Method for preparing feed-grade calcium hydrophosphate by wet-process phosphoric acid organic extraction and purification raffinate

A technology of calcium hydrogen phosphate and wet-process phosphoric acid, which is applied in the field of phosphorus chemical industry, can solve the problems of high energy consumption and cost increase, and achieve the effect of low energy consumption and friendly reaction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

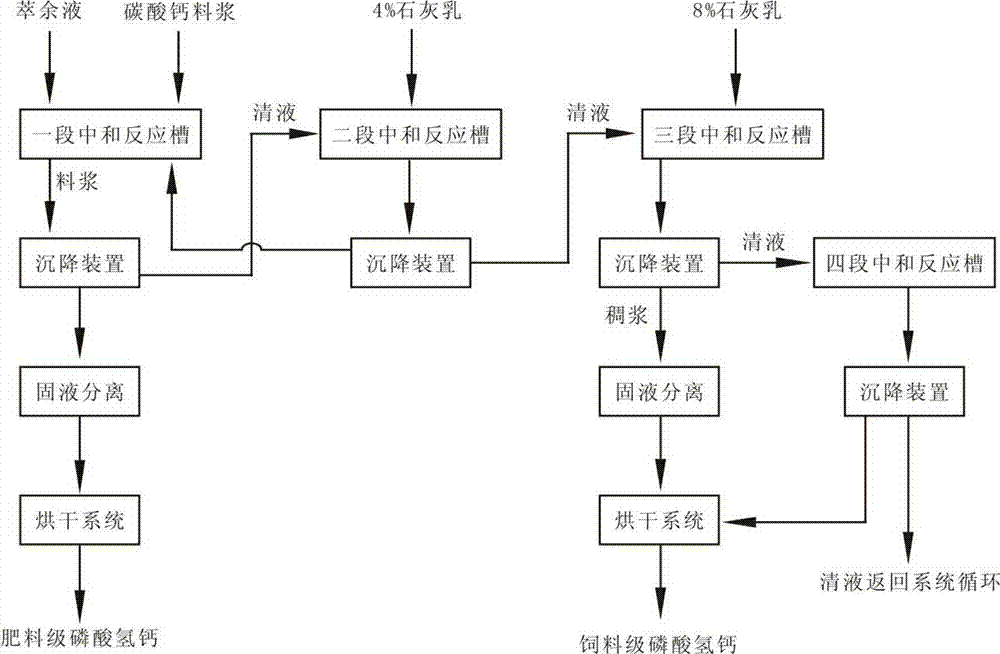

Image

Examples

Embodiment 1

[0025] Will contain 20~25% P 2 o 5 The raffinate with 0.3% F ion is sent to a first-stage neutralization reaction tank, and calcium carbonate slurry with a weight ratio of 15% is introduced until the pH value is 1.8~2.0, and then at 50°C, continue to stir for neutralization React for 1 hour; the slurry is settled by a thickener, and after settling for 1 hour, the solid part of the thick slurry is sent to the drying system for drying treatment to obtain fertilizer grade calcium hydrogen phosphate; the clear liquid is sent to into the second-stage neutralization reaction tank, and then pass through milk of lime with a weight ratio of 3% for neutralization reaction until the pH value is 2.2~2.5; The slurry part is returned to the first-stage neutralization reaction tank, and the clear liquid is sent to the third-stage neutralization reaction tank; the milk of lime with a weight ratio of 8% is passed into the third-stage neutralization reaction tank to carry out neutralization re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com