Novel rough coarse-grinding head cooling water supply facility

A technology of water supply device and rough grinding, which is applied in the direction of grinding/polishing safety device, grinding/polishing equipment, metal processing equipment, etc. It can solve the problem that the cooling water spray point cannot change with the grinding point and the cooling effect is not ideal and other problems, to achieve the effect of simple structure, improved grinding quality and saving cooling water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

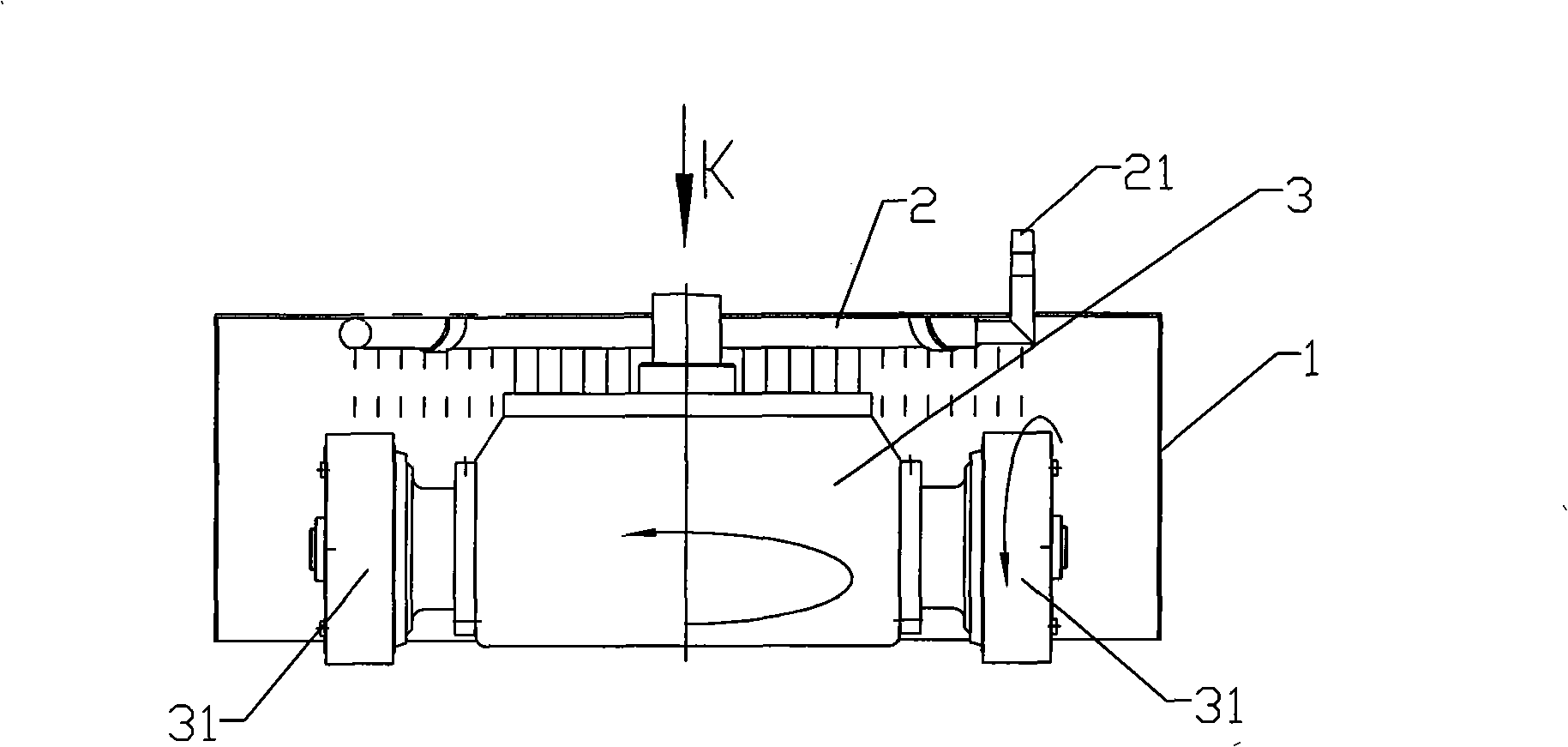

[0029] As shown in FIGS. 4 to 9 , the novel rough grinding head cooling water supply device of the present invention is used in rough grinding equipment for cooling the grinding head and grinding wheel, and includes a water cover, a water supply tank 5 and a water supply pipe 6 . Its specific connection structure is:

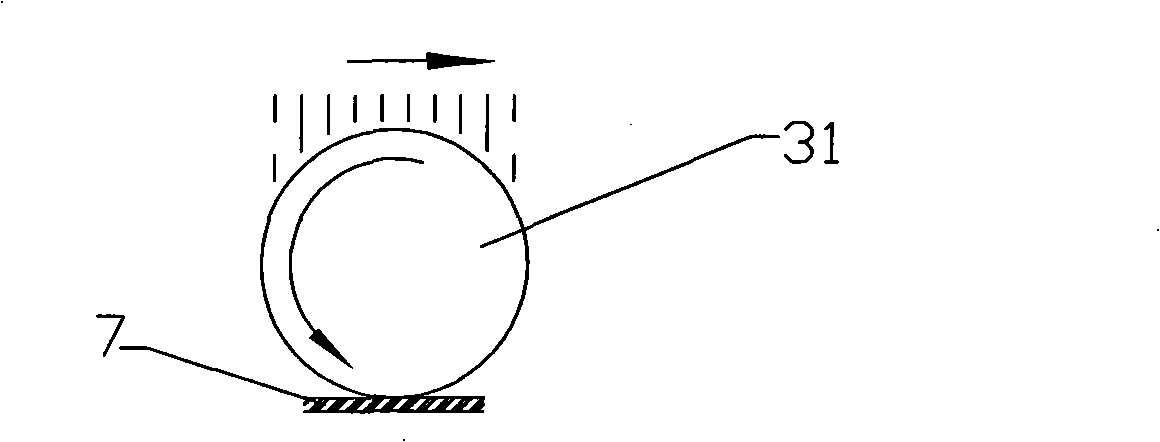

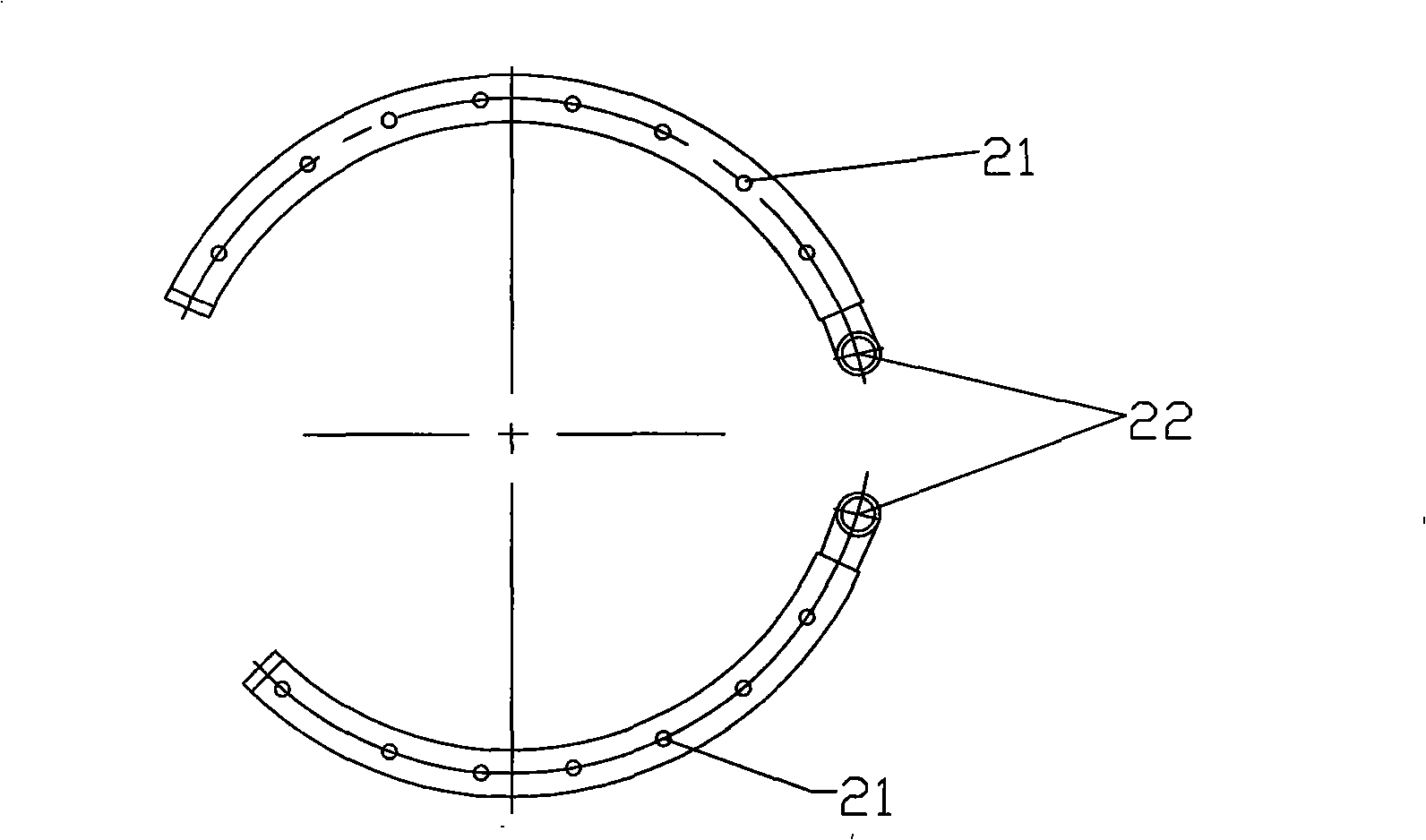

[0030] As shown in Figures 4 and 5, the above-mentioned water cover is an arc-shaped water cover 4, which is installed on the grinding head 3 and surrounds the outer periphery of the grinding wheel 31. The arc-shaped water cover 4 can rotate together with the revolution of the grinding head 3. The ring arc water cover 4 is an excellent arc ring water cover, and its opening is located at the grinding point of the grinding wheel 31. The ring arc water cover 4 is provided with a water diversion 42 and a water outlet 41 connected with the water diversion. The water outlet 41 is two Two of them are respectively located on both sides of the grinding point of the grind...

Embodiment 2

[0034] like Figure 10 As shown, the above-mentioned water supply tank 5 includes an annular water receiving tank 51 and a water inlet hole 53 communicating with the water diversion channel 42. A water diversion tank 55 that is fixedly connected with the annular arc-shaped water cover extends respectively on both sides of the annular water receiving tank 51. The water hole 53 is provided at a position corresponding to the connection between the water guide groove 55 and the arc-shaped water cover 4 . Other structures of this embodiment are as shown in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com