Improved aerator

An aerator, an improved technology, applied in the direction of electromechanical devices, control of mechanical energy, speed/torque control of a single motor, etc., can solve the problems of easy heating and burning, endangering personal safety, energy waste, etc., to avoid economic losses, simplify Structure and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

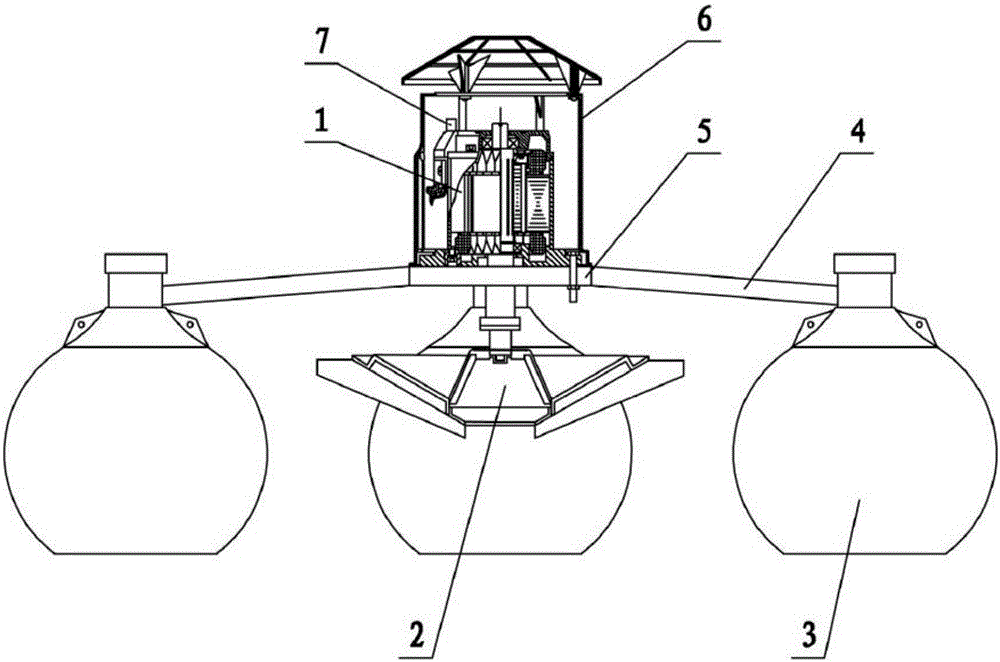

[0021] Such as figure 1 with figure 2 As shown, the aerator of the present invention comprises impeller 2, floating body 3 and motor base 5, and motor base 5 is connected with floating body 3 by support 4, and described motor base 5 is provided with DC brushless motor 1, and motor shaft 1.1 and The impeller 2 is connected.

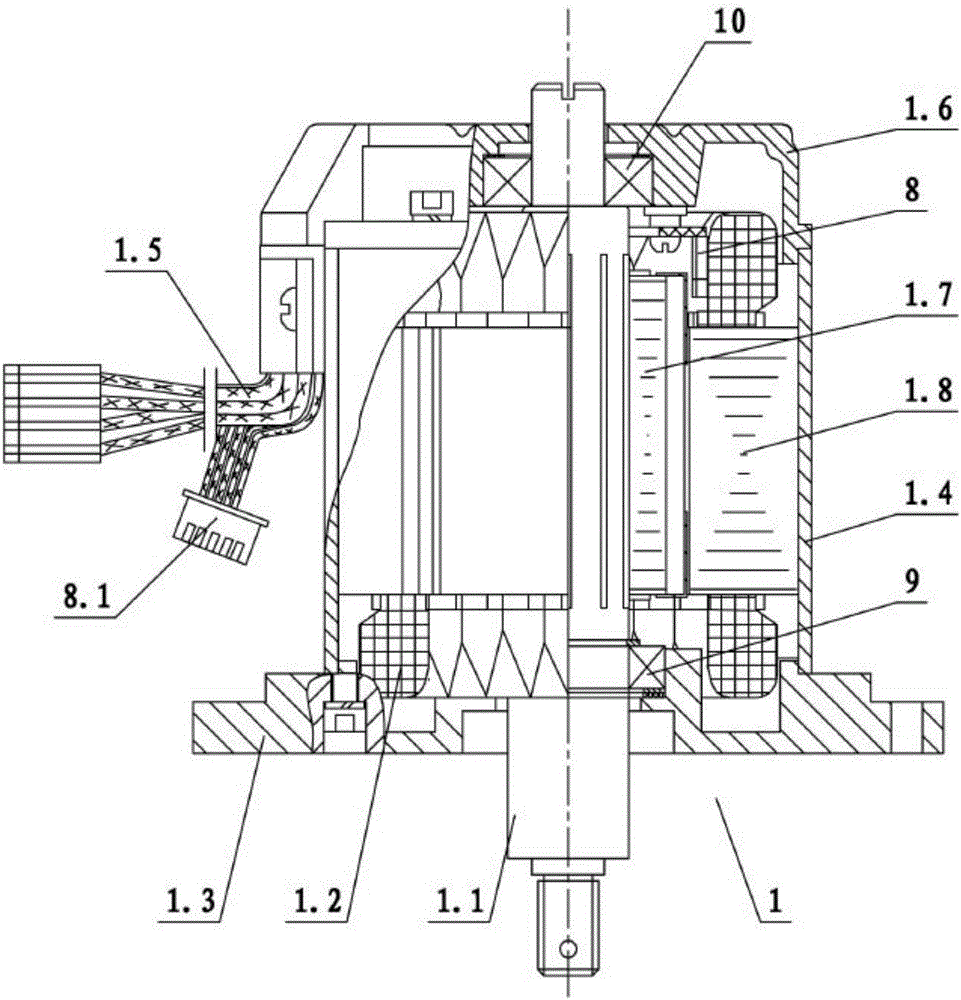

[0022] The DC brushless motor (the DC brushless motor mentioned above is the DC brushless position sensorless motor) includes a housing assembly, a stator assembly, a rotor assembly and a controller; the housing assembly includes a housing 1.4, The front end cover 1.3 and the rear end cover 1.6 connected to both ends of the housing 1.4, the stator assembly includes the stator core 1.8 and the stator winding 1.2, the rotor assembly includes the rotor magnetic steel 1.7 and the motor shaft 1.1, and the rotor magnetic steel 1.7 is fixedly connected to the motor The outer side of the shaft 1.1; the stator core 1.8 is fixed on the inner wall of the housing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com