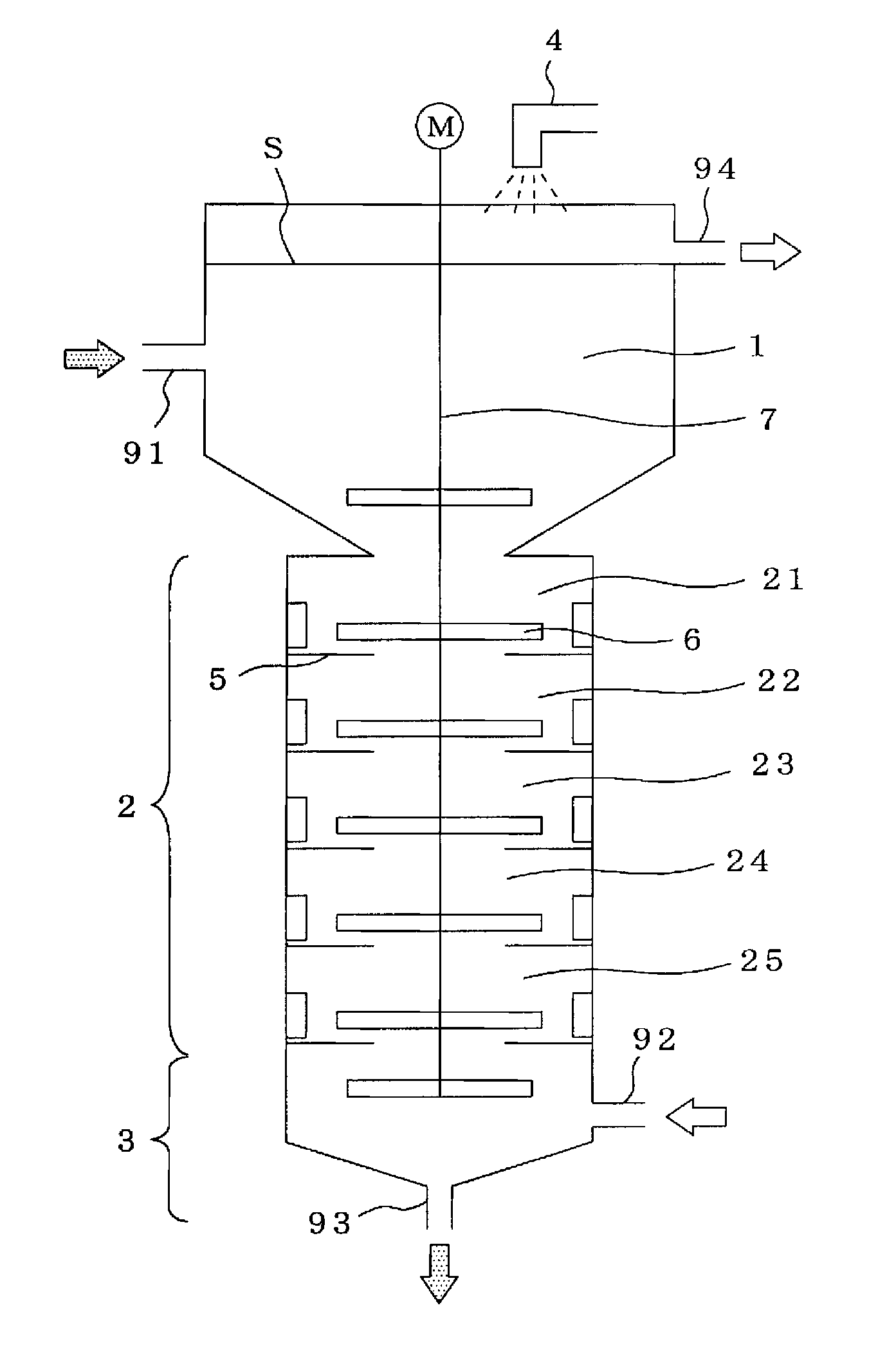

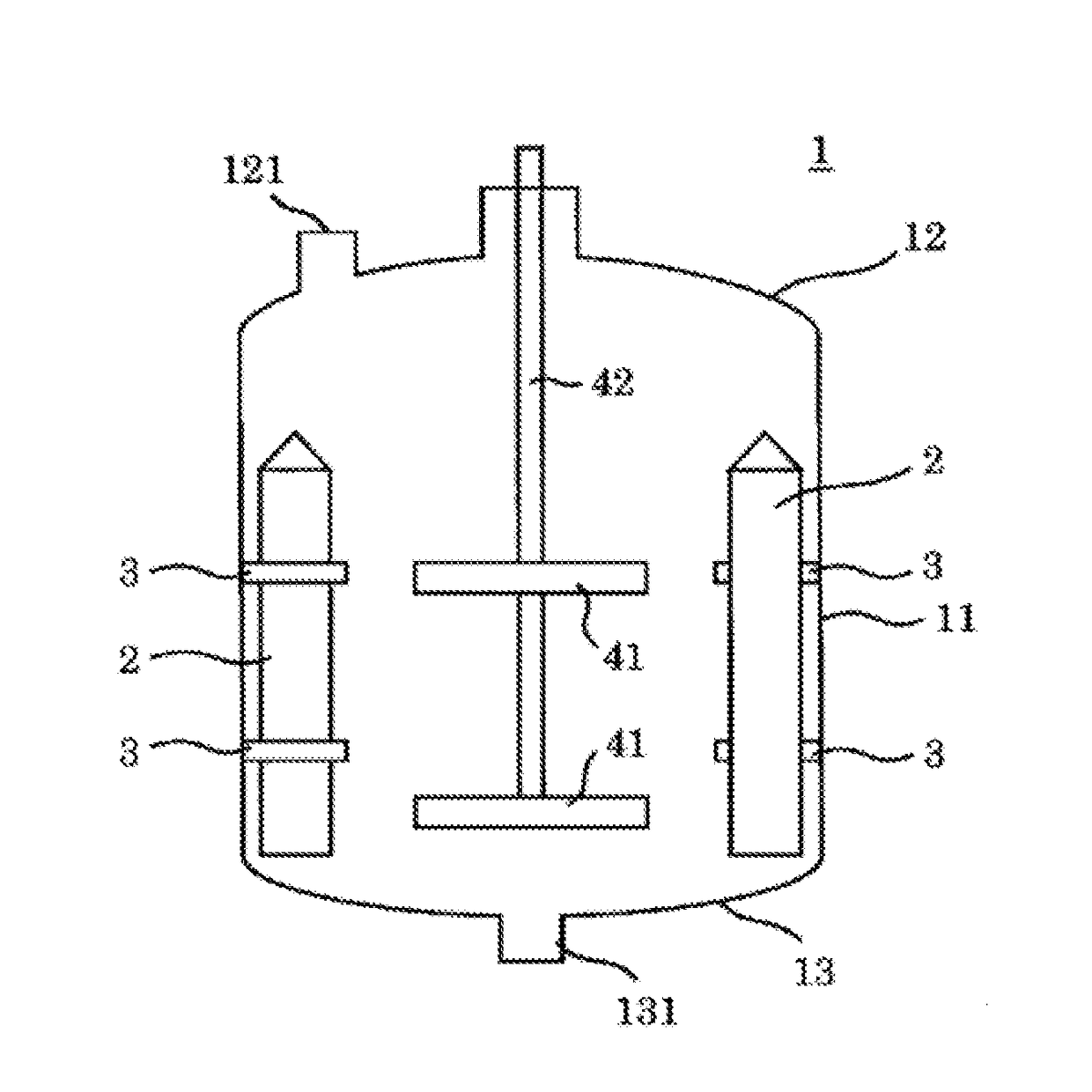

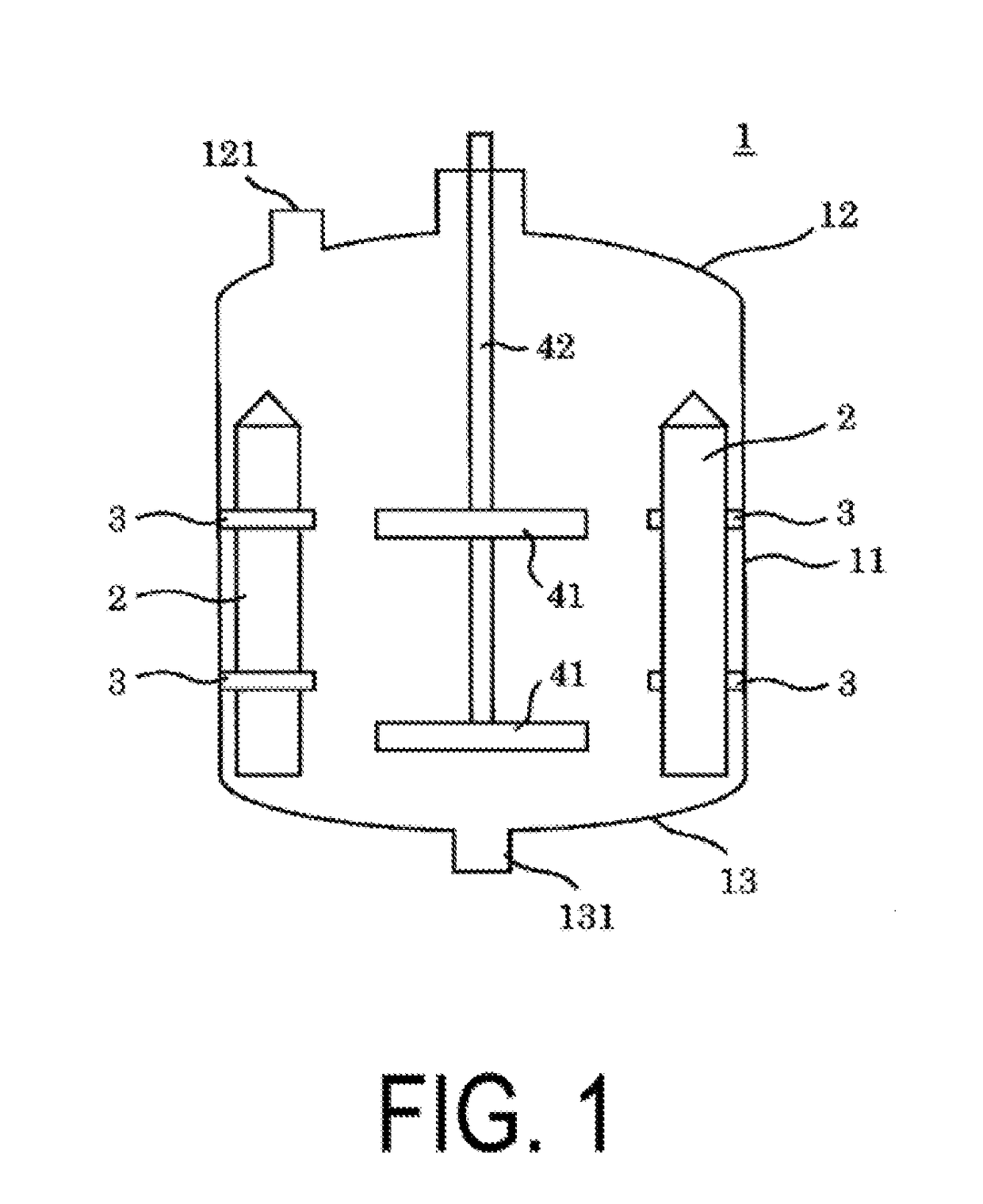

Polyarylene sulfide production device provided with baffle and baffle support

ActiveUS20170313790A1Improve stirring efficiencyLow costRotary stirring mixersTransportation and packagingSulfide productionEngineering

The present invention provides a polyarylene sulfide (PAS) production device which suppresses the accumulation of deposits on a baffle (baffle board) or the like disposed inside a reaction vessel via a baffle support for the purpose of enhanced stirring efficiency or the like, thereby contributing to enhanced production efficiency, reduced cost of removing accumulation, and enhanced quality of the PAS product.The PAS production device of the present invention is a PAS production device provided with a reaction vessel equipped with one or a plurality of baffles; each baffle being supported by one or a plurality of baffle supports provided in a protruding manner on an inside wall of the reaction vessel; and at least one of the baffle supports having one or a plurality of openings preferably passing through the baffle support in the vertical direction.

Owner:KUREHA KAGAKU KOGYO KK

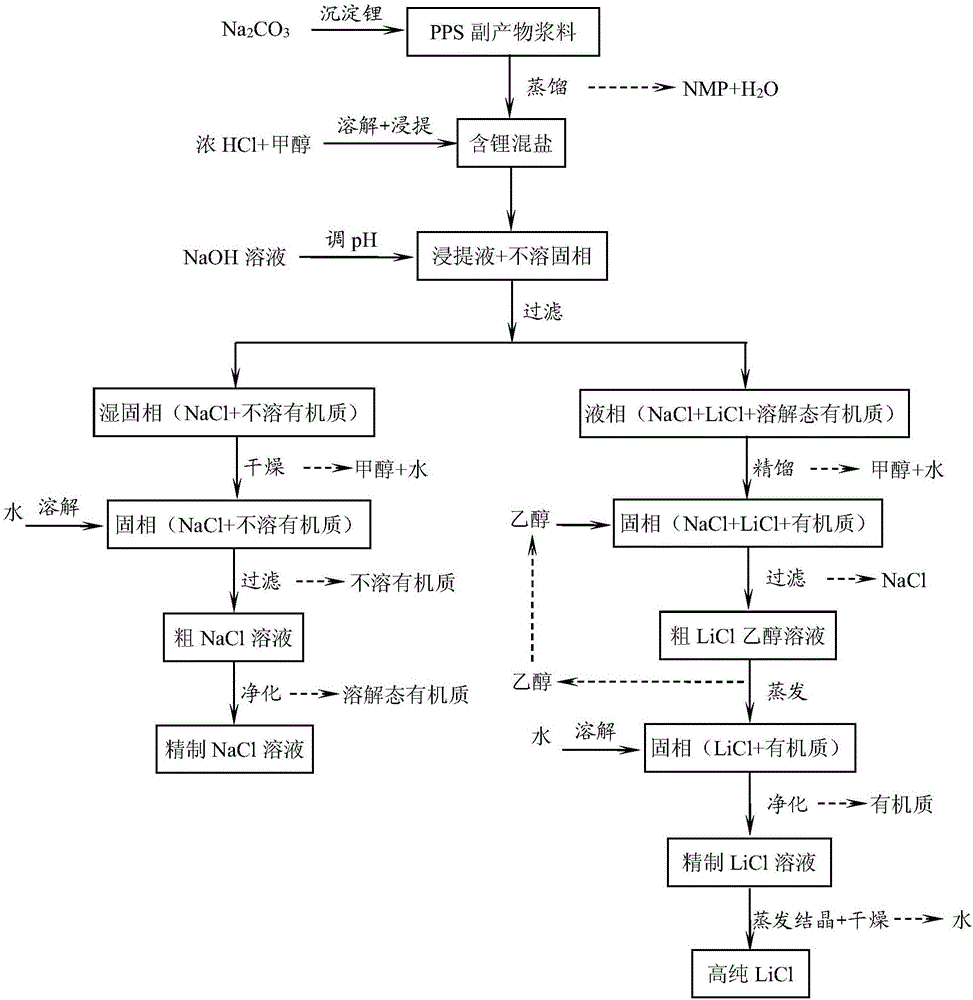

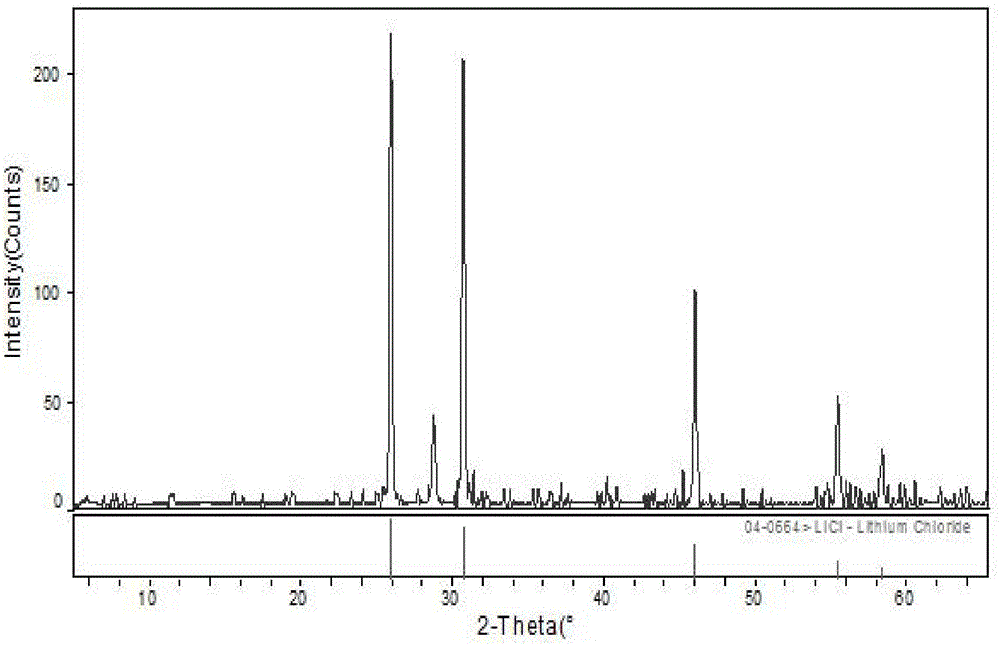

A method for comprehensive recovery and utilization of lithium containing mixed salts in a polyphenylene sulfide production process

ActiveCN106565581AAchieve recyclingEase of industrial productionOrganic chemistryLithium halidesElectrolysisFiltration

A method for comprehensive recovery and utilization of lithium containing mixed salts in a polyphenylene sulfide (PPS) production process is disclosed. Na<2>CO3 is added into PPS byproduct slurry, rectification is performed to separate and recover a solvent that is NMP, then obtained lithium containing mixed salts are subjected to dissolution and leaching through an acidic methanol solution, and a wet solid phase and a liquid phase are obtained after pH adjustment and filtration. The wet solid phase is dried, dissolved with water and purified to obtain a refined NaCl solution. The liquid phase is subjected to rectification, ethanol leaching, evaporation, water leaching, purification and evaporative crystallization to obtain a high-purity water-free LiCl product. The method can be used for comprehensive recovery and utilization of the lithium containing mixed salts in the PPS production process. The recovered refined NaCl solution can be directly used for ionic membrane electrolysis to prepare caustic soda, and the LiCl can be directly used as a PPS production auxiliary agent for cyclic use.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Method for recycling NMP (N-Methyl Pyrrolidone) and LiCl in production of polyphenylene sulfide by using solvent extraction process

The invention discloses a method for recycling NMP (N-Methyl Pyrrolidone) and LiCl in production of polyphenylene sulfide by using a solvent extraction process. The method comprises the following steps: after polyphenylene sulfide production reactions are completed, filtering a reaction mixture through a precise filtering system, adding a certain amount of a solvent into filter residues, performing ultrasonic dissolution, filtering repeatedly, performing distillation on filtrate, respectively recycling the solvent, the NMP and the LiCl, washing the filter residues with a detergent, and respectively collecting a polyphenylene sulfide product and NaCl. Due to adoption of the precise filtering system, cleaning and filtration are implemented for multiple times with the solvent, a polyphenylenesulfide reaction mixed liquid is efficiently separated, the operation is simple, and large-scale industrial application is facilitated.

Owner:ZHUHAI CHANGXIAN CHEM TECH

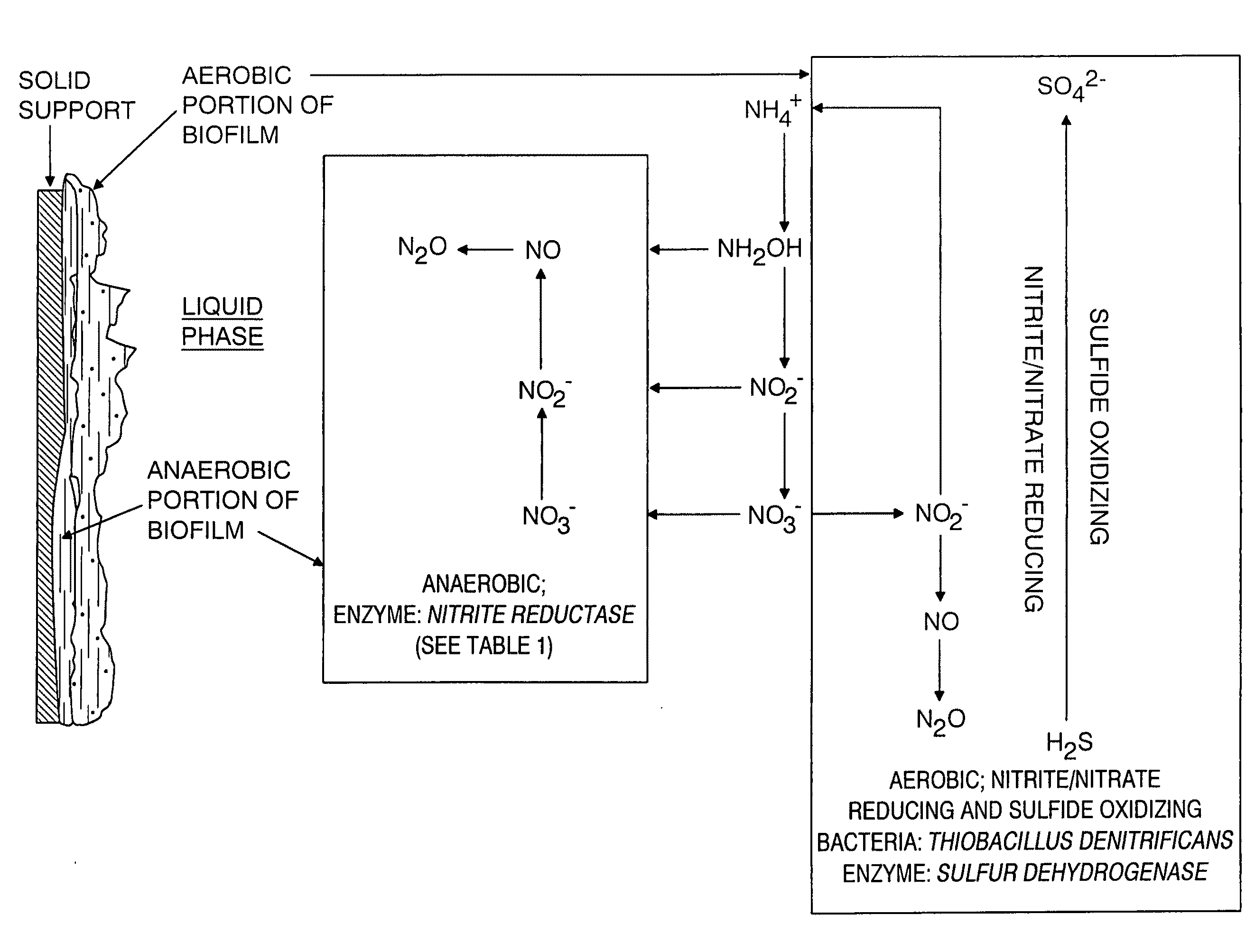

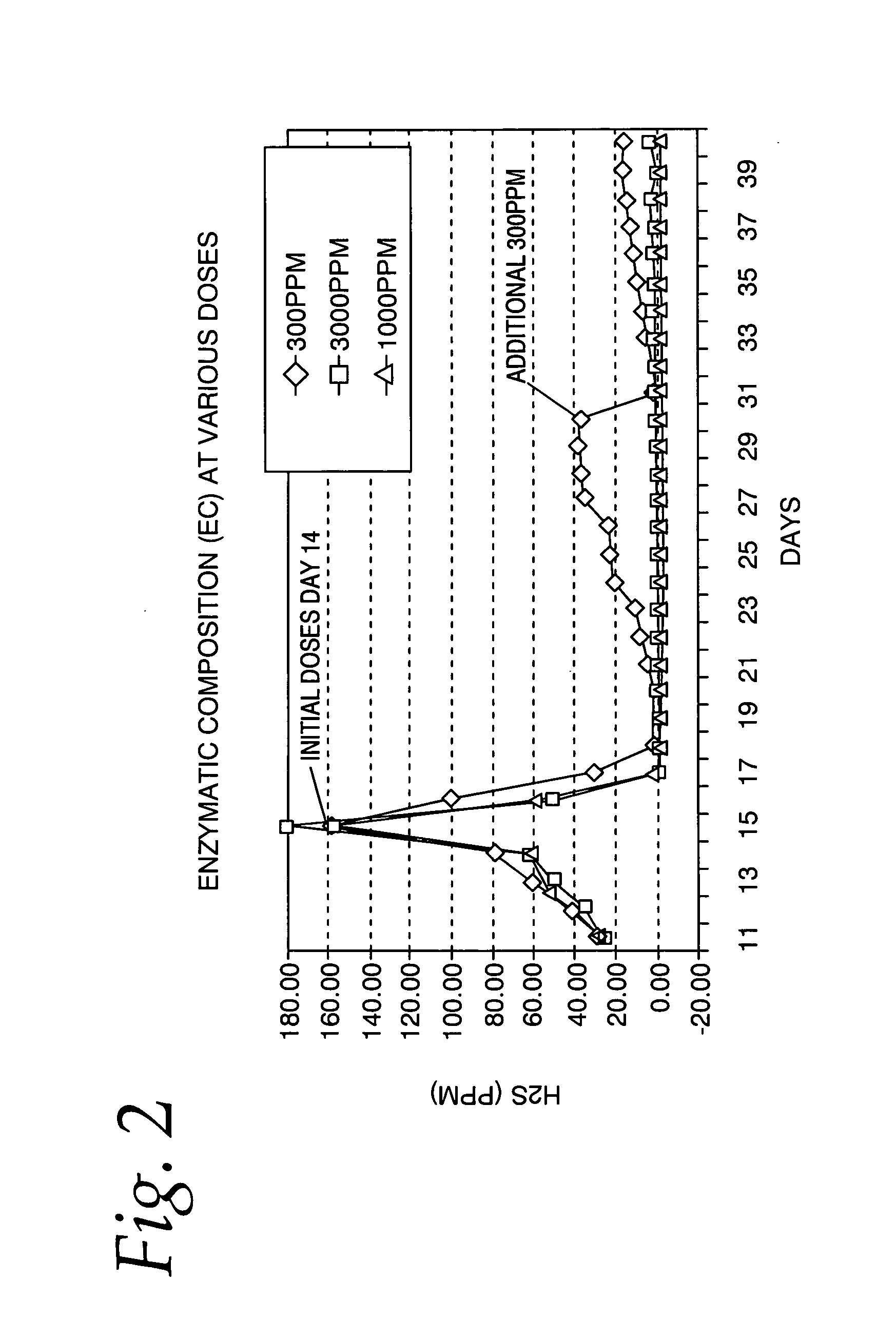

Enzymatically active compositions for suppressing sulfide generation and methods of use thereof

InactiveUS20100239555A1Extended service lifeImprove adverse effectsBiocideBacteriaSulfide generationAlkaline earth metal

The present invention provides an enzymatically active composition for suppressing sulfide generation. The composition is free from sulfur dehydrogenase and comprises at least one enzyme having sufficient sulfide-production inhibiting activity in an acidic medium to at least inhibit biogenic sulfide production, and an oxidized nitrogenous inorganic salt present in an amount sufficient to act as an electron acceptor for the enzyme. The oxidized nitrogenous inorganic salt preferably is selected from an alkali metal nitrite, an alkaline earth metal nitrite, an alkali metal nitrate, an alkaline earth metal nitrate, or a mixture of two or more of the foregoing salts. The enzymatically active composition is free from viable bacteria and is non-toxic (i.e., has an oral LD50 in rats greater than 1000 mg / Kg of body weight at a concentration of about 25,000 parts per million (ppm) in water). The compositions of the present invention are useful for treating and removing biofilms, as well as inhibiting sulfide production in a variety of aqueous systems.

Owner:LCP TECH HLDG

Crystal type polymer synthesis solvent recovery method and polyphenylene sulfide production method

ActiveCN104817716AOvercoming the problem of low purityReduce energy consumptionRecovery methodPolymer science

The invention relates to a crystal type polymer synthesis solvent recovery method and a polyphenylene sulfide production method and belongs to the field of polymer materials. The crystal type polymer synthesis solvent recovery method includes the steps of firstly, performing flash evaporation on reaction liquid under a stirring, negative pressure and heating state after solution polymerization reaction is completed so as to recycle solvent; secondly, washing and drying powder products after solvent recycling to obtain crystal type polymer materials. Compared with the prior art, the crystal type polymer synthesis solvent recovery method has the advantages that the problem that solvent recovery in an existing crystal type polymer production process is high in energy consumption and high in loss, the problem of low polymer product purity caused by the fact that inorganic salt particles wrapped by product particles in a traditional process are not cleaned, a new solvent recovery method is provided to the polymer field, and a production flow is simplified.

Owner:广州力牧实业有限公司

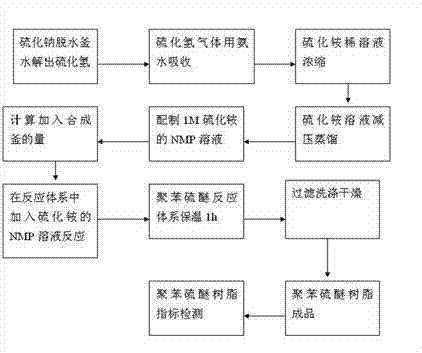

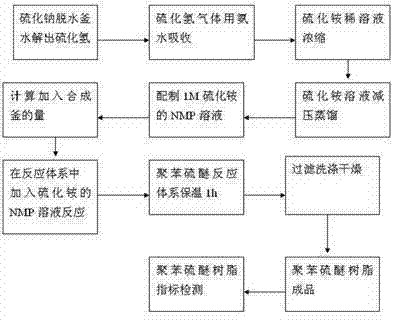

Recovery and utilization method of highly toxic medium hydrothion waste gas generated in polyphenylene sulfide production

The invention discloses a recovery and utilization method of highly toxic medium hydrothion waste gas generated in polyphenylene sulfide production. The method includes: adopting waterish sodium sulphide and p-dichlorobenzene as raw materials to be subjected to process steps such as sodium sulphide dehydration and polycondensation to produce polyphenylene sulfide monomers, leading waste gas rich in hydrogen sulfide to be reacted with ammonia water in an alkali liquor absorption tank, leading the reaction product ammonium sulfide to be concentrated to serve as component conditioning agents for polyphenylene sulfide production to be conveyed to a reaction kettle so as to effectively regulate polymerized polyphenylene sulfide resin molecules, wherein the molecular weight distribution coefficient after regulation can keep between 1.91-1.93. After being subjected to ammonium sulfide processing and regulating, content of various metal chloride ions and non-metal chloride ions in the polyphenylene sulfide resin is small, and the total amount of metal ions is 200-300 ppm. By adopting the method, highly toxic medium hydrothion waste gas is treated and good environment protection effect is achieved; and a virtuous closed circle is formed due to the fact that the orginal water gas is converted into production raw materials capable of being reused.

Owner:SICHUAN DEYANG ENG PLASTIC DEV

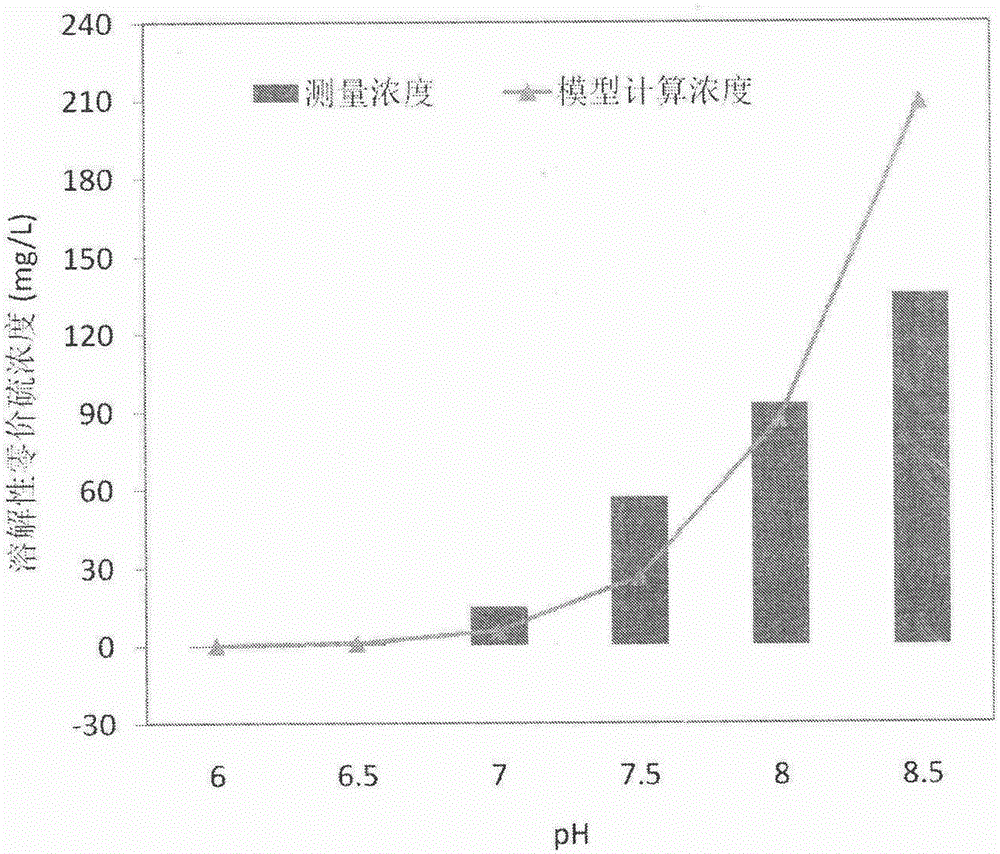

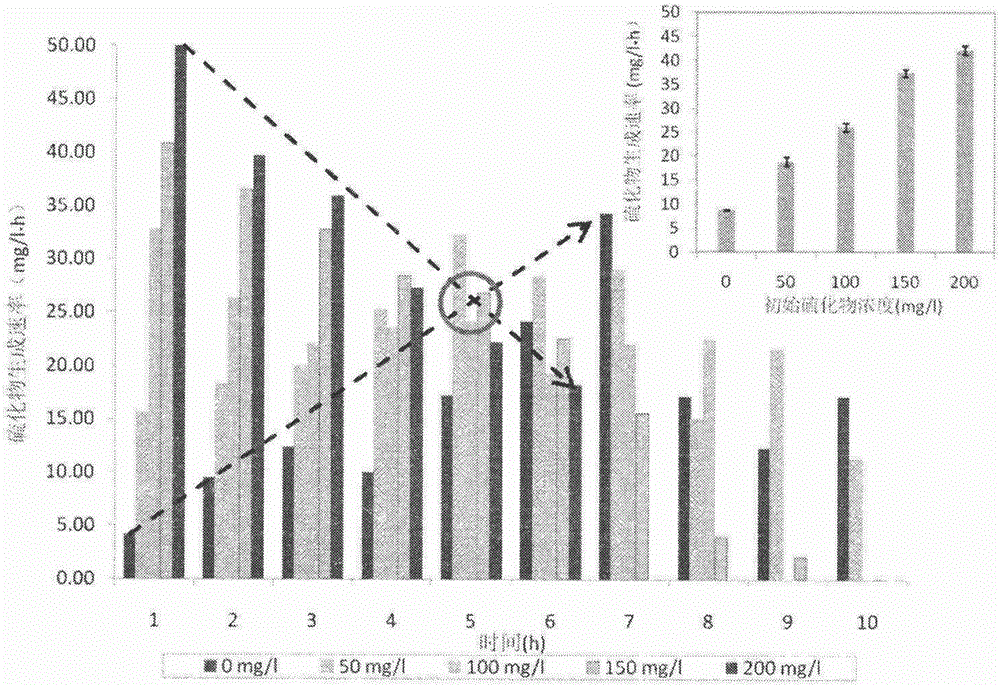

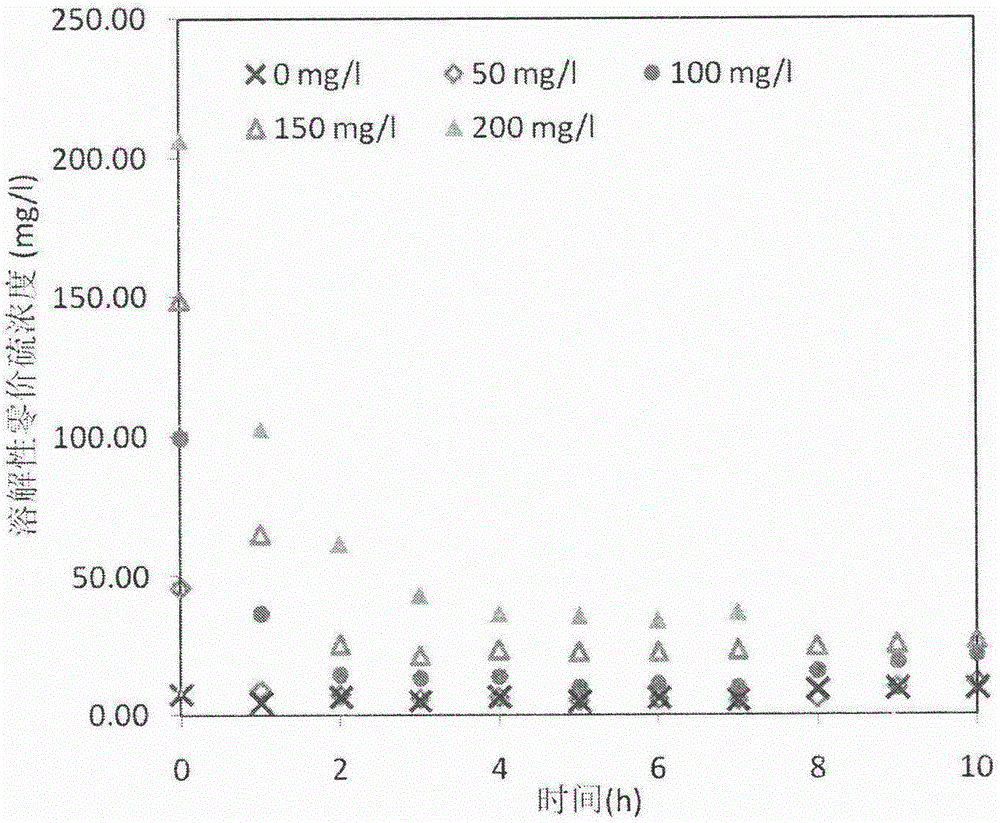

Method for improving bio-availability of sulfur by means of converting sulfur into polysulfide

InactiveCN105947993AImprove recovery rateIncrease spawn rateSulfide/polysulfide preparationSolubilityReduction rate

The invention belongs to the field of wastewater treatment, and provides a method for improving bio-availability of sulfur by means of converting the sulfur into polysulfide. The method is characterized in that solid elemental sulfur in an aqueous solution is quickly dissolved and is converted into the polysulfide under normal temperature and normal pressure by means of controlling a pH value and an initial HS<-> concentration, so that the bio-availability of the sulfur is improved. The method disclosed by the invention has the advantages that a synthesis process of dissolved zero-valent sulfur is explained, the biological reduction rate of the elemental sulfur is improved by the dissolved zero-valent sulfur, meanwhile the sulfide production rate is also accelerated, and the synthesis rate of the dissolved zero-valent sulfur is increased with the increasing of the biological reduction rate of the elemental sulfur, therefore a positive feedback reaction among the biological reduction rate of the elemental sulfur, the sulfide production rate and the dissolved zero-valent sulfur is formed under the conditions limited by the method.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Polyarylene sulfide production method and polyarylene sulfide

A method of producing polyarylene sulfide (PAS) by subjecting a sulfur source and a dihalo aromatic compound (DHA) to polymerization reaction in an organic amide solvent under alkaline conditions, the method suppressing side reactions or the like and yielding PAS having a high degree of polymerization at a high yield is provided; and PAS having a high degree of polymerization are provided.A method of producing PAS, including: a preparation step of preparing a preparation mixture containing an organic amide solvent, a sulfur source, an alkali metal hydroxide, water, and DHA, and having a pH of 12.5 or higher; a first-stage polymerization step of heating the preparation mixture to 170° C. or higher to initiate a polymerization reaction and continuing the polymerization reaction at 240 to 280° C., thereby forming a prepolymer having a DHA conversion rate of 50% or greater (at this time, a temperature increasing rate from 220° C. to 240° C. is lower than a temperature increasing rate for 240° C. or higher); and a second-stage polymerization step of adding, in the reaction system, an alkali metal hydroxide in an amount of 1 to 20 mol % per 1 mol of the sulfur source in the presence of a phase separation agent to continue the polymerization reaction at 245 to 290° C. PAS having a melt viscosity (310° C.; shear rate: 1216 sec-1) of 0.1 to 8000 Pa·s produced by the method.

Owner:KUREHA KAGAKU KOGYO KK

Polyarylene sulfide production method and polyarylene sulfide

A method of producing polyarylene sulfide (PAS) by subjecting a sulfur source and a dihalo aromatic compound (DHA) to polymerization reaction in an organic amide solvent under alkaline conditions, the method suppressing side reactions or the like and yielding PAS having a high degree of polymerization at a high yield is provided; and PAS having a high degree of polymerization are provided.A method of producing PAS, including: a preparation step of preparing a preparation mixture containing an organic amide solvent, a sulfur source, an alkali metal hydroxide, water, and DHA, and having a pH of 12.5 or higher; a first-stage polymerization step of heating the preparation mixture to 170° C. or higher to initiate a polymerization reaction and continuing the polymerization reaction at 240 to 280° C., thereby forming a prepolymer having a DHA conversion rate of 50% or greater (at this time, a temperature increasing rate from 220° C. to 240° C. is lower than a temperature increasing rate for 240° C. or higher); and a second-stage polymerization step of adding, in the reaction system, an alkali metal hydroxide in an amount of 1 to 20 mol % per 1 mol of the sulfur source in the presence of a phase separation agent to continue the polymerization reaction at 245 to 290° C. PAS having a melt viscosity (310° C.; shear rate: 1216 sec−1) of 0.1 to 8000 Pa·s produced by the method.

Owner:KUREHA KAGAKU KOGYO KK

System and method of utilizing monitoring data to enhance seafloor sulfide production for deepwater mining system

Applicants have created a method and system of deep sea mining comprising mining SMS deposits from the sea floor with a subsea miner, pumping the solids from the subsea miner through a jumper and pumping the solids from the jumper up a riser to a surface vessel. Further, applicants have created a method of deploying a deep sea mining system, comprising stacking a riser hangoff structure on top of a subsea pump module forming an assembly; picking up the assembly by a hanging mechanism, hanging the assembly on a moon pool, attaching a first riser joint; disconnecting the riser hangoff structure from the assembly; and attaching at least one second riser joint to form the riser.

Owner:EDA KOPA SOLWARA

Polyphenylene sulfide production method

The invention discloses a polyphenylene sulfide production method. The production method comprises the following steps: (1) firstly pumping an NMP solvent and liquid p-dichlorobenzene into a pre-dissolving vessel with a metering pump to carry out pre-dissolving to form a pre-solution, wherein the weight ratio of the NMP solvent to liquid p-dichlorobenzene added to the pre-dissolving vessel is 1 to (1-1.5); (2) then adding the NMP solvent to a reaction kettle with the metering pump, then adding water-containing sodium sulfide and an alkali chloride catalyst to the reaction kettle, then filling nitrogen, raising the temperature to 170-195 DEG C and maintaining the temperature for 20-30 minutes and removing the moisture, wherein the weight ratio of water-containing sodium sulfide to the alkali chloride catalyst to liquid p-dichlorobenzene is 1 to (0.2-0.5) to (1.1-1.3); (3) after dehydration is completed, adding the NMP solvent to the reaction kettle with the metering pump, then heating the materials to 170-195 DEG C and then stopping filling nitrogen; (4) pumping the pre-solution into the reaction kettle with the metering pump; (5) raising the temperature to 280-300 DEG C to carry out condensation polymerization to generate polyphenylene sulfide. The production method has the advantage of quickness and safety in production of polyphenylene sulfide.

Owner:ZHANGJIAGANG XINSHENG NEW MATERIAL

Polyphenylene sulfide production wastewater deep treatment method

InactiveCN105036454ASolve the constraints of industrial productionSolve constraintsMultistage water/sewage treatmentNature of treatment waterElectrolysisSulfide production

The invention discloses a polyphenylene sulfide production wastewater deep treatment method which comprises the following steps: (1) taking polyphenylene sulfide production wastewater, adjusting the pH value to be 7-10, adding PAC and stirring for 30-60 minutes, adding PAM, precipitating, and then taking supernatant liquid; (2) adjusting the pH value of the supernatant liquid to be 4-6, carrying out iron-carbon micro-electrolysis treatment for 2-6 hours, and then taking supernatant liquid; (3) adjusting the pH value of the supernatant liquid to be 7-10, adding PAC and stirring for 30-60 minutes, adding PAM, precipitating, and then taking supernatant liquid; (4) adding active sludge into the supernatant liquid, and then stirring for 6-24 hours, wherein the addition of the active sludge accounts for 20-80% of the weight of the supernatant liquid obtained in the step (3); and (5) carrying out oxygenic aeration for 32-40 hours, and then carrying out centrifugal separation to obtain active sludge and qualified polyphenylene sulfide production wastewater. The polyphenylene sulfide production wastewater deep treatment method has the advantage of treating polyphenylene sulfide production wastewater into qualified industrial wastewater.

Owner:ZHANGJIAGANG XINSHENG NEW MATERIAL

Polyarylene sulfide production method and polyarylene sulfide production apparatus

ActiveUS9908974B2Stable production of high-qualityImprove production yieldCleaning using liquidsStationary filtering element filtersSulfide productionSlurry

The present invention provides a production method and a production apparatus for a polyarylene sulfide (PAS), thus the formation of a floating polymer and the leakage of the floating polymer to the outside of the vessel in a washing step are prevented, to achieve steady production of the polymer with high quality, to improve the yield of the polymer and to reduce environmental load, wherein the floating polymer refers to a particles of the polymer which are floating on the surface of a washing solution, in the upper part of the inside of a washing vessel, as a result of the adhesion of a gas onto the surface of the particles of the polymer.The present invention provides a production method for a PAS comprising step (I), performing polymerization, step (II), separating and collecting a polymer, step (III), washing a slurry, and step (IV), collecting the polymer after washing, wherein an aqueous medium is sprayed onto a PAS floating on the surface of the aqueous washing solution in the upper part of the inside of the washing vessel in step (III) (step (IIIa), washing a slurry using a counter current, and / or step (IIIb), treating a slurry with acid using a counter current, or the like); and a production apparatus for a PAS comprising a washing device (counter current washing device and / or a counter current contact / acid treatment device or the like) having an aqueous medium spray means.

Owner:KUREHA KAGAKU KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com